Device transfer method

A transfer method and device technology, which can be used in the manufacture of electrical solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as yield problems, and achieve the effects of reducing costs, improving transfer yield, and improving device transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

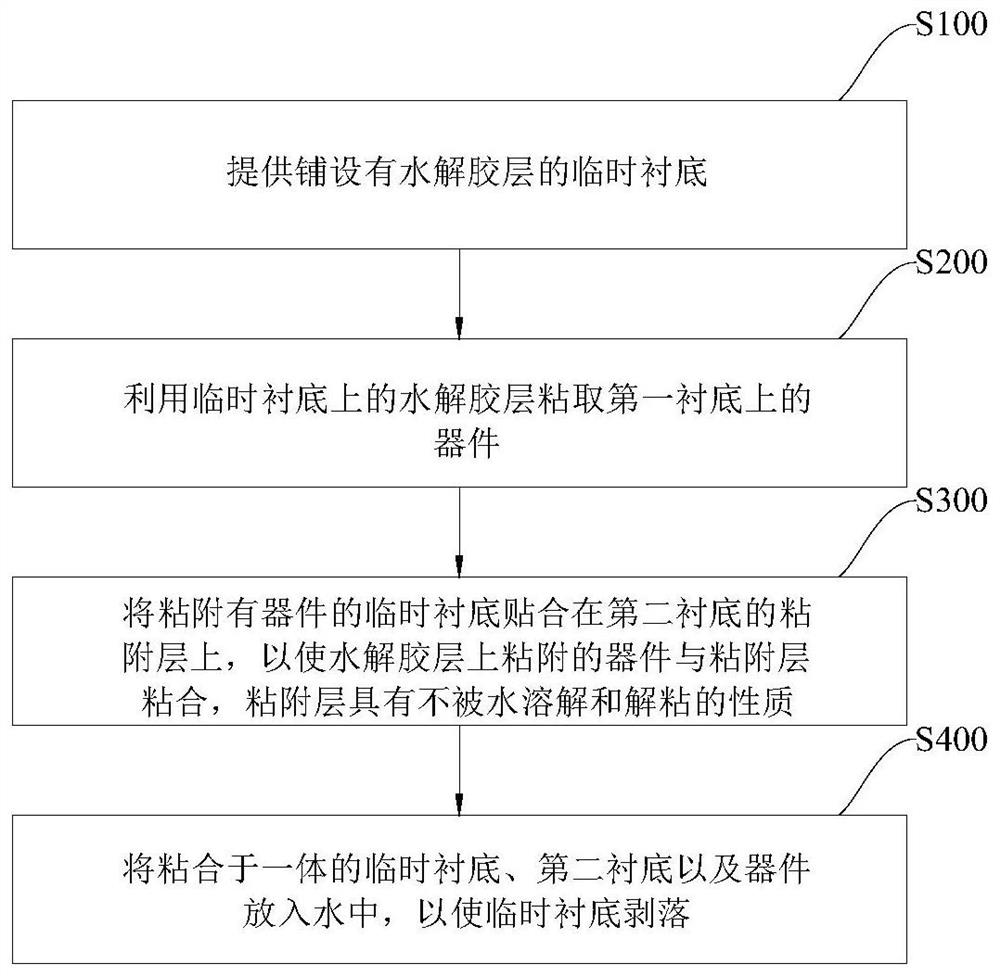

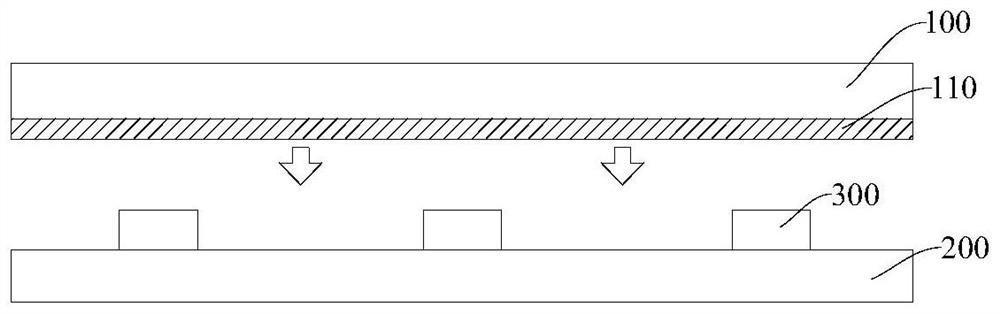

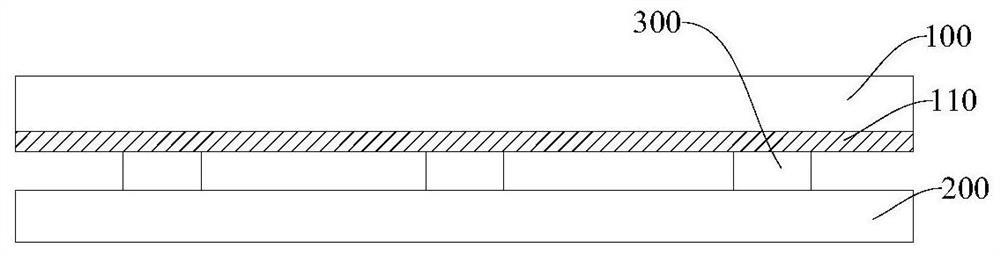

[0043] figure 1 It is a flowchart of a device 300 transfer method in an embodiment of the present application; Figure 2 to Figure 7 It is a schematic diagram of the transfer process of the device 300 in an embodiment of the present application. Please refer to figure 1 and Figure 7 , the device 300 transfer method provided by the embodiment of the present application includes:

[0044] Step S100, providing a temporary substrate covered with a hydrolytic glue layer.

[0045] In an optional embodiment of the present application, the temporary substrate 100 may be a rigid or flexible substrate, and its material includes but is not limited to glass, sapphire, polyester resin (Polyethylene terephthalate, PET) or polyimide resin (Polymide, PI). In this embodiment, the temporary substrate 100 may be flat, and the hydrolytic glue layer 110 is evenly laid on one side of the temporary substrate 100 as a transfer adhesive.

[0046] Specifically, in this embodiment, the hydrolytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com