Needle selector for tubular knitting towel knitting machine

A technology of circular knitting towels and knitting machines, which can be used in weft knitting, knitting, textiles and papermaking, etc., and can solve the problems of complex needle design, insufficient stability, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

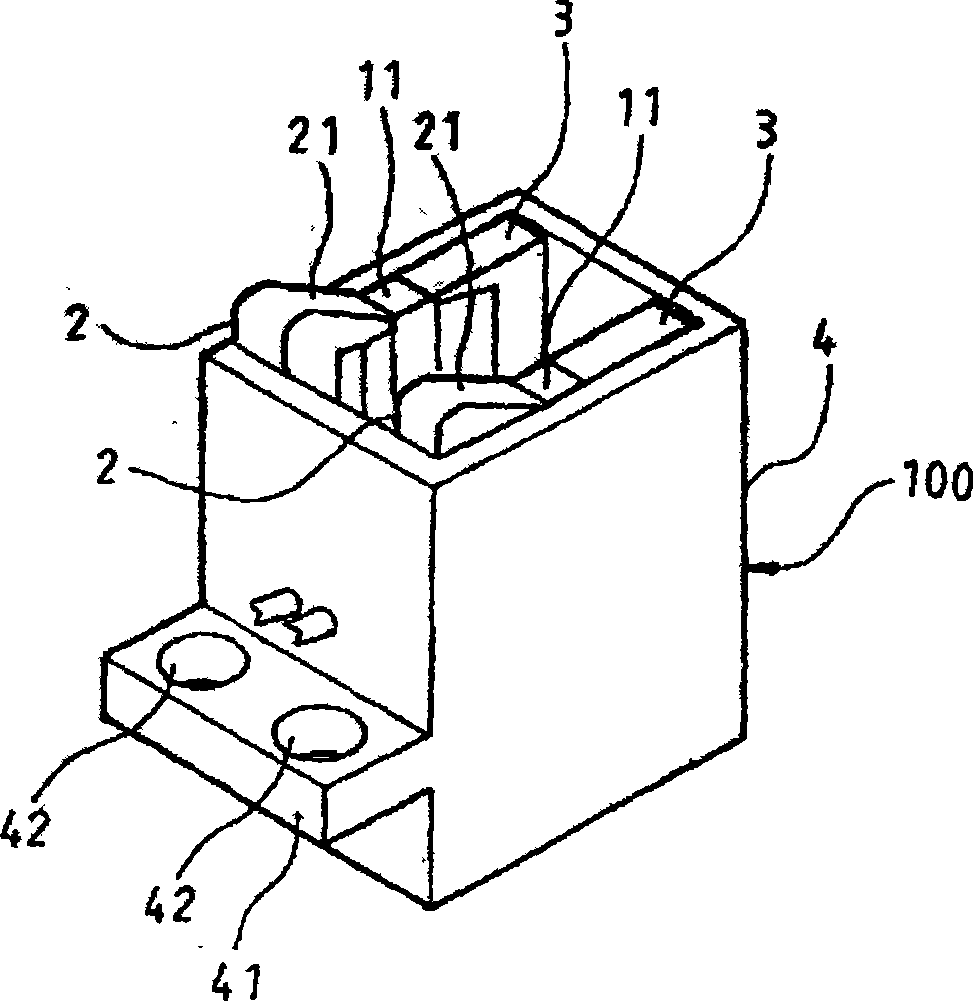

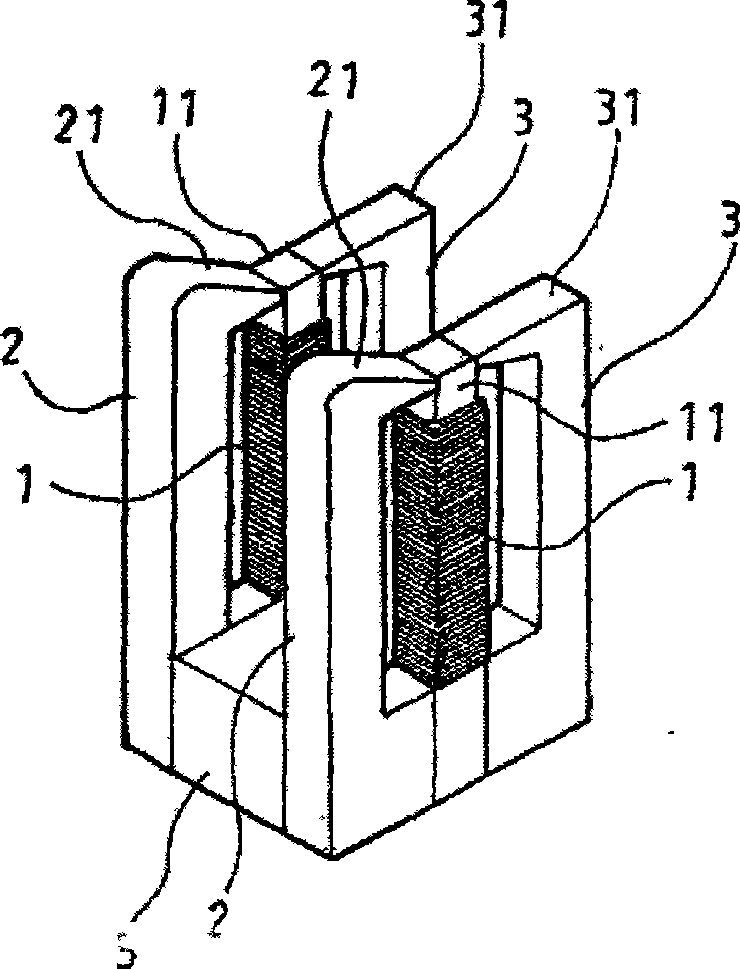

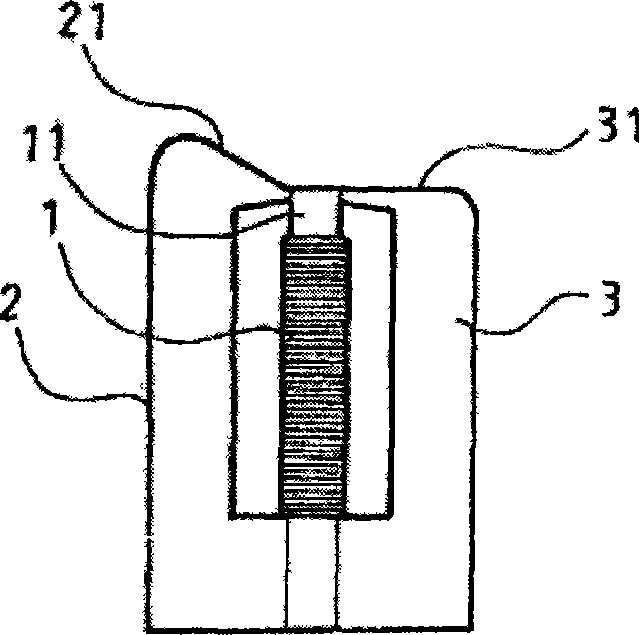

[0032] refer to figure 1 , figure 2 , image 3 As shown, the present invention mainly includes two coils 1 and symmetrical first steel plates 2 and second steel plates 3; wherein, the two coils 1 are wound around an axis 11, and the top of the first steel plates 2 is set on one side thereof Arc-shaped, the other side is then set as an inclined surface 21 from top to bottom, and the bottom edge of the inclined surface 21 is inwardly hooked. The top edge of the second steel plate 3 is a plane 31, and the bottom edge of the plane 31 is It is hook-shaped inwardly; the side of the casing 4 is provided with a protruding device part 41, and a fixing hole 42 is provided on the device part 41; by means of the combination of the aforementioned components, the two coils 1 and the symmetrical first steel plate 2 , the second steel plate 3 is placed on a magnetic steel 5, assembled in the casing 4, and the slope 21 of the second steel plate 2 protrudes from the upper surface of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com