Method for preparing InGaN/AlGaN MQW ultraviolet LED

A purple light and pressure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high preparation cost, limited application, time-consuming, etc., and achieve the effect of low preparation cost and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

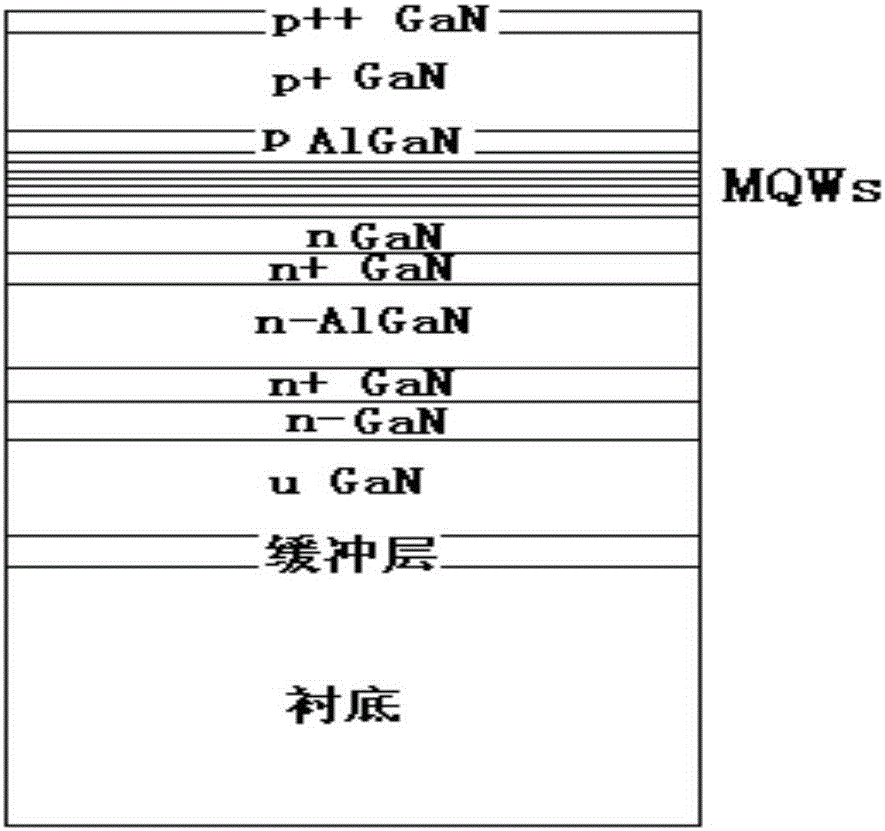

[0046] Such as figure 1 As shown, this embodiment is a method for preparing high-performance InGaN / AlGaN MQW violet LED, using blue ammonia, trimethylindium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.9999% as N , In, Ga sources, respectively SiH 4 and Cp2Mg as n and p-type dopants, comprising the steps of:

[0047] Step 1: Pass N at a temperature of 1070°C and a pressure of 150torr 2 Baking for 20min, nitriding the sapphire substrate;

[0048] Step 2: Lower the temperature of the sapphire substrate after nitriding in step 1 to 515°C and a pressure of 800torr, then grow a GaN buffer layer with a thickness of 15nm on the substrate, then raise the temperature to 1030°C and a pressure of 400torr to regenerate the GaN buffer layer Crystallization and re-growth 1.8um u-GaN nucleation layer, the raw materials are TMGa and NH 3 ;

[0049] Step 3: Raise the temperature to 1070°C and the pressure is 200torr to grow a low Si-doped n-GaN layer wi...

Embodiment 2

[0065] Such as figure 1 As shown, this embodiment is a method for preparing a high-performance InGaN / AlGaN MQW violet LED, using blue ammonia, trimethylindium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.99999% as N , In, Ga sources, respectively SiH 4 and Cp2Mg as n and p-type dopants, comprising the steps of:

[0066] Step 1: Pass N at a temperature of 1080°C and a pressure of 150torr 2 Baking for 25min, nitrided SiC substrate;

[0067] Step 2: Cool down the SiC substrate after nitriding in step 1 to 525°C and a pressure of 800torr, then grow a GaN buffer layer with a thickness of 30nm on the substrate, then raise the temperature to 1040°C and a pressure of 400torr to regenerate the GaN buffer layer Crystallization and re-growth 2.1um u-GaN nucleation layer, the raw materials are TMGa and NH 3 ;

[0068] Step 3: Raise the temperature to 1080°C and the pressure is 200torr to grow a low Si-doped n-GaN layer with a thickness of 60nm, and...

Embodiment 3

[0084] Such as figure 1 As shown, this embodiment is a method for preparing high-performance InGaN / AlGaN MQW violet LED, using blue ammonia, trimethylindium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.9999% as N , In, Ga sources, respectively SiH 4 and Cp2Mg as n and p-type dopants, comprising the steps of:

[0085] Step 1: Pass N at a temperature of 1090°C and a pressure of 150torr 2 Baking for 30min, nitrided Si substrate;

[0086] Step 2: Cool down the Si substrate after nitriding in Step 1 to 535°C and a pressure of 800torr, then grow a GaN buffer layer with a thickness of 50nm on the substrate, then raise the temperature to 1050°C and a pressure of 400torr to recrystallize the GaN buffer layer , and then grow a 2.5um u-GaN nucleation layer, the raw materials are TMGa and NH 3 ;

[0087] Step 3: Raise the temperature to 1090°C and the pressure is 200torr to grow a low Si-doped n-GaN layer with a thickness of 100nm, and then grow a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com