Tail processing device and method, and resin film roll

A processing device and processing method technology, which is applied in thin material processing, coiling strips, transportation and packaging, etc., can solve the problems of complicated drive motor rotation control, complex structure, damage to the end of paper tube, etc., and achieve the goal of suppressing costs Lifting, simple structure, and the effect of improving the reliability of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

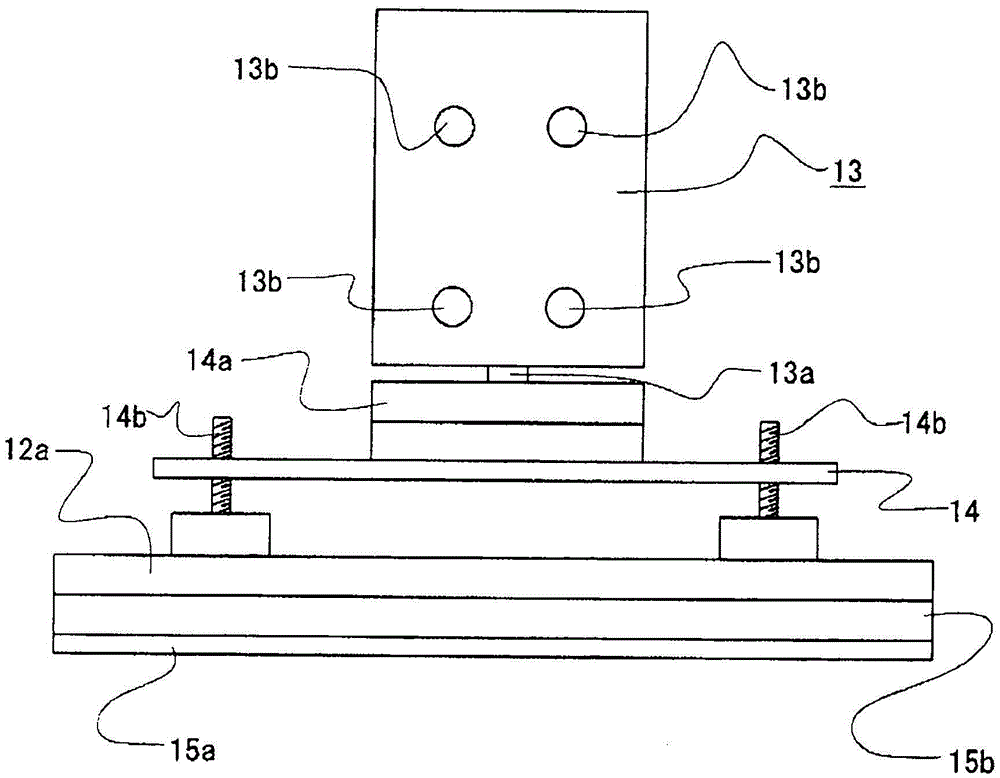

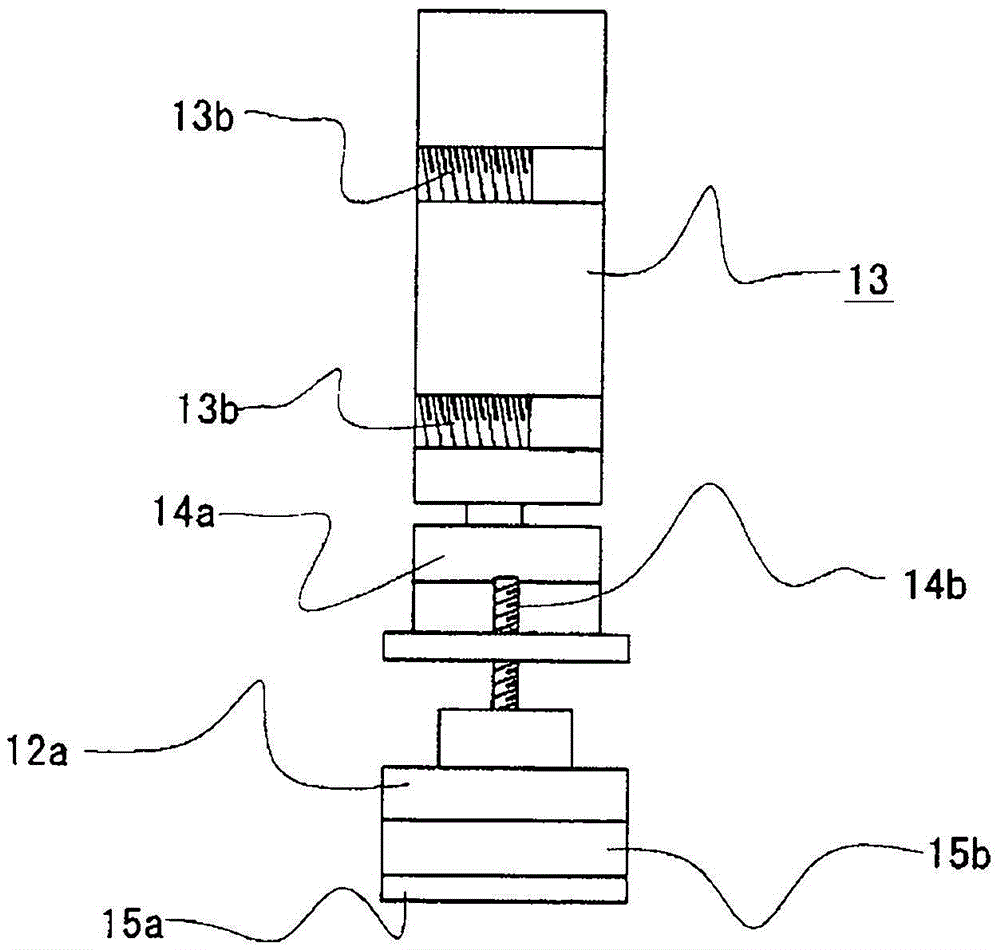

[0041] Next, according to the preferred embodiment shown in the drawings, the tail processing device of the resin film roll according to the present invention will be described, together with the tail processing method of the resin film roll and the tail processing device formed by the processing method. Resin film rolls and the resin film roll products.

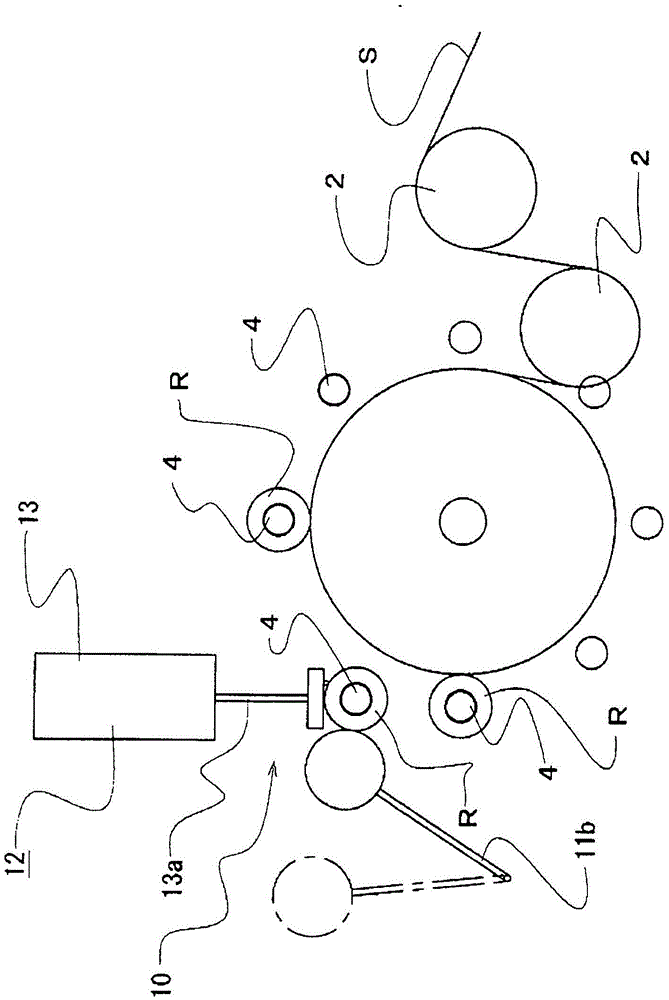

[0042] Figure 4 It is a figure which shows the outline|summary of the manufacturing apparatus 1 of the resin-made film roll suitably equipped with the tail processing apparatus 10 of the resin-made film roll which concerns on this invention. The film sheet to be produced is wound up and supplied to a winding device, cut into the width at the time of shipment, wound up, processed into a raw material roll P, and supplied to the manufacturing device 1 . In addition, in order to provide for the manufacture of the next film roll, prepare the raw material roll P 1 standby.

[0043] The film sheet unwound from the raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com