Patents

Literature

34results about How to "Action indeed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

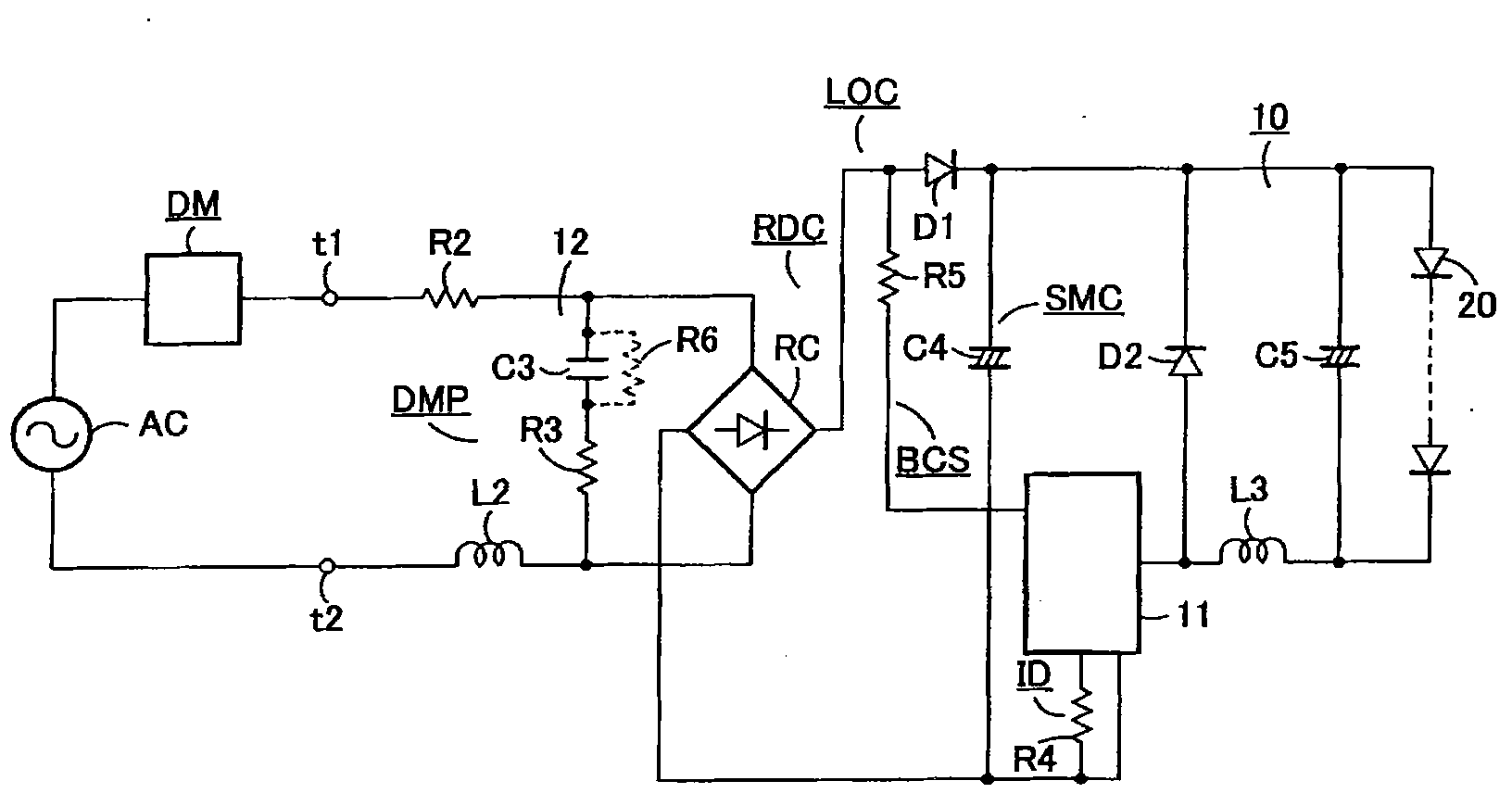

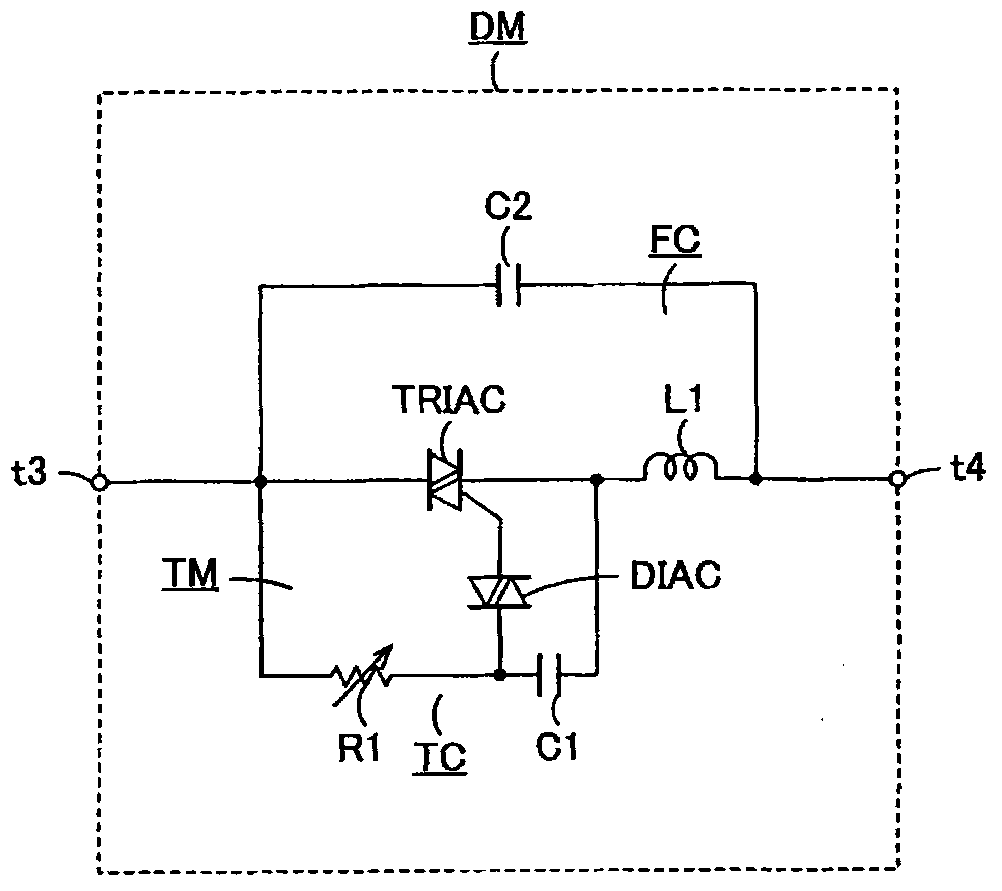

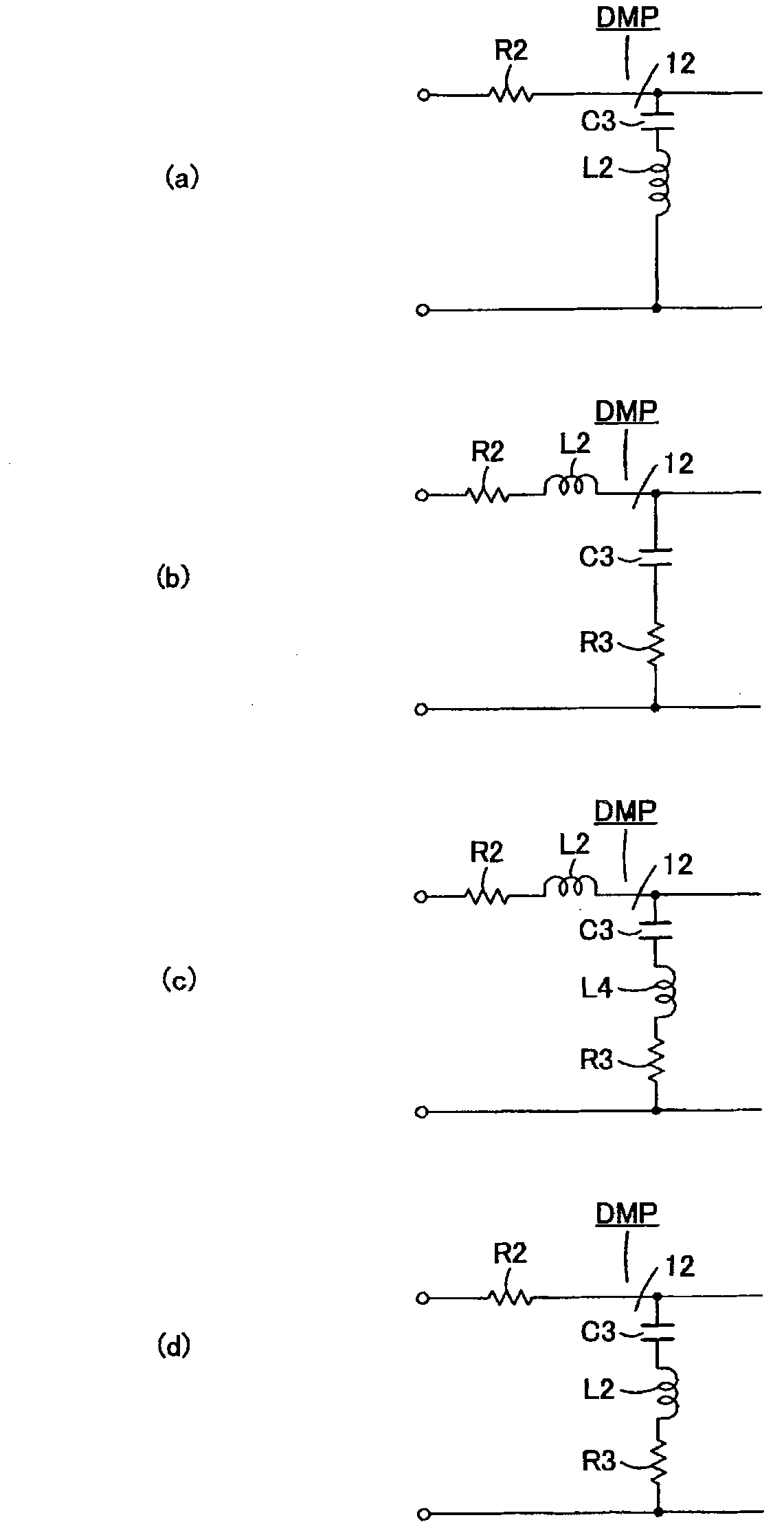

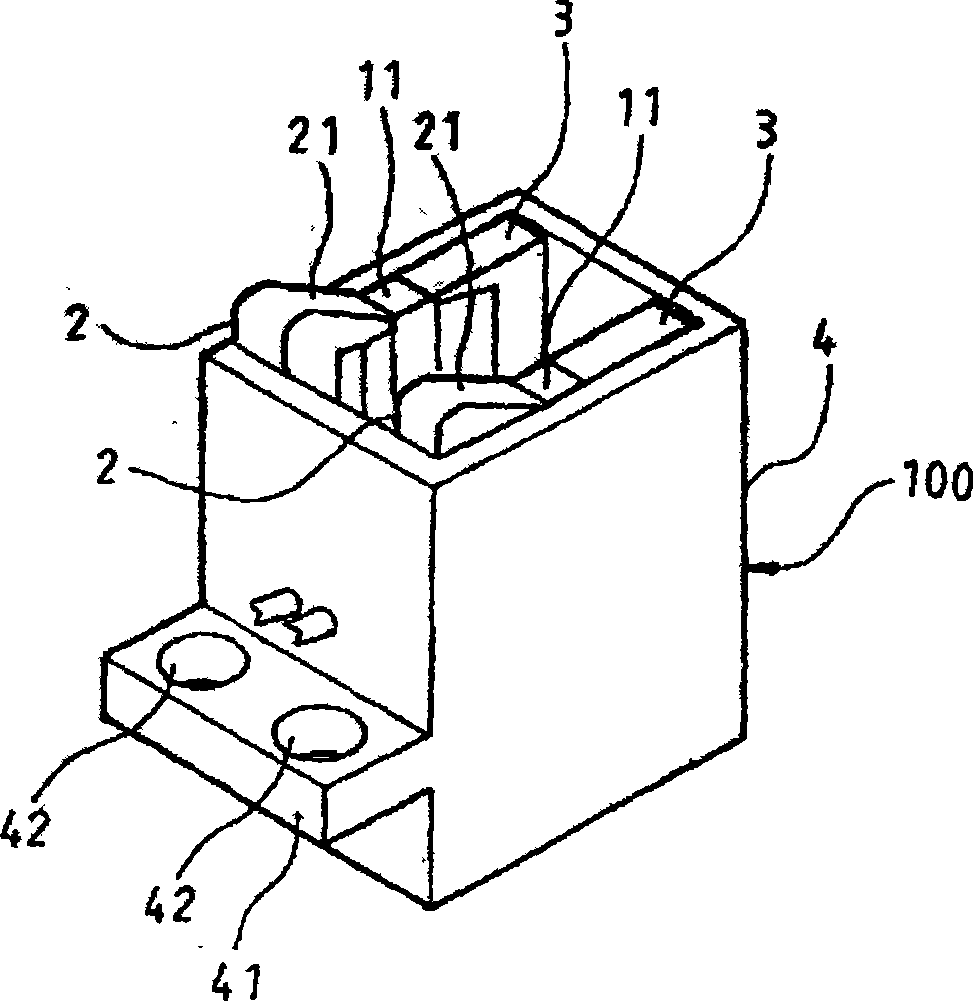

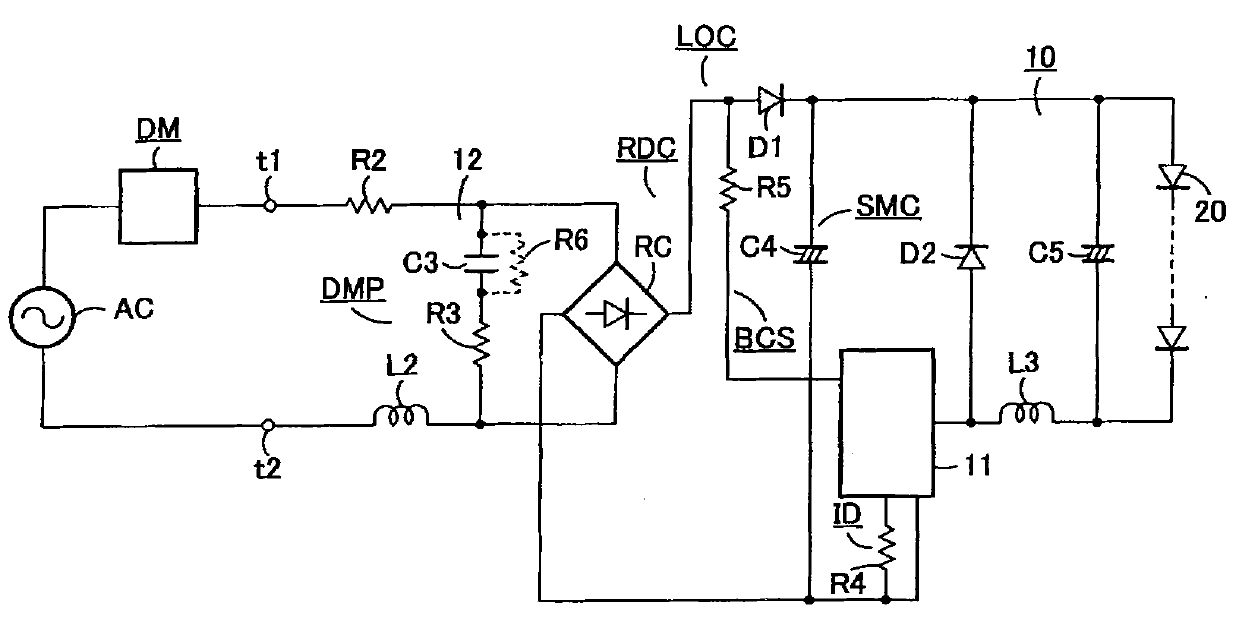

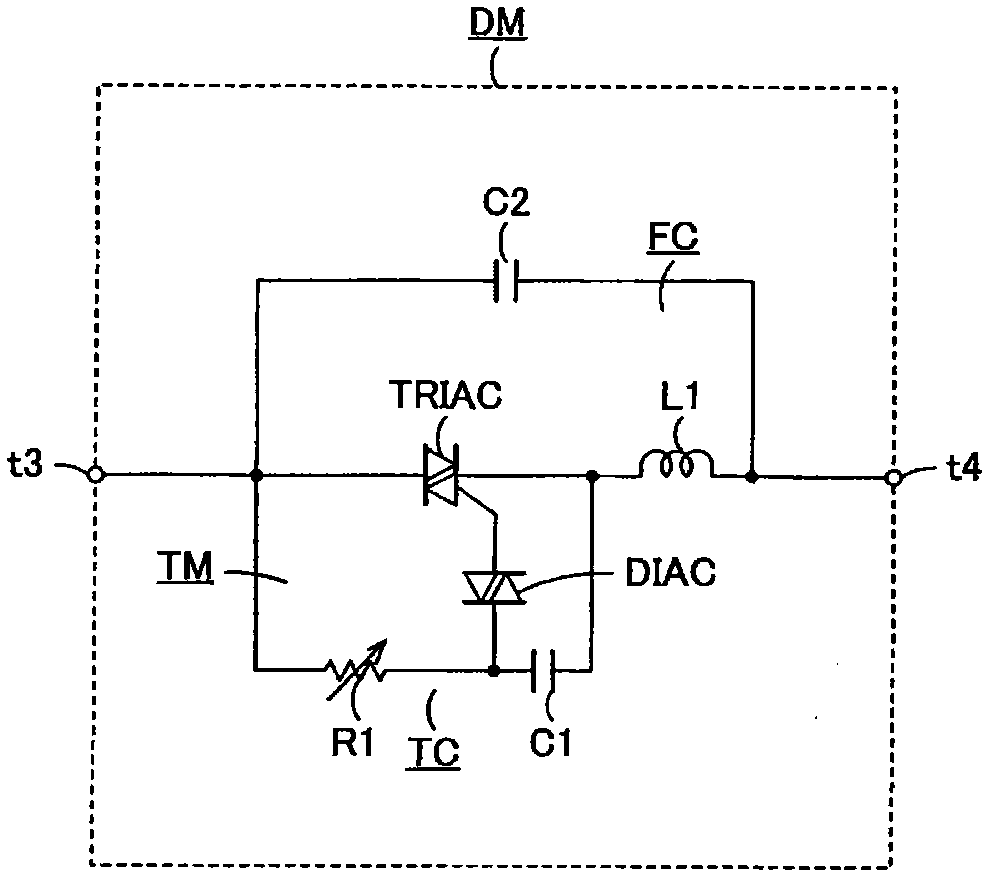

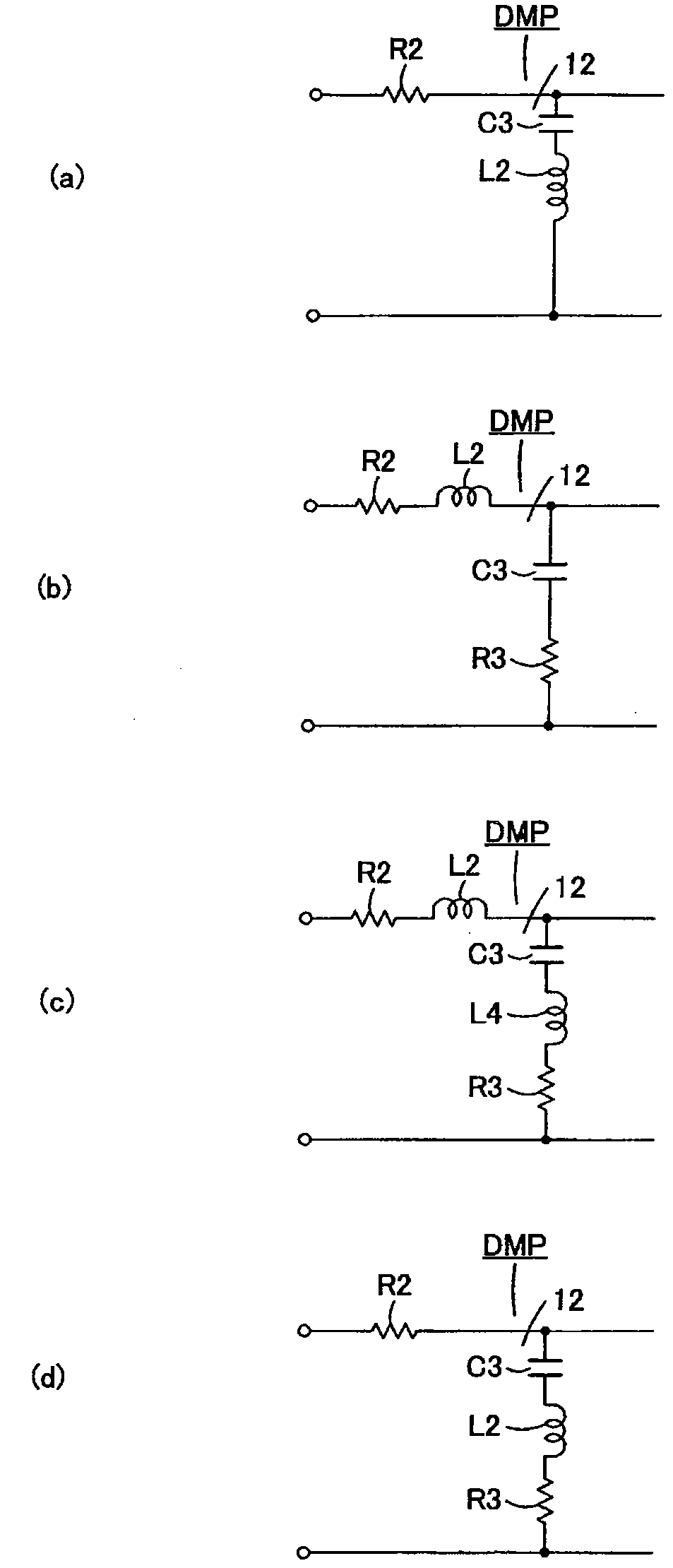

Led lighting device and illumination apparatus

ActiveCN102014546AReduce heat and power consumptionReduced inrush currentPoint-like light sourceElectrical apparatusInductorPower flow

The present invention provides an LED lighting device and an illumination apparatus, wherein the LED lighting device includes a pair of input terminals to which AC voltage is input, the AC voltage being phase-controlled by a dimmer for phase-controlling AC voltage of an AC source; a damping circuit which has a resistor inserted to a position, into which input current flows from the AC source via the dimmer in series, and a capacitor and an inductor which form a closed circuit together with the AC source and the dimmer, and suppresses high-frequency vibration generated in the dimmer when a phase control element of the dimmer is turned on; and an LED lighting circuit which rectifies AC voltage phase-controlled and input via the pair of input terminals, converts DC output voltage, which is obtained by rectification, so that the voltage adapts to a load, and lights the LED. The illumination apparatus includes an illumination apparatus body, an LED lighting device and an LED.

Owner:TOSHIBA LIGHTING & TECH CORP

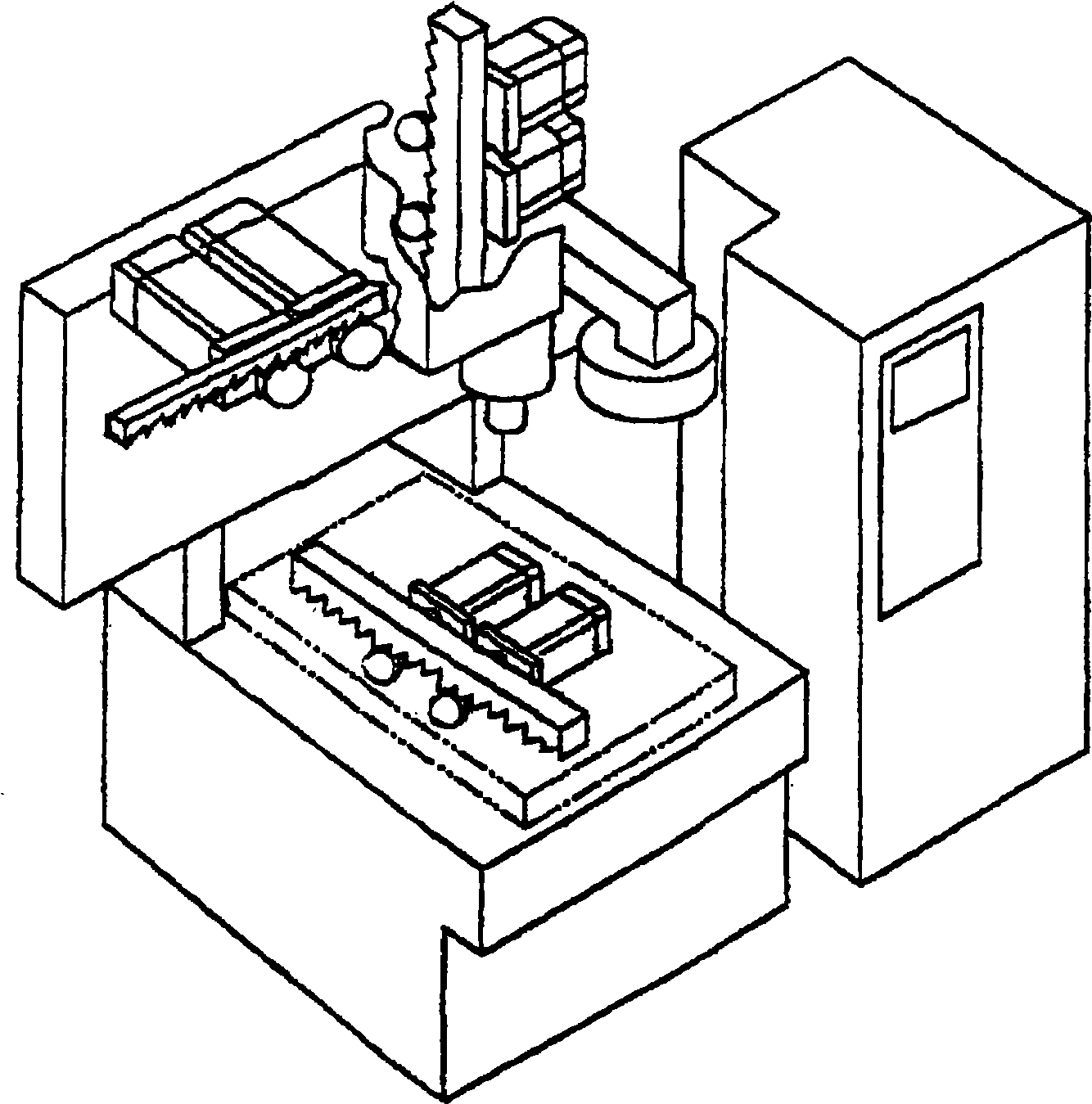

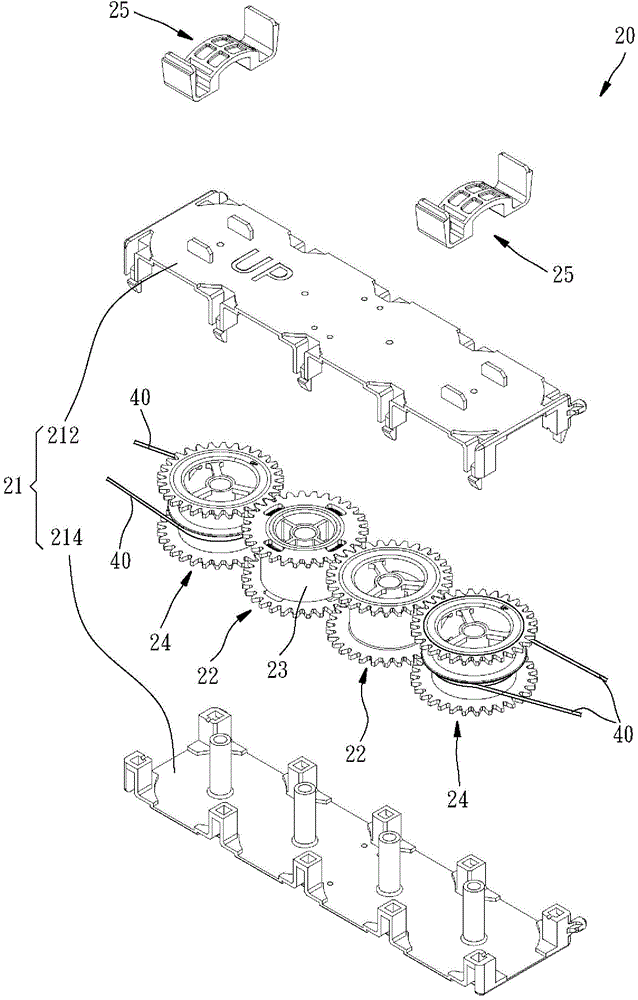

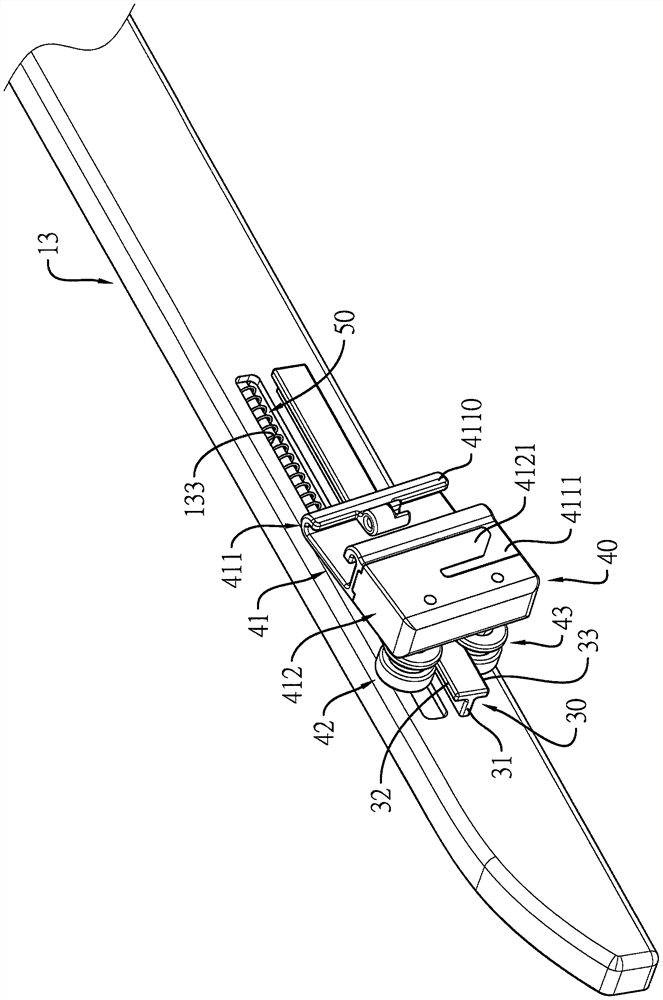

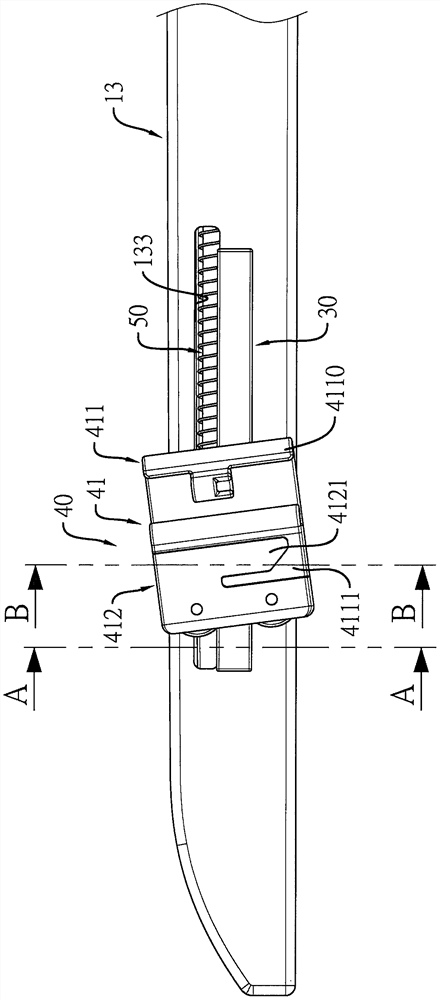

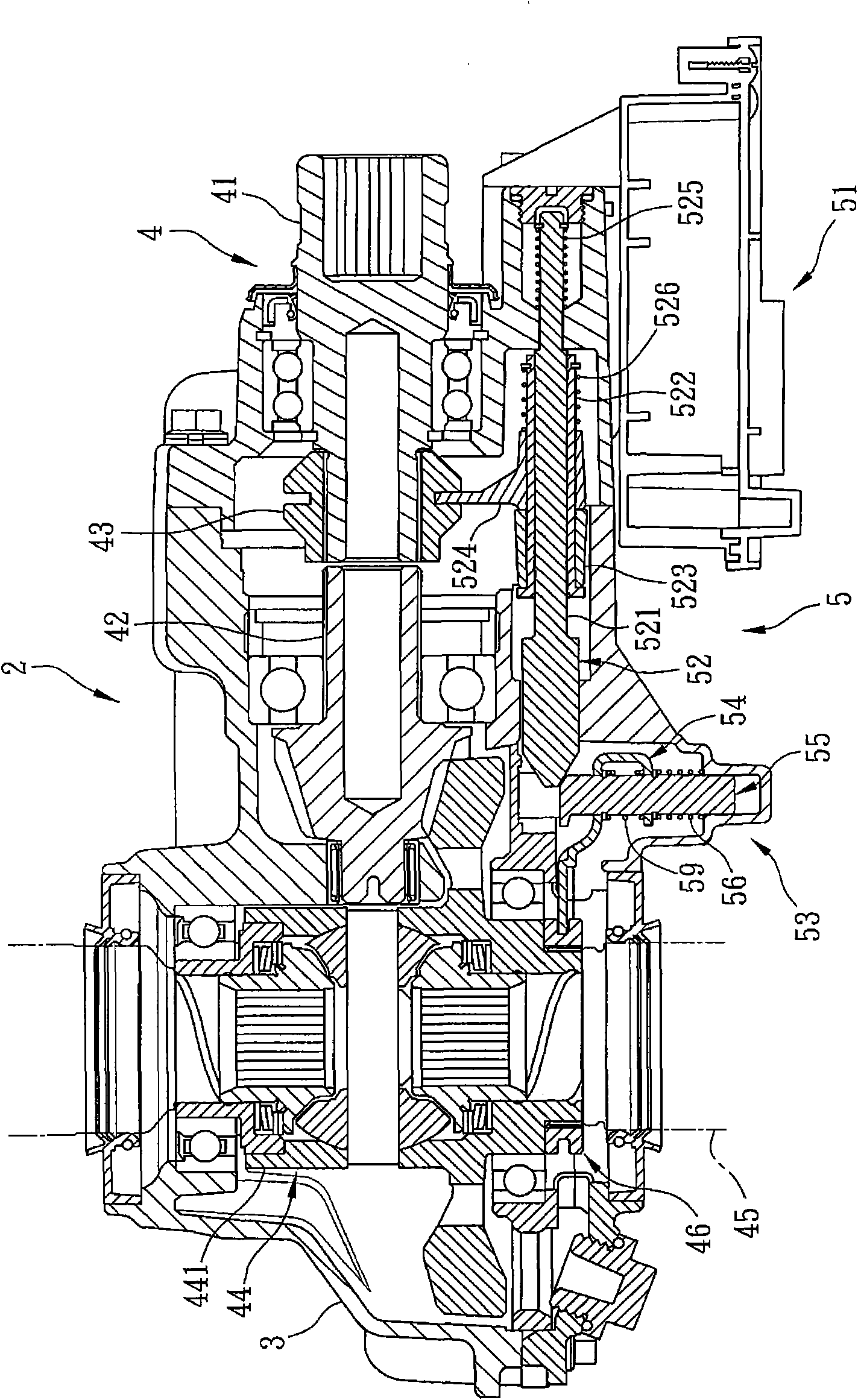

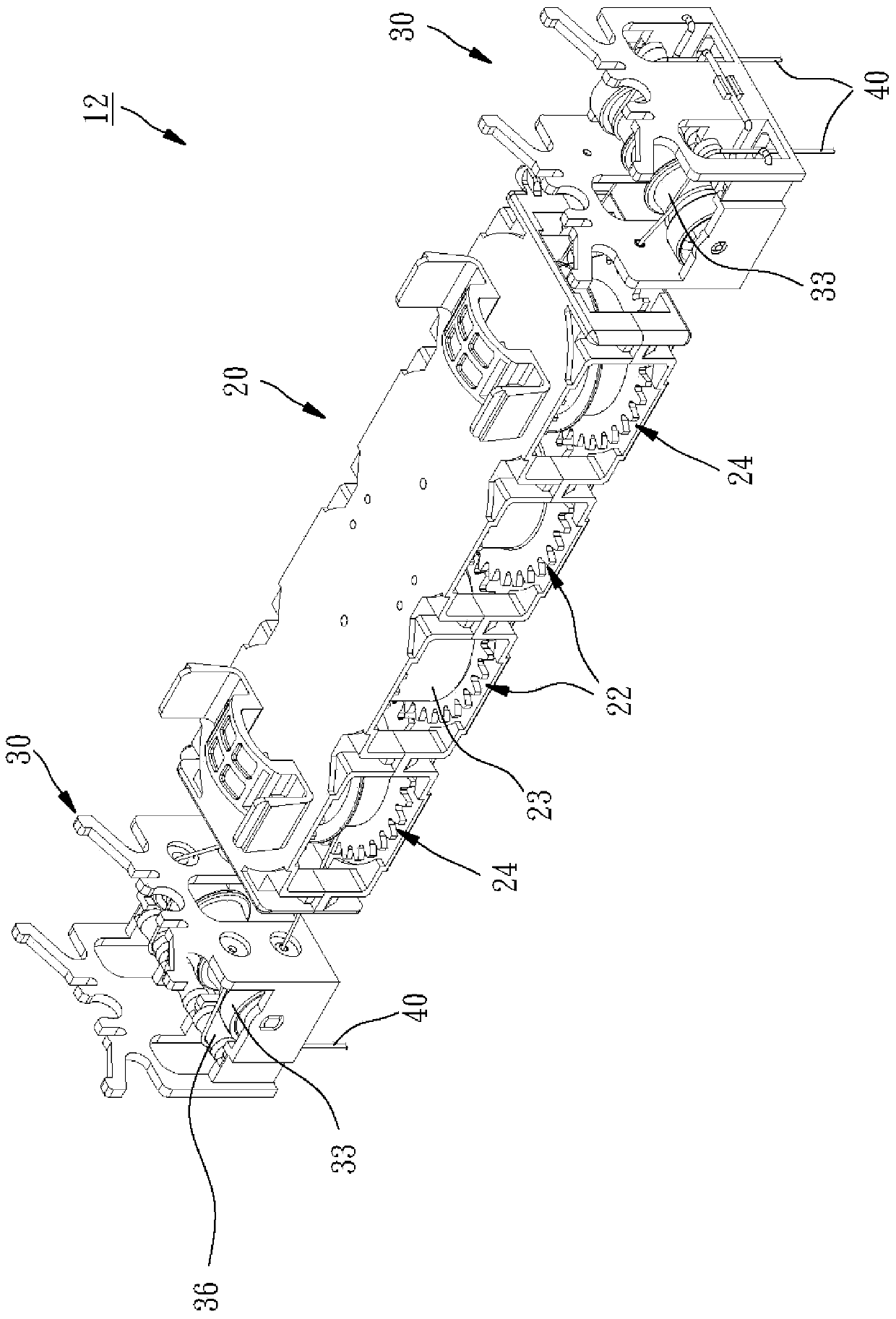

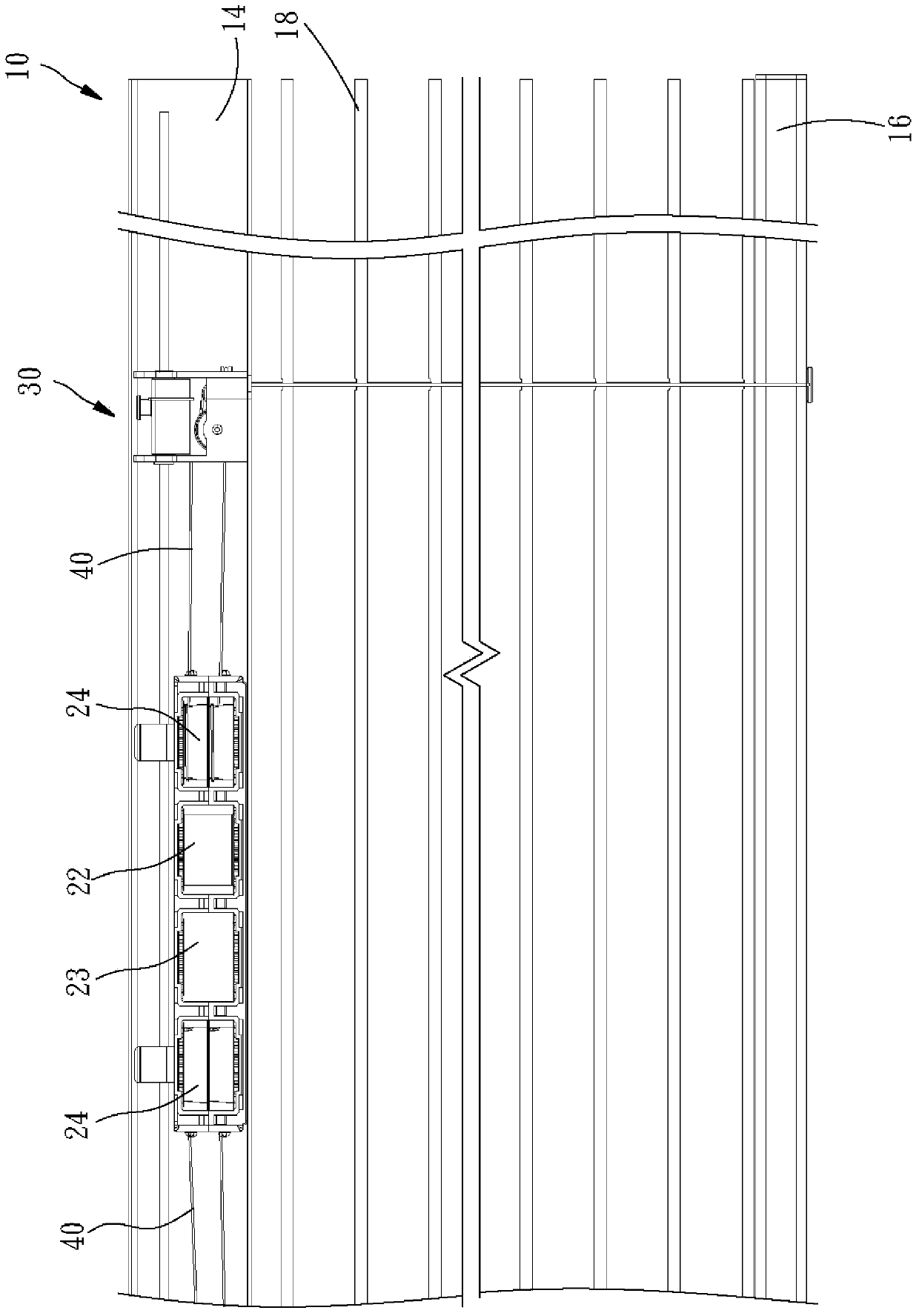

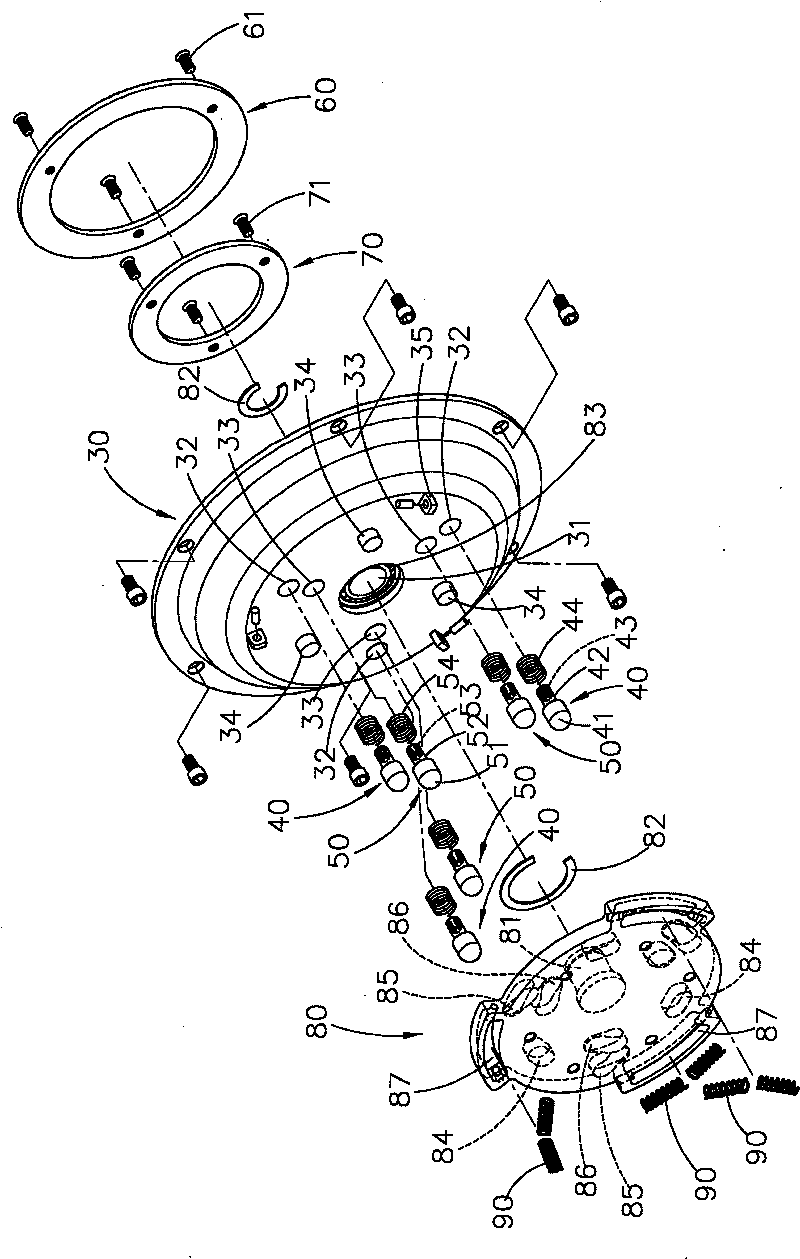

Backlash elimination structure of transmission mechanism

InactiveCN101487526ASave assembly spaceSmooth movementPortable liftingGearing elementsSlant angleEngineering

The invention provides a tooth space eliminating mechanism of a driving mechanism. The invention relates to a driving mechanism which is composed of a mechanism body, a motor, a driving gear, a driven gear, an elastic unit, and the like and can move along and be meshed with the rack. Essentially, the elastic unit set is arranged at the appropriate position of one side of the driven gear adjacent to the mechanism body, so that the elastic unit can apply an elastic force to the driven gear and the force application direction is coincided with the slant angle positioned between the driving gear and the rack, and furthermore, the driven gear can constantly and simultaneously move towards the driving gear and the rack, thus eliminating the tooth space.

Owner:崴立机电股份有限公司

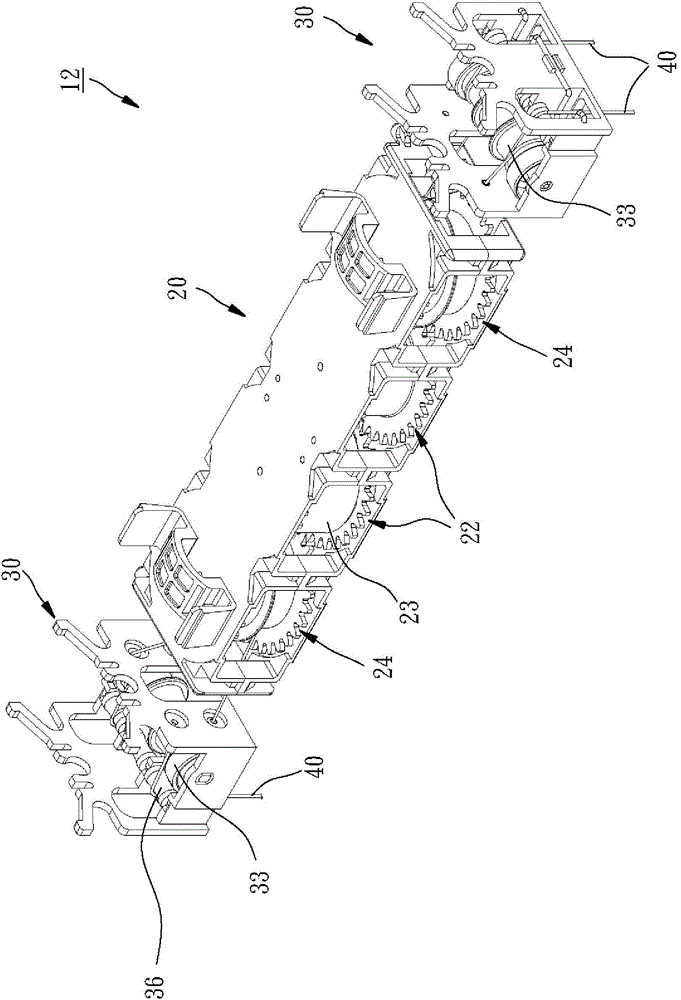

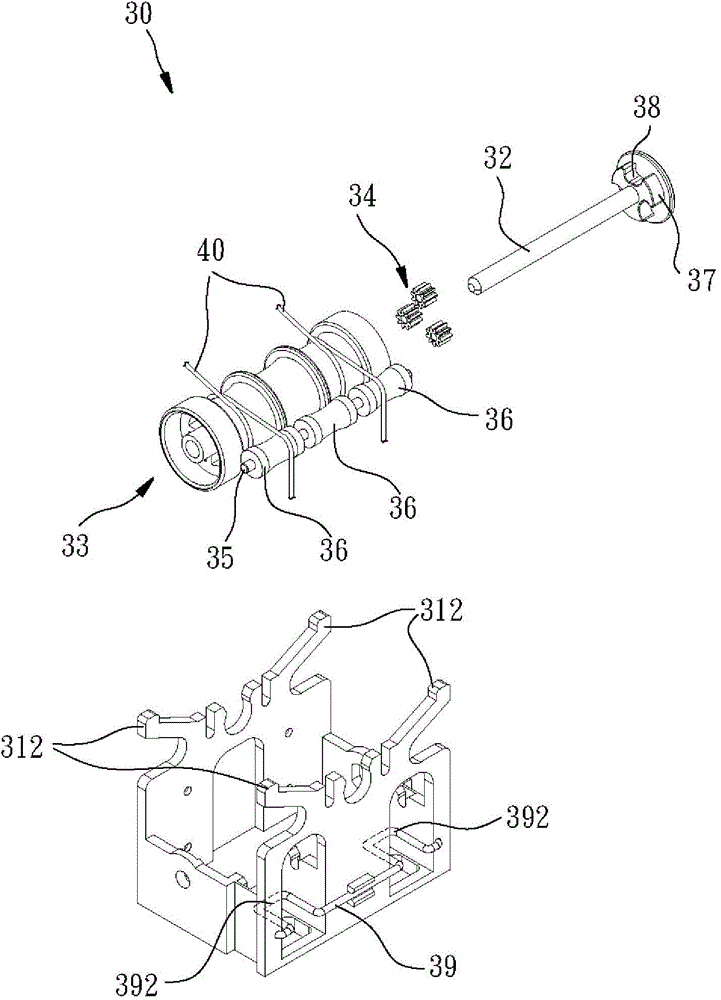

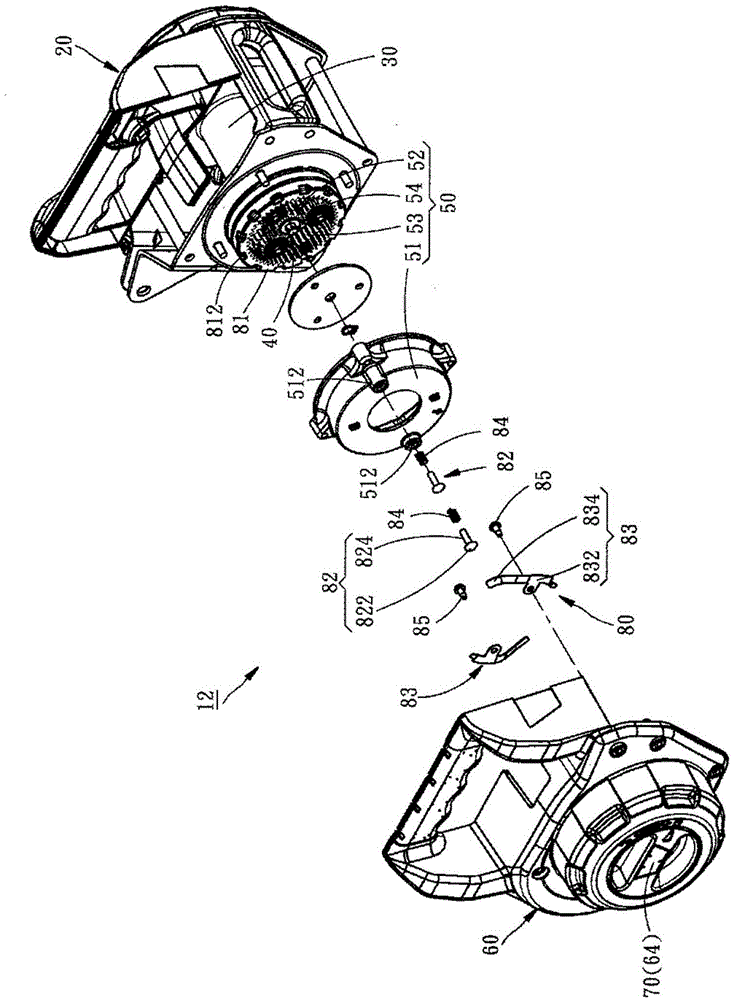

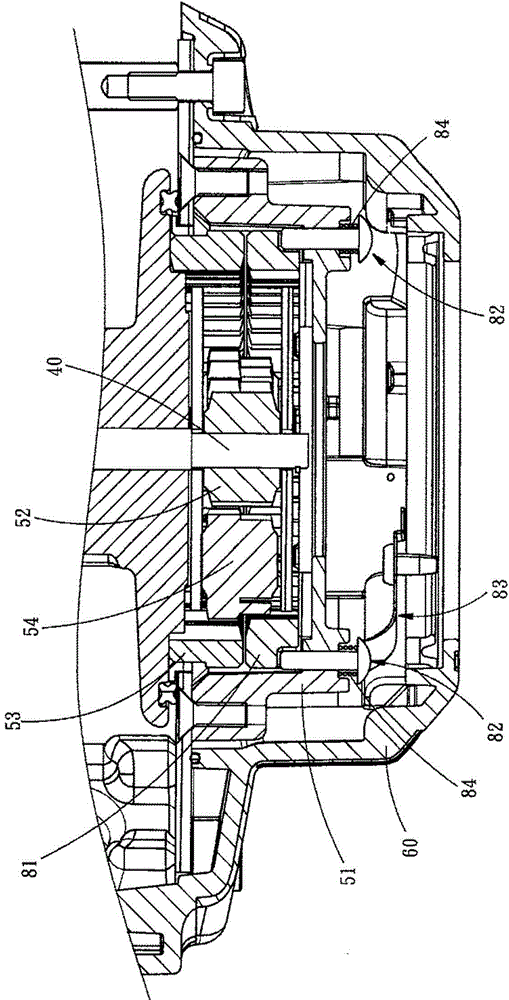

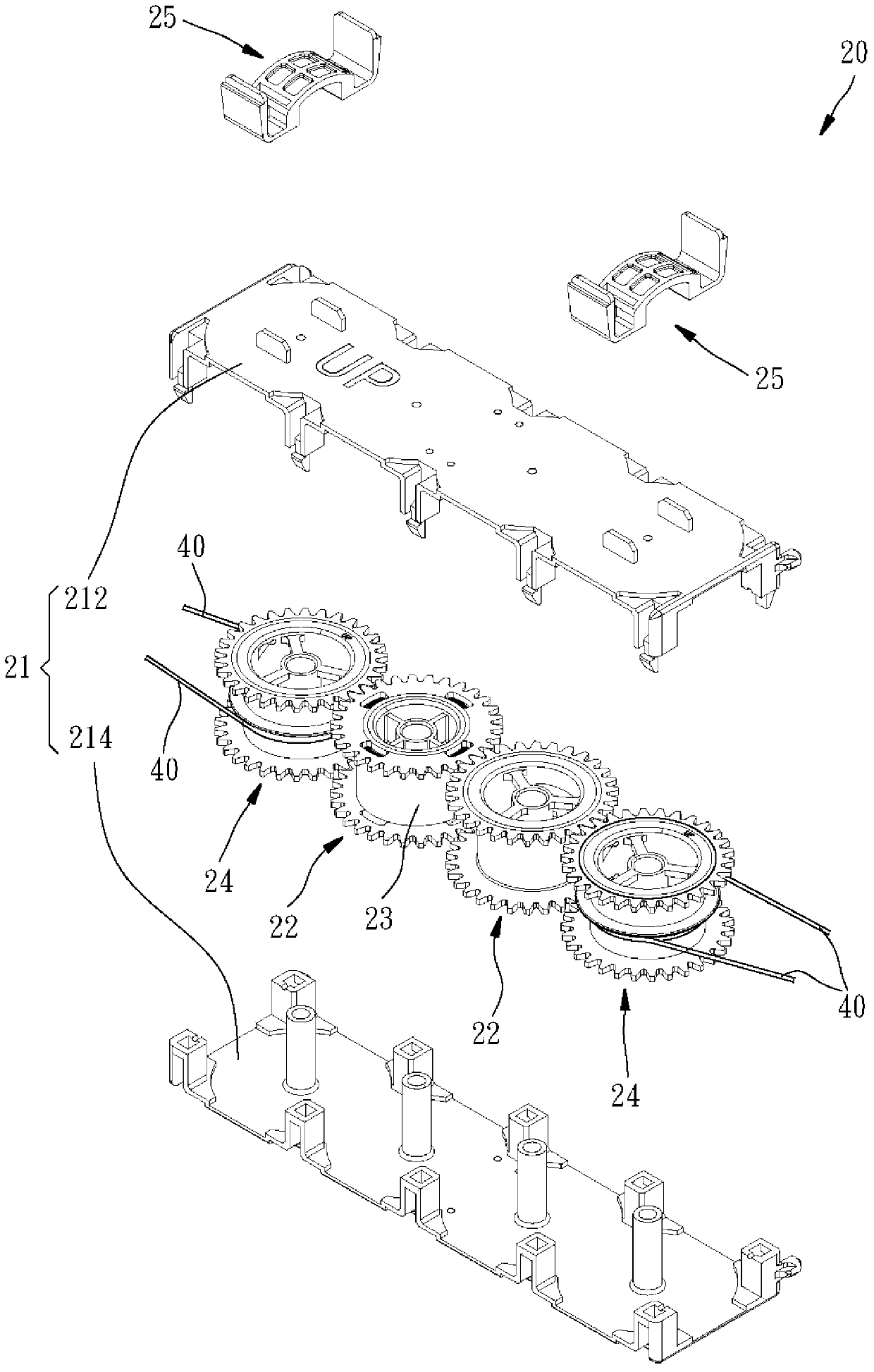

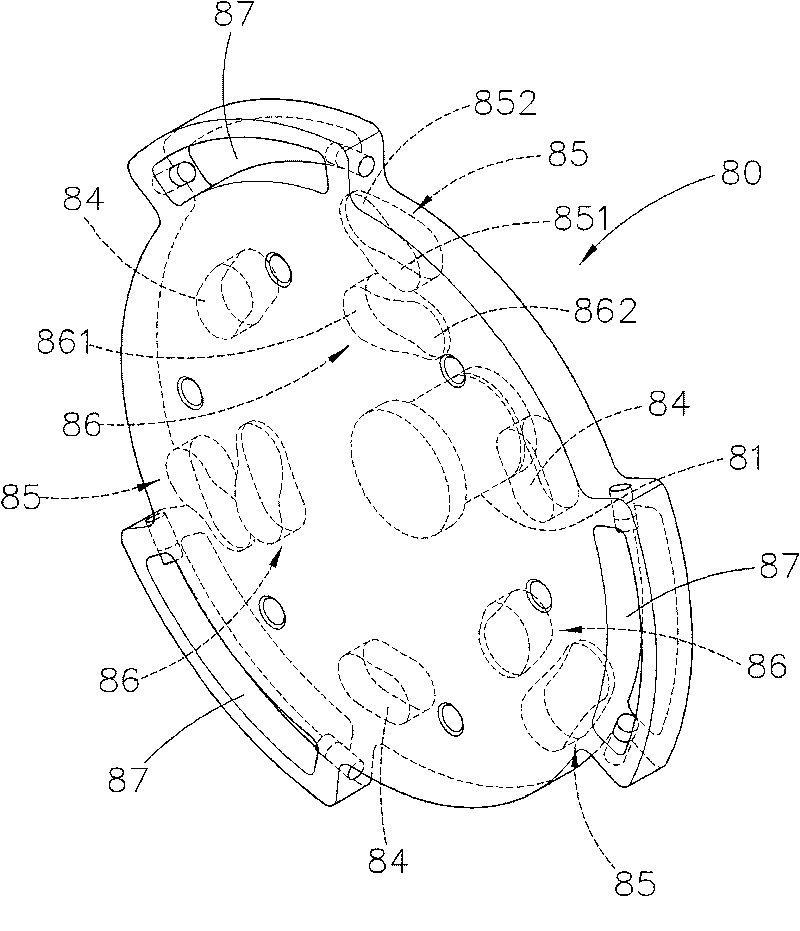

Curtain body braking mechanism of curtain without pulling rope

The invention provides a curtain body braking mechanism of a curtain without a pulling rope. Motion of a transmission rope is controlled mainly by a one-way clutch unit. The one-way clutch unit is provided with a wheel shaft base, a wheel shaft, a clutch wheel and two planetary gears. The wheel shaft is fixed to the wheel shaft base and provided with two spaced brake blocks, a rolling groove is formed between the two brake blocks, the clutch wheel is arranged on the wheel shaft in a sleeving and rolling mode and provided with an inner annular tooth part, the inner annular tooth part surrounds the peripheries of the two brake blocks, and the planetary gears are arranged in a brake groove of the wheel shaft and meshed with the inner annular tooth part of the clutch wheel in a rolling mode, so the planetary gears are driven by the inner annular tooth part of the clutch wheel and clamped with or separated from the brake blocks of the wheel shaft. Thus, when the planetary gears are clamped to the brake blocks, the transmission rope cannot be stretched, and positioning of a curtain body is finished.

Owner:陈金福

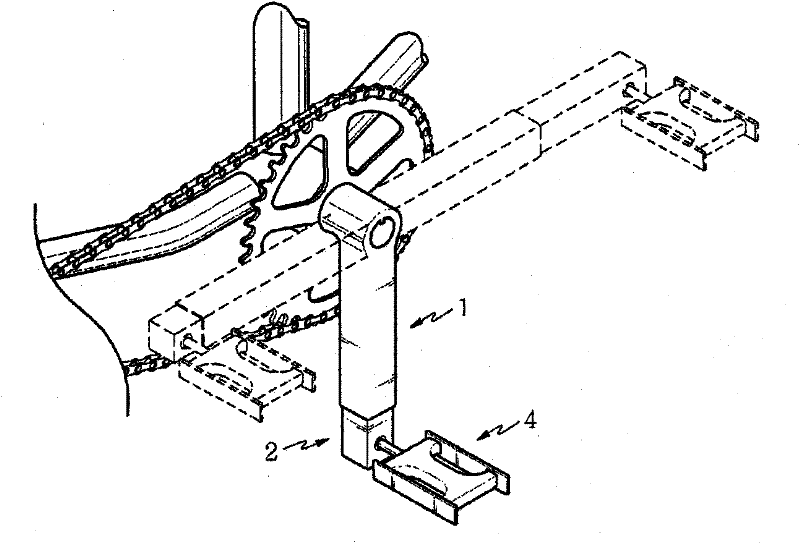

Retractable/extendable crank using a cylindrical cam, an end cam, or a swash plate cam, and bicycle using the same

InactiveCN102099245AHigh torqueSmooth swivel movementMechanical apparatusVehicle cranksEngineeringCam

The present invention relates to a mechanical element, and more particularly, to a crank connected to a bicycle pedal or a handle for rotating a rotary body and to a bicycle using the same. The present invention uses a cylindrical cam, an end cam, or a swash plate cam, and the shafts of these cams and a shaft of a pedal or a handle for applying force are equipped with a miter gear (a bevel gear the number of teeth of which is 1:1 and the shaft angle of which is 90 degrees), such that the crank retracts / extends one time per one rotation of the pedal or the handle. The retractable / extendable crank of the present invention is advantageous in that the length of the crank is elongated to generate a large amount of rotating force in a force-applying section, and shortened in a section where no force is applied to reduce the actuating space occupied by the crank and apply a large amount of torque to the rotary body from the same force, without deviating from the normal motion range of the arms or legs during rotation. The retractable / extendable crank of the present invention has a significantly rigid structure and provides reliable operation, and thus is suitable as a driving crank to beconnected to a pedal of a bicycle. As compared with conventional bicycles, the bicycle using the crank of the present invention is supplied with a larger amount of rotating force in proportion to theelongation of the crank from the same force, thus enabling the bicycle of the present invention to travel quickly with less force and climb a steep upward slope in an easy manner.

Owner:李根亨

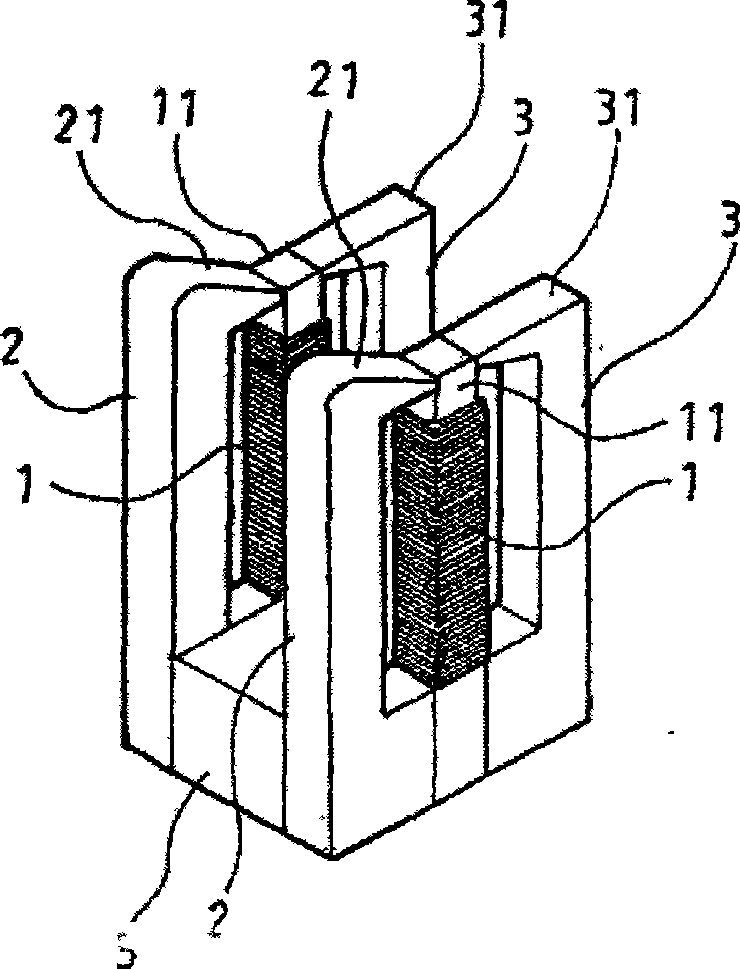

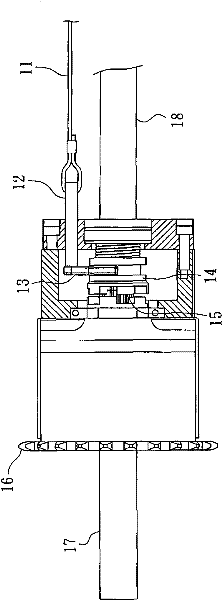

Needle selector for tubular knitting towel knitting machine

The invention relates to a needle selecting device of a circular knitting towel knitting machine, comprising: two coils winding an axis; two first steel plates which are positioned at one sides of the coils, and the top end of which is an inclined plane form top to bottom; two second steel plates which are positioned at the other sides of the coils, and a parietal margin of which is a plane; magnet steel which is positioned at bottom flanges of the components; and a machine shell used for holding the components. The combination of the components forms the needle selecting device which is installed below a lever needle combined by the knitting needle of the circular knitting towel knitting machine and a sinker in an embedding way; by electrifying the positive and negative directions of the coils and forming excitation or demagnetization by the first steel plates and the second steel plates, the lever needle can be adsorbed or released to cause the stitch of the lever needle to be separated from or enter a triangular orbit and further control the up and down yarn knitting stroke of the knitting needle and the front and back displacement of the sinker so as to form the function of needle selecting, achieve the effect of jacquard weave and cause the knitting machine to knit the towel cloth with different patterns, and convex or concave solid patterns such as long wool, long wool in rows, short wool or no wool and the like.

Owner:洪荣豪

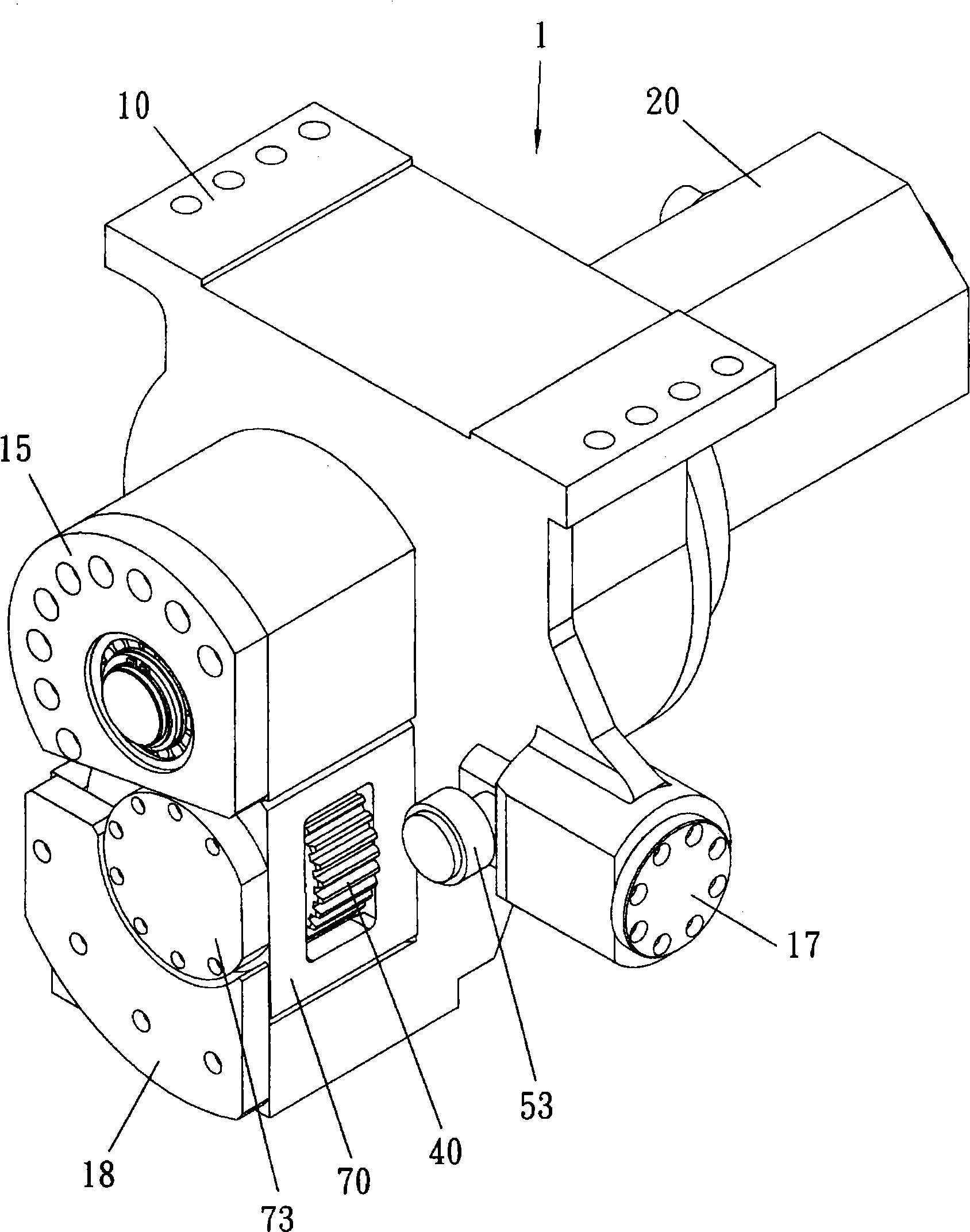

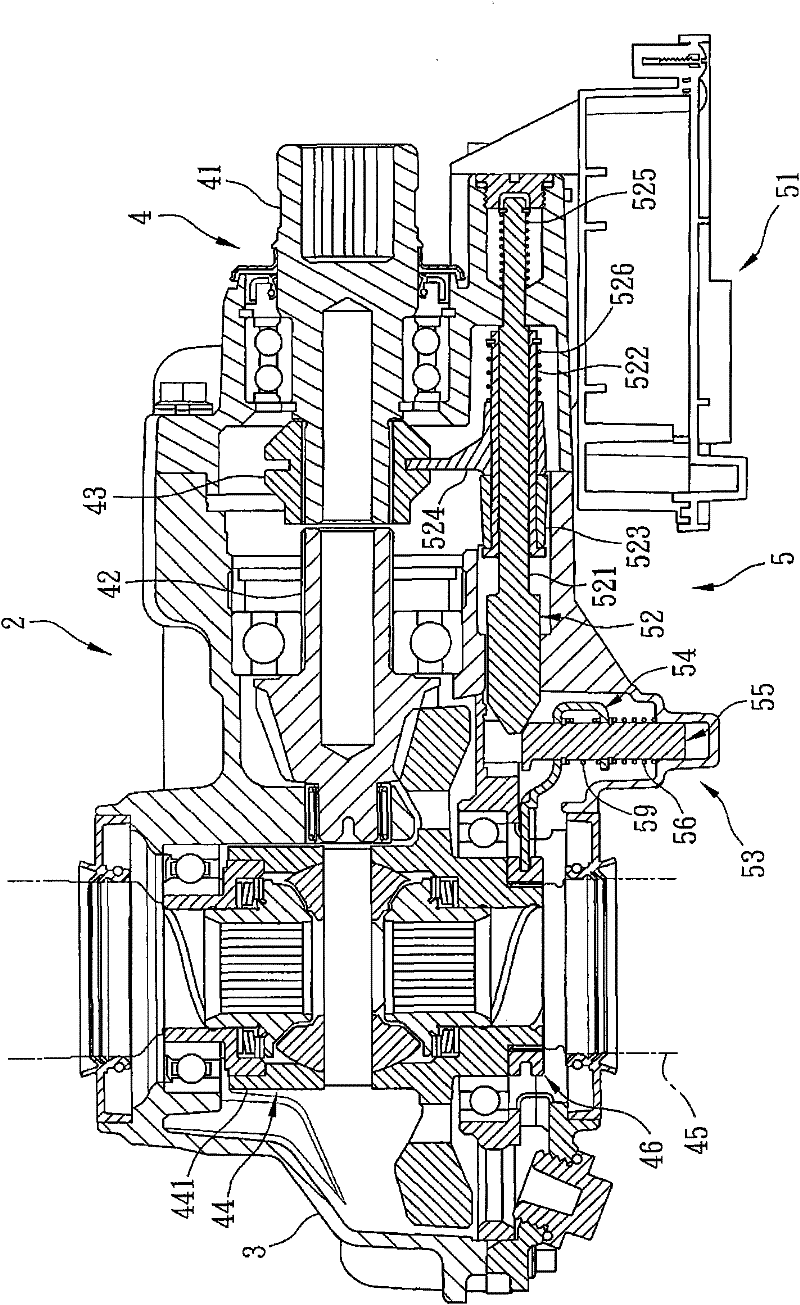

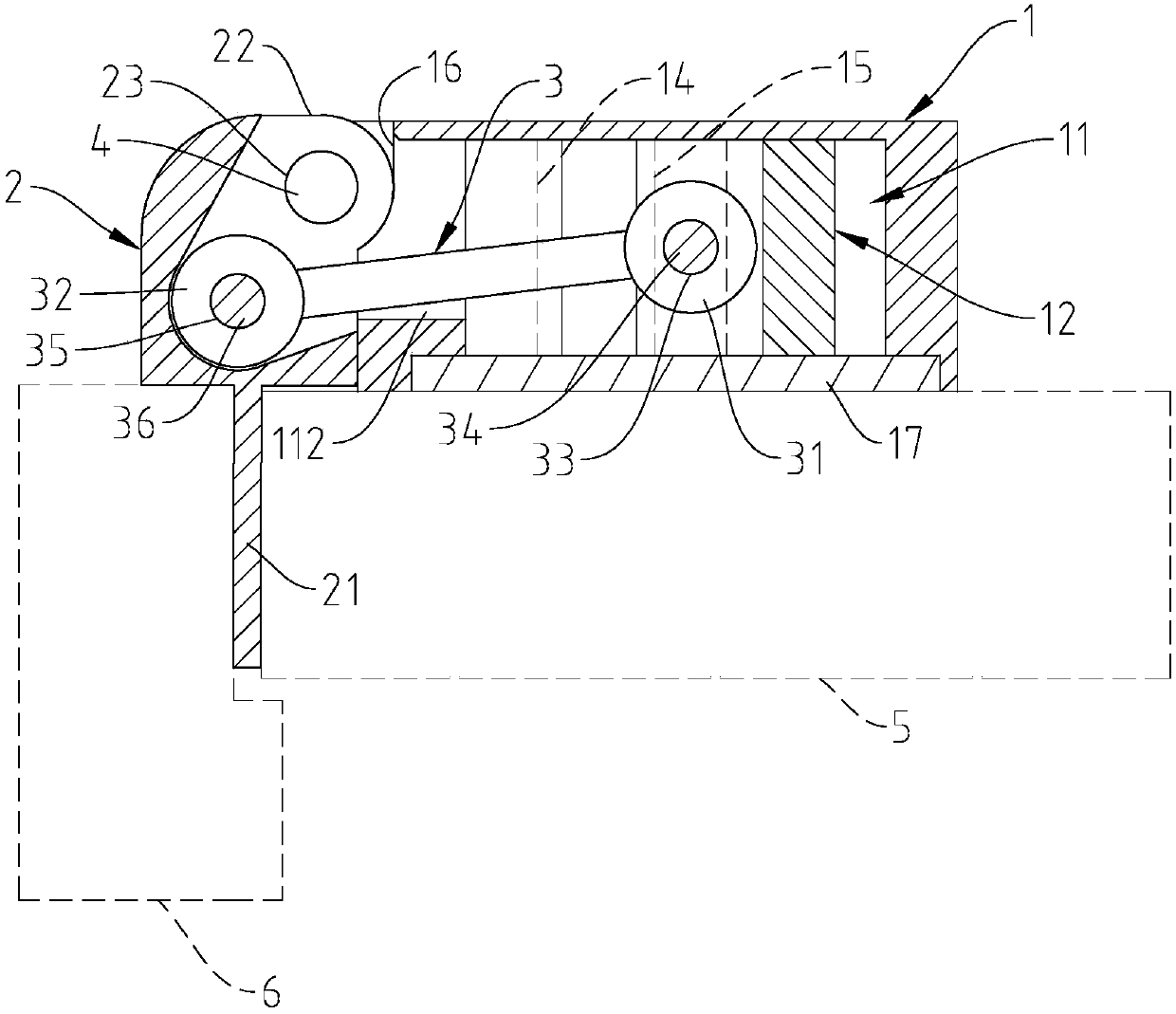

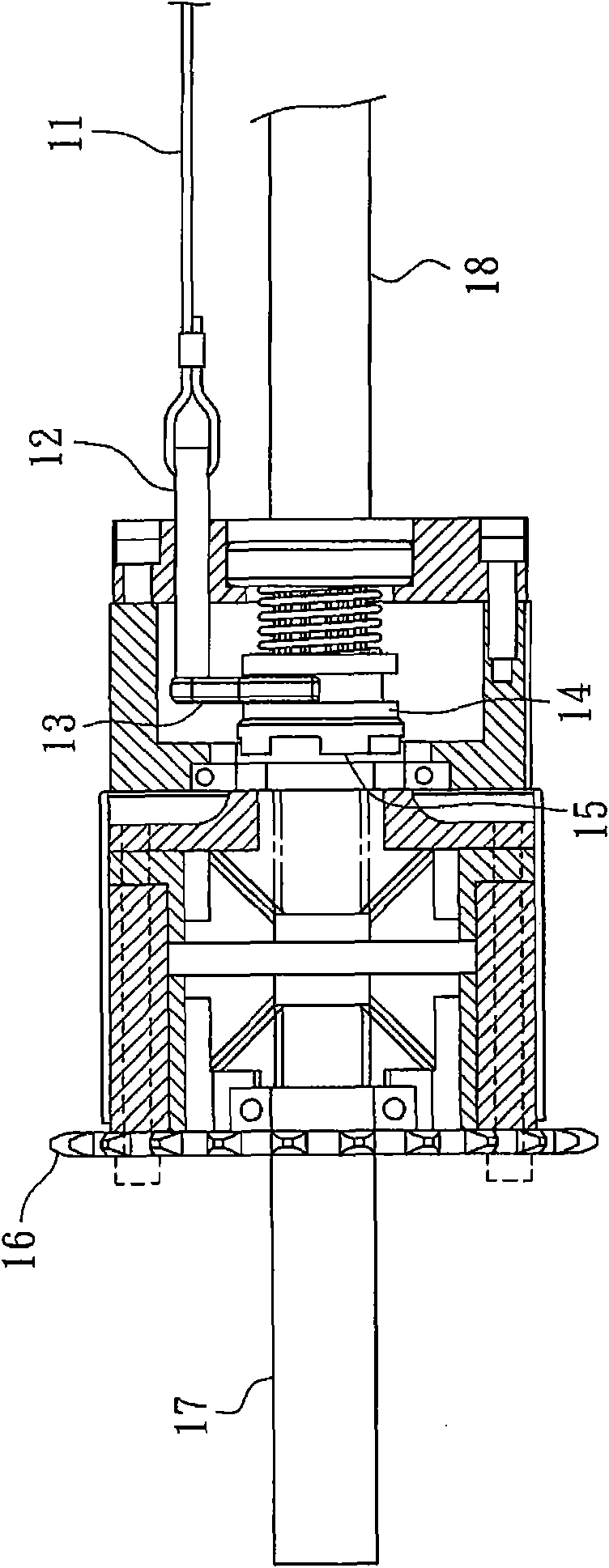

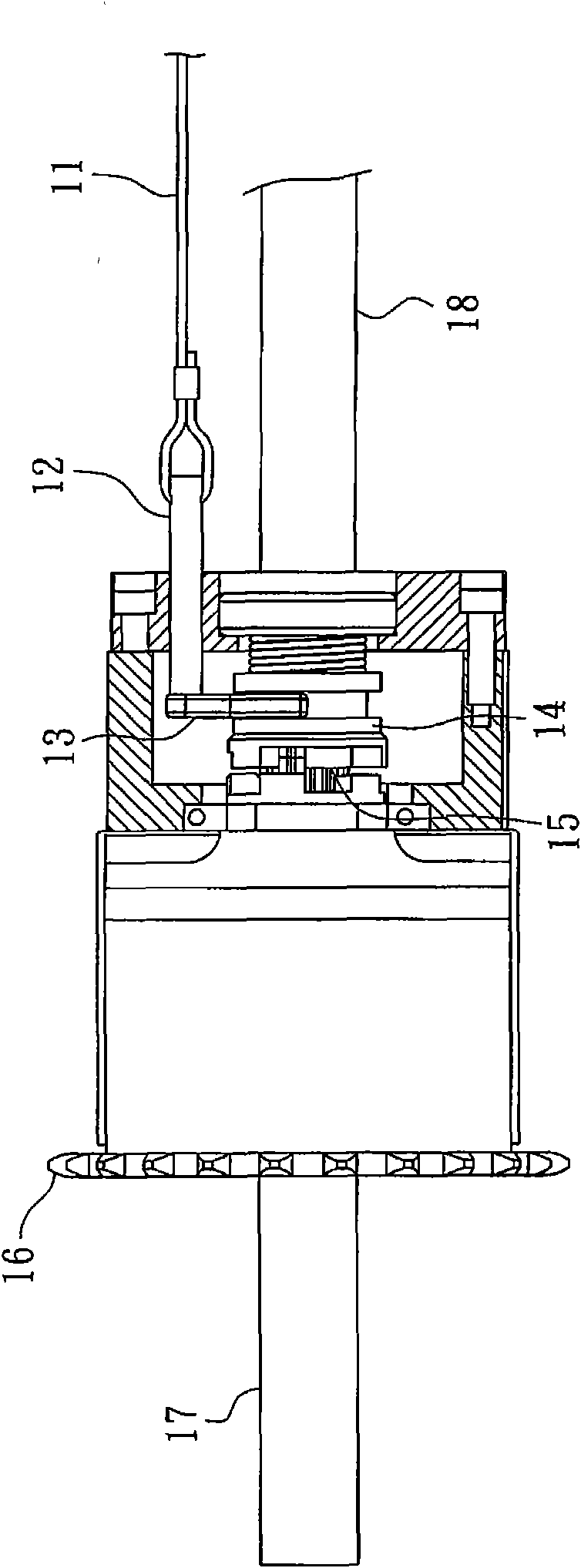

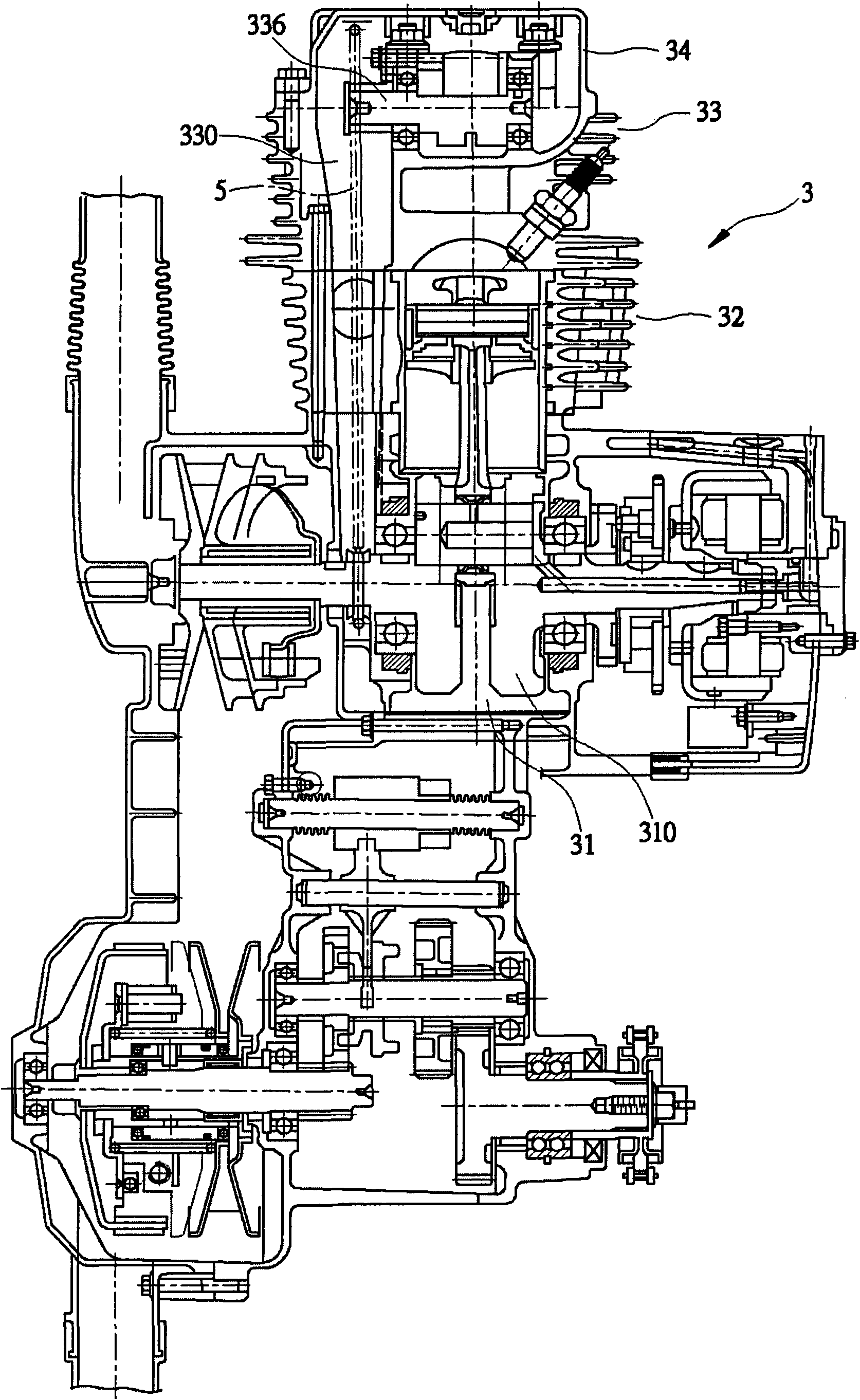

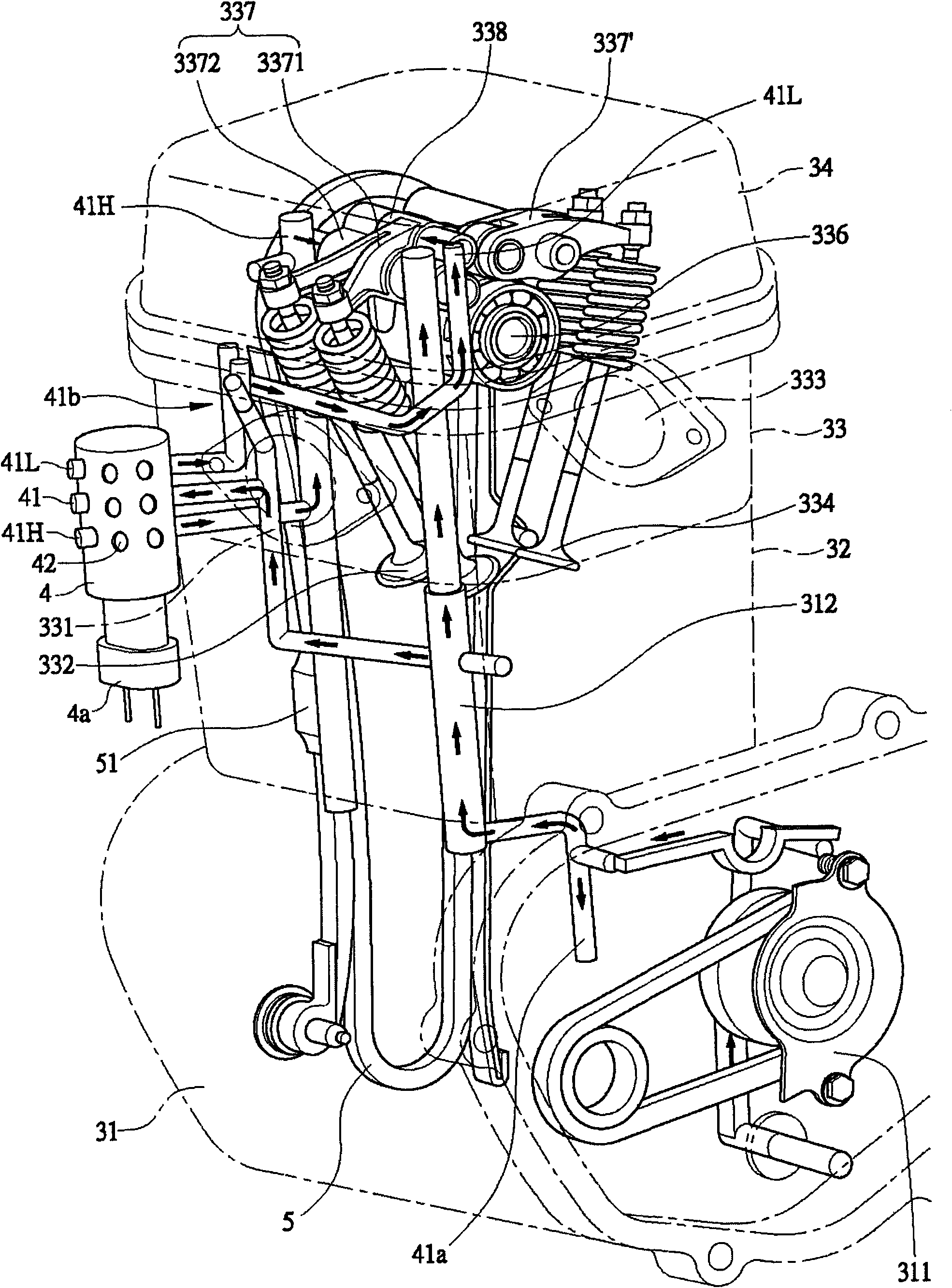

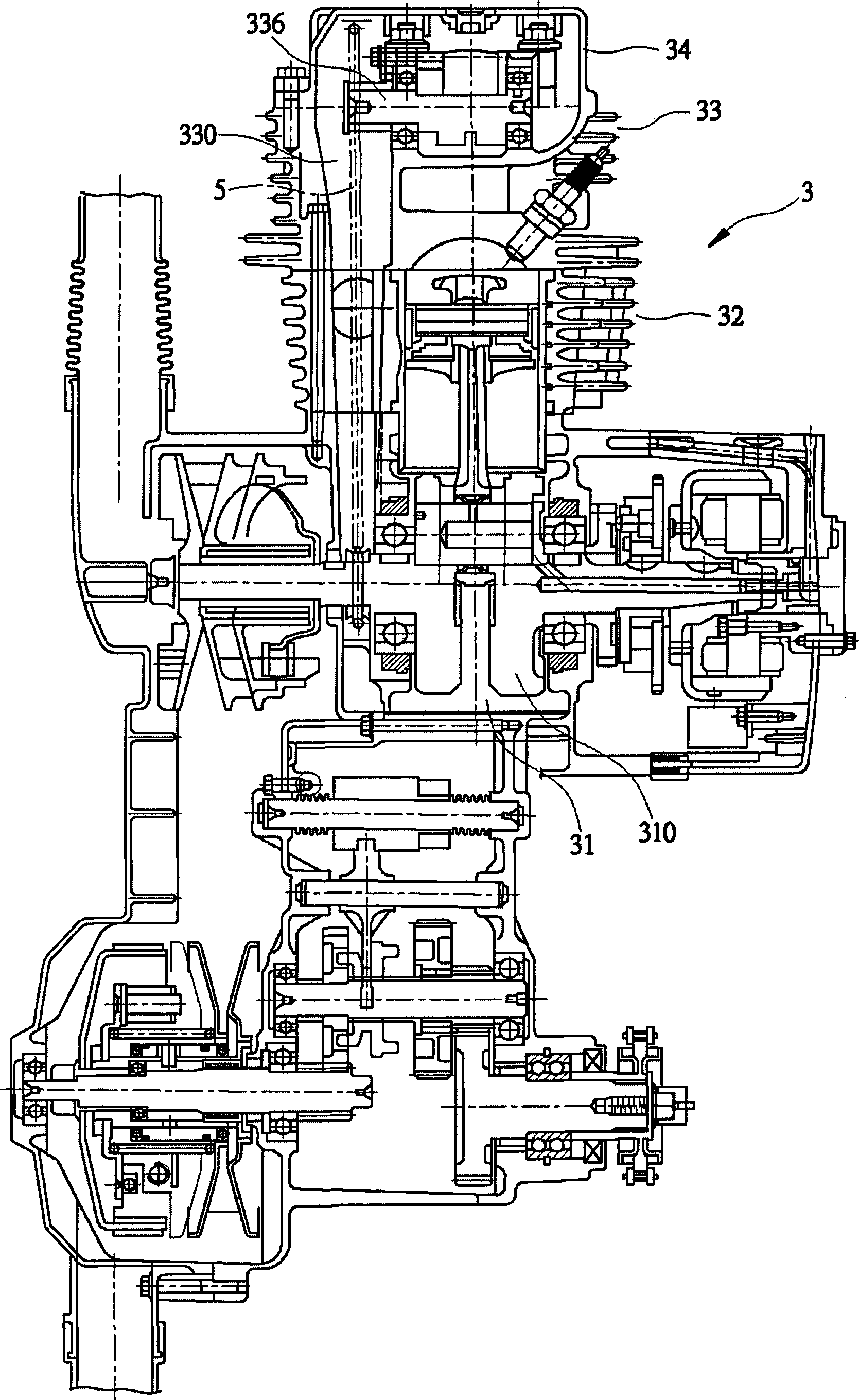

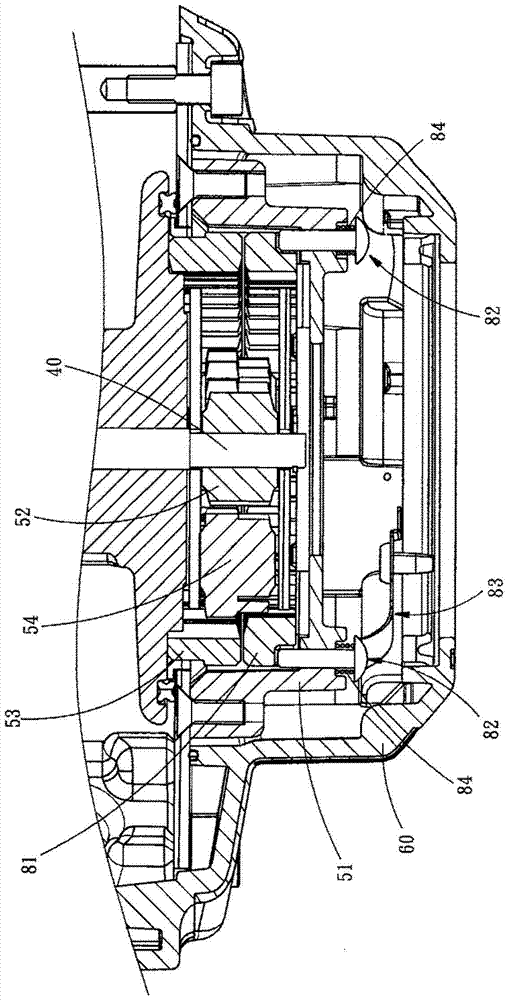

Power switching device for vehicle

InactiveCN102343814ASimple designHigh power switching stabilityControl devicesPower switchingCoupling

The invention discloses a power switching device for a vehicle. The power switching device comprises a power transferring unit and a drive unit. The power transferring unit comprises an input shaft, an output shaft which is separated from the input shaft, a second coupling piece which can move on the input shaft and the output shaft, and a first coupling piece which can move on an axle cylinder of a wheel axle and a differential. The drive unit comprises a control box, a first drive mechanism and a second drive mechanism. The control box can drive the first drive mechanism to drive the second drive mechanism to move, so that the first coupling piece is poked; therefore, the wheel axle does not generate differential power, or the first drive mechanism pokes the second coupling piece so as to switch drive power of the vehicle, the effects of high power switching stability and exact actuating are achieved, and a control mode can be simplified to ensure that the power switching device has the optimum integral design.

Owner:KYMCO

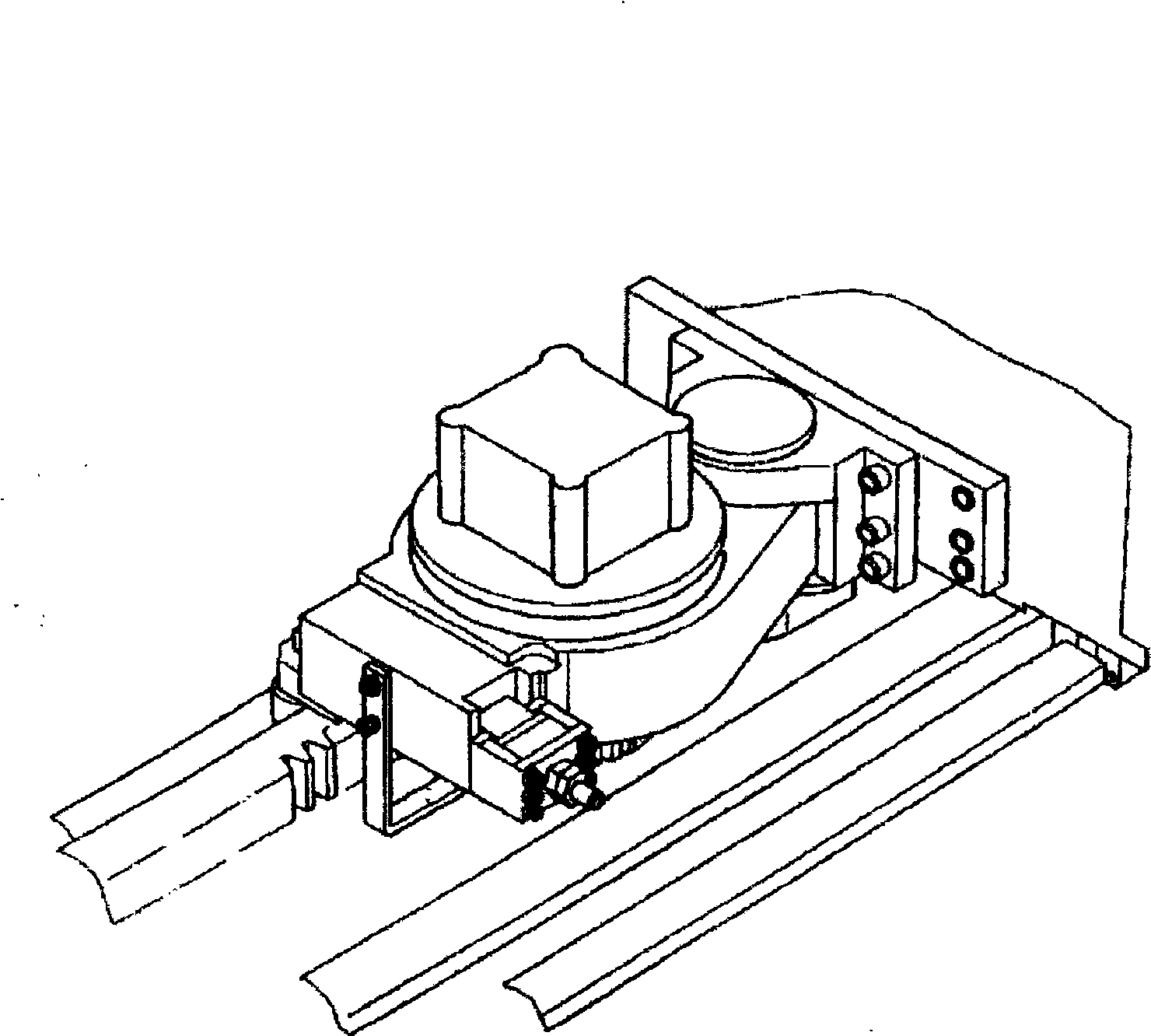

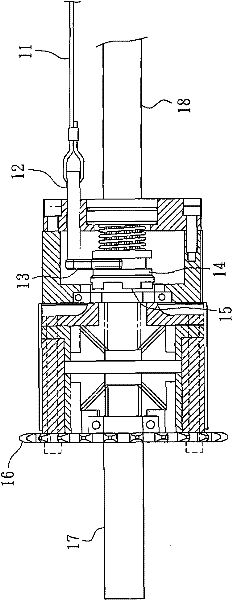

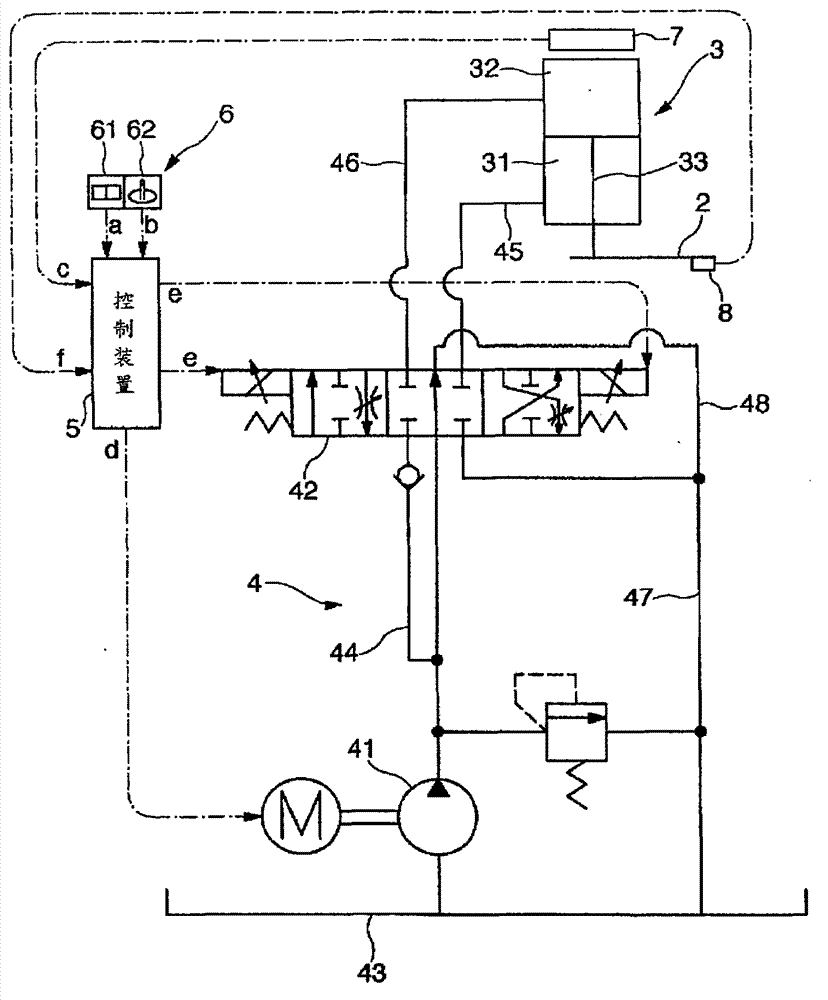

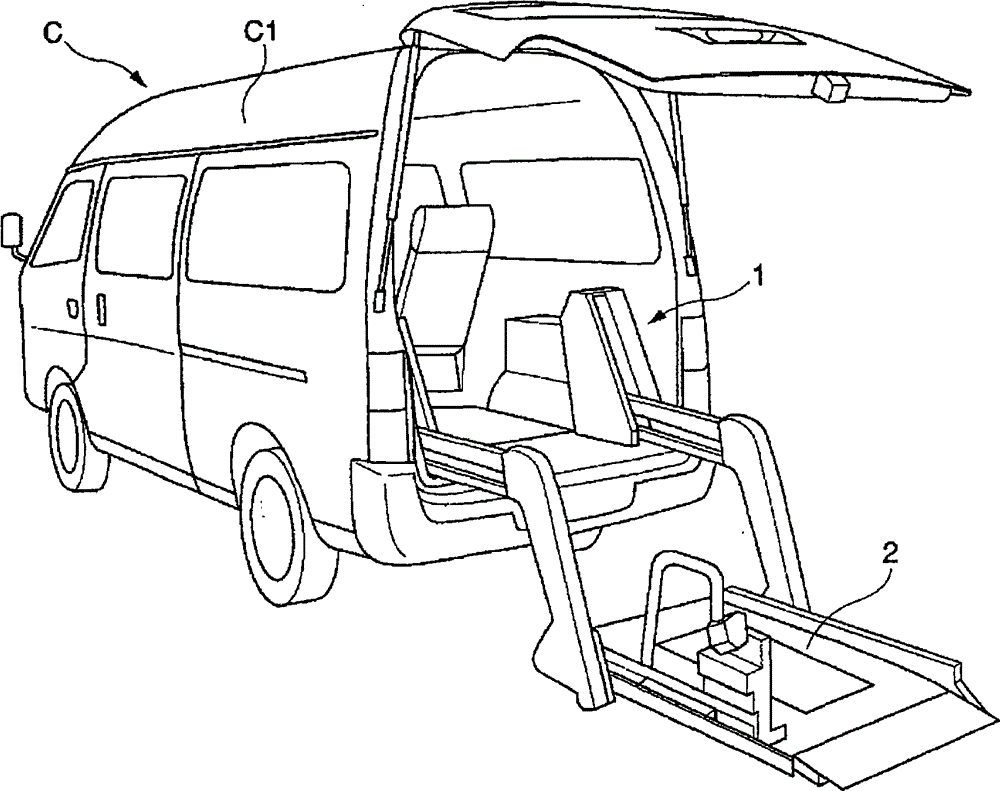

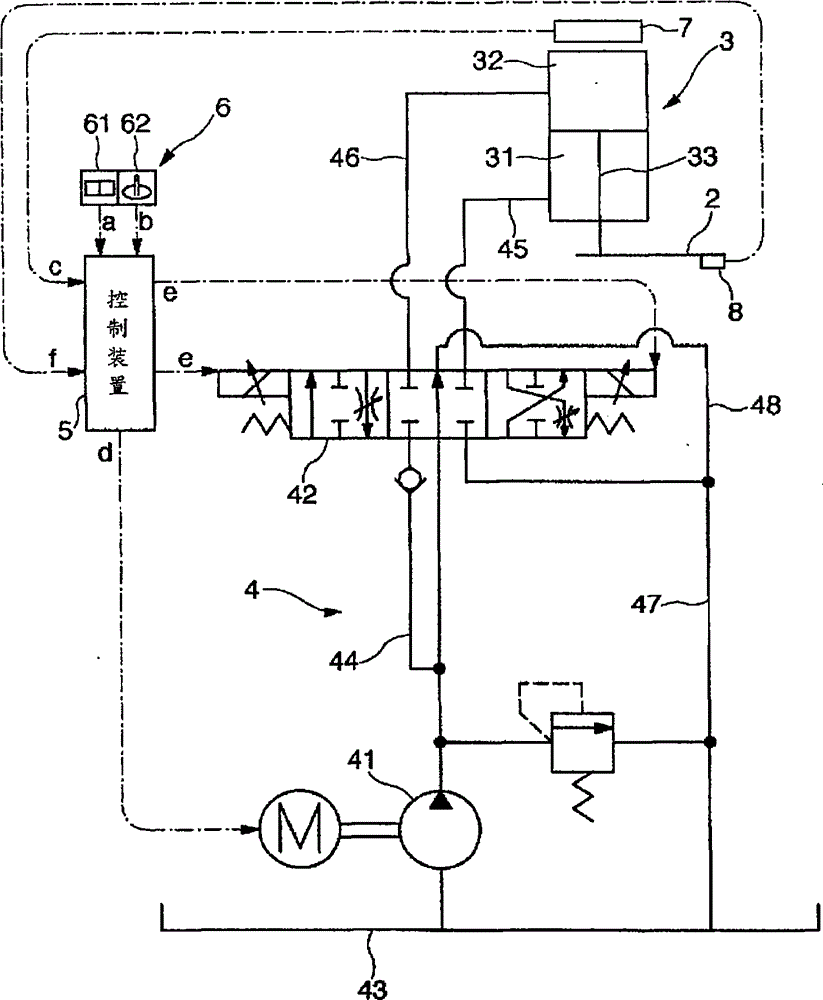

Hydraulic lifter

The invention provides a hydraulic lifter, of which the hydraulic unit comprises a hydraulic pump connected to a motor serving as a driving source and supplies working pressure to a lifting plate to drive an actuator, and a proportional valve which receives the signals form a controller to change opening degree and change the quantity of the work liquid supplied to the actuator via the hydraulic pump. The controller controls the rotation speed of the hydraulic pump and the quantity of the work liquid supplied to the actuator is controlled by the opening degree of the proportional valve. The controller at least carrying following control processes: receiving input of lifting speed of the lifting plate, allowing the motor to rotate at the lowest speed enabling generating torque after a switch starts lifting operation, changing the proportional valve from a fully-closed state to a fully-opened state after the motor rotates in the lowest speed, and gradually increasing the rotating speed of the motor to an object speed corresponding to the elevating speed of the lifting plate received from the switch at the completion of the control of the proportional valve.

Owner:SHIMADZU CORP

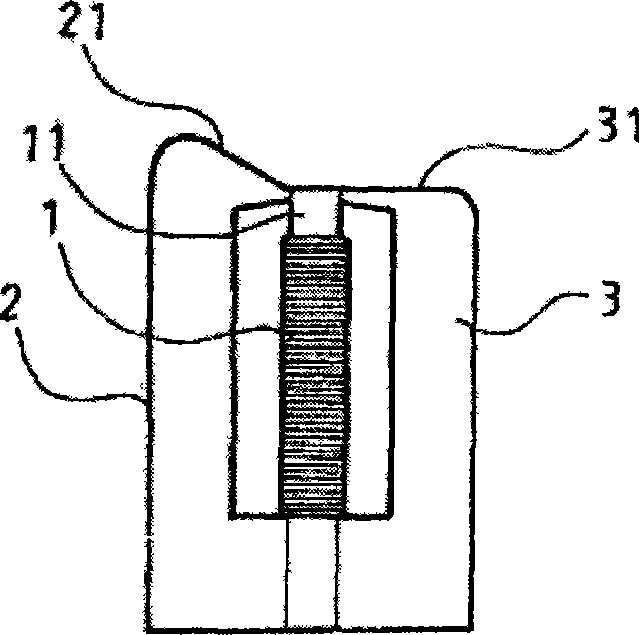

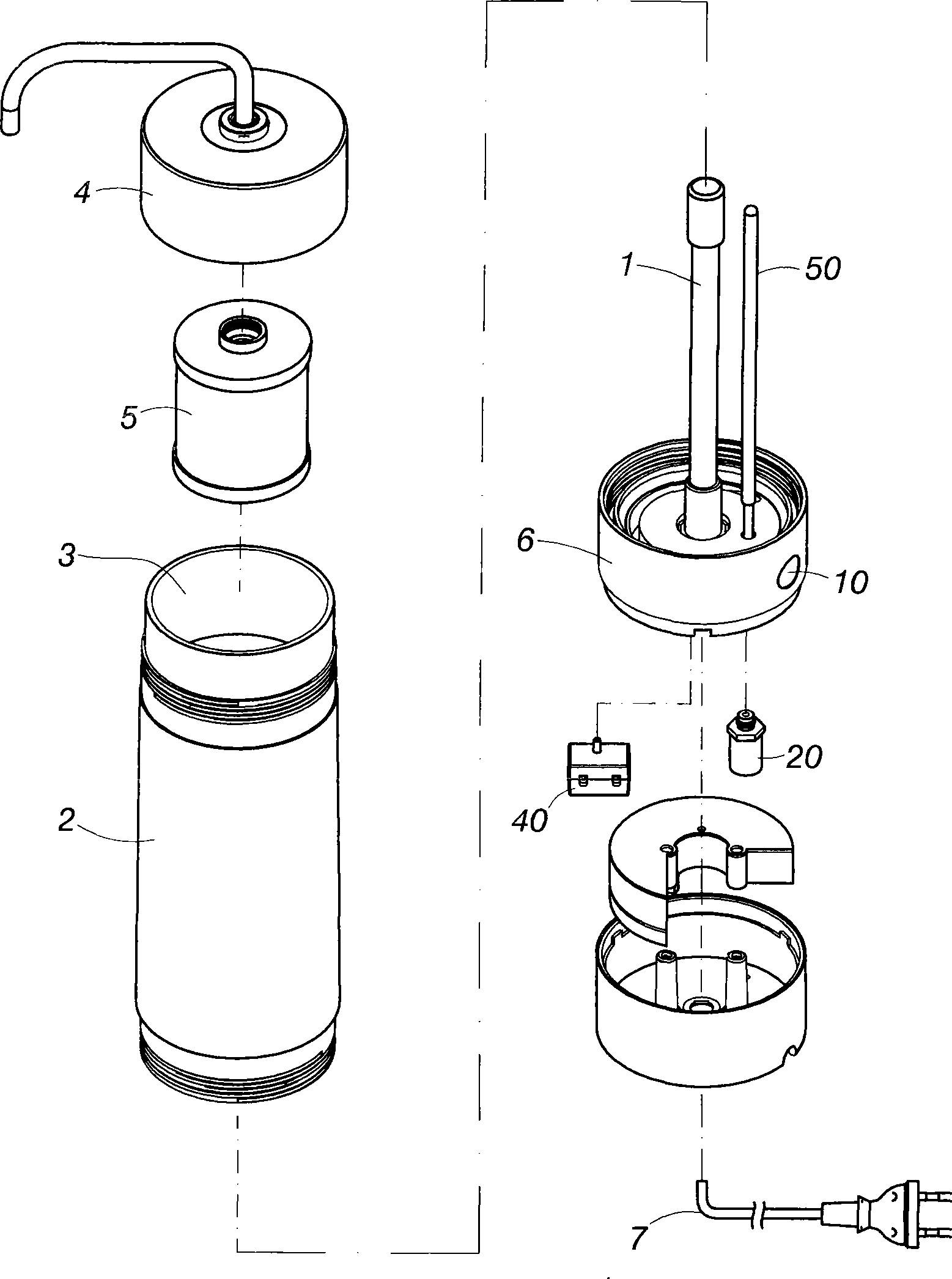

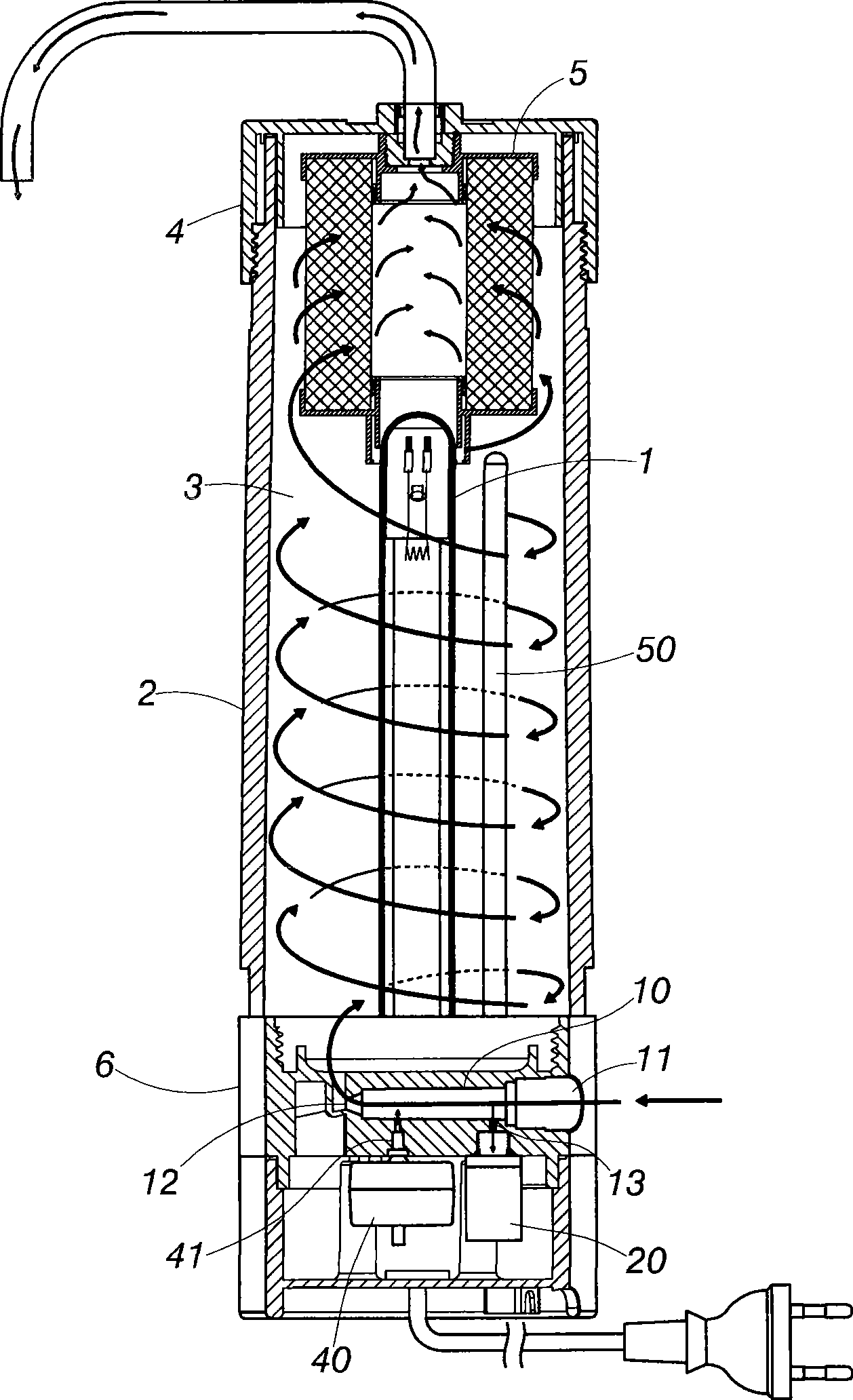

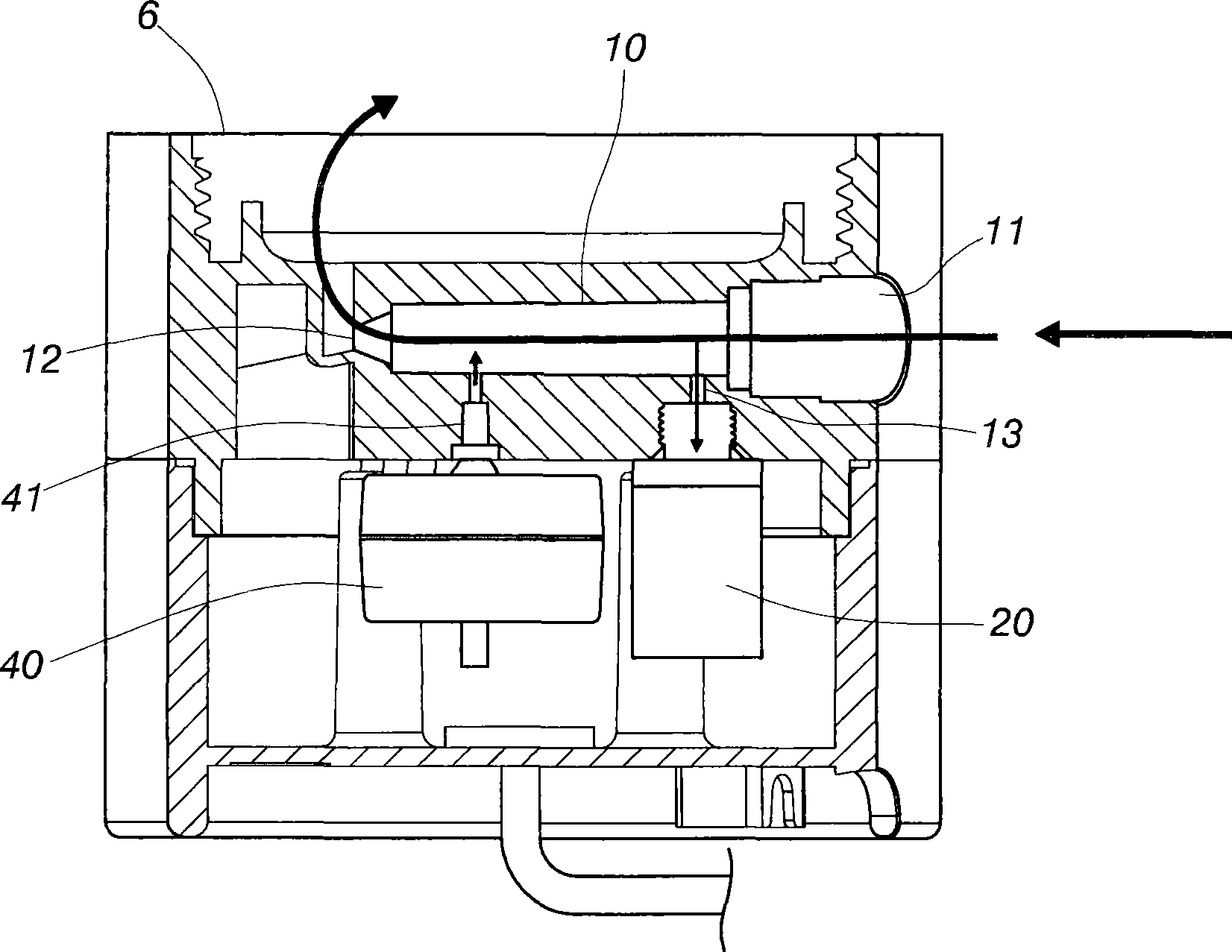

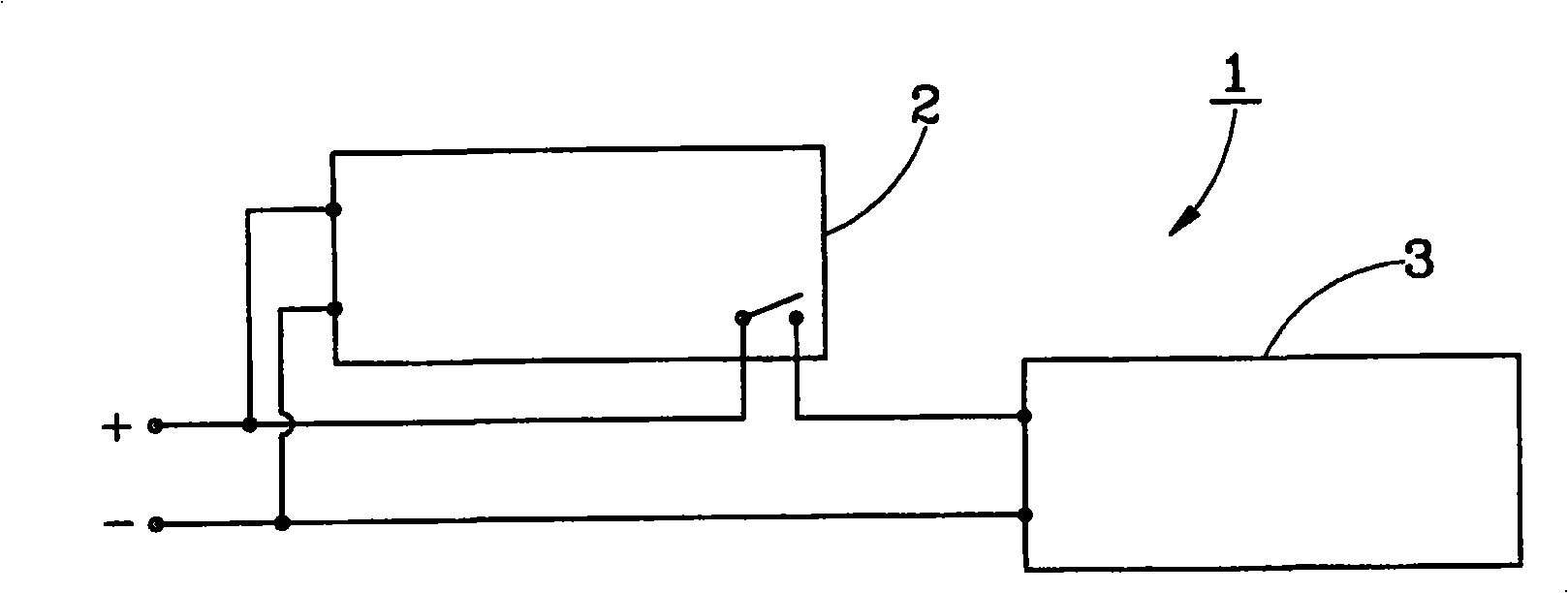

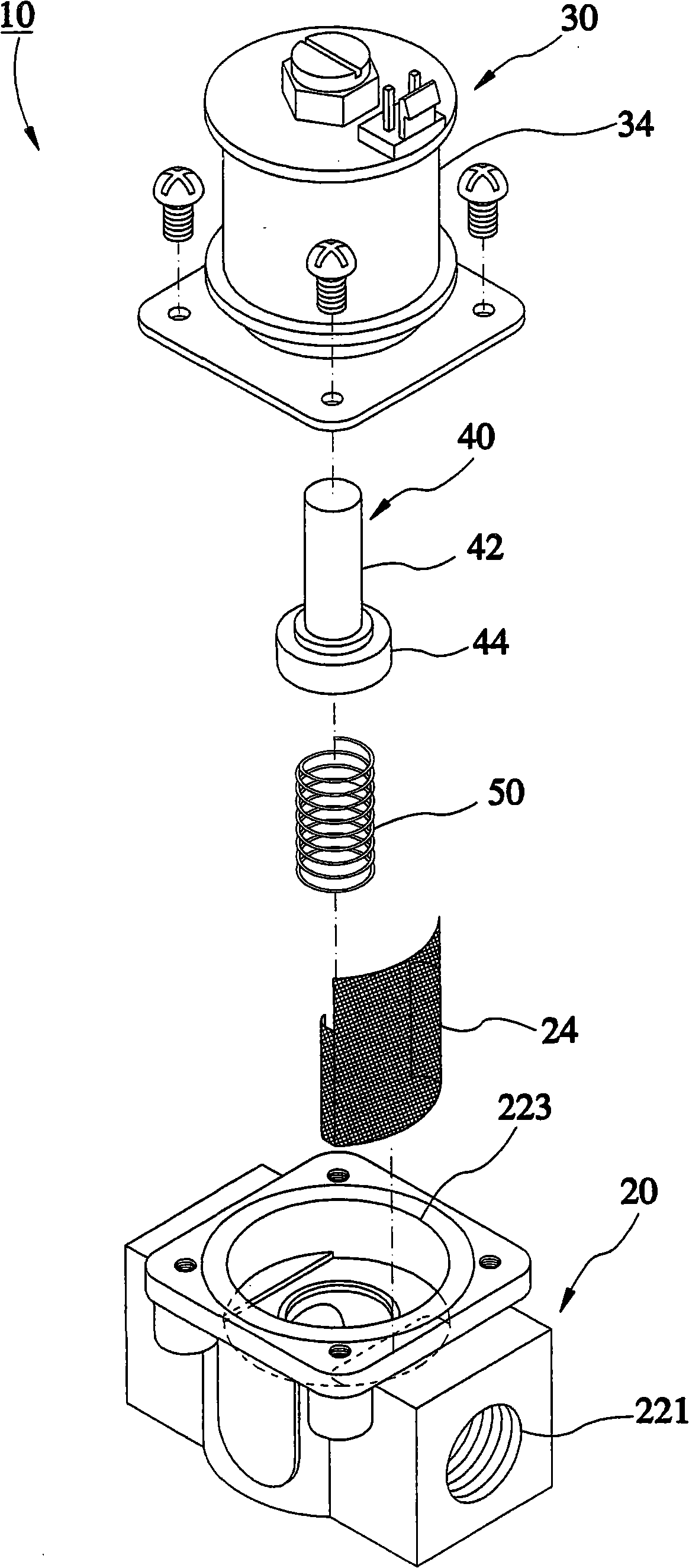

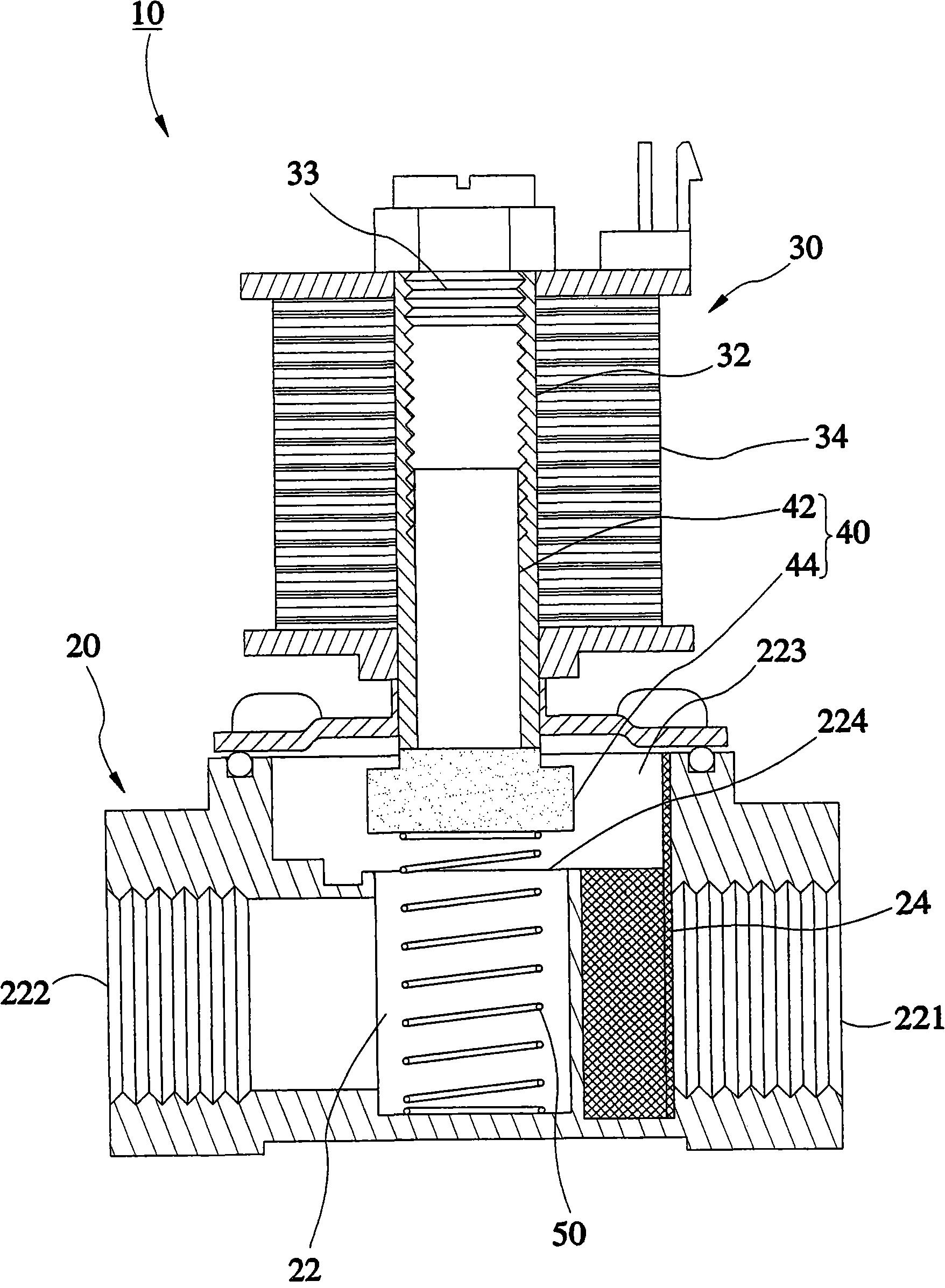

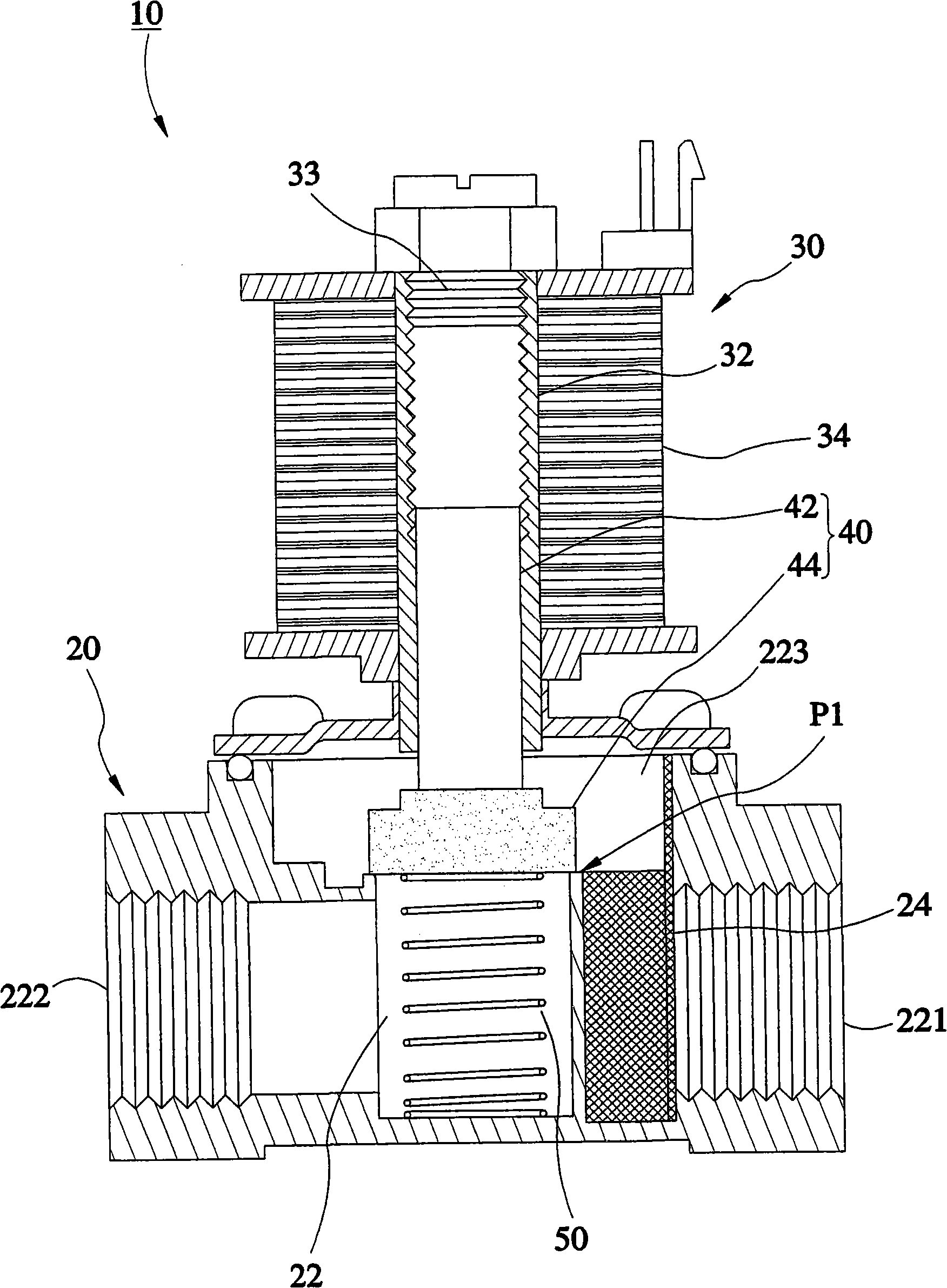

UV water-filter control device and water pressure switch group

InactiveCN101391162AAction indeedExtended service lifeWater/sewage treatment by irradiationElectrical apparatusInlet channelWater filter

The invention relates to a control device of an ultraviolet water filter and a hydraulic pressure switching group, wherein, the control device is arranged in a water inlet seat below the water filter, and is provided with a water inlet channel, and the water inlet channel is equipped with a by-pass port for connecting with the mechanical hydraulic pressure switching group, when water passes through the water inlet channel to enter the water filter, the hydraulic pressure switching group can be synchronously switched on to start up an ultraviolet lamp in the water filter to send out ultraviolet rays for sterilization, and when the water stops flowing, the hydraulic pressure switching group can delay the closing time of the ultraviolet lamp, and fully sterilize the residual water in the water filter.

Owner:游素琴

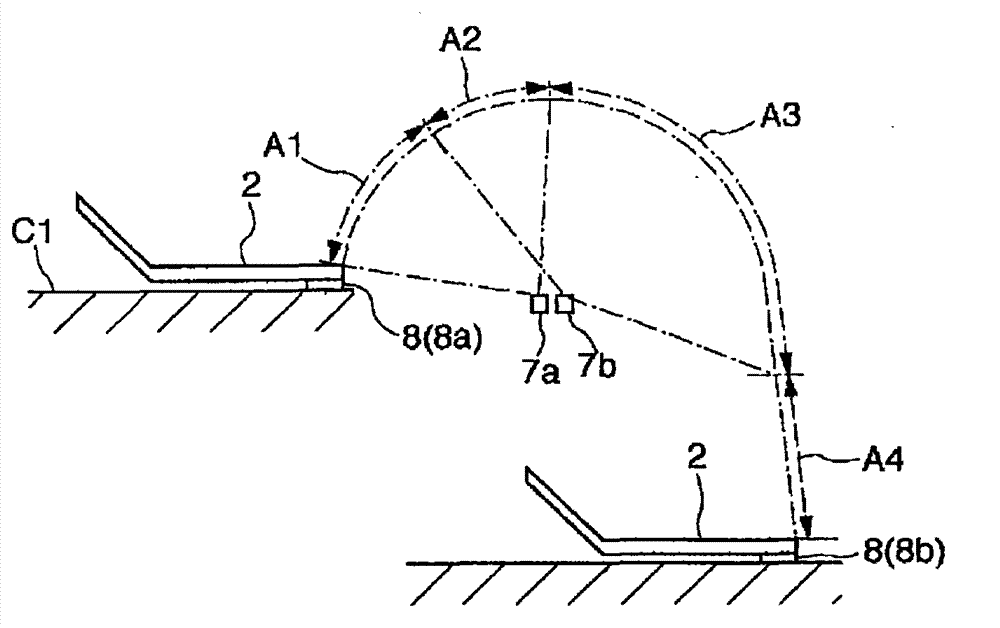

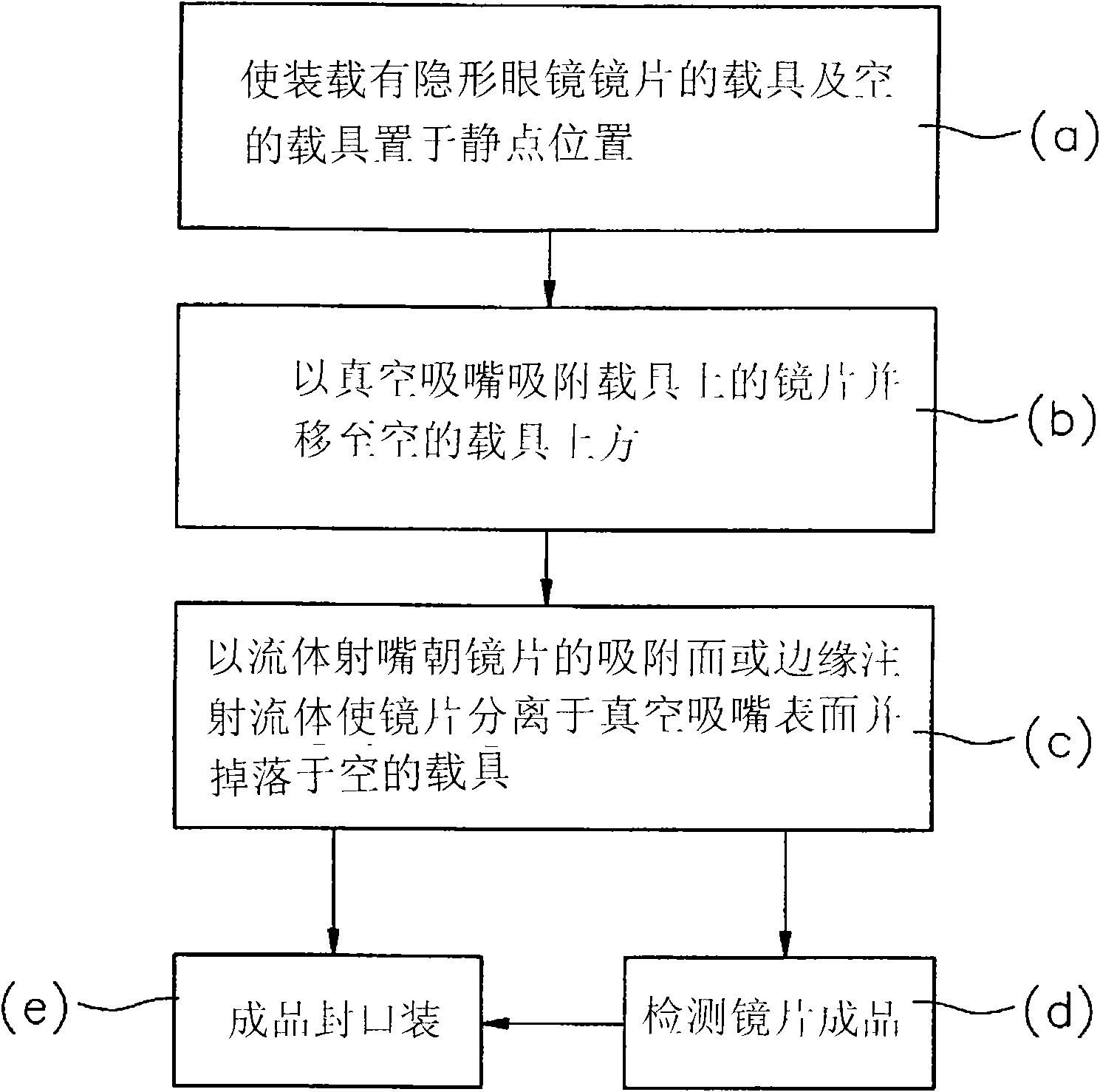

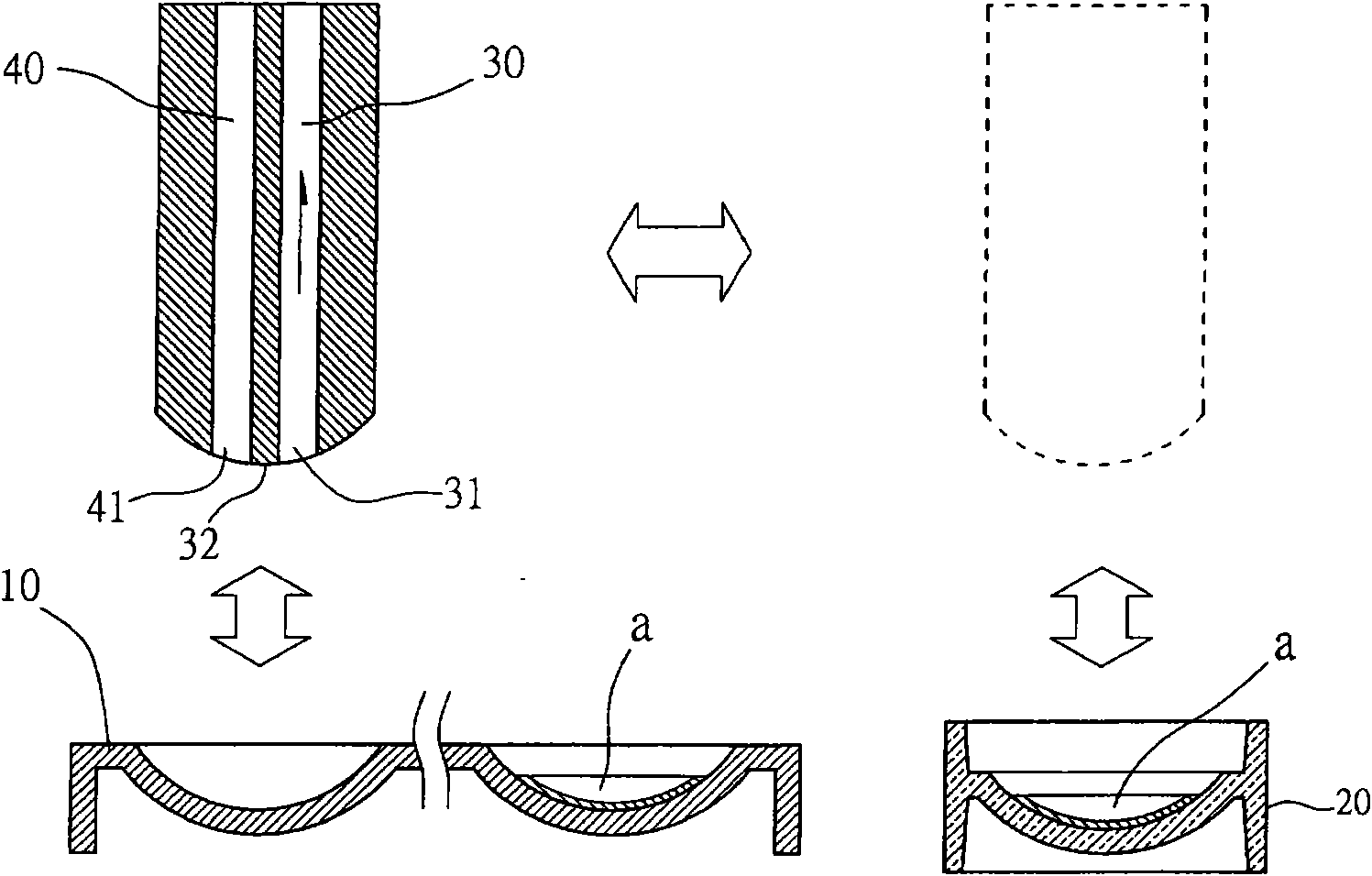

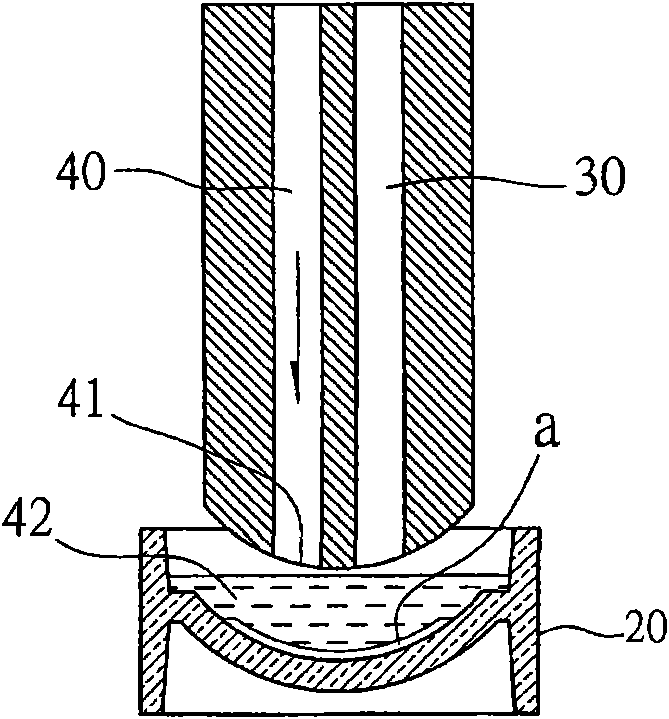

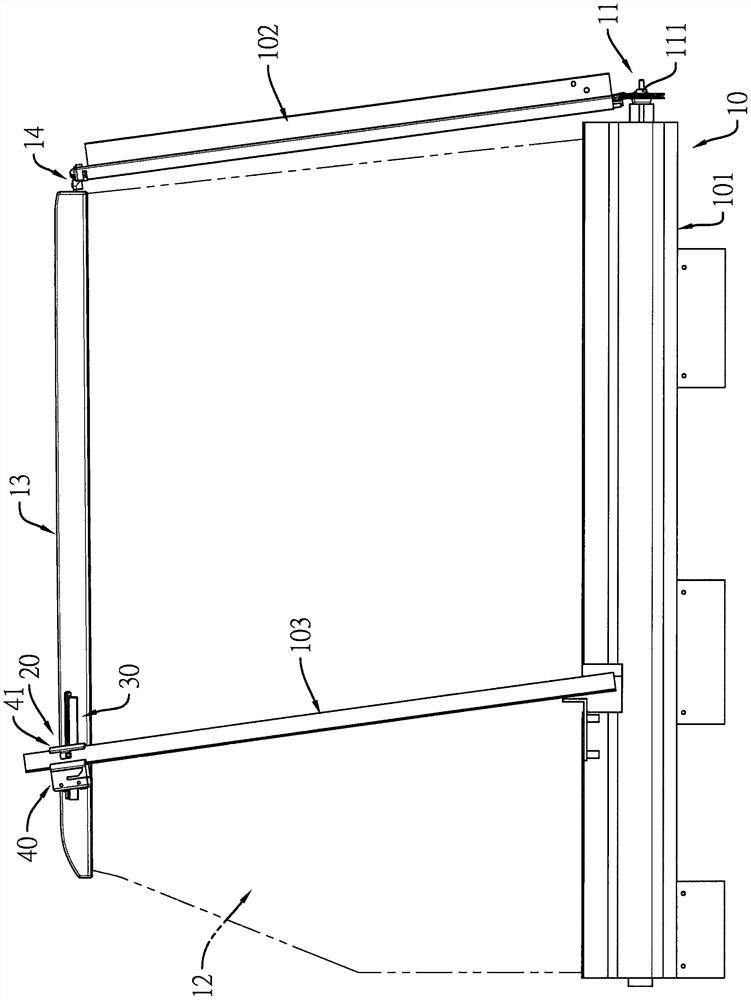

Method for shifting contact lenses

InactiveCN101559883AImprove transfer yieldImprove transfer efficiencyGripping headsUsing protective liquidsLens plateBiomedical engineering

The invention relates to a method for shifting contact lenses, comprising the following steps: (a) a carrier loaded with the contact lenses and an empty carrier are placed into fixed point positions; (b) the lenses in the carrier are absorbed by a vacuum nozzle and shifted on the empty carrier; (c) fluid is injected towards the absorbing surfaces or edges of the lenses by a fluid nozzle to enable the lenses to be separated from the surface of the vacuum nozzle by the fluid and shifted to the empty carrier in a falling mode. The invention has the effects of high shifting efficiency and accurate actions, can save the time and the cost required by manpower and manufacture procedures and can improve the shifting yield of the lenses.

Owner:BINGJIAN ENTPR

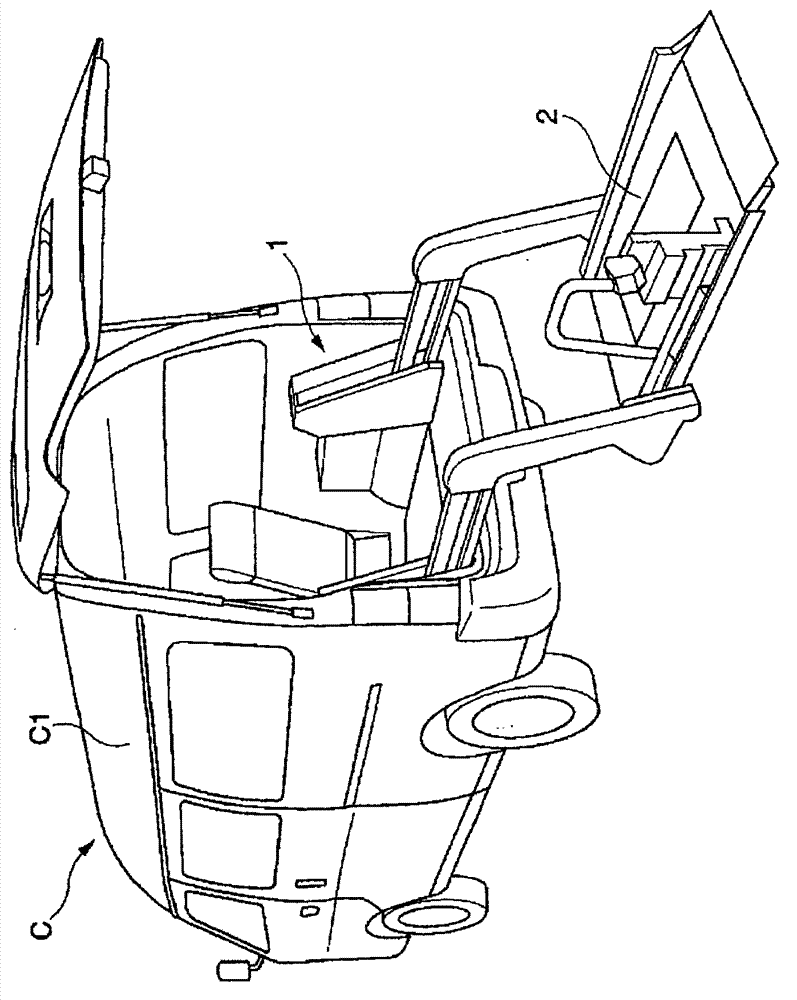

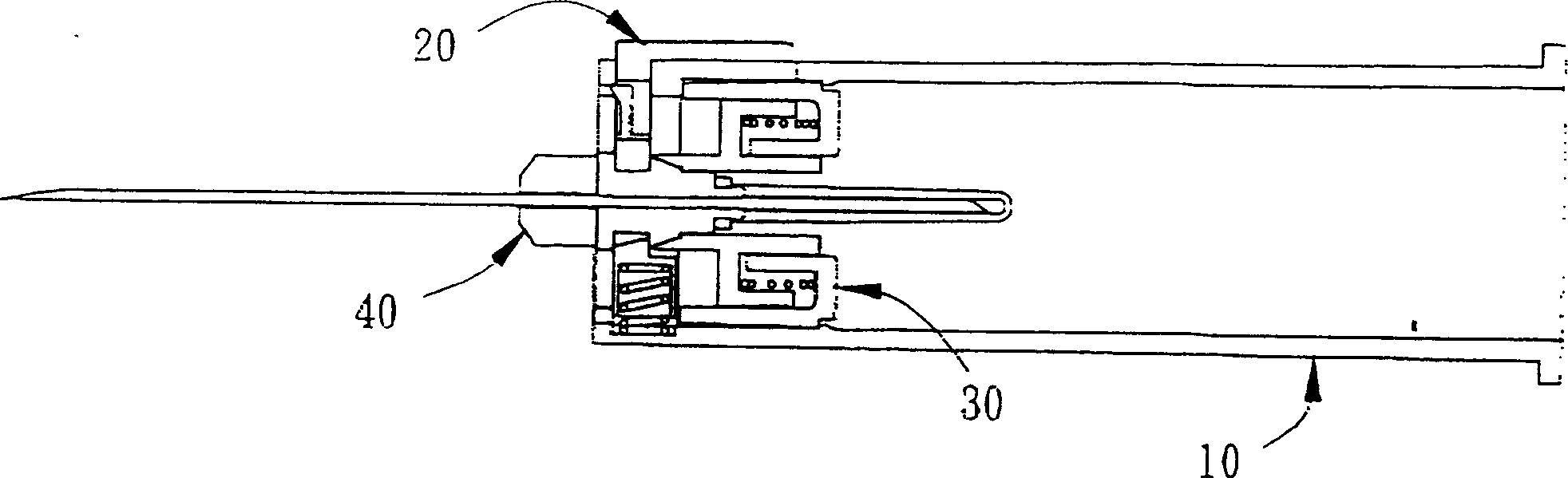

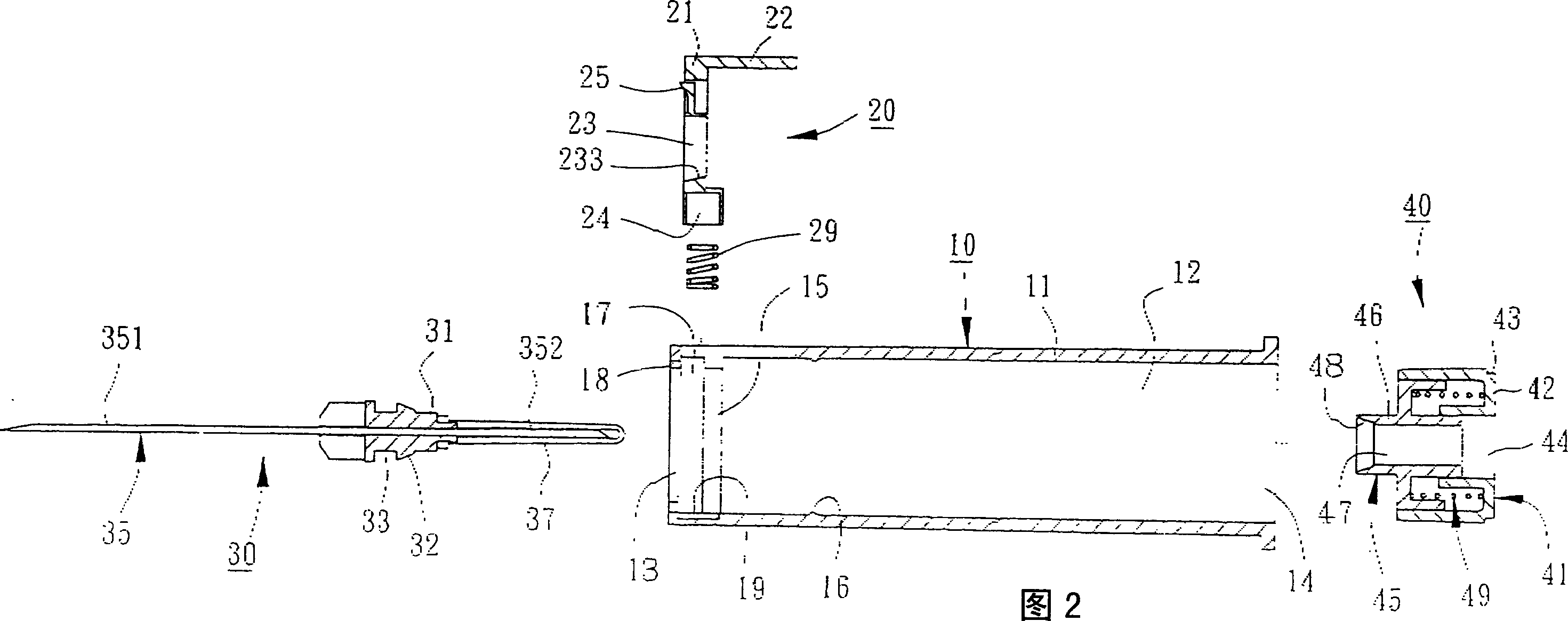

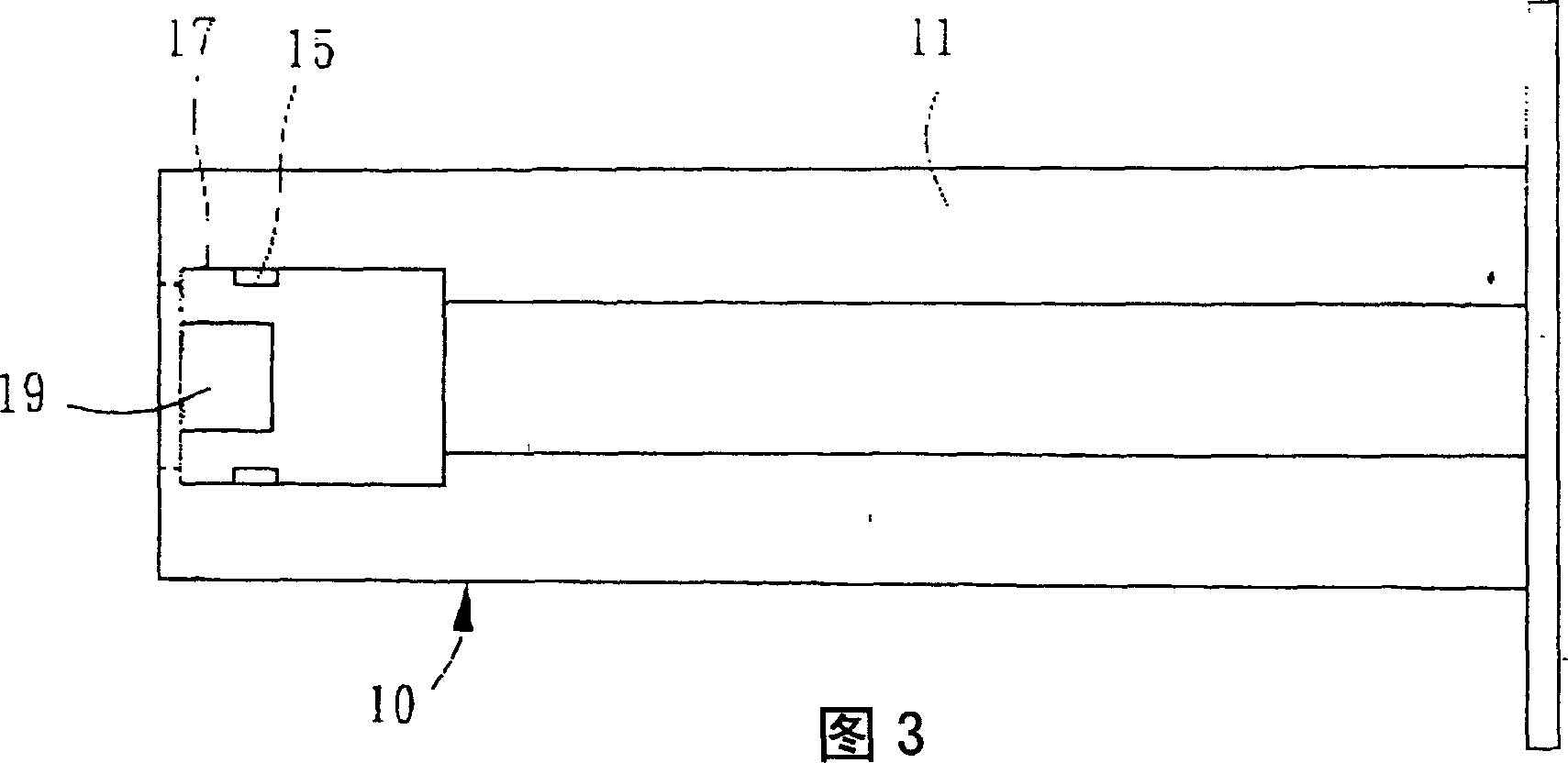

Auxiliary guide structure of side window roller shutter device

The invention relates to an auxiliary guide structure of a side window roller shutter device, which is connected between a curtain cloth edge plate and a guide post of a side window roller shutter toprovide a position compensation function, and comprises a transverse slide rail, an auxiliary guide assembly and an elastic force supply component. The transverse slide rail is arranged on one side ofthe curtain cloth edge plate; the auxiliary guide assembly is connected with the guide post through an auxiliary guide part of the auxiliary guide assembly and can slide up and down, and two pulleyspivoted to the side face of the auxiliary guide part are arranged on the upper side and the lower side of the transverse sliding rail respectively, so that the auxiliary guide structure, the curtain cloth edge plate and the guide post can be assembled conveniently; and the elastic force supply component is used for providing elastic thrust for transverse position compensation for the auxiliary guide assembly, so that the transverse position compensation action is more reliable and smooth.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

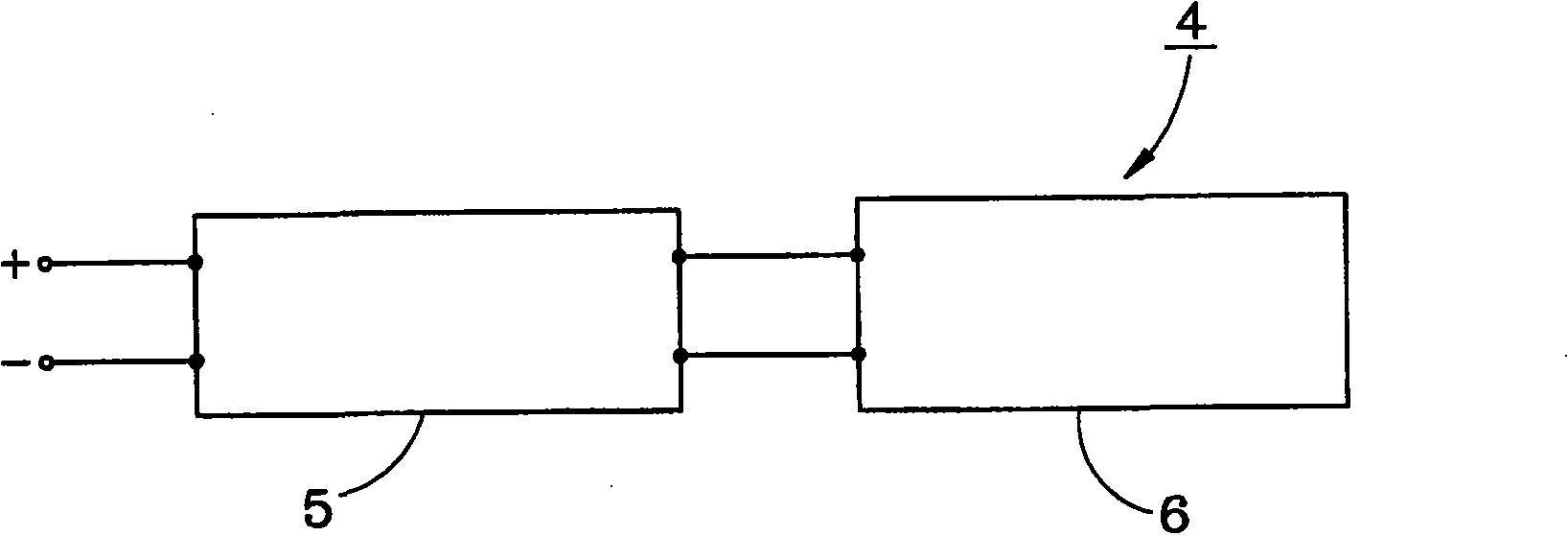

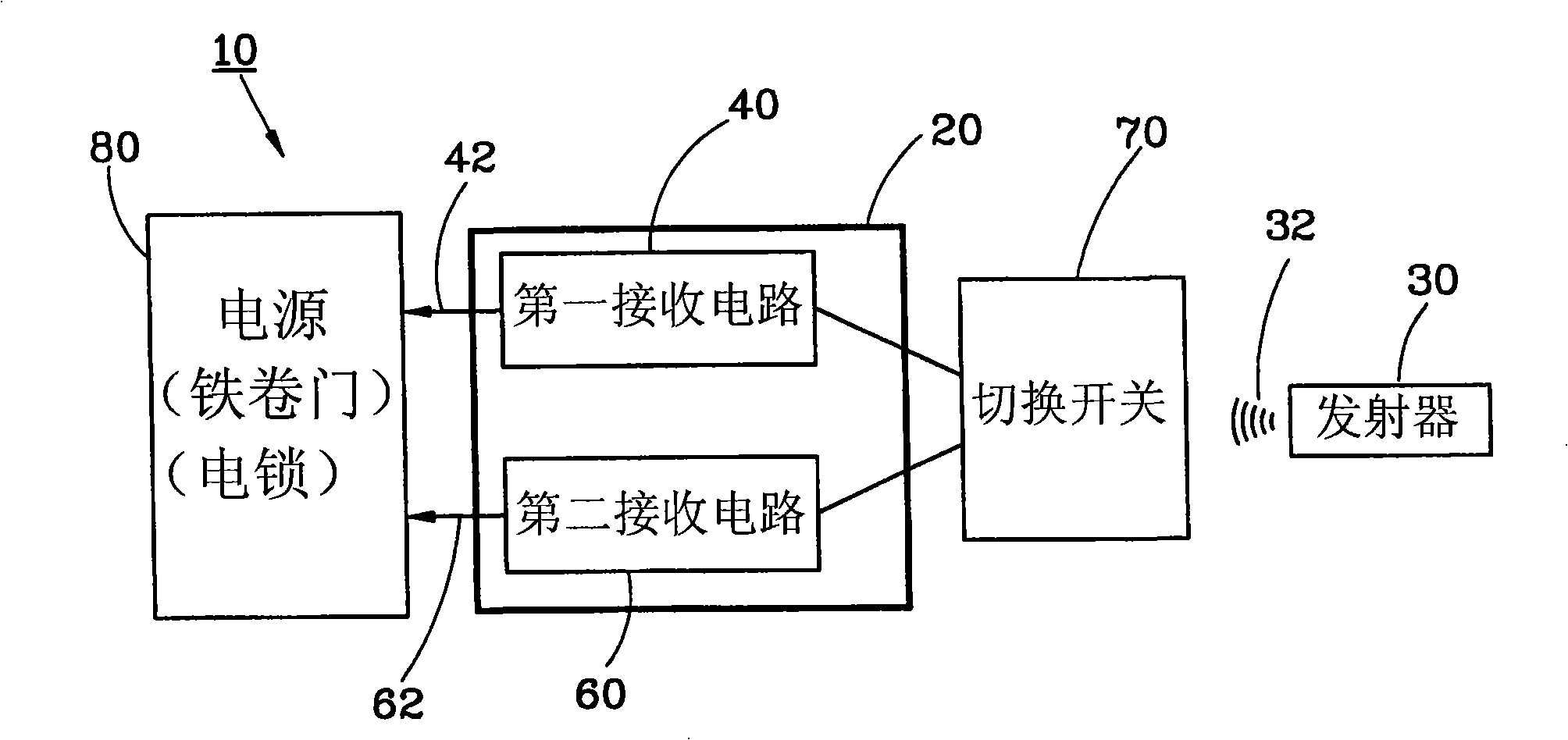

Alternation type receiving module

The invention relates to an alternative type receiving module, including a host computer case; a first receiving circuit arranged in the host computer case, for transmitting a first control signal when the first receiving circuit receives a trigger signal of a transmitter, for driving the load device; a second receiving circuit arranged in the host computer case, connected with the first receiving circuit in parallel, for transmitting a second control signal when the second receiving circuit receives the trigger signal, for driving the load device; a diverter switch electrically connected with the first receiving circuit and the second receiving circuit, for switching between the first receiving circuit and the second circuit for the users. According to the invention, when one receiving circuit goes wrong, the other receiving circuit also can normally drives the electrolock or the electrical roller door.

Owner:翁酩富

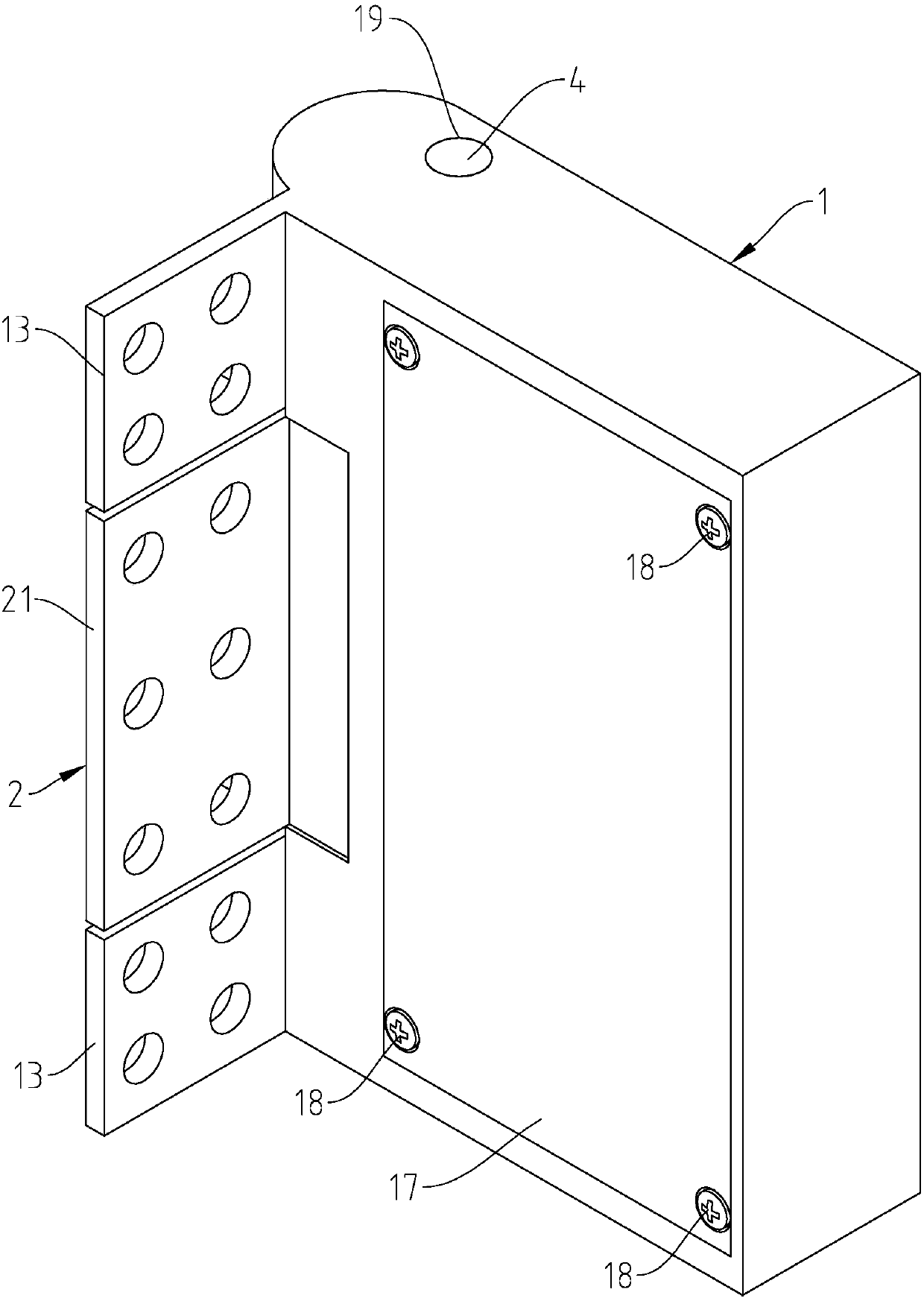

Magnetic-repulsion type hinge device

InactiveCN107663980AEasy to installEasy to useMan-operated mechanismPin hingesRepulsion forceEngineering

The invention relates to a magnetic-repulsion type hinge device comprising at least a first connection member and a second connection member pivoted with the first connection member via a fulcrum. A first magnetic member, a movable member and a second magnetic member are disposed in an accommodating slot of the first connection member; the movable member is in a pivoted connection with one end ofa connection rod via a first pivot shaft; the second connection member deviated from the fulcrum part is in a pivoted connection with the other end of the connection rod via a second pivot shaft, so the movable member can be moved to the accommodating slot at a pivoting angle formed when the first connection member pivots with the connection rod; and relative magnetic repulsion force can be produced between the first magnetic member and the second magnetic member due to the closeness thereof; and the first and second connection members can be driven to move by each other due to the repulsion force, and automatic door close and shielding functions can be obtained.

Owner:邹国和

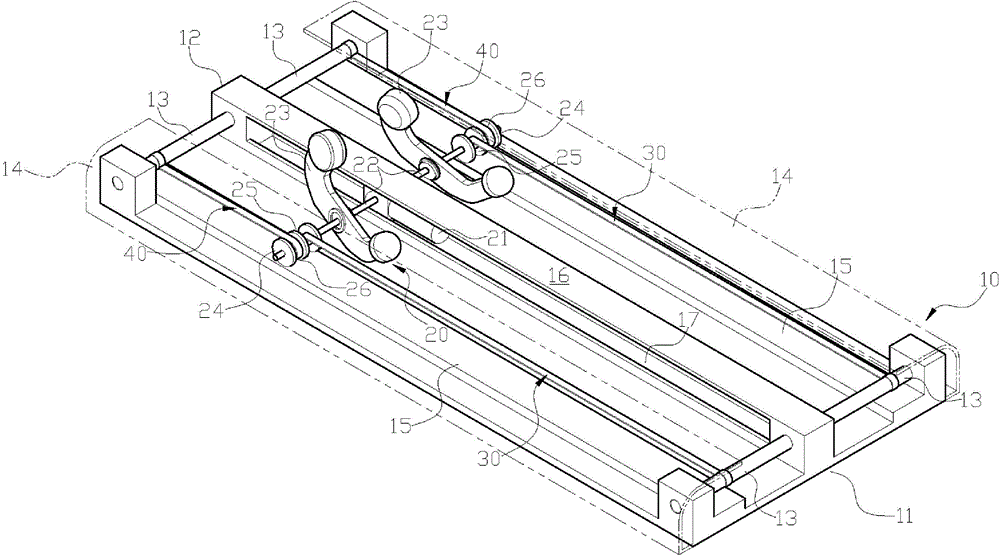

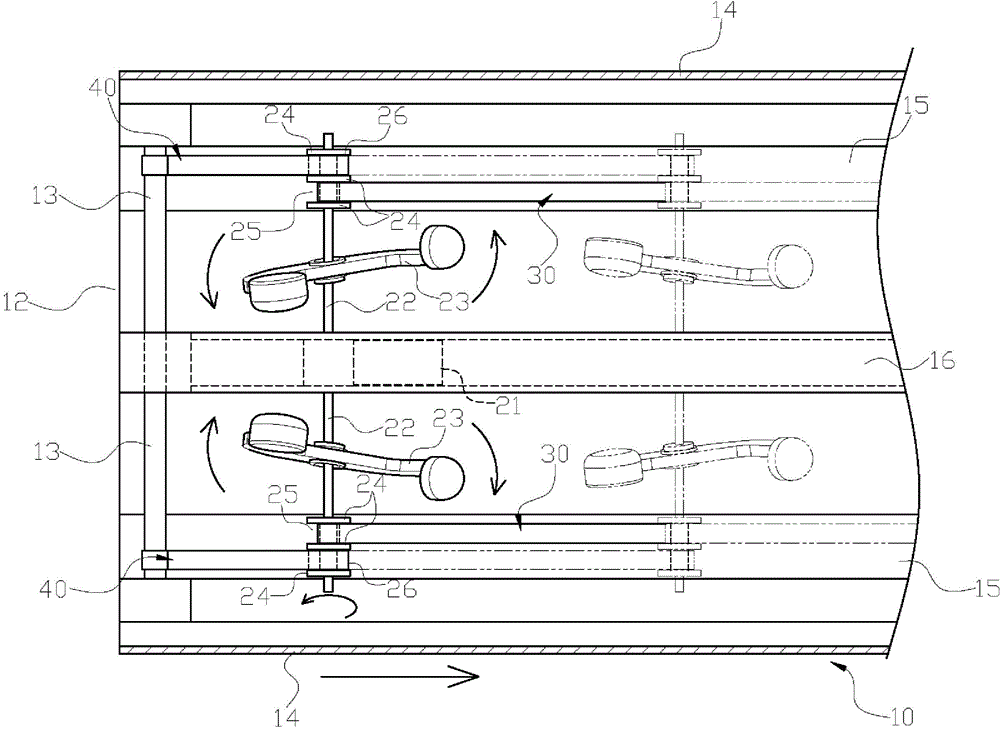

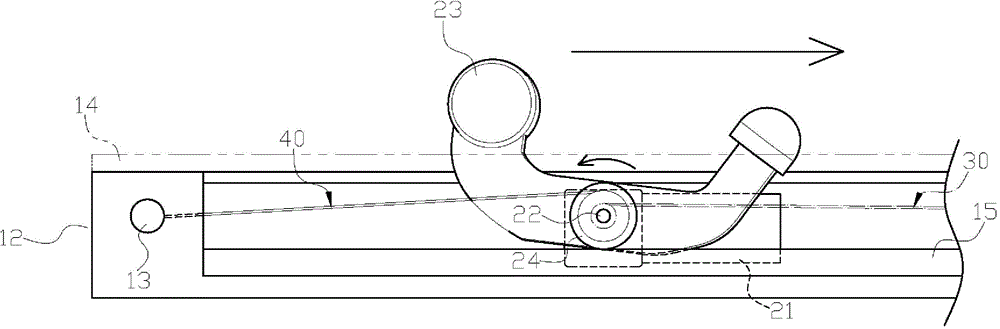

Automatic massaging apparatus

InactiveCN105267020APrevent slippingSimple structureDevices for pressing relfex pointsChiropractic devicesPhysical medicine and rehabilitationDrive shaft

An automatic massage apparatus may include a main body, a massaging unit, at least two first belts and at least two second belts. The main body has two positioning units, a cover, a long guiding groove. A rail is disposed underneath the cover and aligned with the top surface of the main body. The guiding rail is hollow to provide a space for a driving unit of a massaging unit, and a long groove is formed on both sides of the guide rail. The driving unit has a driving shaft extending towards both sides of the driving unit. When the driving unit is disposed into the space of the guiding rail, the long groove is used for the extension of the driving shaft, so the driving unit can be connected to an eccentric massaging body through the driving shafts. Furthermore, both ends of the driving shaft have a plurality of wheels disposed against the rail of the main body, and these wheels are appropriately spaced. Both sides of the massaging unit have at least a first compartment and a second compartment. One end of the first belt is secured on the first end of the positioning unit, and the other end is wrapping the driving shaft in the first compartment. Likewise, one end of the second belt is secured on the second end of the positioning unit, and the other end is wrapping the driving shaft in the second compartment.

Owner:巫东和

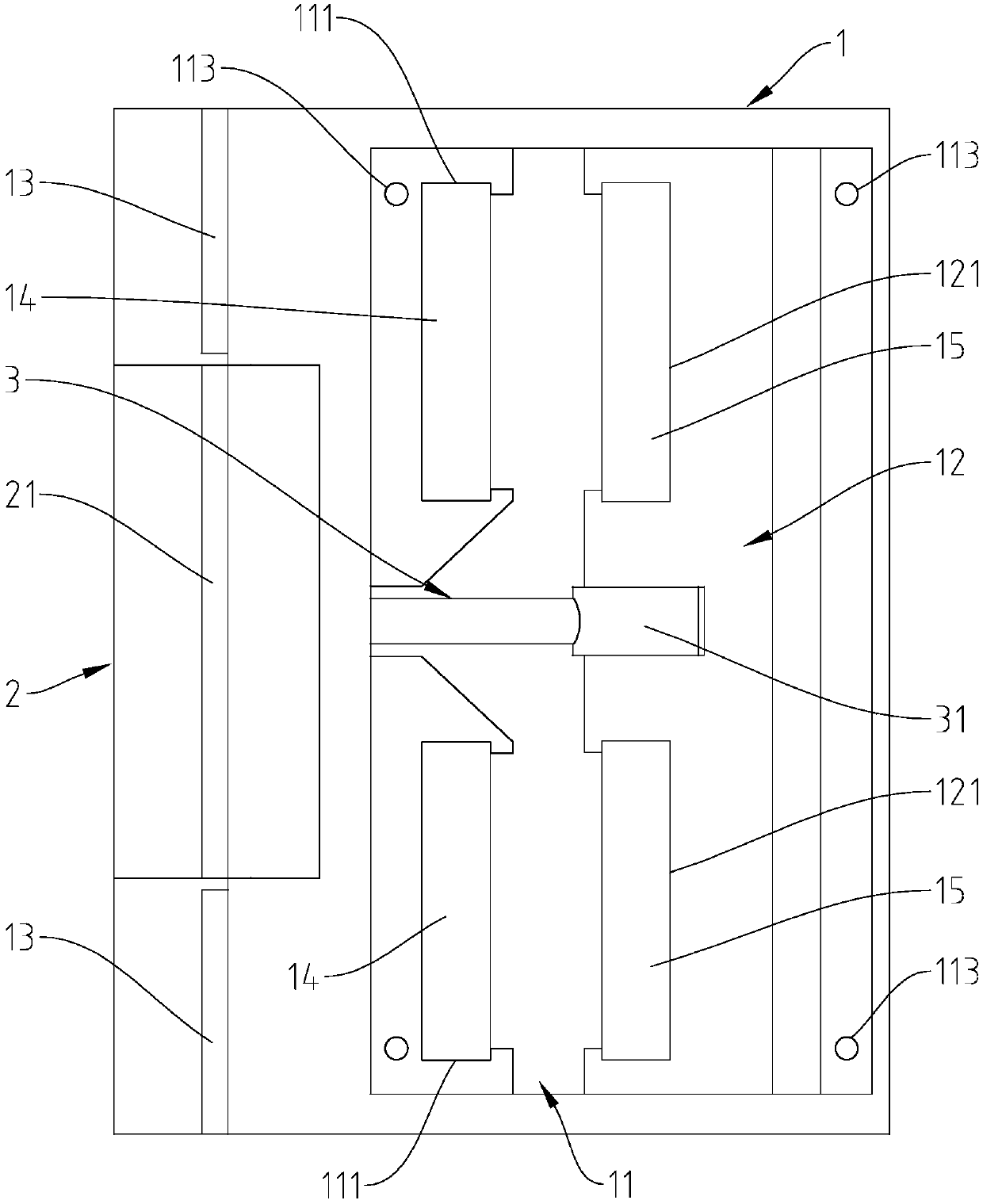

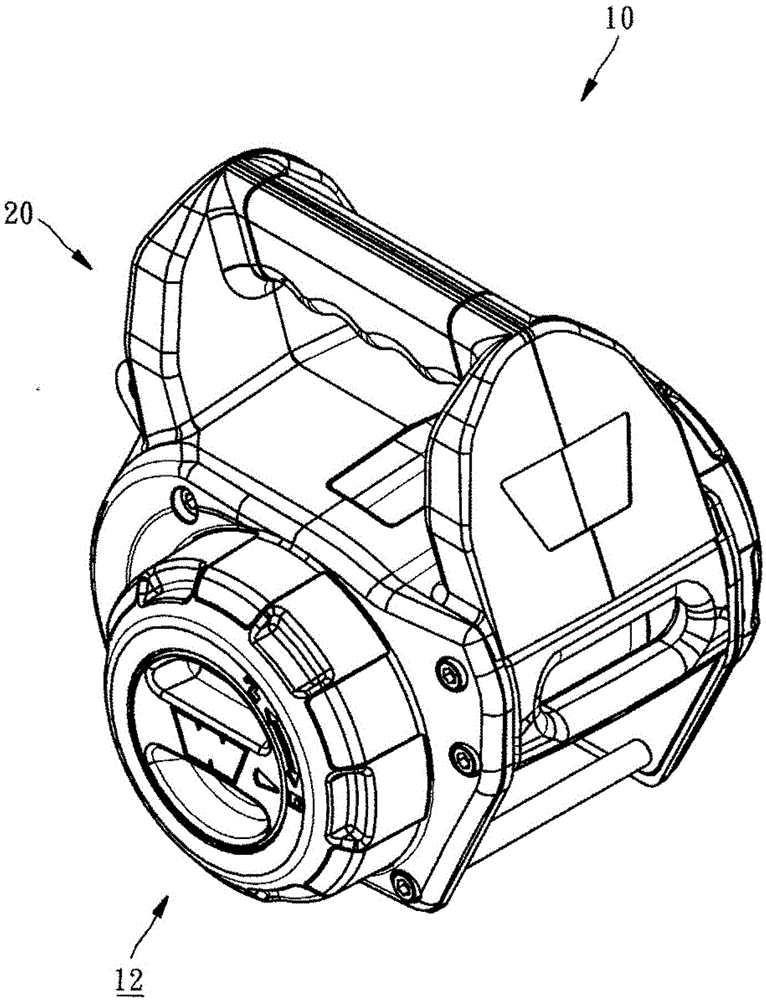

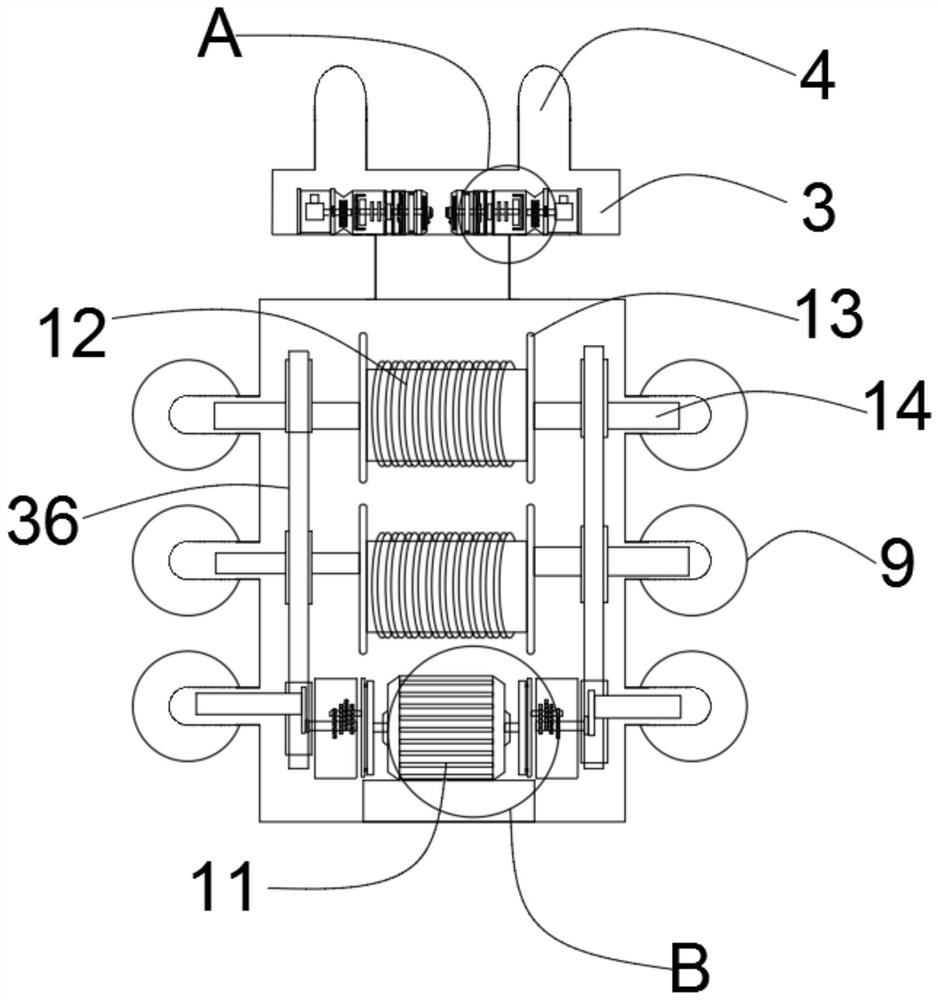

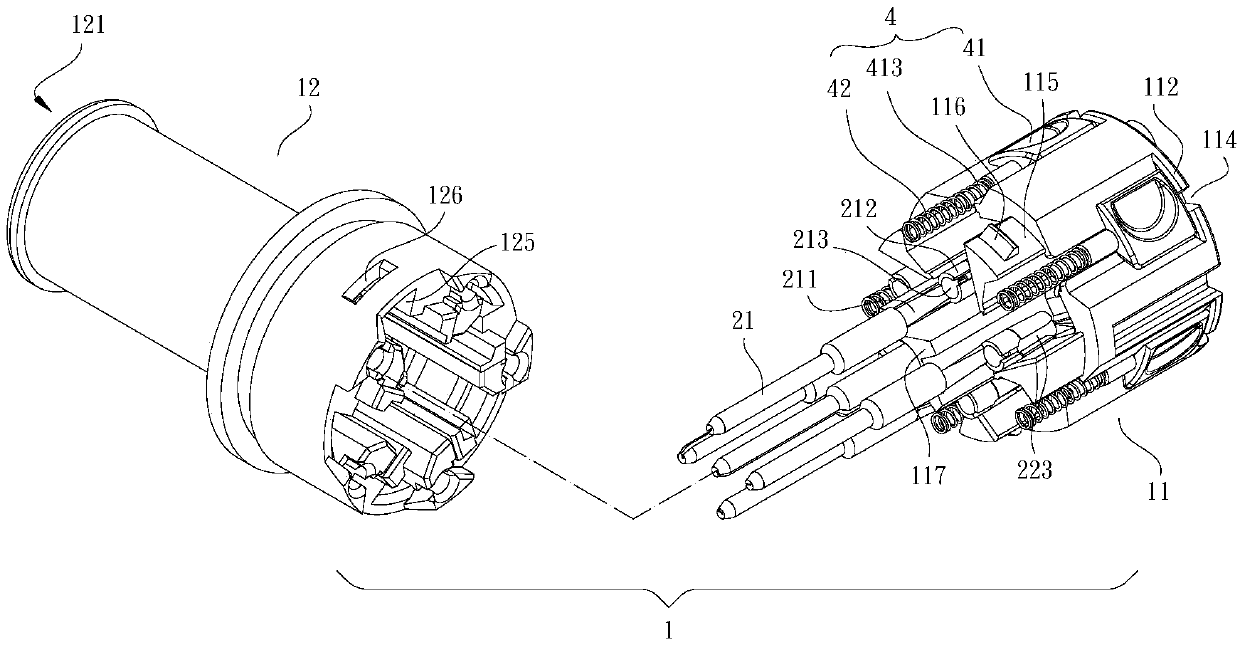

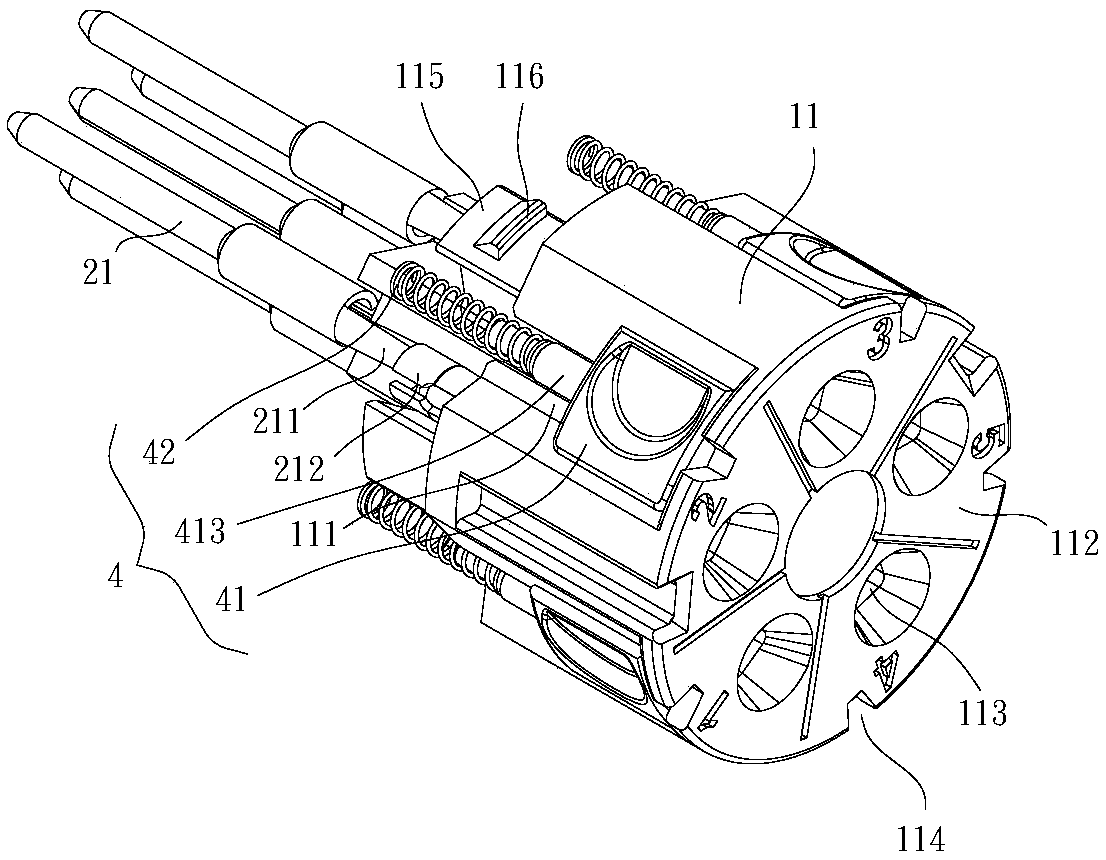

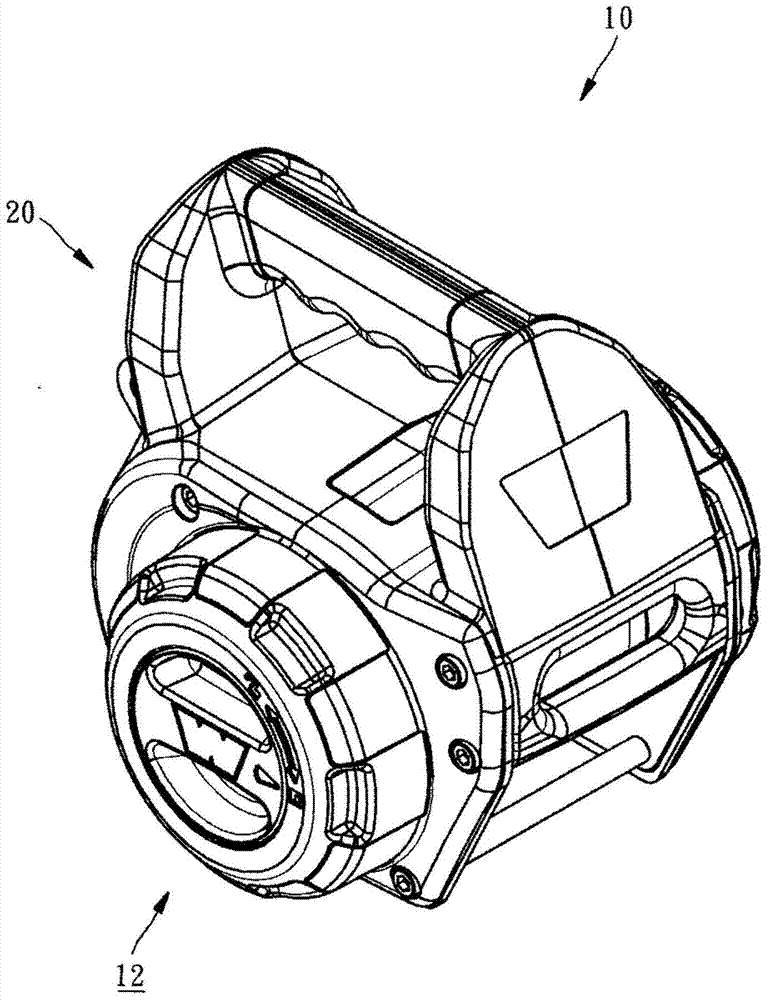

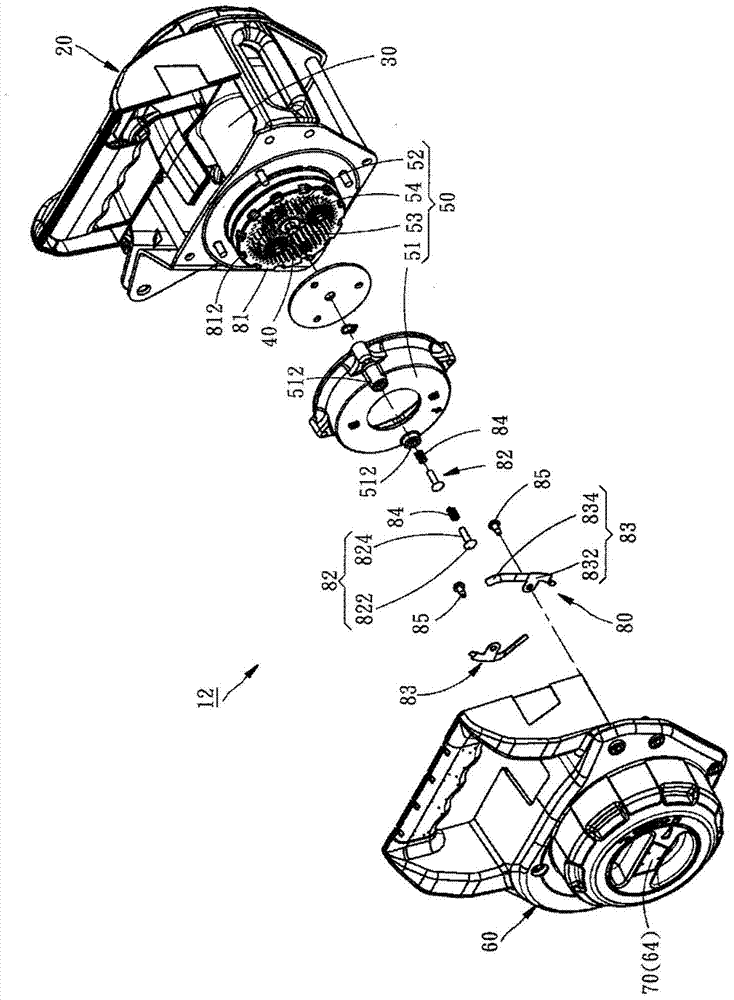

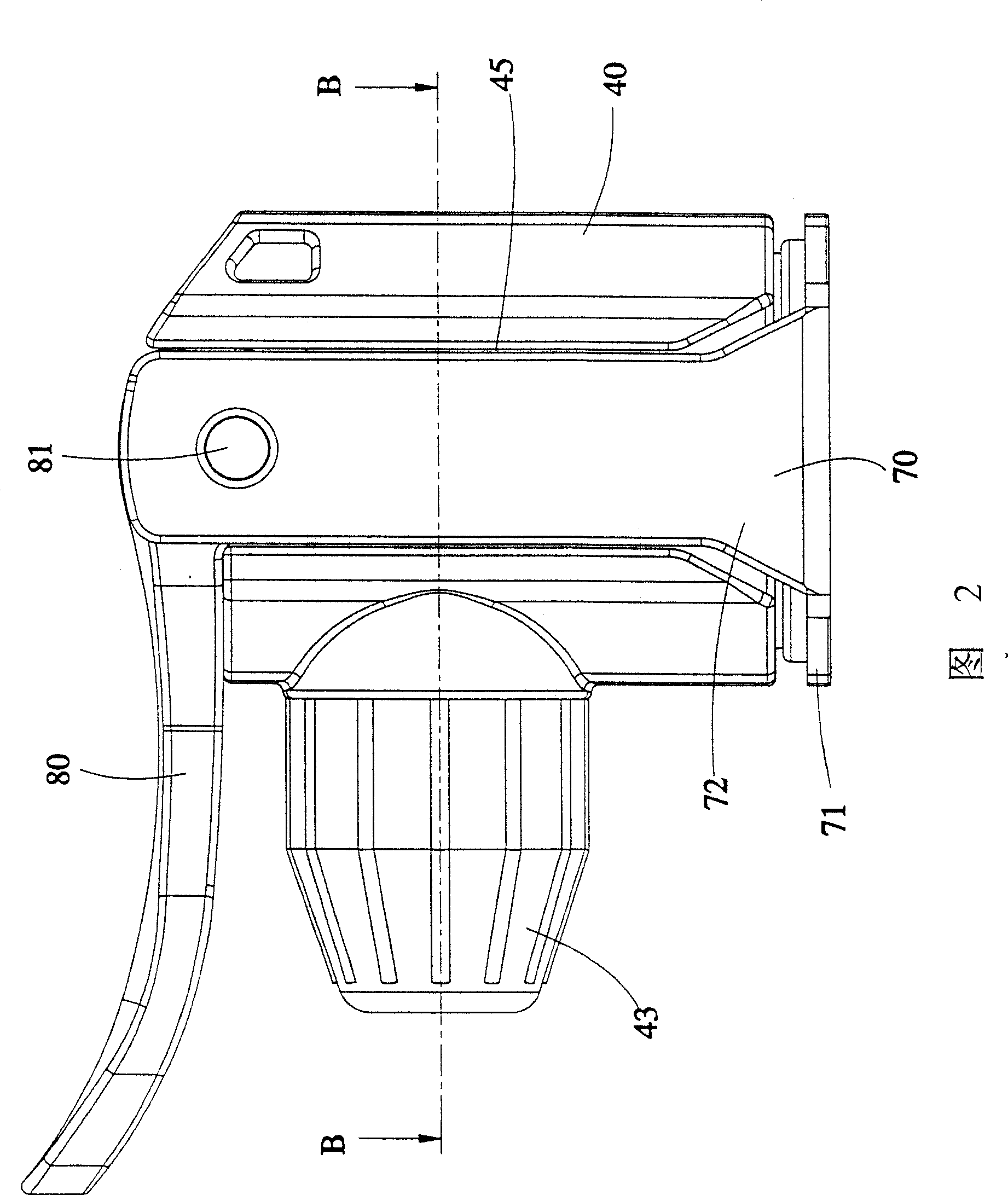

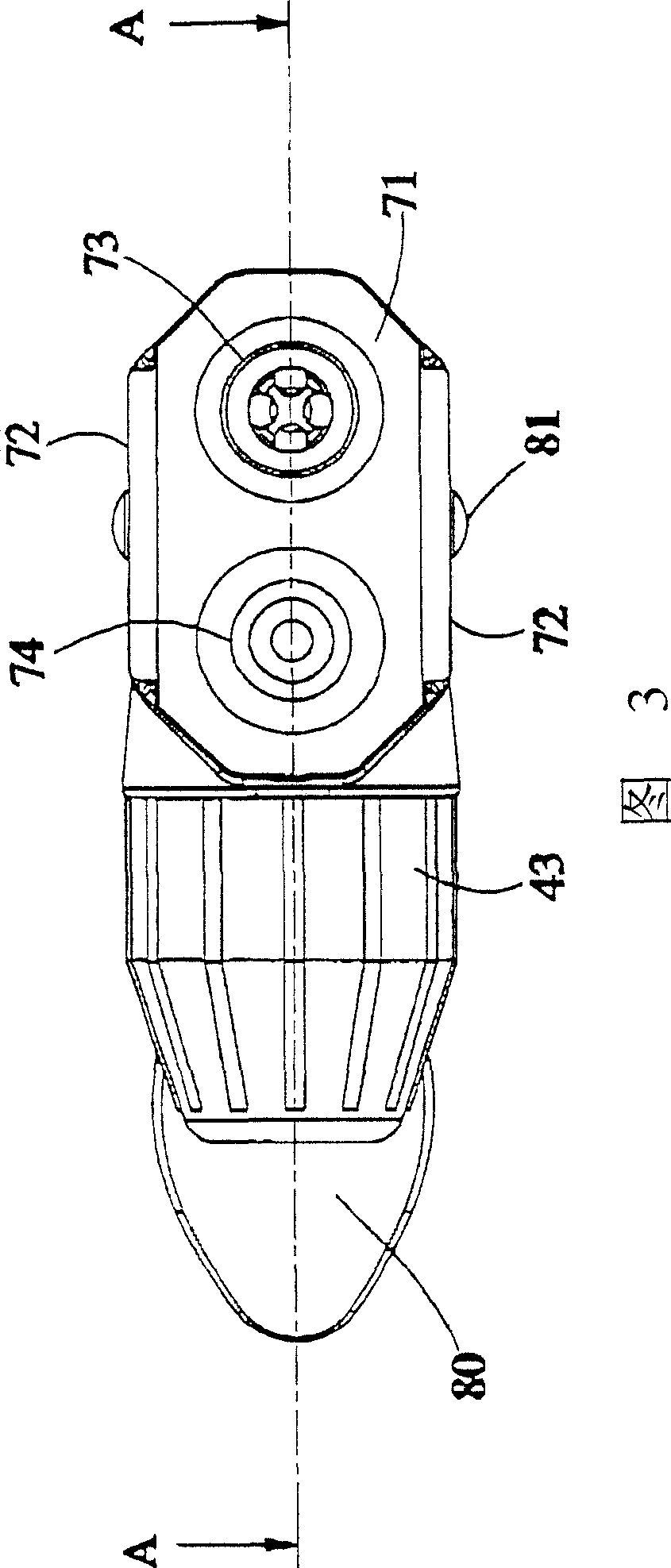

Engaging and disengaging device for winch and winch using engaging and disengaging device

ActiveCN105271034ASimple structureAction indeedInterengaging clutchesWinding mechanismsEngineeringWinch

An engaging and disengaging device for a winch comprises a rotary knob and an engaging and disengaging assembly. The engaging and disengaging assembly comprises an engaging and disengaging gear, a positioning bolt, an elastic sheet and an elastic piece. A plurality of positioning grooves are formed in the periphery of the engaging and disengaging gear at intervals. The positioning bolt is arranged between the rotary knob and the engaging and disengaging gear in an axially-moving mode. One end of the elastic sheet is fixed to the rotary knob, and the other end of the elastic sheet abuts against the positioning bolt so that the positioning bolt can be pushed towards the engaging and disengaging gear to be plugged into one positioning groove of the engaging and disengaging gear. The elastic piece is arranged on the positioning bolt and used for pushing the positioning bolt away from the engaging and disengaging gear, so that the positioning bolt is disengaged from the positioning groove where the positioning bolt is originally plugged. In this way, the engaging and disengaging effect can be achieved with the simple structural cooperation.

Owner:REXON IND CORP LTD

Power switching device for vehicle

InactiveCN102343814BSimple designHigh power switching stabilityControl devicesCouplingControl manner

The invention discloses a power switching device for a vehicle. The power switching device comprises a power transferring unit and a drive unit. The power transferring unit comprises an input shaft, an output shaft which is separated from the input shaft, a second coupling piece which can move on the input shaft and the output shaft, and a first coupling piece which can move on an axle cylinder of a wheel axle and a differential. The drive unit comprises a control box, a first drive mechanism and a second drive mechanism. The control box can drive the first drive mechanism to drive the second drive mechanism to move, so that the first coupling piece is poked; therefore, the wheel axle does not generate differential power, or the first drive mechanism pokes the second coupling piece so as to switch drive power of the vehicle, the effects of high power switching stability and exact actuating are achieved, and a control mode can be simplified to ensure that the power switching device has the optimum integral design.

Owner:KYMCO

Led lighting device and illumination apparatus

ActiveCN102014546BReduced inrush currentReduce power lossPoint-like light sourceElectrical apparatusEffect lightAlternating current

Owner:TOSHIBA LIGHTING & TECH CORP

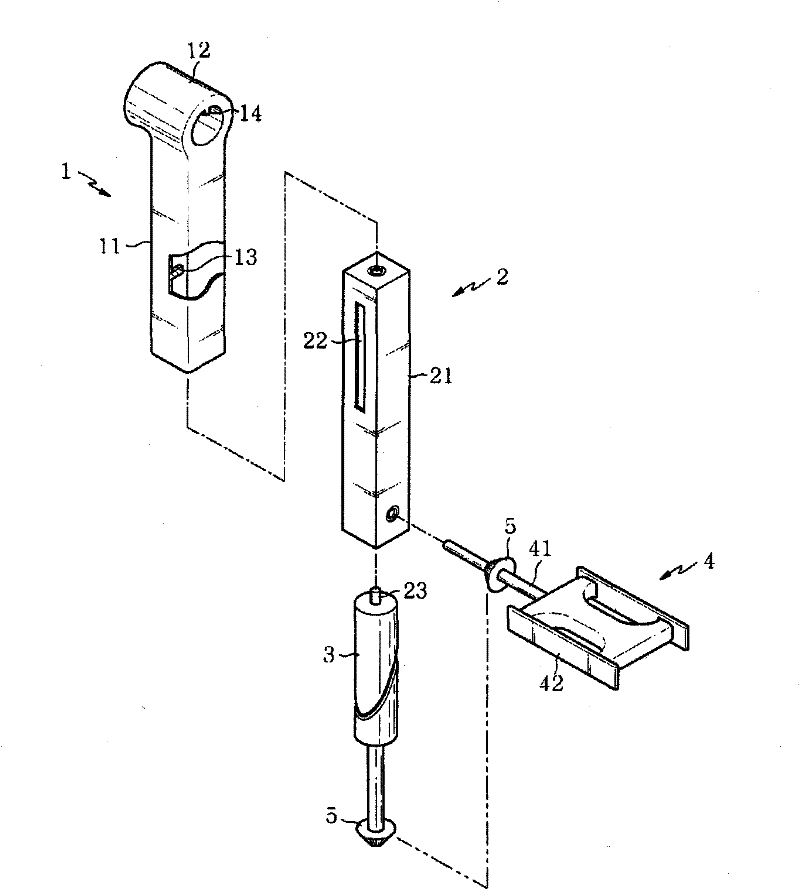

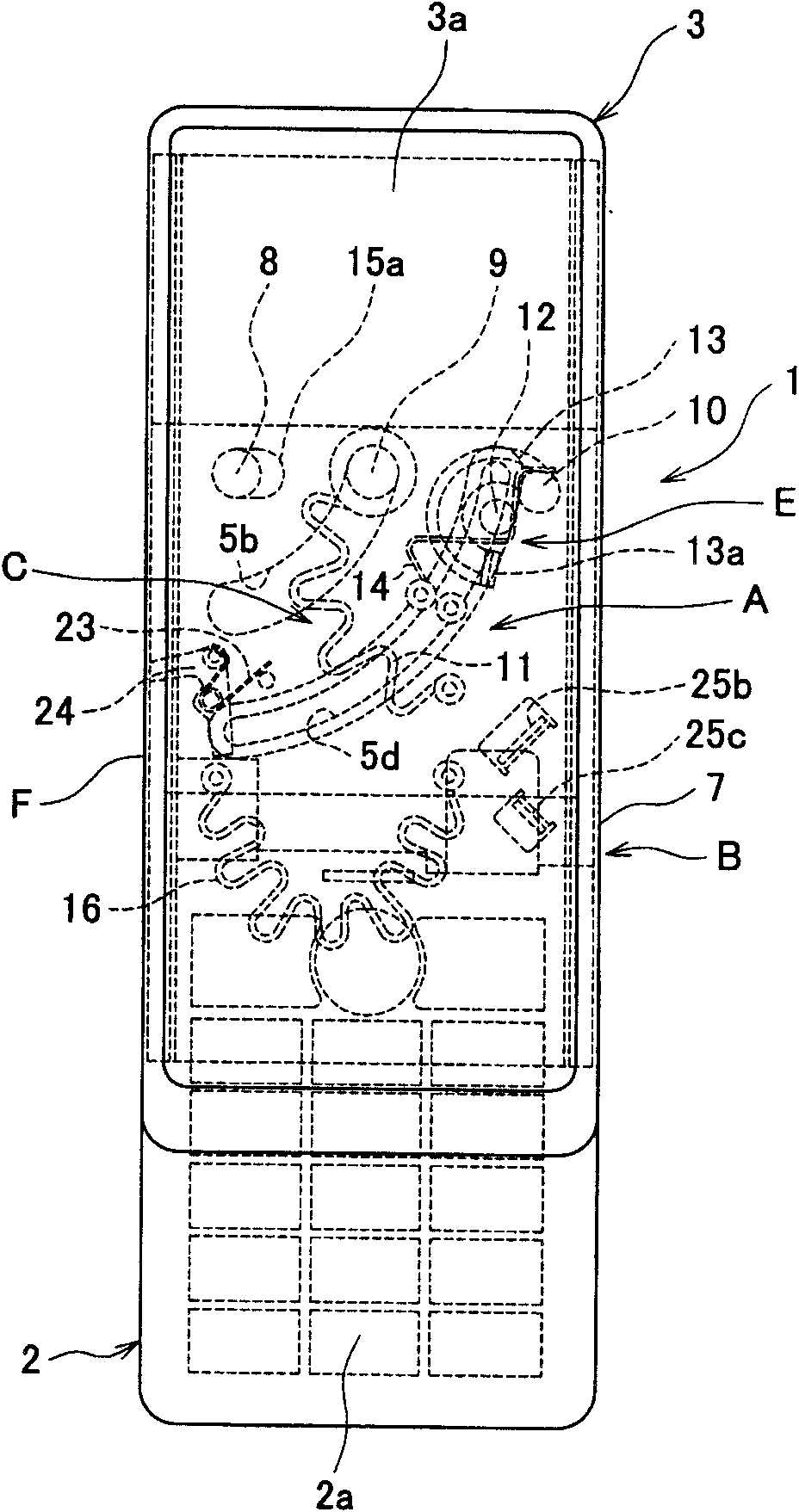

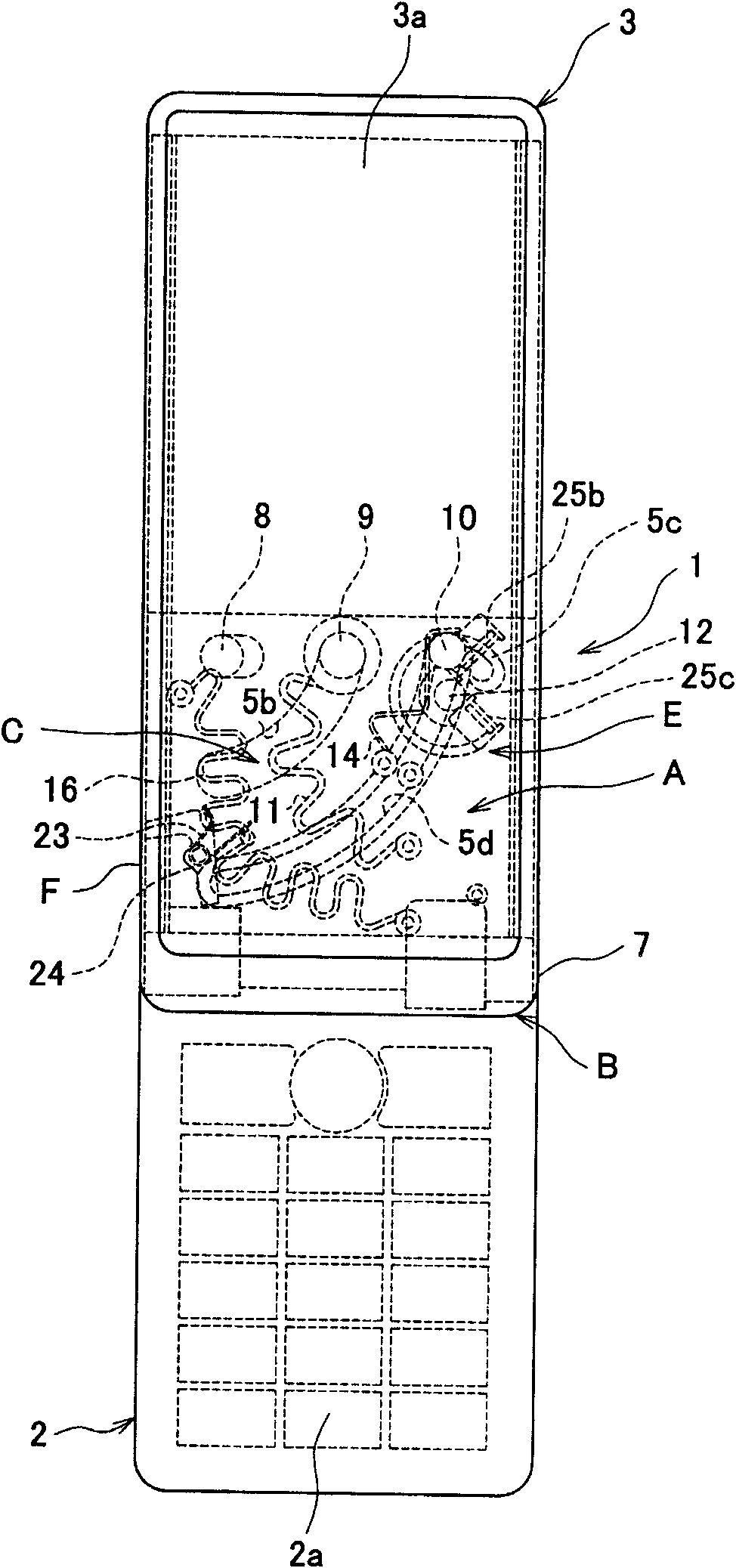

Portable electronic equipment and operating mechanism of housing

InactiveCN101848616BEasy to watchAction indeedDigital data processing detailsCasings/cabinets/drawers detailsSlide plateEngineering

An operating mechanism of a housing for a portable electronic equipment and portable electronic equipment with the same. The operating mechanism has simple structure as possible, and comprises a shoe plate, a base plate, a sliding plate and rotating motion control means. The shoe plate is erected at the front of an operating part on the upper surface of a first housing towards the operating part by an inclining mechanism. The sliding is arranged at the lower surface of the a second housing, the rotating motion control means is used for controlling the rotating motion of the base plate. The second housing slides to the front relative to the first housing to be fully opened, the second housing rotates at 90 DEG from the horizontal direction relative to the first housing, after the second housing rotates at 90 DEG from the horizontal direction, the second housing is erected to the operating part relative to the first housing.

Owner:KATOH ELECTRIC MACHINERY

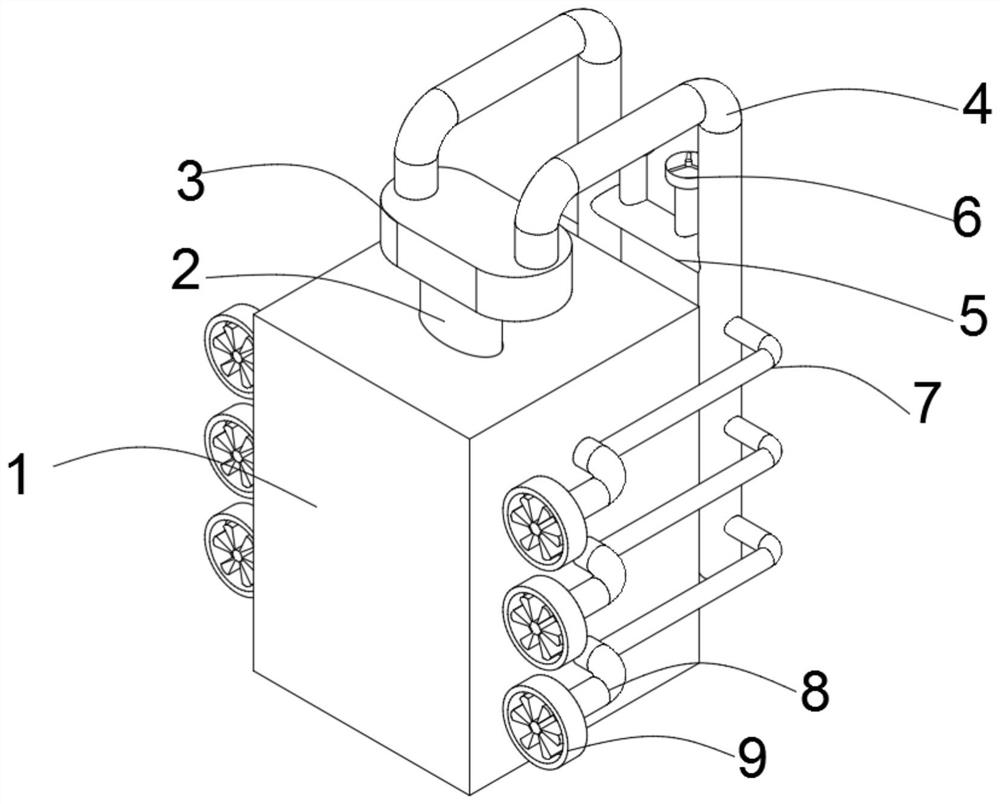

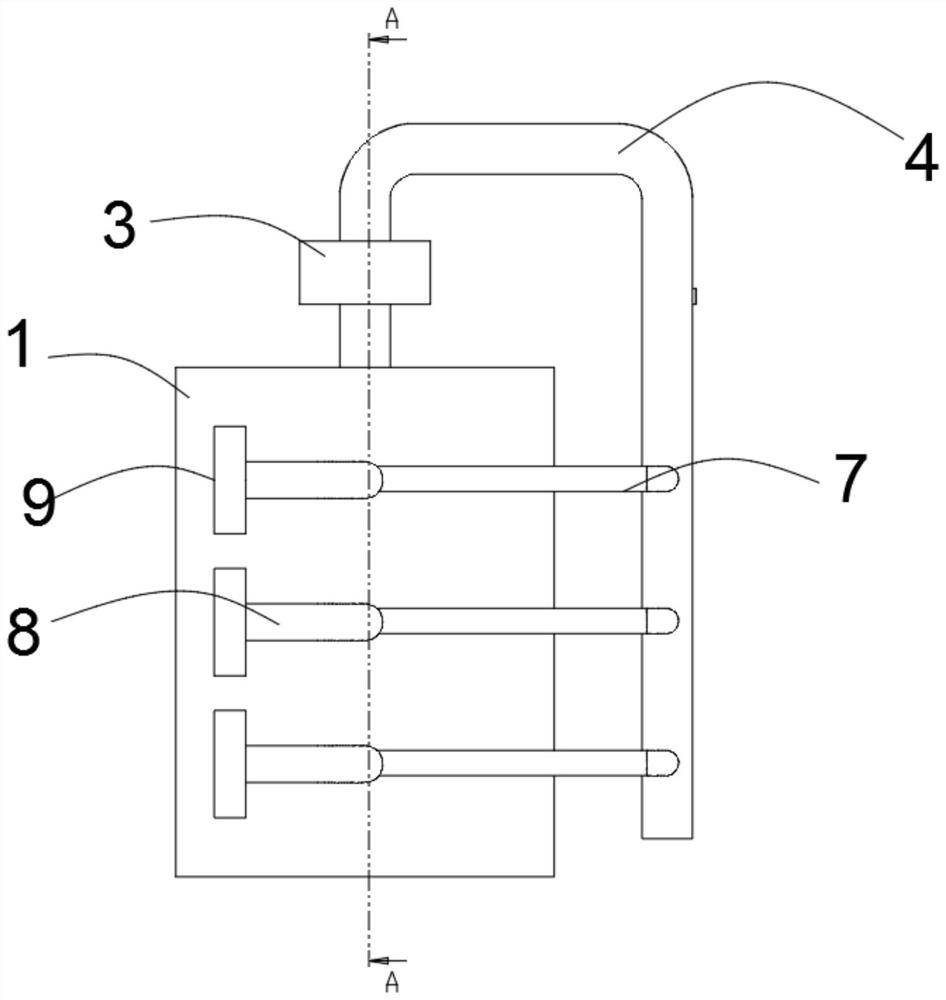

Agricultural power mechanical device between rice fields

PendingCN112922688AImprove work efficiencyIncreased durabilityMechanical energy handlingSteam engine plantsDrive wheelElectric machine

The invention discloses an agricultural power mechanical device between rice fields, and relates to the technical field of power machinery. The device comprises a power supply box, the upper surface of the power supply box is provided with a pressurization air source seat, the upper surface of the pressurization air source seat is provided with a pressurization air source device, the upper surface of the pressurization air source device is provided with pressurization pipes, a connecting pipe is arranged between the pressurization pipes, and the upper surface of the connecting pipe is provided with a pressurization airflow switch and a decompression airflow switch; a second pressurization airflow pipe is arranged on the side face of the power supply box, and one end of the second pressurization airflow pipe is connected with a power turbine; and a motor and a rotating coil are arranged in the power supply box, power rotating cylinders are arranged at the two ends of the rotating coil and connected with power rotating shafts, driving wheels are arranged on the circumferential side faces of the power rotating shafts, and rotating belts are arranged on the circumferential side faces of the driving wheels. By arranging the pressurization airflow switch and the decompression airflow switch, the air pressure can be conveniently adjusted; and by arranging the power turbine, power can be conveniently provided for the device.

Owner:王琰

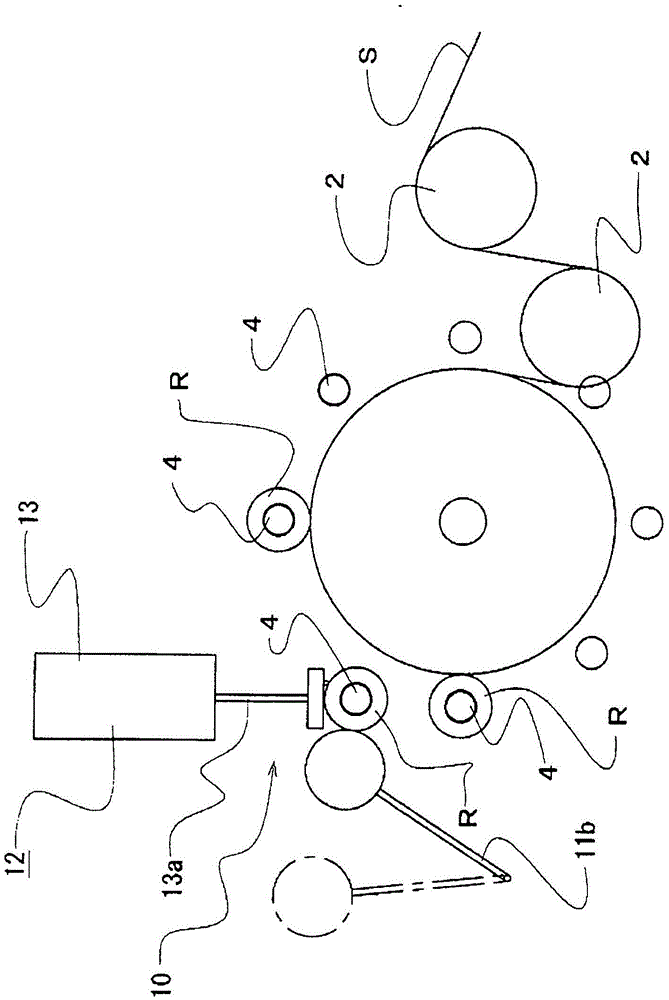

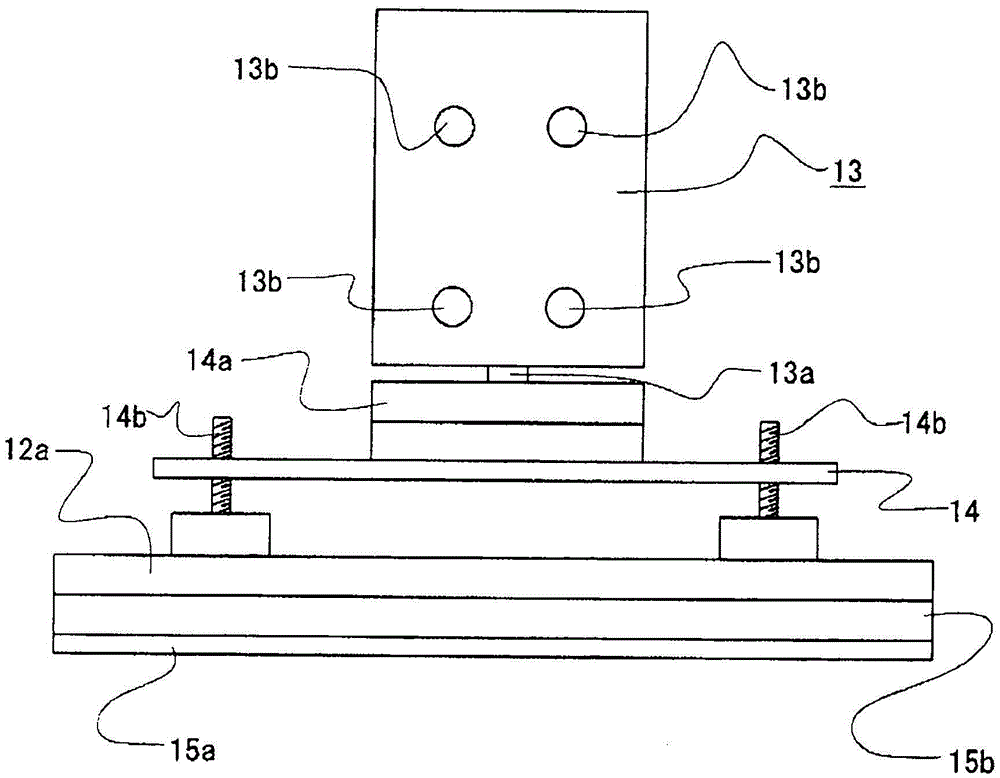

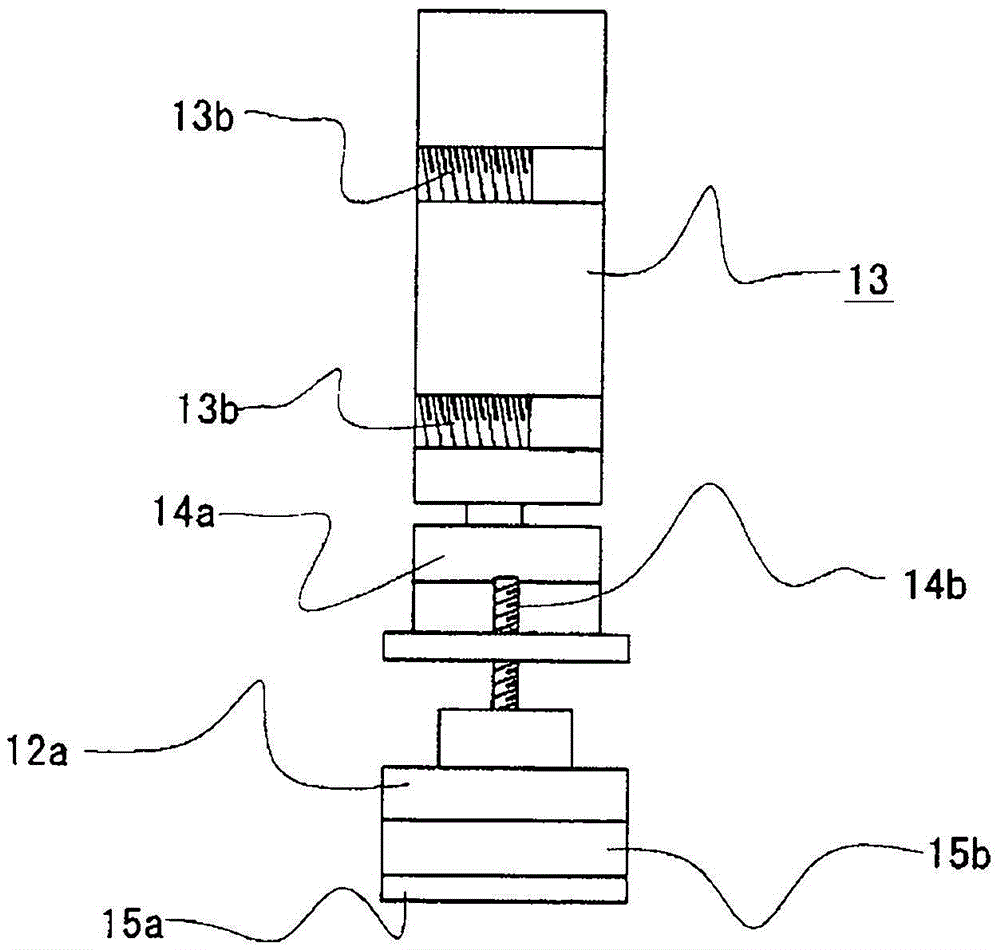

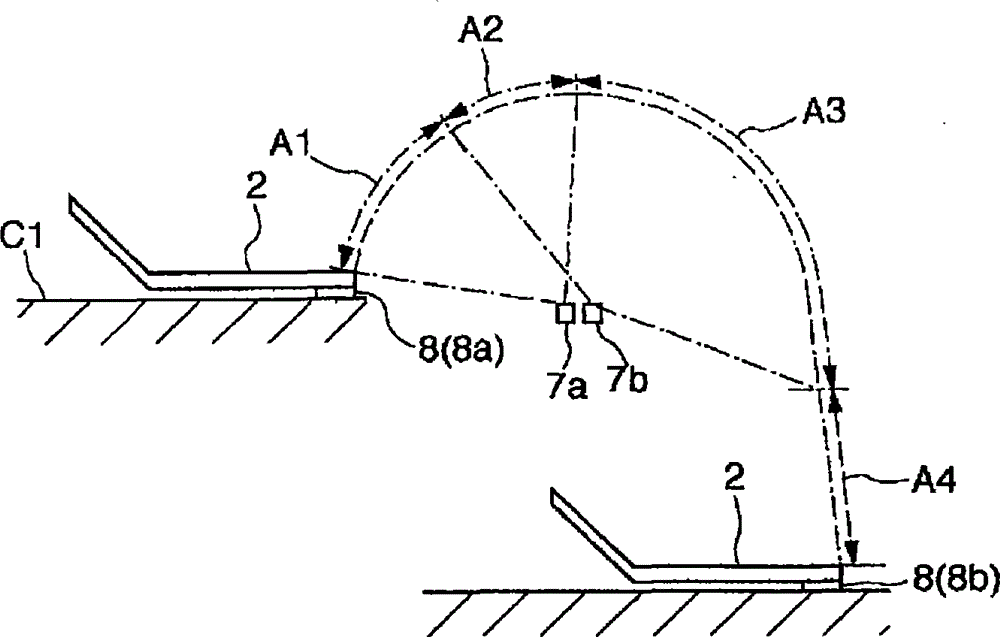

Tail processing device and method, and resin film roll

The trailing end-processing device (10) comprises a turret plate (3a), a film roll rotation roller (11), and a trailing end-contacting plate (12a). Just prior to completion of winding of a film sheet (S) on a paper tube (4) at a roll formation position (42), the turret plate (3a) transfers the film roll (R) to the trailing end-processing position (43). In the process thereof, the roll (R) is severed from the succeeding sheet (S) and a trailing end is formed on the roll (R). At the processing position (43), the roller (11) contacts the roll (R) by the pivoting of a pivot arm (11b) to stop the rotation of the roll (R). Moreover, the plate (12a) contacts the roll (R) by the forward movement of a piston rod (13a). When the roller (11) then rotates the roll (R) in the unwinding direction, the plate (12a) prevents the movement of the unwound trailing end and the trailing end is rounded and forms a rolled grip (20).

Owner:RIKEN TECHNOS CORP

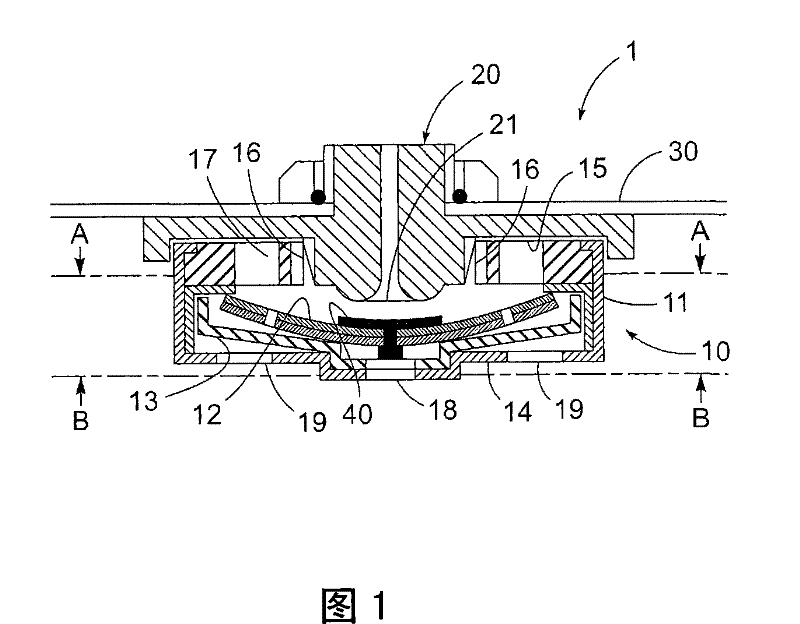

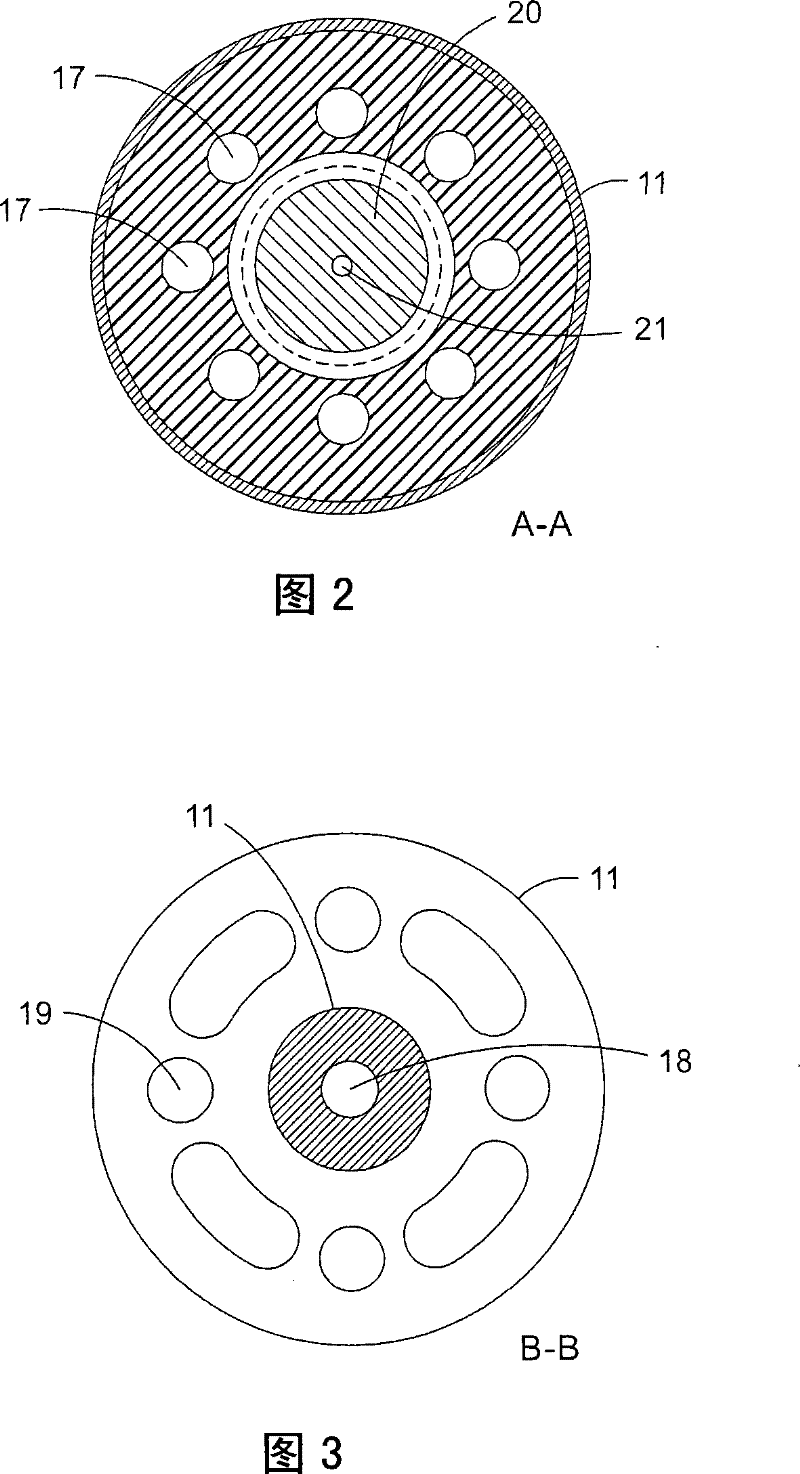

Air vent valve of steaming tool with button-shaped actuator device

InactiveCN101485545BEasy to operateAction indeedOperating means/releasing devices for valvesPressure-cookersTemperature controlActuator

Owner:徐佳义

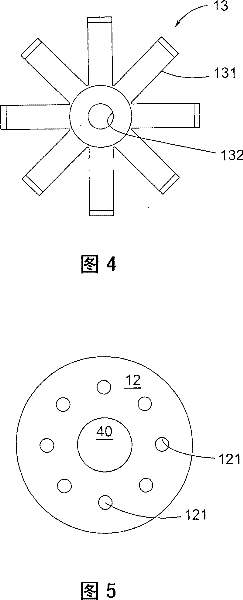

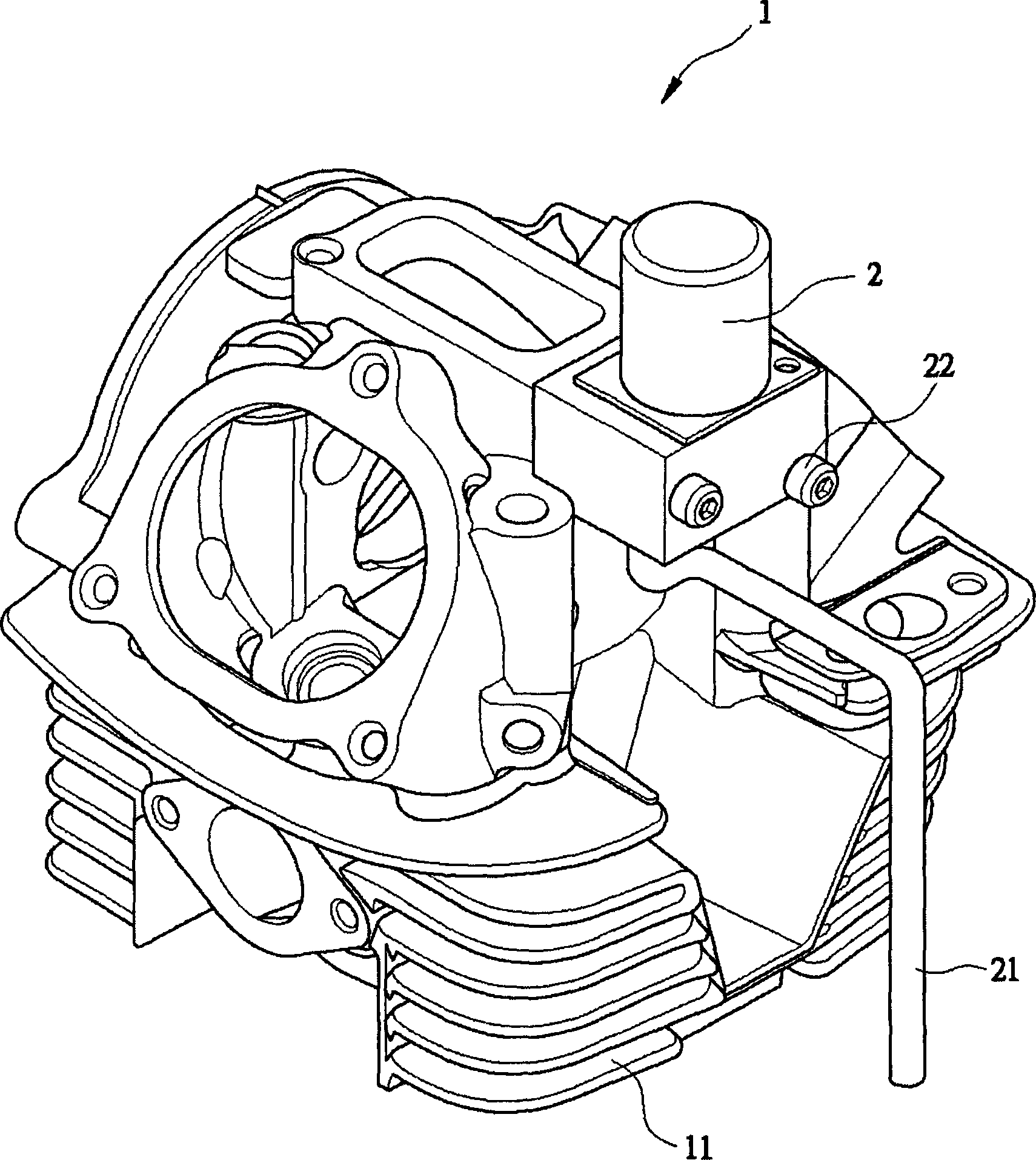

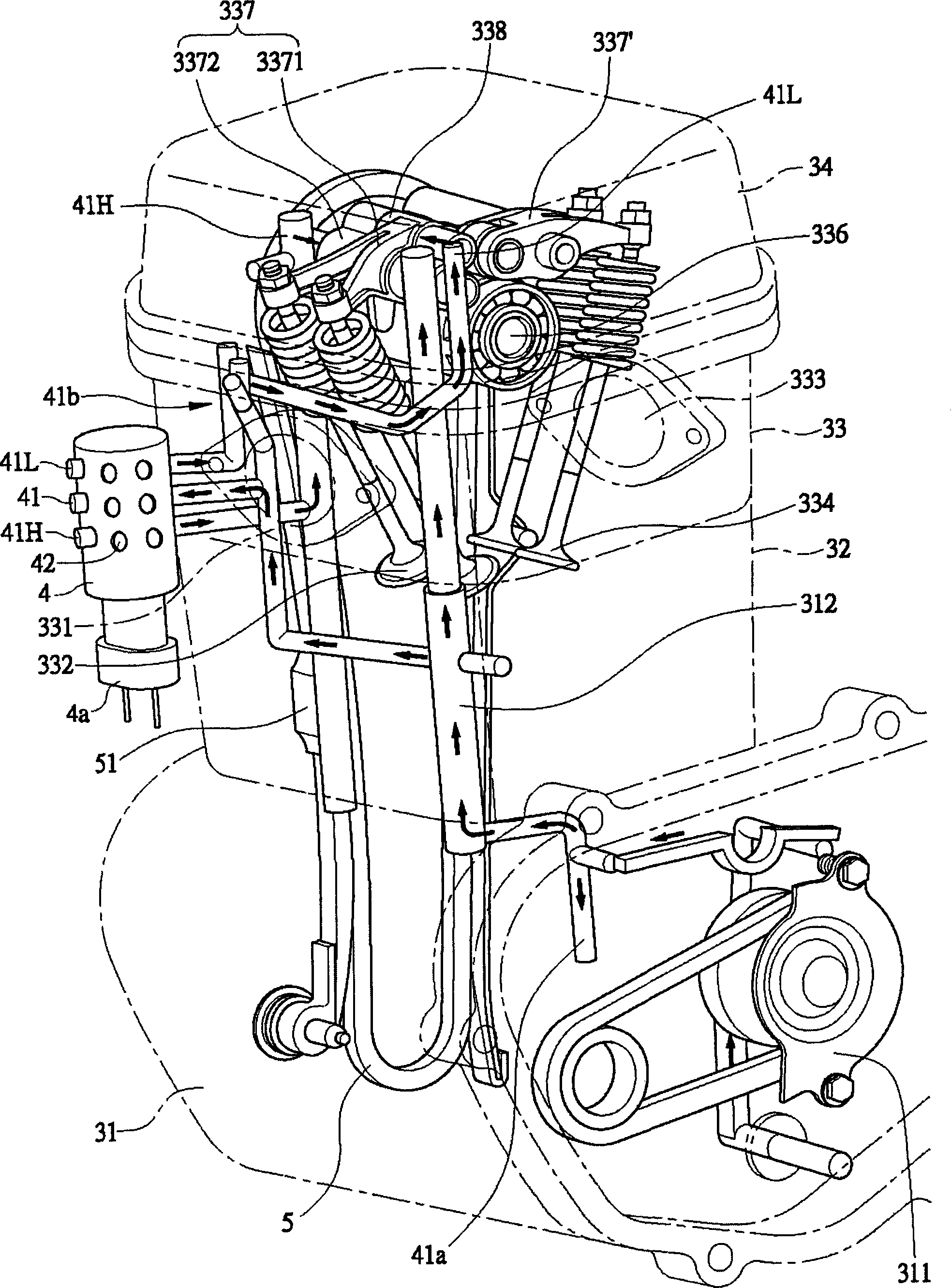

Configuration structure of variable valve lift mechanism and oil controlled valve of engine

InactiveCN102465730AIncreased durabilityAction indeedCylinder headsGearingHydraulic cylinderExhaust valve

The invention discloses a configuration structure of a variable valve lift mechanism and an oil controlled valve of an engine. The engine is provided with a cylinder head, one side of the cylinder head is provided with a gas inlet and a gas inlet valve, the other side of the cylinder head is provided with an exhaust hole and an exhaust valve, a throttling valve body penetrates through a gas inlet pipe to be communicated with the gas inlet, a cam shaft seat is arranged between the gas inlet valve and the exhaust valve and provided with a cam shaft, the cam shaft is provided with a gas inlet cam and an exhaust cam which can push a gas inlet valve push member and an exhaust valve push member, the gas inlet cam is provided with a first gas inlet cam and a second gas inlet cam, the gas inlet valve push member is provided with a low-lift push member and a high-lift push member corresponding to the first gas inlet cam and the second gas inlet cam respectively, the low-lift push member and the high-lift push member are provided with oil hydraulic cylinders which are communicated, pistons are arranged in the oil hydraulic cylinders; and the oil controlled valve is provided with a drive oil path communicated with the oil hydraulic cylinders, a lower-lift push member of the high-lift push member is closer to the oil controlled valve, and a path of a drive oil path of the oil controlled valve and the high-lift push member is shorter than that of a drive oil path of driving the low-lift push member by the oil controlled valve.

Owner:KYMCO

Gas flow control valve

InactiveCN101526144AChange the cross-sectional areaLess componentsOperating means/releasing devices for valvesEqualizing valvesAxial displacementGas passing

The invention provides a gas flow control valve, which comprises a lower valve seat having a flow passage for supplying gas; an upper valve seat is fixed on the top of the lower valve seat and has a pipe body and an electromagnetic coil group sleeved outside the pipe body; the pipe body is communicated with the flow passage; the electromagnetic coil group can generate a magnetic field after being powered; a magnetic cylinder group has a magnetic part and a sealing part, the magnetic part is a permanent magnet inserted into the pipe body and the magnetic part makes the magnetic cylinder group move along the axial direction of the pipe body under the action of the magnetic field of the electromagnetic coil group; when the magnetic cylinder group moves, the sealing part changes the proportion of the covered cross section of the flow passage correspondingly to control the flow of the gas passing through the flow passage; and a spring is arranged on one the top and bottom sides of the magnetic cylinder group and is positioned in the axial direction of the magnetic cylinder group for providing acting force for the balance and positioning of the magnetic cylinder group.

Owner:GRAND MATE

Configuration structure of variable valve lift mechanism and oil controlled valve of engine

InactiveCN102465730BIncreased durabilityAction indeedGearingCylinder headsHydraulic cylinderExhaust valve

Owner:KYMCO

Improved structure of connector

ActiveCN110896173AReduce display sizeReduce wasteRelieving strain on wire connectionCoupling contact membersEngineeringMechanical engineering

Owner:SWITCHLAB SHANGHAI +1

Clutch device for winch machine and winch machine using the clutch device

ActiveCN105271034BSimple structureAction indeedInterengaging clutchesWinding mechanismsEngineeringWinch

An engaging and disengaging device for a winch comprises a rotary knob and an engaging and disengaging assembly. The engaging and disengaging assembly comprises an engaging and disengaging gear, a positioning bolt, an elastic sheet and an elastic piece. A plurality of positioning grooves are formed in the periphery of the engaging and disengaging gear at intervals. The positioning bolt is arranged between the rotary knob and the engaging and disengaging gear in an axially-moving mode. One end of the elastic sheet is fixed to the rotary knob, and the other end of the elastic sheet abuts against the positioning bolt so that the positioning bolt can be pushed towards the engaging and disengaging gear to be plugged into one positioning groove of the engaging and disengaging gear. The elastic piece is arranged on the positioning bolt and used for pushing the positioning bolt away from the engaging and disengaging gear, so that the positioning bolt is disengaged from the positioning groove where the positioning bolt is originally plugged. In this way, the engaging and disengaging effect can be achieved with the simple structural cooperation.

Owner:REXON IND CORP LTD

Air-valve joint of air-inflating device

A nozzle joint of an air charging device comprises a shell with an air inlet channel, a least a nozzle component inside the shell and connected with the air inlet channel, the nozzle component composed of a spring sleeve, a hold part with a bottom, extending two parallel arm from the bottom, the shell contained between two arms of the holding parts, whose bottom corresponding to each nozzle part having a through hole, a banner part setting between holder two arms through a pin, with two end surfaces with one of it having smaller distance to the pivot center than the other. When the first end surface contacts with the shell, spring component of the nozzle sleeve at loose ends, and when the second end surface contacts with the shell, bottom of the holder part attaches to the shell and spring sleeve of the squeeze nozzle component deformed. It is convenient assembly, solid action and labor saving.

Owner:王罗平

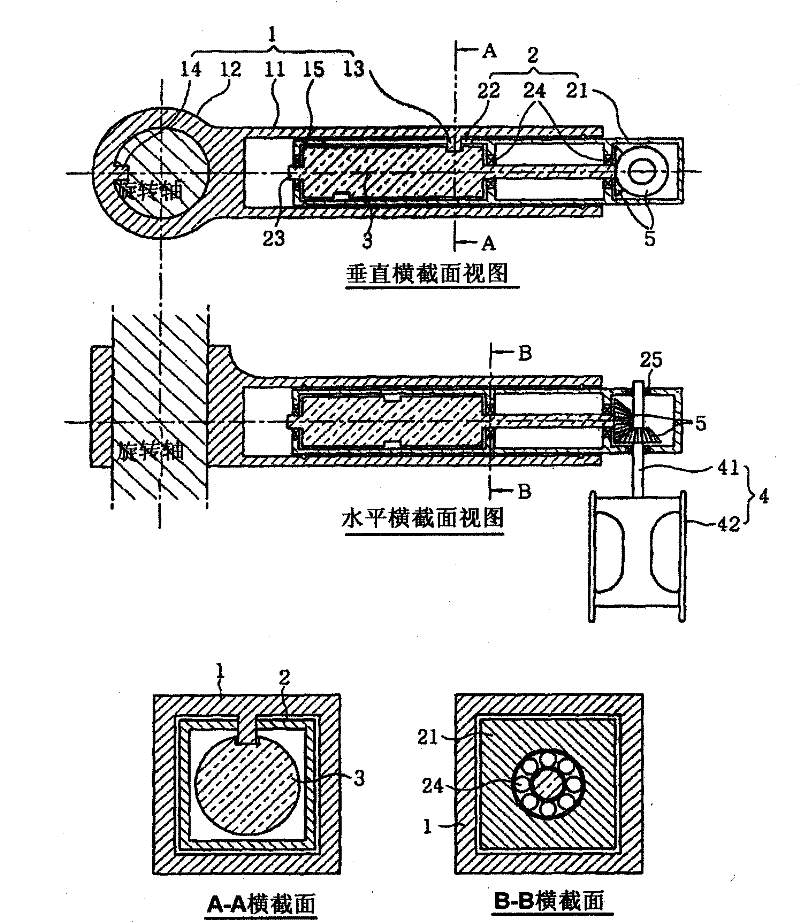

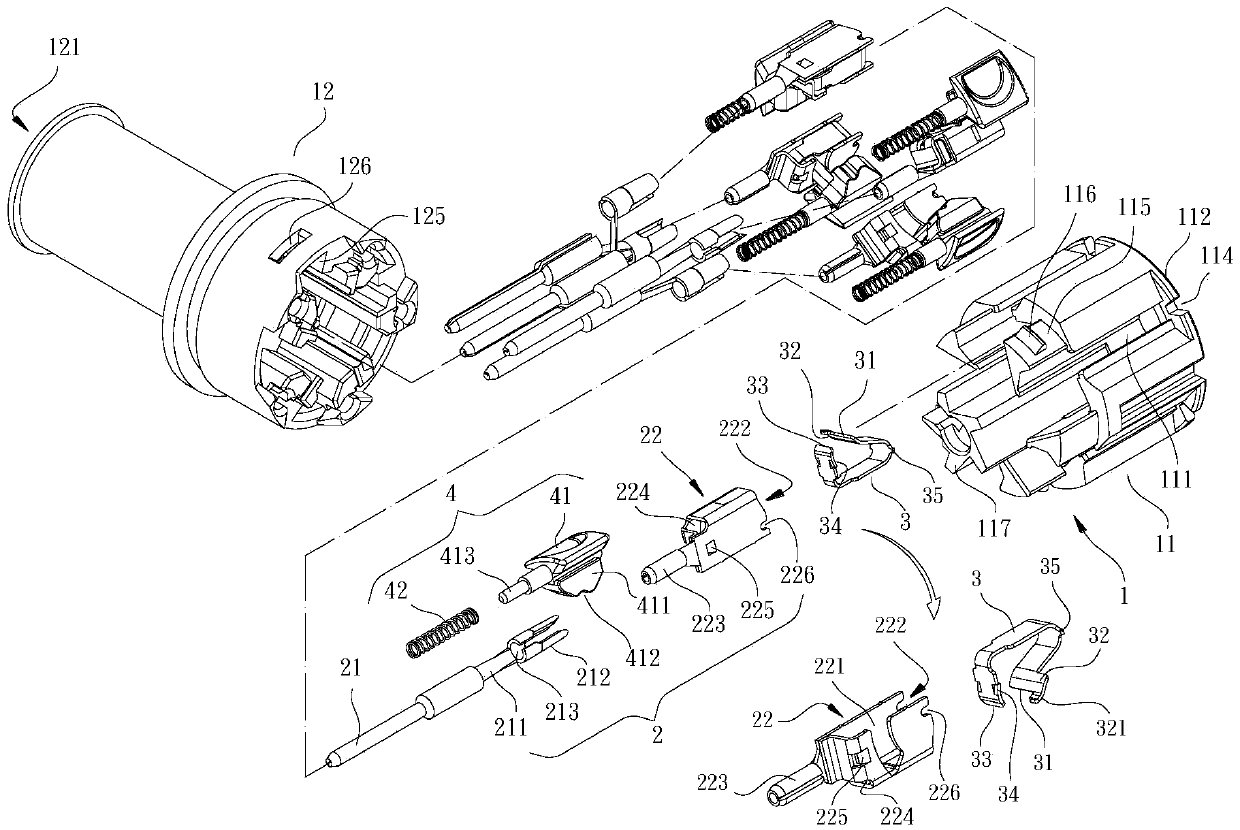

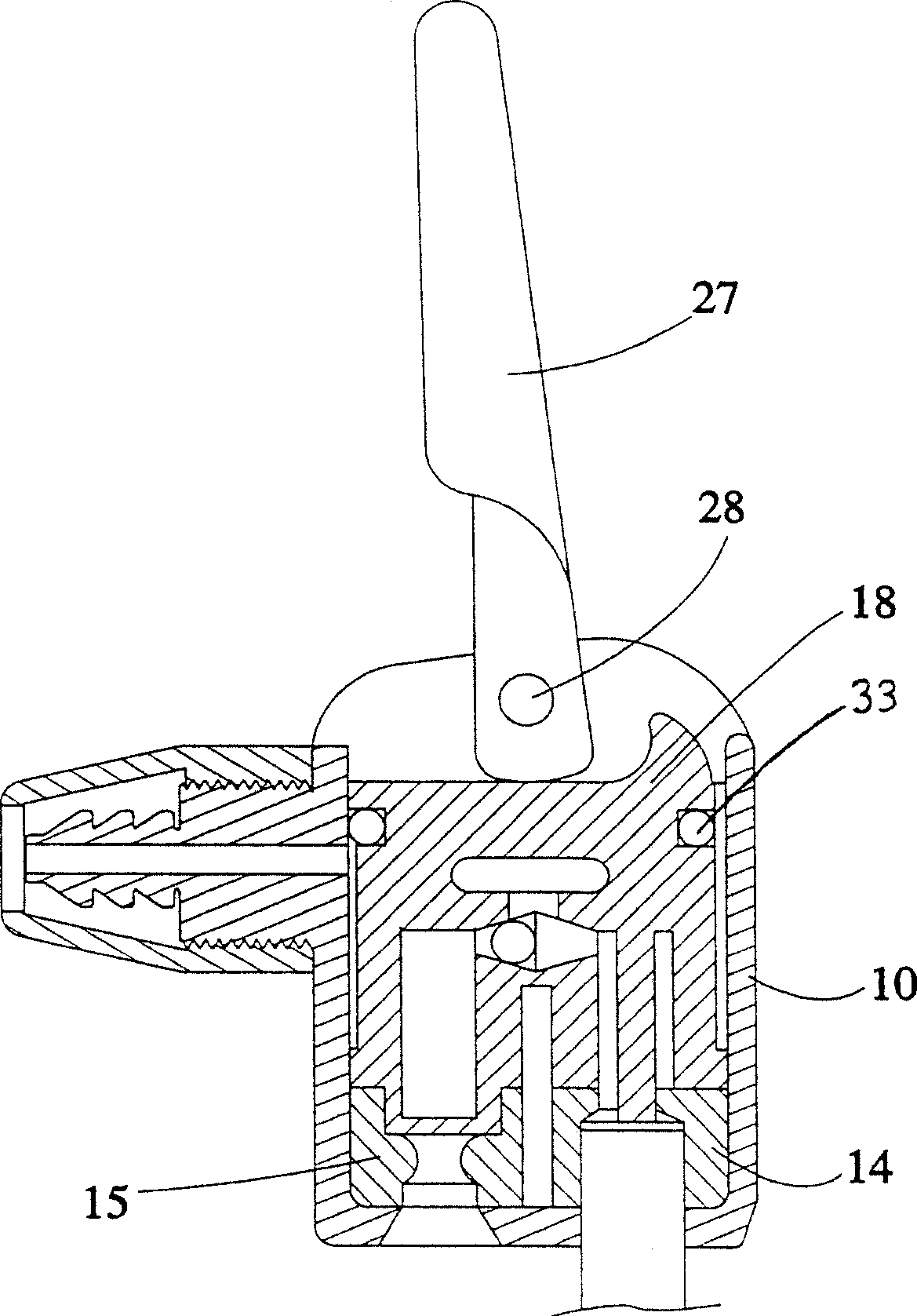

Pinhead easy to be loaded to and unloaded from hemostix

InactiveCN1518950AEasy loading and unloadingEasy to operateBlood sampling devicesSuction devicesLimiterBiomedical engineering

A blood taking device with a needle detachable easily has an injection-type tube with a hole, a needle interface and a blood-collecting interface which are arranged at both ends of said hole respectively, a slide coupling and an elastic stop part, a control unit consisting of a slide coupling matched with said coupling of said injection-type tube, a jamming hole, an elastic stop part and a pressing part, a needle unit comprises a needle seat, an insertion part, a movement limiter and a needle, and an ejecting unit arranged in said hole of injection type tube with an ejection part and a needle seat holder.

Owner:刘 蓉娥

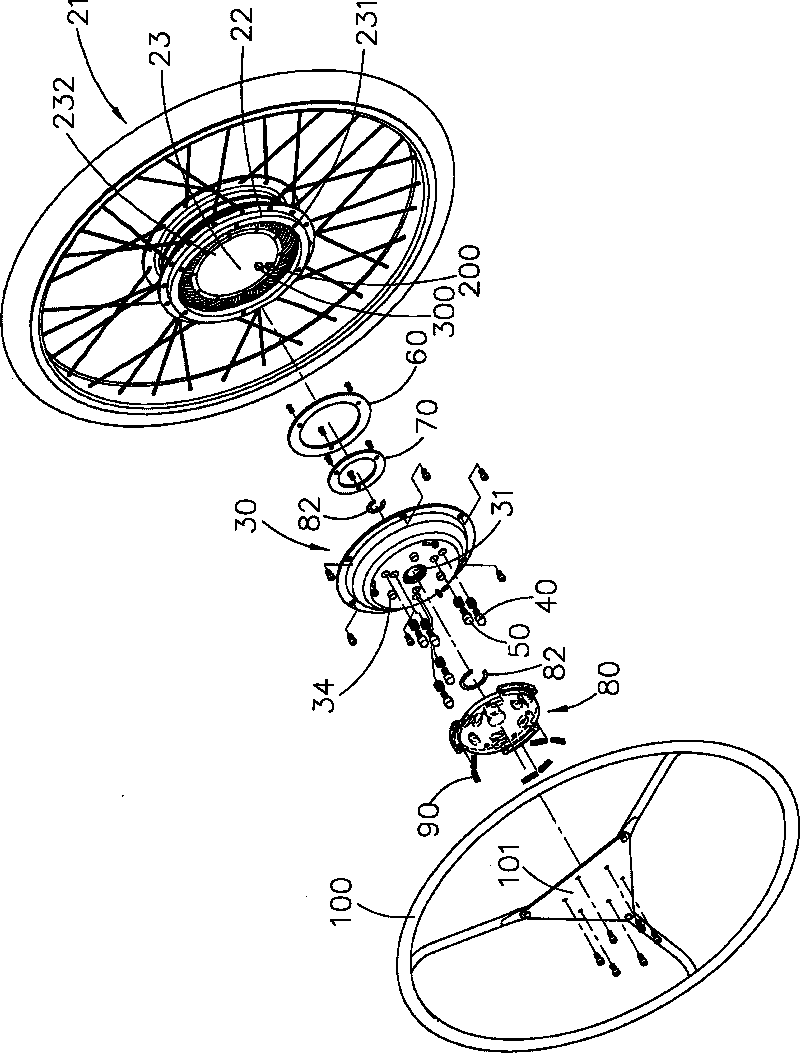

Dynamic start arrangement of power-assisted wheelchair

InactiveCN1919163BMeet needsConducive to production assemblyWheelchairs/patient conveyanceWheelchairFault rate

Owner:PIHSIANG MACHINERY MFG

hydraulic lift

The invention provides a hydraulic lifter, of which the hydraulic unit comprises a hydraulic pump connected to a motor serving as a driving source and supplies working pressure to a lifting plate to drive an actuator, and a proportional valve which receives the signals form a controller to change opening degree and change the quantity of the work liquid supplied to the actuator via the hydraulic pump. The controller controls the rotation speed of the hydraulic pump and the quantity of the work liquid supplied to the actuator is controlled by the opening degree of the proportional valve. The controller at least carrying following control processes: receiving input of lifting speed of the lifting plate, allowing the motor to rotate at the lowest speed enabling generating torque after a switch starts lifting operation, changing the proportional valve from a fully-closed state to a fully-opened state after the motor rotates in the lowest speed, and gradually increasing the rotating speed of the motor to an object speed corresponding to the elevating speed of the lifting plate received from the switch at the completion of the control of the proportional valve.

Owner:SHIMADZU SEISAKUSHO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com