Hydraulic lifter

A hydraulic and lift technology, applied in the direction of lifting devices, etc., can solve the problems of increased motor output, power consumption, and impaired safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] One embodiment of the present invention will be described below.

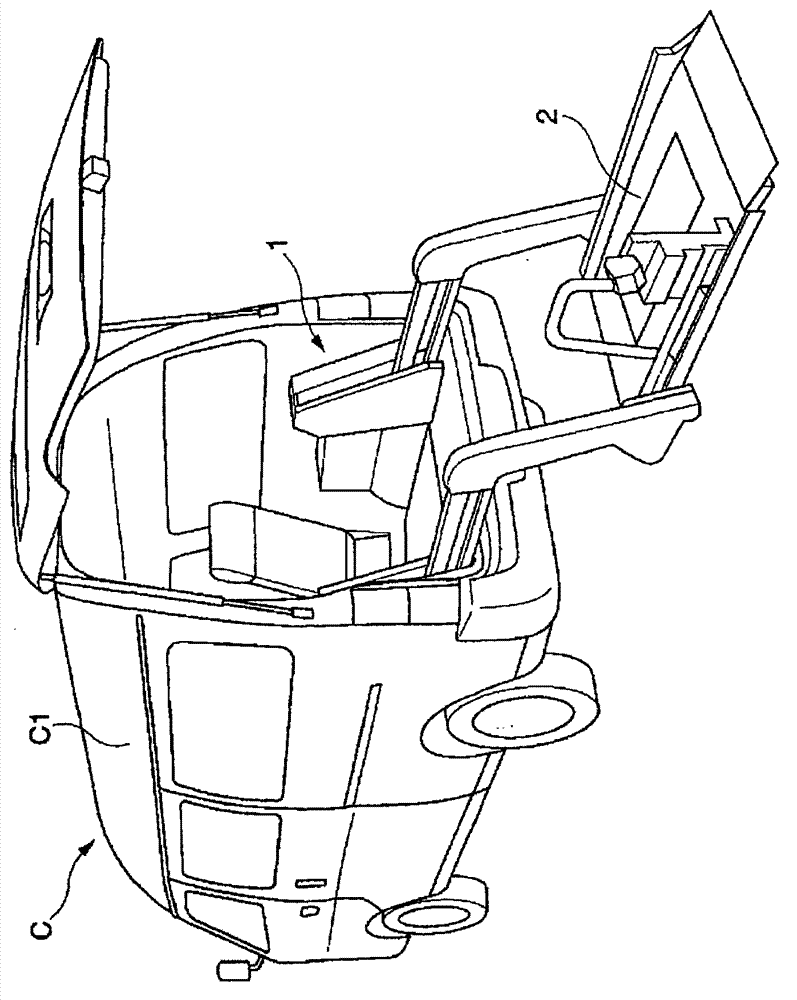

[0043] Such as figure 1 As shown, the vehicle C of this embodiment includes: a vehicle body C1, and a hydraulic lift 1 provided at the rear of the vehicle body C1.

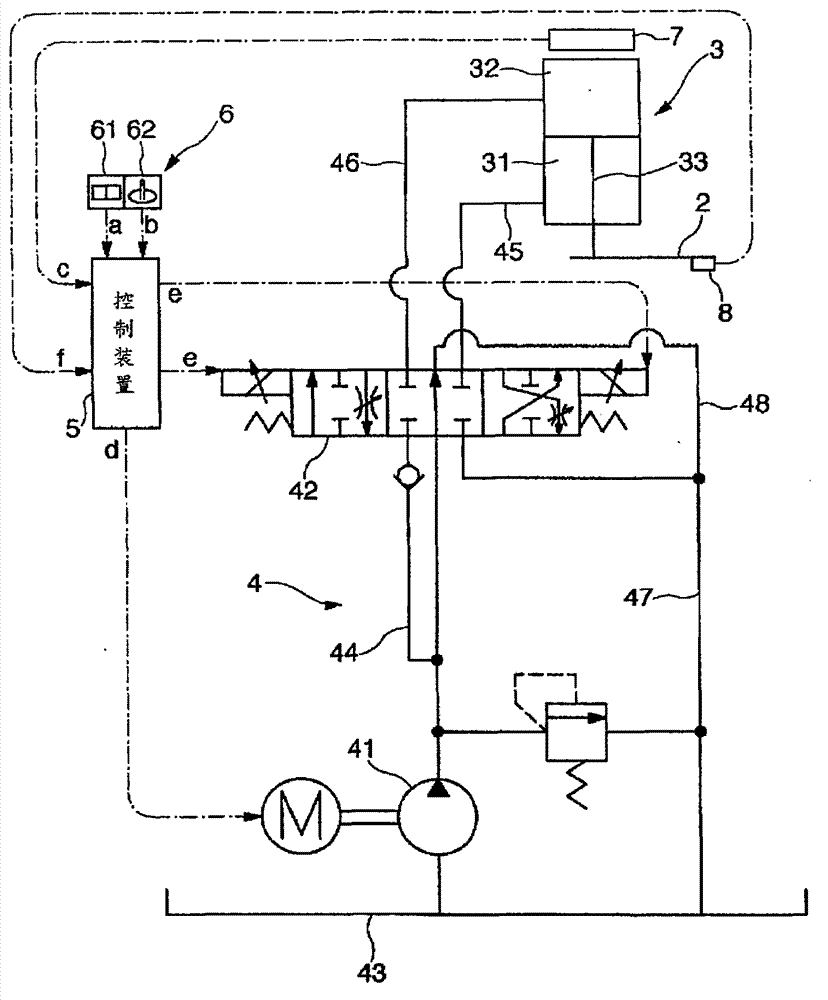

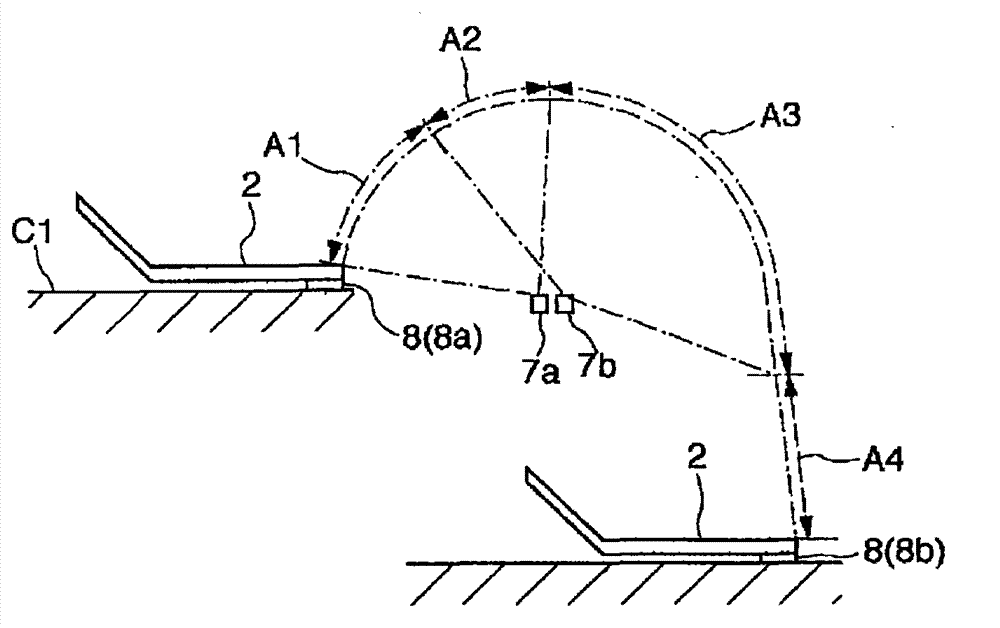

[0044] Such as figure 2 As shown, the hydraulic lift 1 includes: a lifting plate 2 for taking a person in need of care; an actuator 3 to drive the lifting plate 2; a hydraulic unit 4 including a hydraulic pump 41 and a proportional valve 42, The hydraulic pump 41 is connected to the motor M as a driving source, and hydraulic pressure is supplied to the actuator 3. The proportional valve 42 is a valve whose opening degree can be changed. The amount of hydraulic fluid supplied to the actuator 3 is changed; the control device 5 receives the position of the elevator from the position sensor 7 using a proximity sensor or the like in order to control the amount of hydraulic fluid supplied to the actuator 3 etc. to control the rotation speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com