Air-valve joint of air-inflating device

An inflatable device and air nozzle technology, which is applied to the valve, valve device, functional valve type and other directions for inflation, can solve problems such as large force and difficulty, and achieve the effect of reliable action and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

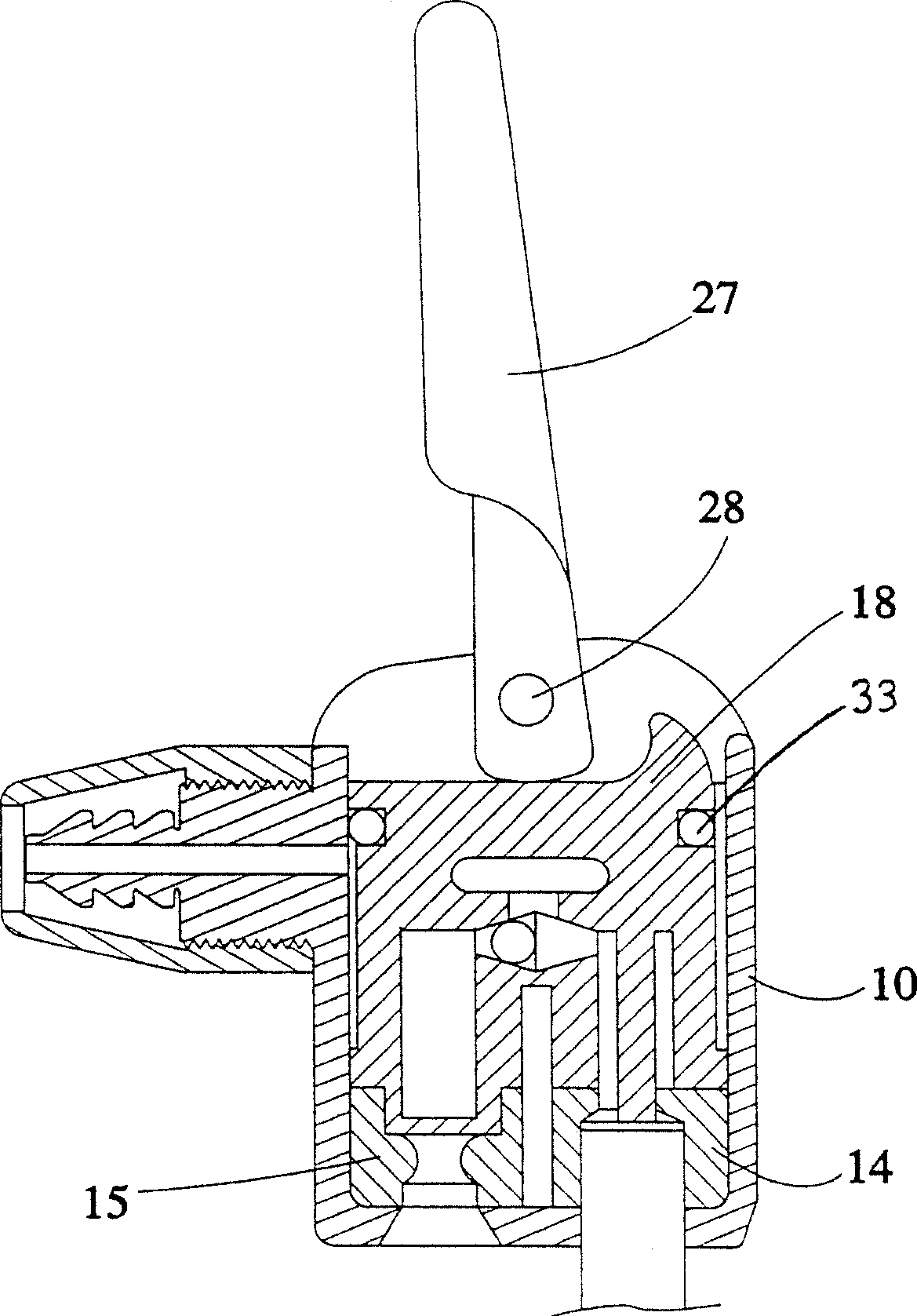

[0016] In order to illustrate the structure and achieved effects of the present invention in detail, a preferred embodiment is given and described with accompanying drawings.

[0017] The embodiment of the present invention is illustrated by a double-air nozzle joint, and its structure can also be applied to a single-air nozzle joint.

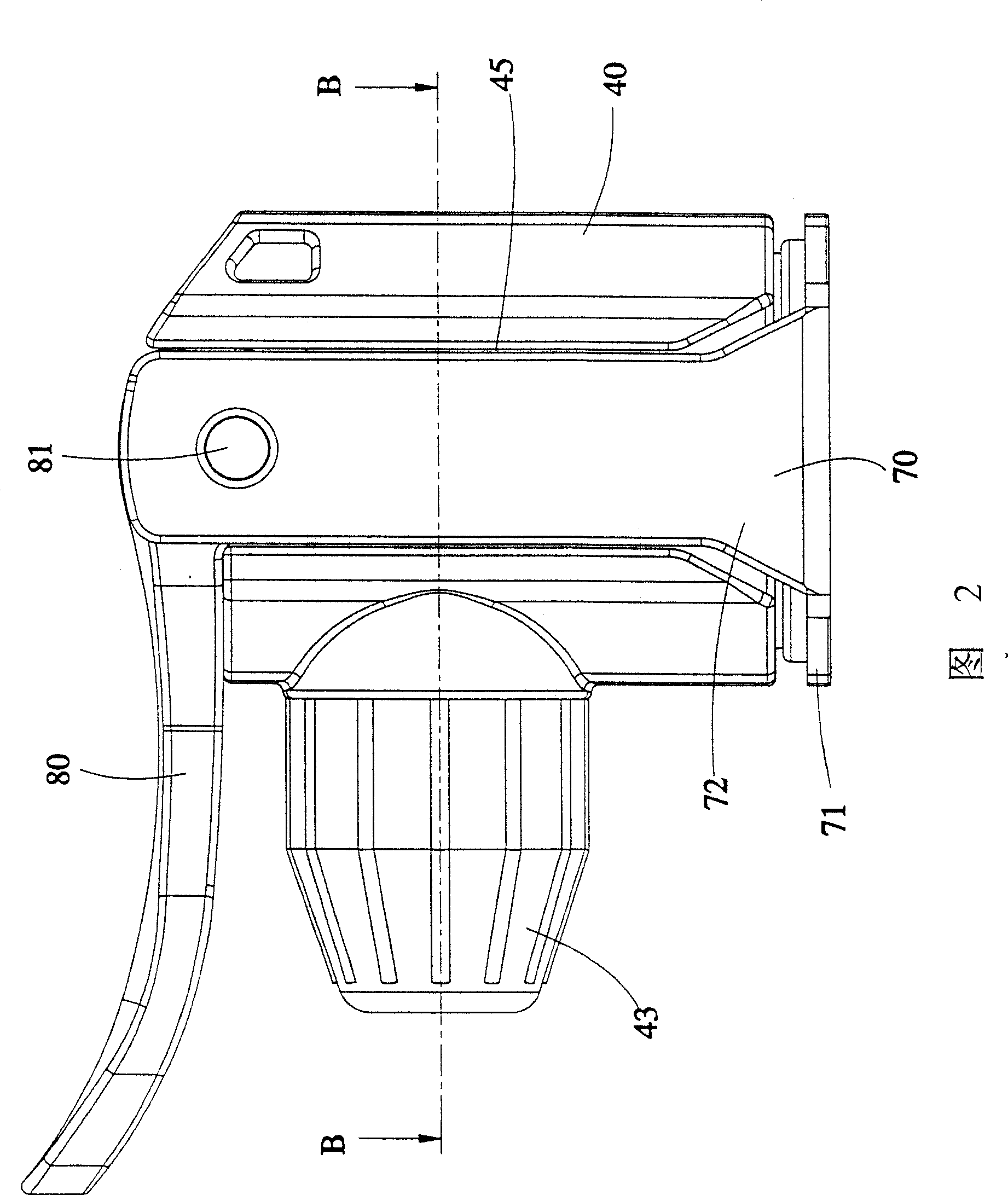

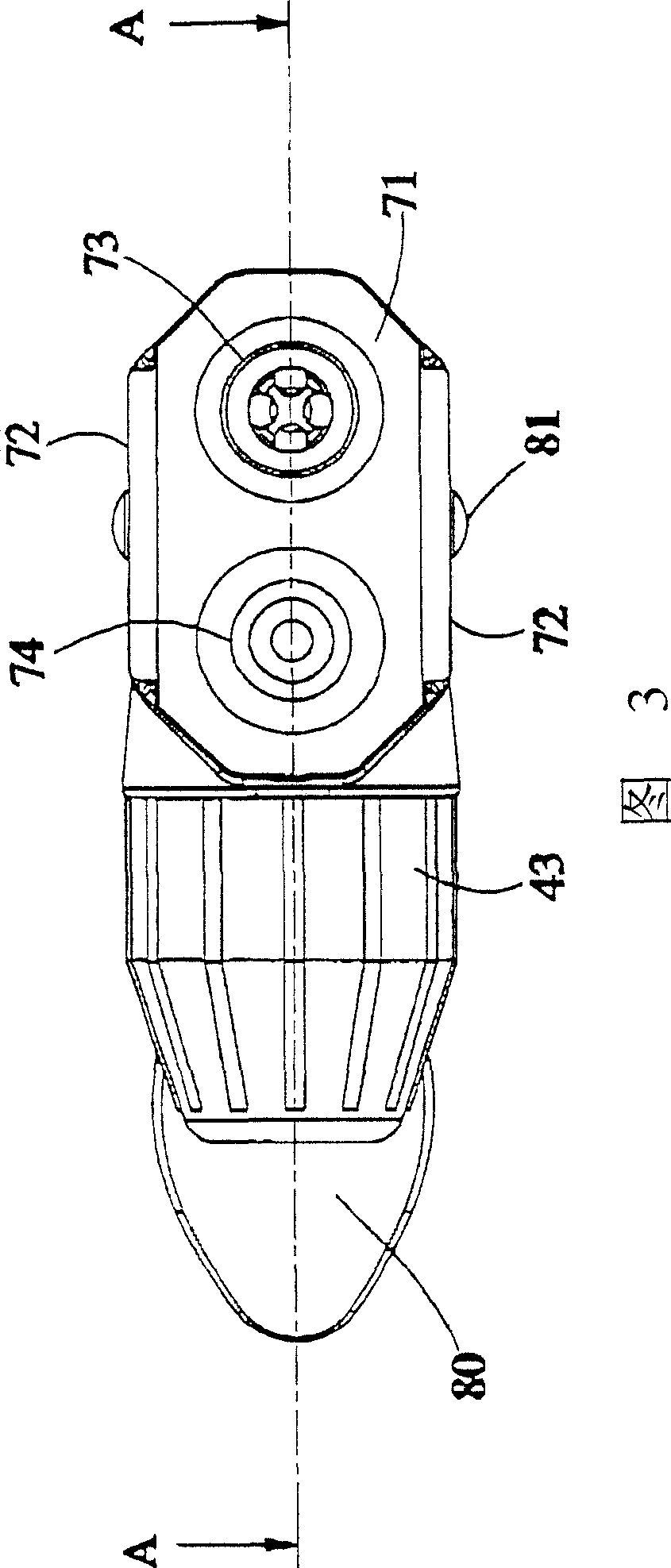

[0018] As shown in Figure 2 to Figure 5, the air nozzle connector in this example includes:

[0019] A housing 40, which has an air inlet channel 41, communicates with the outlet flow channel (not shown in the figure) of the inflator, and in this embodiment, a plug joint 42 is provided at the outer end of the air inlet channel 41 for a flexible pipe (shown in the figure). (not shown in the figure), and then screwed and locked on the preset thread 44 of the housing 40 with a bolt cover 43. This type can be used for floor pumps (FloorPump) and other inflatable devices with inflatable hoses. The housing 40 can also be directly connected to the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com