Method for shifting contact lenses

A contact lens and lens technology, applied in the direction of using protective fluid, single objects, manipulators, etc., can solve the problems of defect rate, inability to effectively control the position of lens blown off, labor and time-consuming, etc., to save labor and the time required for the process and Lower cost, higher transfer yield, and higher transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

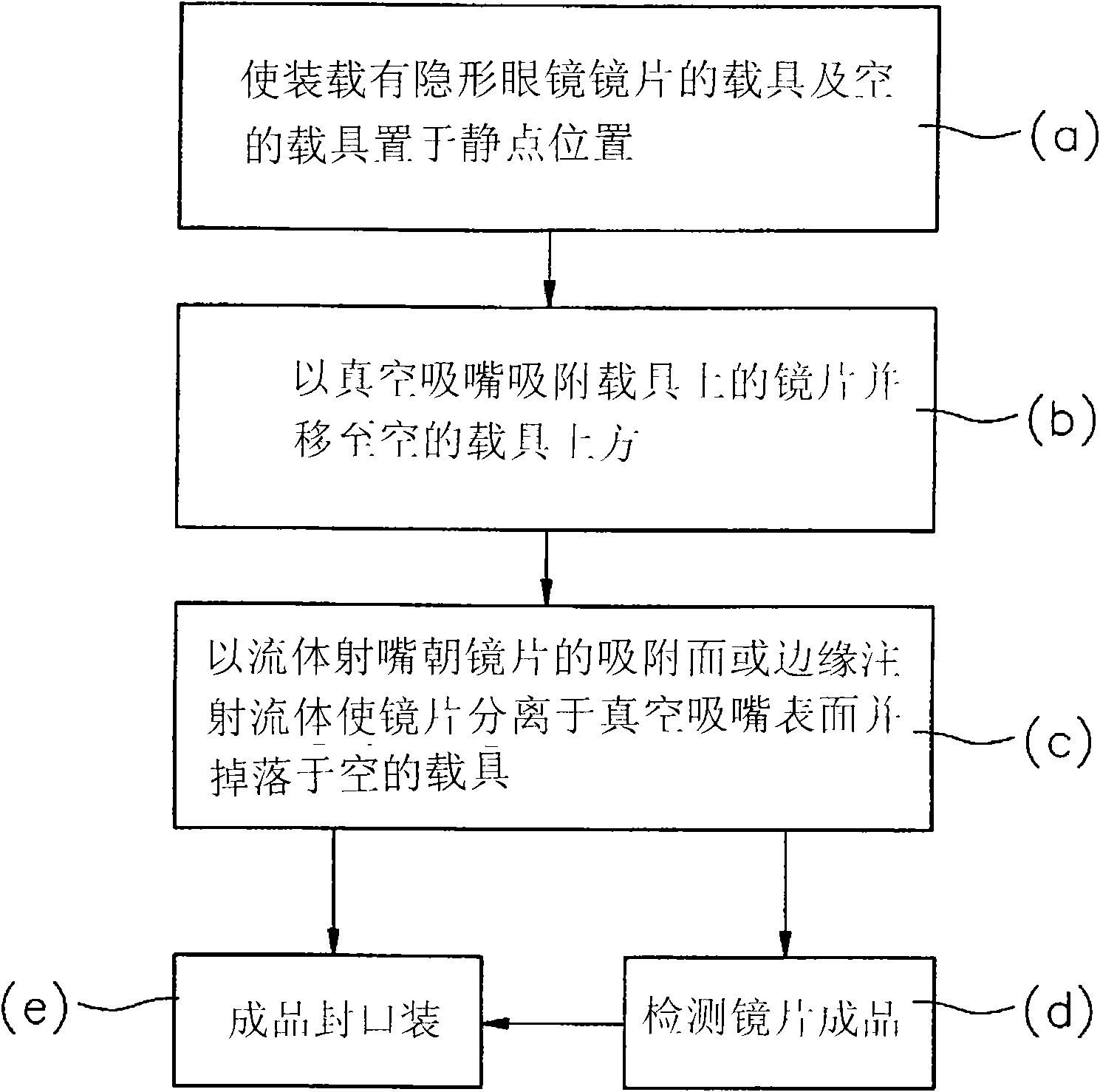

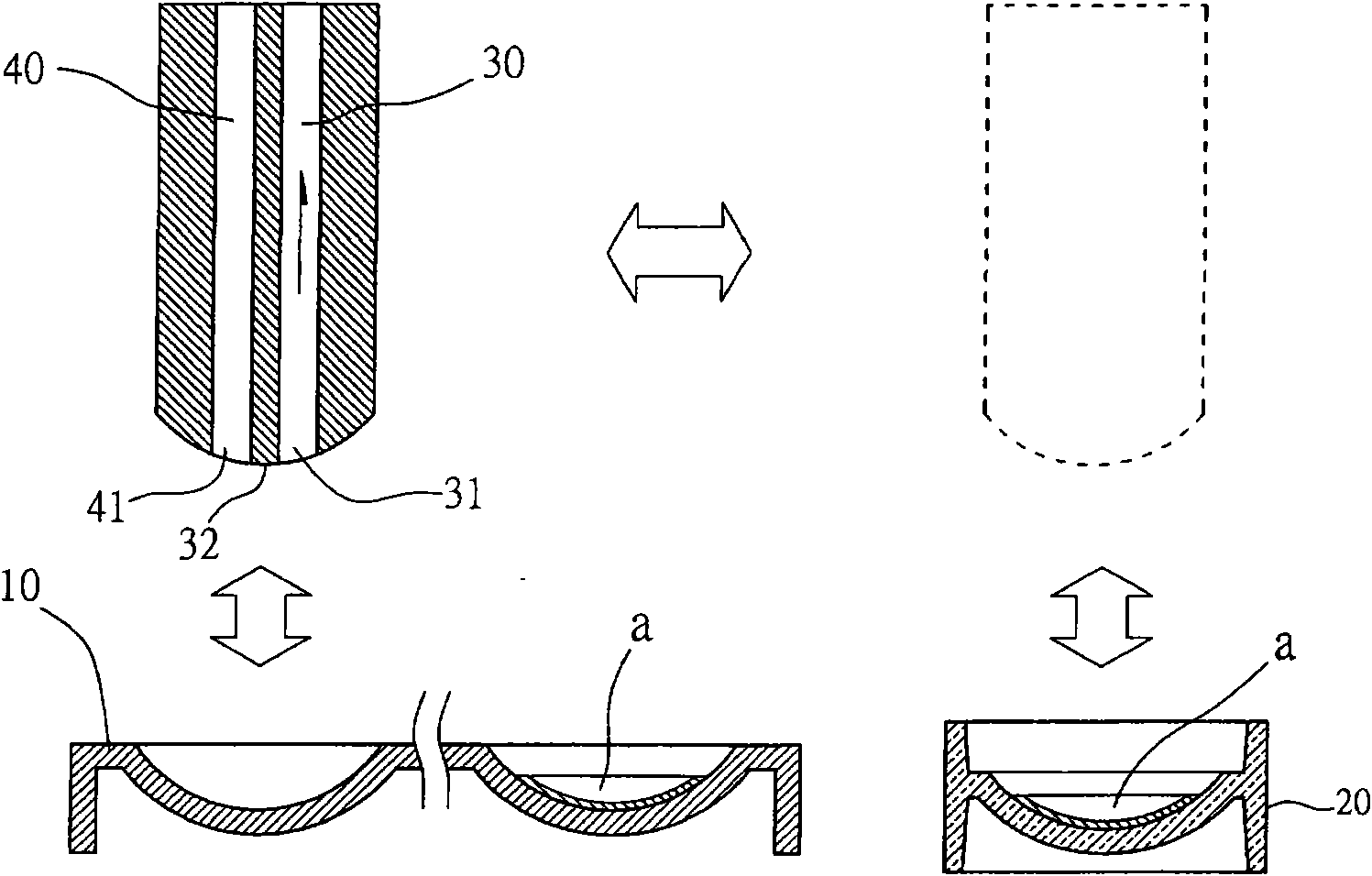

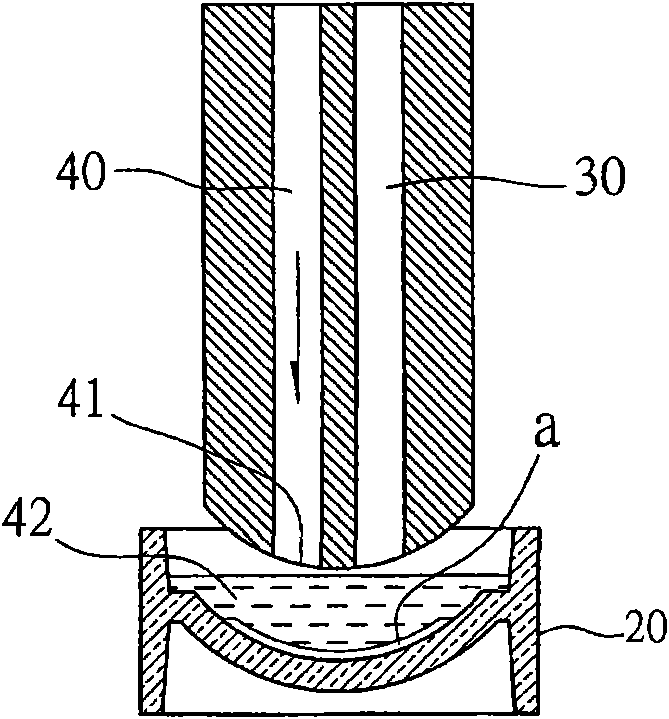

[0038] See first figure 1 Shown is the flowchart of the first embodiment of the present invention, the transfer method of the contact lens lens of the present invention includes the following implementation steps: (a) make the carrier 10 loaded with the contact lens lens a and another empty carrier 20 is placed in static point position; (b) with a vacuum suction nozzle 30 suction lens a in the carrier 10 and moves to the empty carrier 20 top (as figure 2 shown); (c) use a fluid nozzle 40 to inject fluid toward the adsorption surface or edge of the lens a, so that the lens a is separated from the surface of the vacuum nozzle 30 by the fluid, and the dropped one is transferred to the empty carrier Tool 20 (such as image 3 shown). In this way, the transferred lenses can be further inspected on the carrier (d), and then transferred to another empty carrier for sealing and packaging (e); or directly together with the carrier for sealing and packaging (e )Operation.

[0039] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com