Transfer substrate, driving backboard, transfer method and display device

A technology for transferring substrates and driving backplanes, used in identification devices, static indicators, instruments, etc., can solve the problems of low transfer yield of miniature light-emitting diodes, improve the transfer yield, not easy to lose and wear, and improve the accuracy of the transfer. The effect of bit precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] To solve the problem of low transfer yield of micro light emitting diodes in the prior art, embodiments of the present invention provide a transfer substrate, a driving backplane, a transfer method and a display device.

[0051] The specific implementation manners of the transfer substrate, the driving backplane, the transfer method and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The thickness and shape of each film layer in the drawings do not reflect the real scale, and the purpose is only to illustrate the content of the present invention.

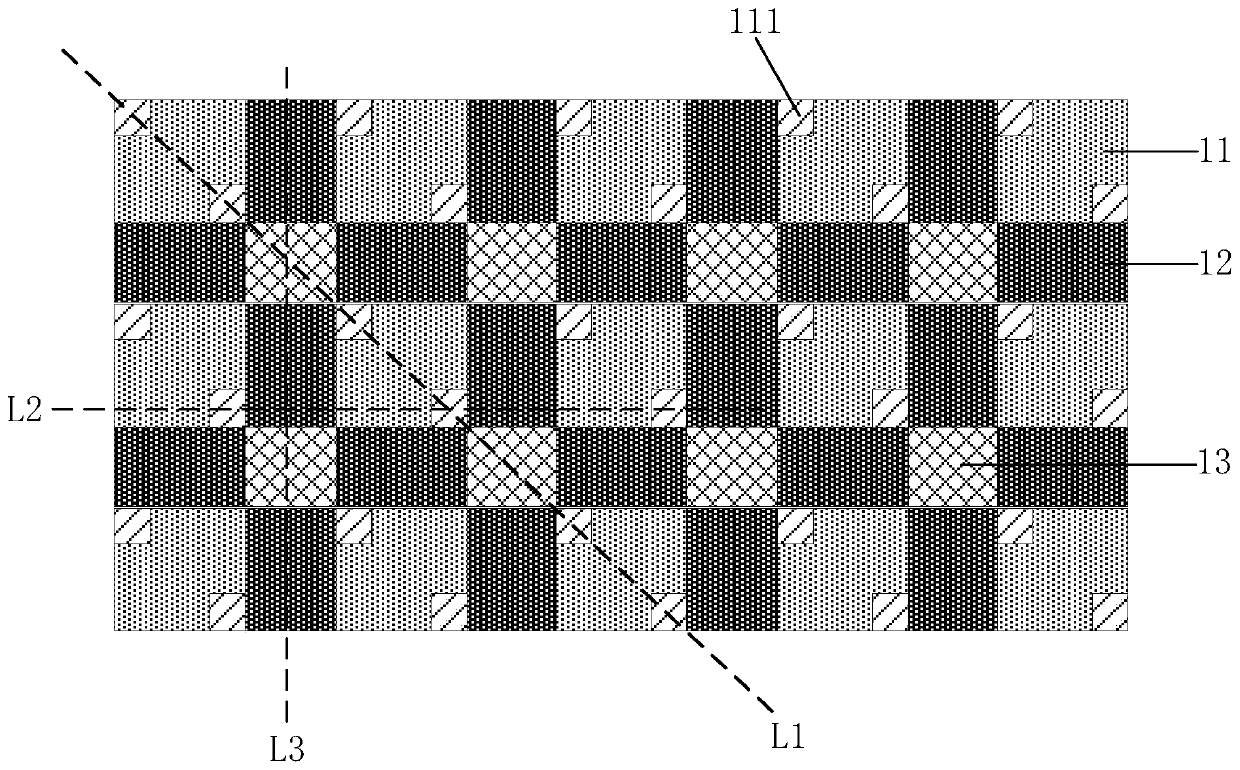

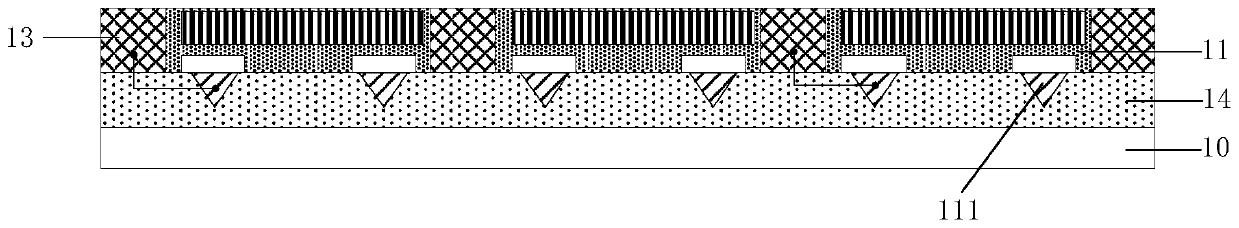

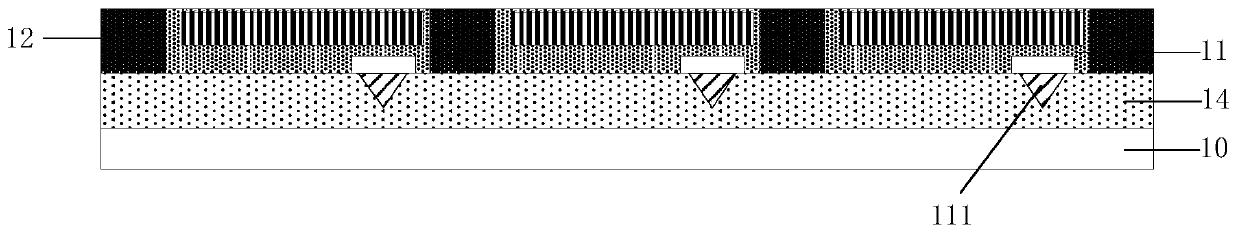

[0052] In a first aspect, an embodiment of the present invention provides a transfer substrate, figure 1 It is a schematic diagram of the planar structure of the transfer substrate provided by the embodiment of the present invention, figure 2 for figure 1 The cross-sectional schematic diagram at the dotted line L1 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com