Retractable/extendable crank using a cylindrical cam, an end cam, or a swash plate cam, and bicycle using the same

一种圆柱凸轮、端面凸轮的技术,应用在机械零件领域,能够解决曲柄旋转机构复杂、难以安装自行车、制造费用高等问题,达到结构简单、简单适用、使用方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

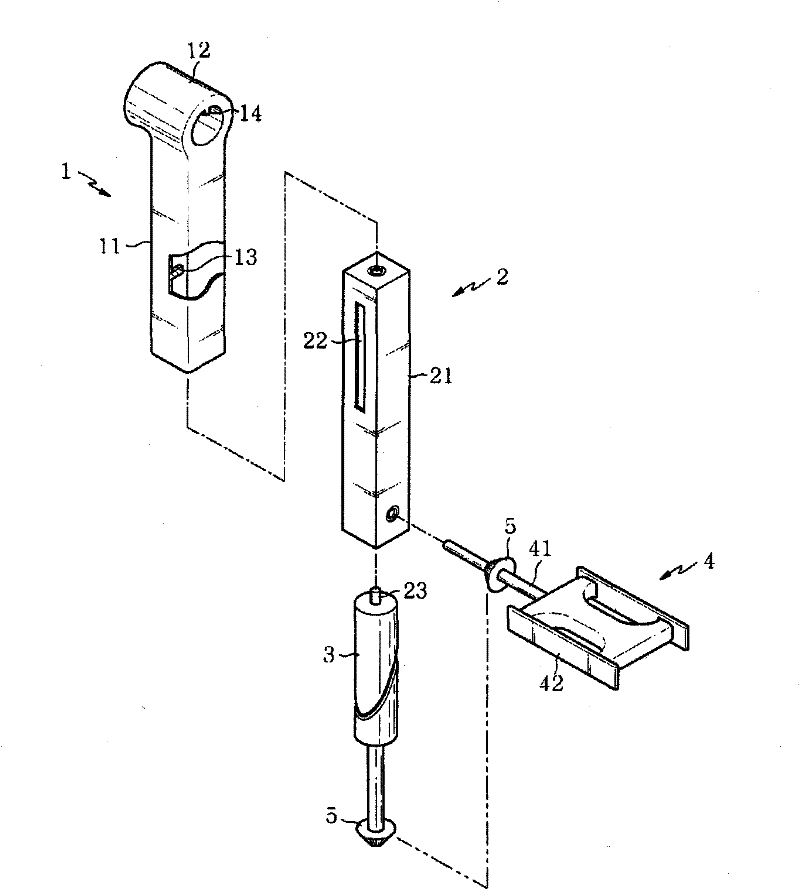

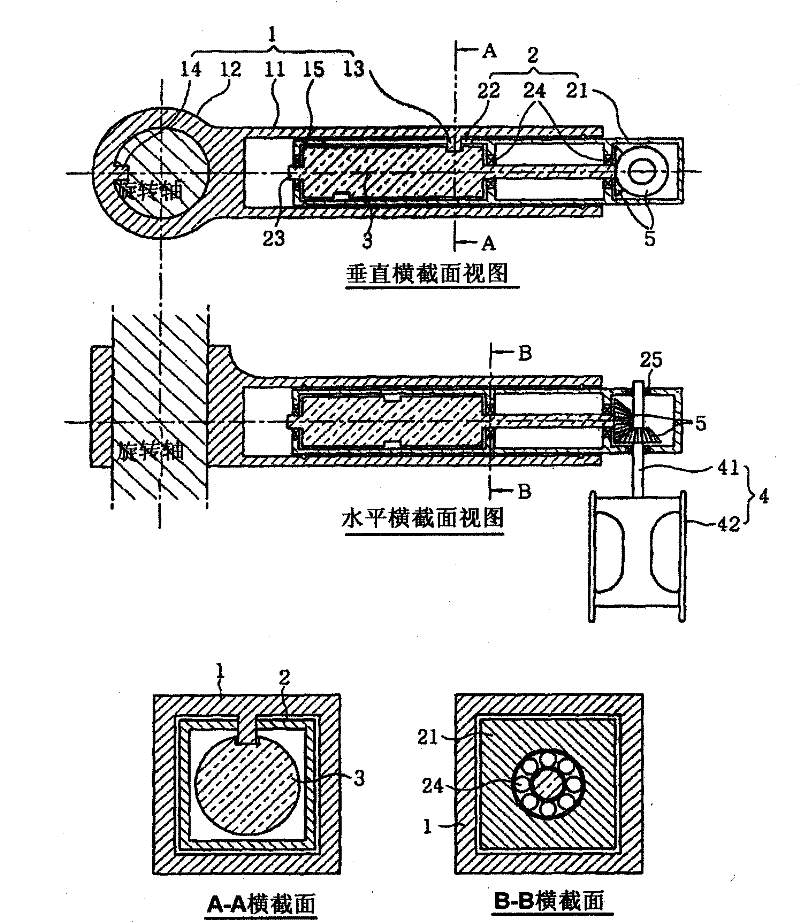

[0027] Utilize the retractable crank of cylindrical cam of the present invention, as figure 1 As shown, it includes: a crank, which is composed of a fixed arm 1 and a movable arm 2; the fixed arm 1 is connected to the rotating shaft of the rotating body; the movable arm slides inside the fixed arm 1; The inside of the arm 2 rotates; a pedal 4 , which is connected to the exposed end of the movable arm 2 ;

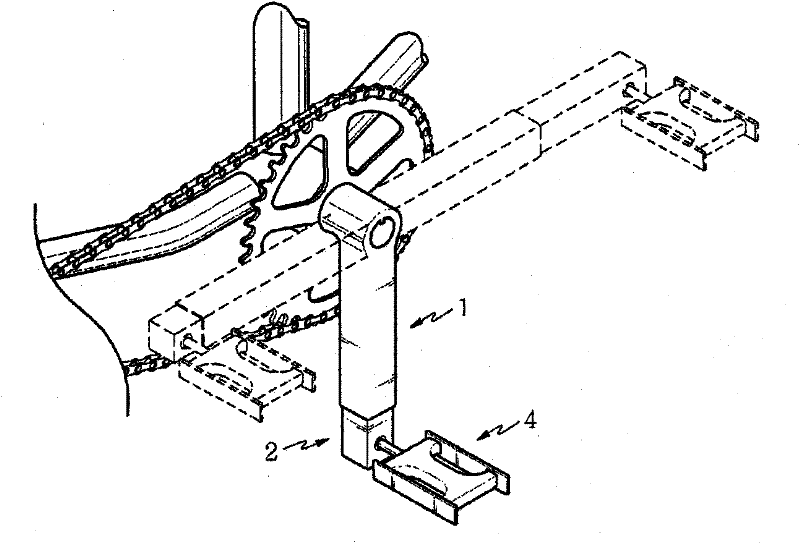

[0028] figure 2 is a diagram for driving a bicycle with a telescoping crank using a cylindrical cam with the above structure according to the present invention.

[0029] Such as image 3 As shown, the fixed arm 1 has a fixed arm body 11; one end of the fixed arm body 11 is formed with a hub 12, the hub 12 is coupled with the rotating shaft, and the other end of the fixed arm body 11 forms an opening to insert the movable arm 2-1 and make the The movable arm 2 expands and contracts. The cam guide 13 protrudes inwardly from the side of the fixed arm body 11 . The hub 12 ...

Embodiment 2

[0048] The retractable crank can also use end face cam 3-1 or swash plate cam 3-2 to replace cylindrical cam 3. When using the end face cam or the swash plate cam, there should be a tight spring 6, so that the cam surface and the cam guide 13 of the fixed arm are kept in close contact.

[0049] The shape of the end face cam 3-1 is as Figure 6 (a) shown. The end face cam 3-1 is manufactured by coupling a rotating shaft to a cam body formed by machining one end of a tube or cylinder of predetermined thickness into an inclined surface against which the cam guide 13 is snugly attached. When the end cam 3-1 rotates around the cam shaft, the end cam 3-1 reciprocates through the cam guide 13 fixed on the fixed arm, thus, the movable arm of the end cam 3-1 is installed 2 Telescopic movement when reciprocating sliding.

[0050] The shape of the swash plate cam 3-2 is as Figure 6 (b) shown. The swash plate cam 3-2 is manufactured by forming a disk-shaped slant plate inclined on t...

Embodiment 3

[0057] Same as the first embodiment, a cylindrical cam is also used as another embodiment of the present invention, and the crank at this time installs the cylindrical cam inside the fixed arm instead of inside the movable arm.

[0058] Such as Figure 8 As shown, the telescopic crank using a cylindrical cam according to this embodiment includes: a crank consisting of a fixed arm 1-1 and a movable arm 2-1, the fixed arm 1-1 is connected to the rotating shaft of the rotating body, The movable arm 2-1 slides outside the fixed arm 1-1; a cylindrical cam 3-1 rotates inside the fixed arm 1-1; a pedal (not shown in the figure) is connected to the movable arm 2 -1 end; a pair of bevel gears (5), one of which is connected to the shaft of the cylindrical cam 3-1, and the other is connected to the shaft of the pedal.

[0059] The fixed arm 1-1 is the same as that of Embodiment 1, a hub 12-1 connected to the rotating shaft is formed at one end of the fixed arm body 11-1, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com