Liquid-gas dual-state Mini/Micro LED chip mass transfer crystal film and manufacturing method thereof

A production method, liquid gas technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of crystal film material waste, uneven chip drop, pollution of the working environment, etc., to avoid the difficulty of falling posture control, achieve repeated use, and avoid uneven viscosity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

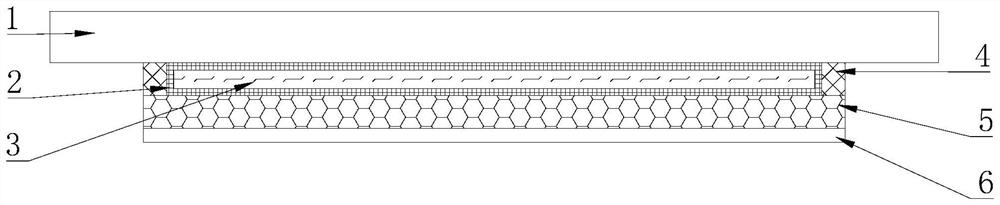

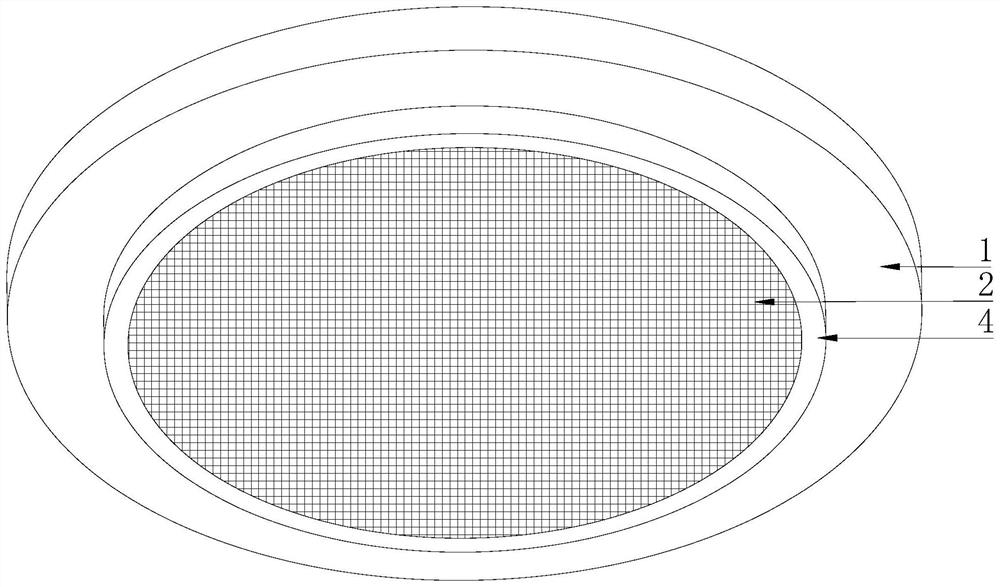

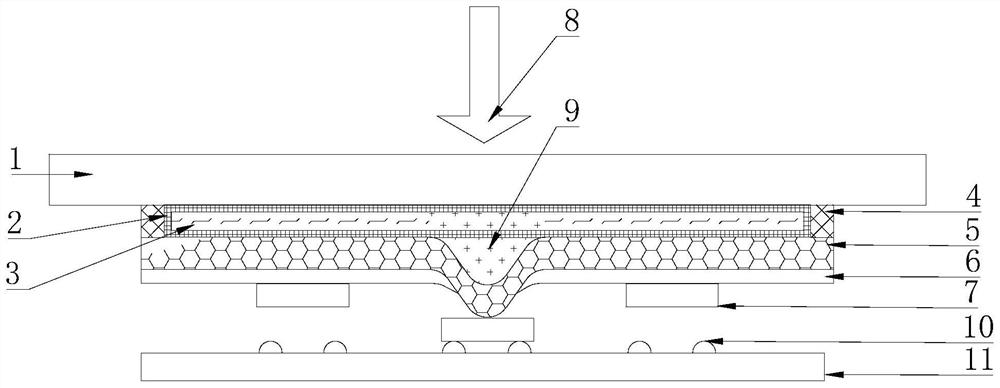

[0043] like figure 1 As shown, a liquid-gas dual-state Mini / Micro LED chip mass transfer crystal film consists of a substrate 1, a medium storage grid 2, a liquid-gas dual-state medium 3, a sealant 4, an elastic layer 5 and an adhesive layer 6 composition. It is characterized in that: the substrate 1 is located above the medium storage grid 2, the liquid-gas dual-state medium 3, the sealant 4, the elastic layer 5 and the adhesive layer 6, and the medium storage grid 2, the liquid-gas dual-state medium 3 and the sealing The glue 4 is located below the substrate 1 and above the elastic layer 5, the medium storage grid 2 is laid on the lower surface of the substrate 1, the liquid-gas two-state medium 3 is distributed in the medium storage grid 2, and the sealant 4 is located in the medium storage grid 2. On the radial outer side of the grid 2 and the liquid-gas dual-state medium 3, the substrate 1, the sealant 4 and the elastic layer 5 form a closed space, and the medium storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com