Gas flow control valve

A technology for flow control valves and gas, applied in sliding valves, valve details, safety valves, etc., can solve problems such as inconvenient use, unsafety, and insufficient gas supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

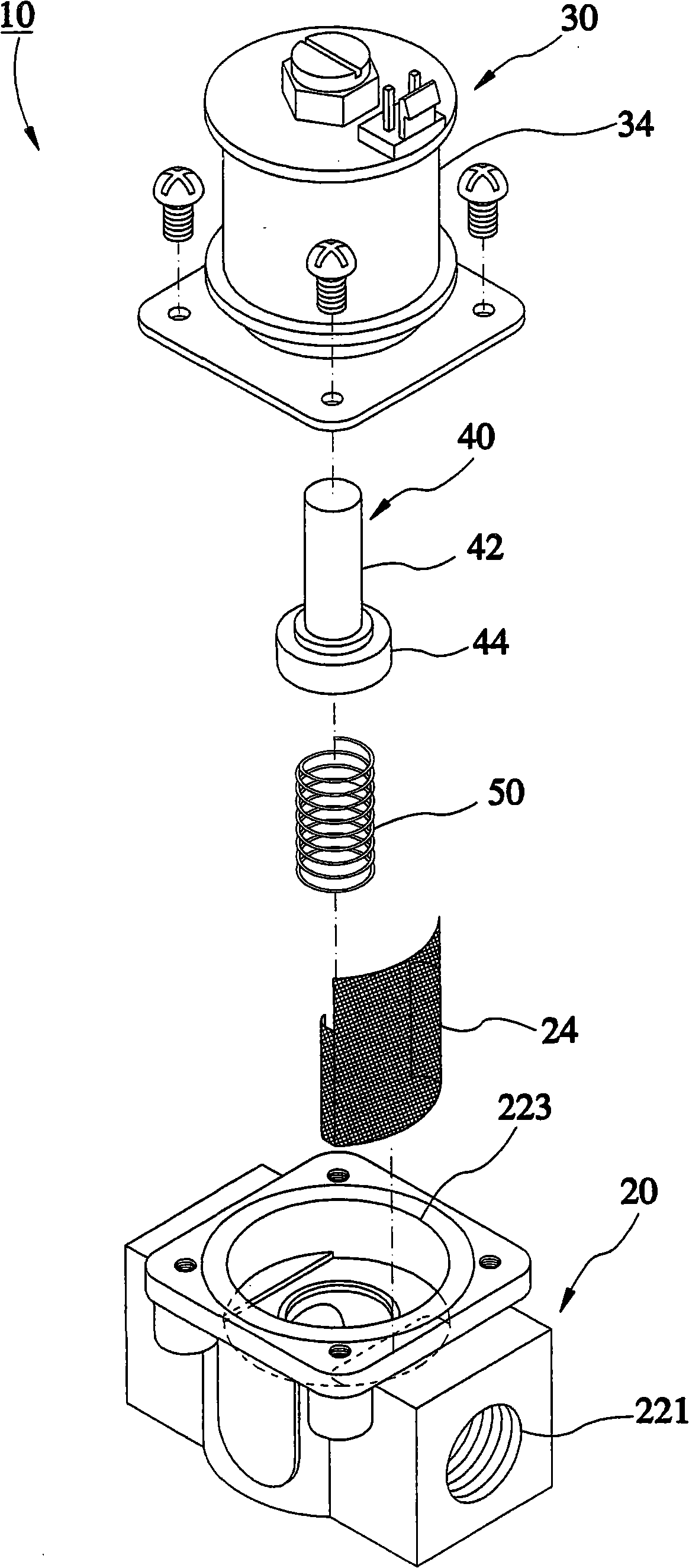

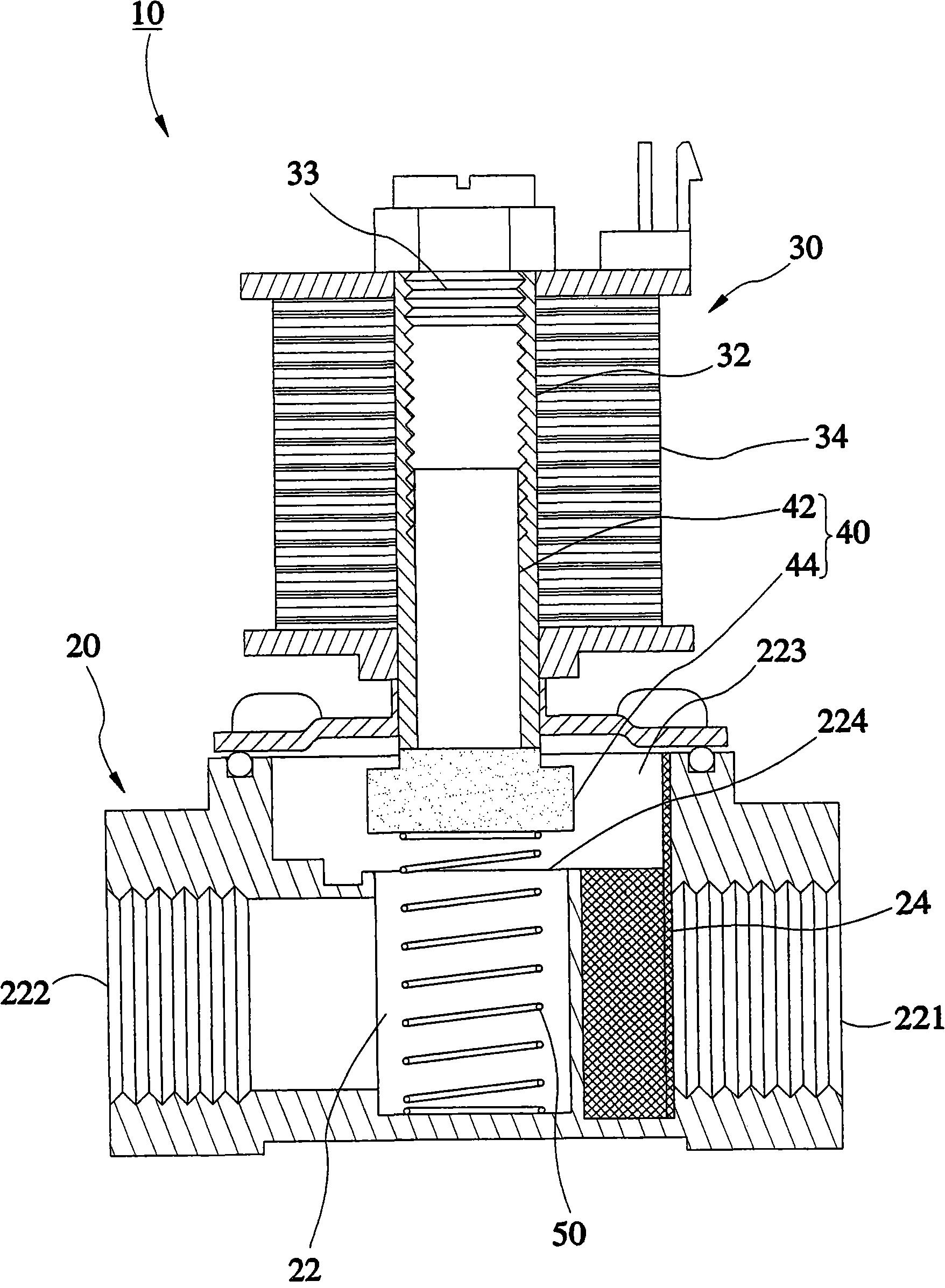

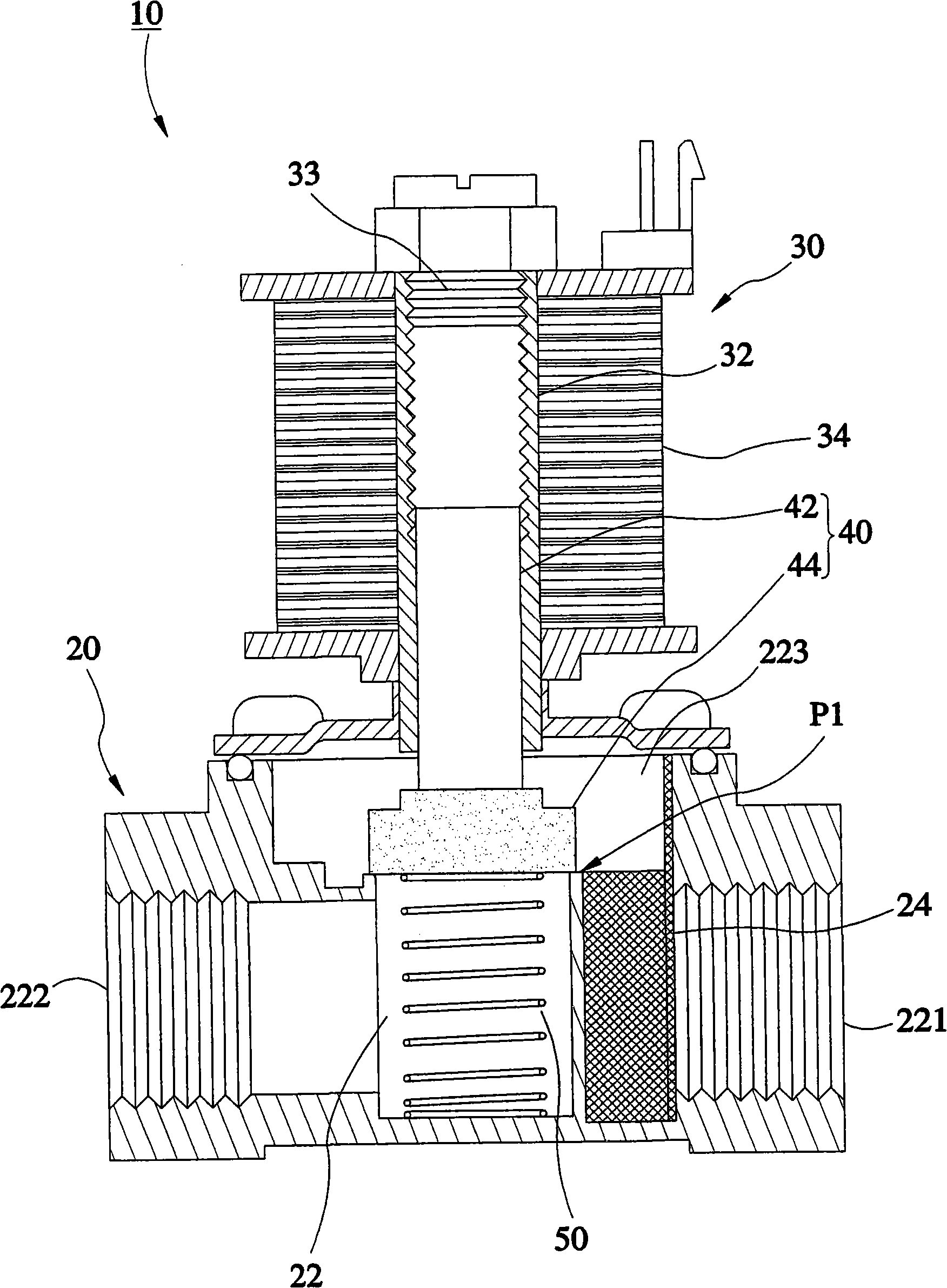

[0036] see Figure 1 to Figure 3 , which is a gas flow control valve 10 provided in the first preferred embodiment of the present invention, including: a lower valve seat 20 , an upper valve seat 30 , a magnetic column set 40 and a spring 50 .

[0037] The lower valve seat 20 has a flow channel 22 inside for the passage of gas; the flow channel 22 forms an inlet 221, an outlet 222 and a through hole 224 between the inlet 221 and the outlet 222 on the lower valve seat 20, And an opening 223 above the through hole 224; the inlet 221 is used for gas to flow into the lower valve seat 20; the outlet 222 is used for outputting gas; the opening 223 communicates with the middle section of the flow channel 22 and is located at the top of the lower valve seat 20 Through this, under normal passage, the gas can enter the opening 223 from the inlet 221 and then go from the through hole 224 to the outlet 222 . The lower valve seat 20 further includes a filter screen 24, which is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com