Integrally packaged micro-display chip and preparation method thereof

A micro-display chip and integrated packaging technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of growing Micro-LEDs, increasing costs, and the high cost of Micro-LEDs. The effect of high transfer yield and great convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

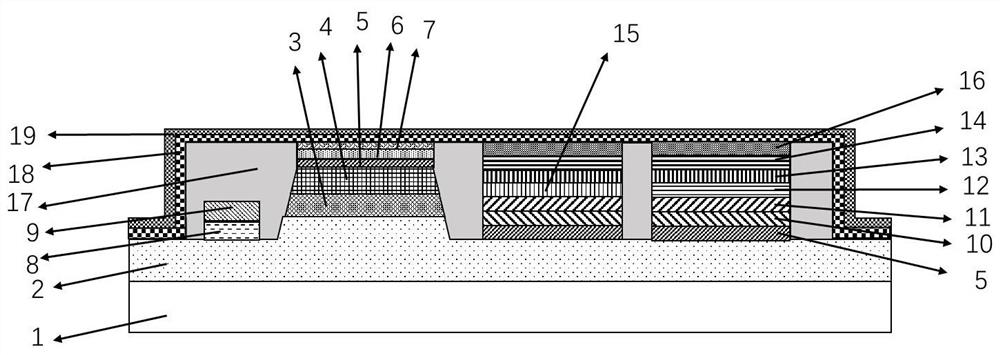

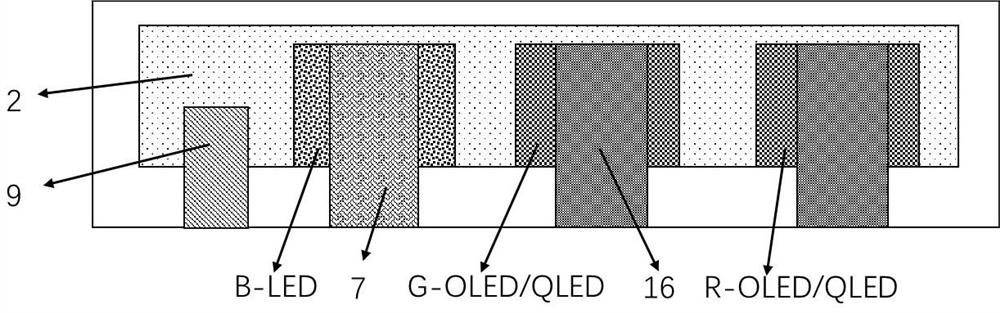

[0038] refer to figure 1 , the present invention provides an integrated package micro display chip, characterized in that it includes a substrate, a blue Micro-LED sub-pixel, a red Micro-OLED or Micro-QLED sub-pixel and a green Micro-OLED or Micro-QLED sub-pixel ; The n-electrode of the Micro-LED sub-pixel is connected to one of the electrodes of the Micro-OLED or Micro-QLED, the p-electrode of the Micro-LED sub-pixel, the other electrode of the red Micro-OLED or Micro-QLED, the green light The other electrode of the Micro-OLED or Micro-QLED is drawn out separately to form the lead-out electrodes of four integrated packaged micro-display chips. Micro-LED sub-pixels, red Micro-OLED or Micro-QLED sub-pixels and green Micro-OLED or Micro-QLED sub-pixels are integrated into a micro-display pixel with three-primary-color controllable light emission through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com