Configuration structure of variable valve lift mechanism and oil controlled valve of engine

An oil control valve seat and oil control technology, applied in valve devices, non-mechanically actuated valves, mechanical equipment, etc., can solve problems such as engine embrittlement and damage, complicated assembly, and oil drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make it easier to understand the structure of the present invention and the effect that can be achieved, it is described as follows in conjunction with the drawings:

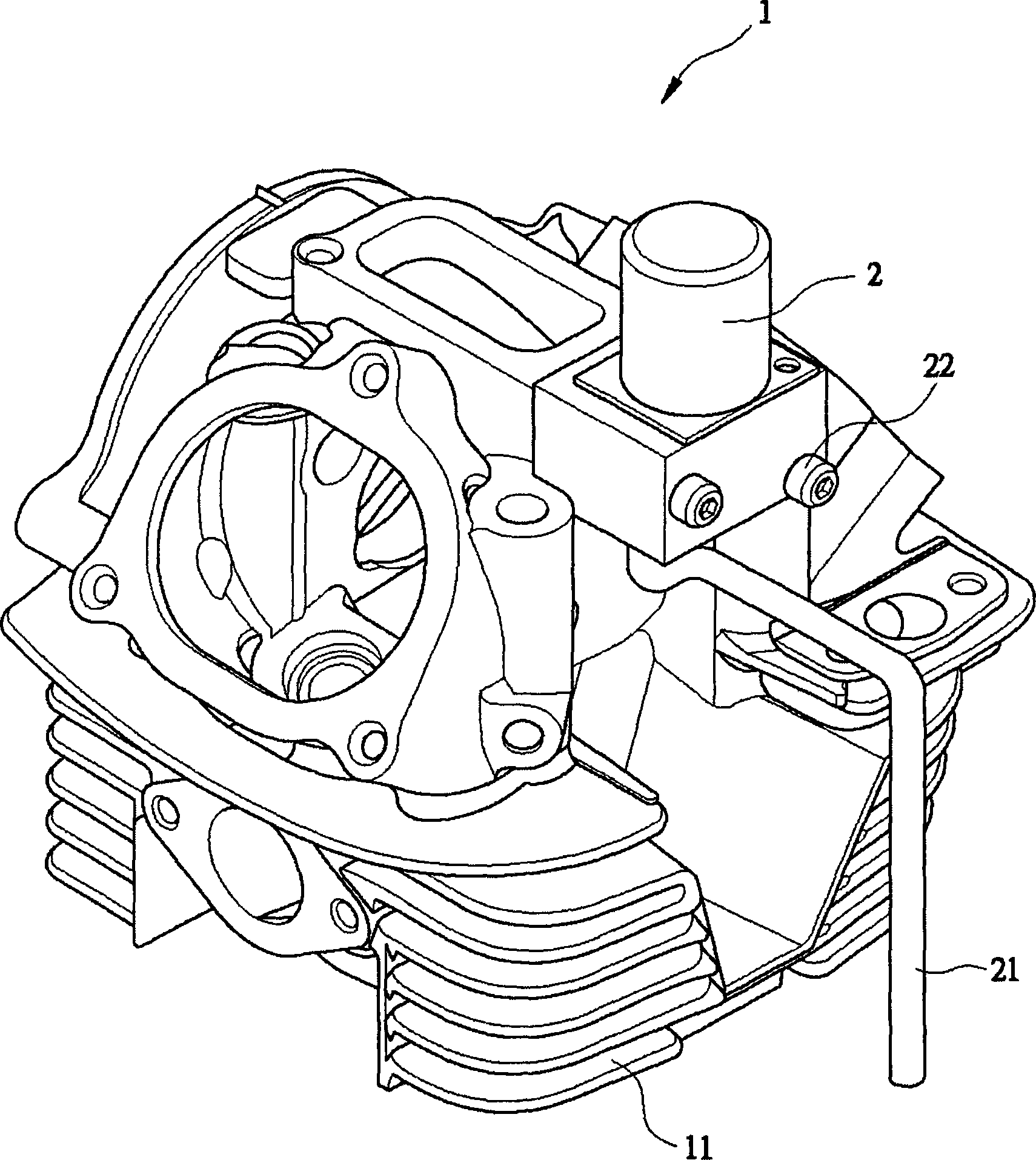

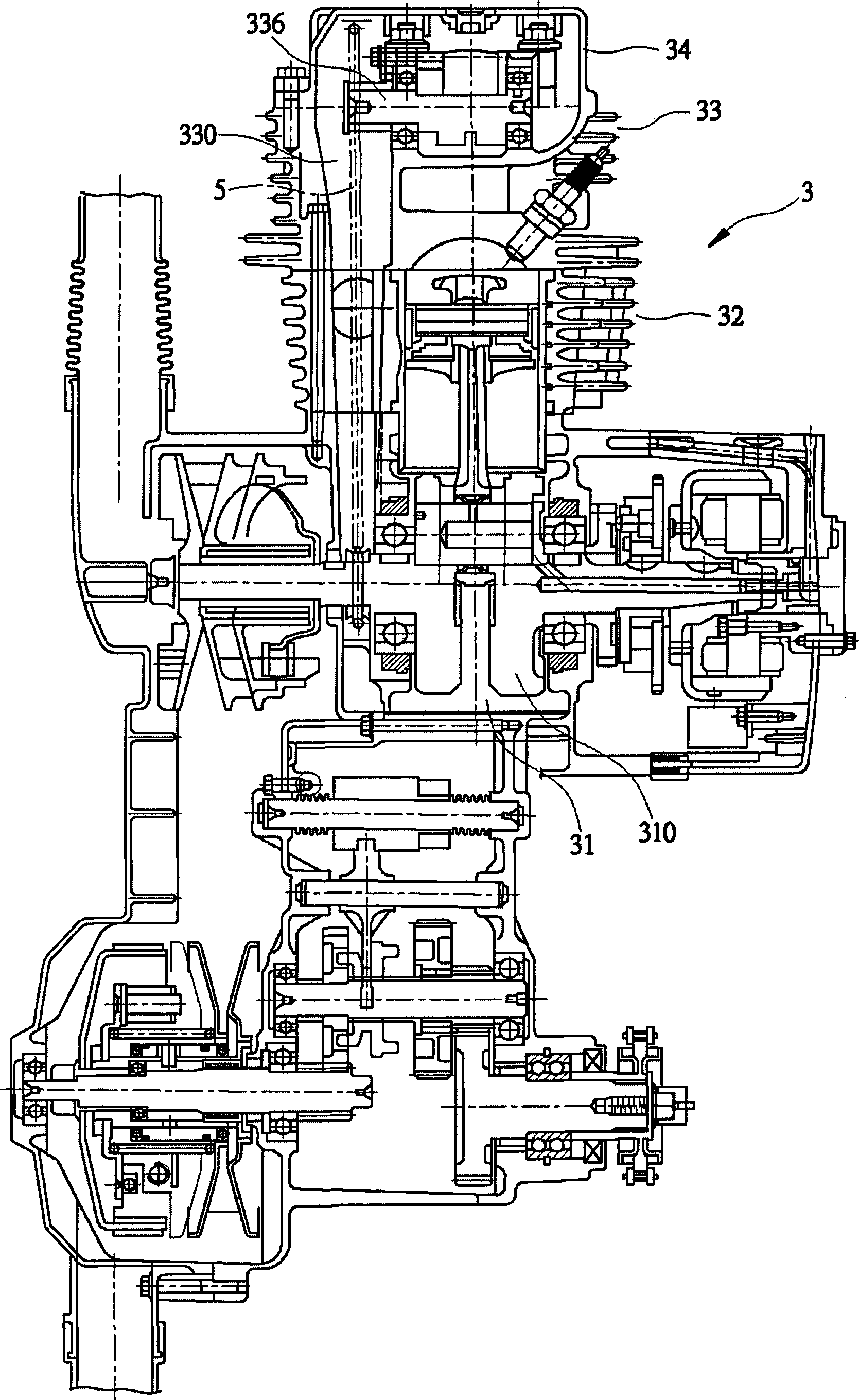

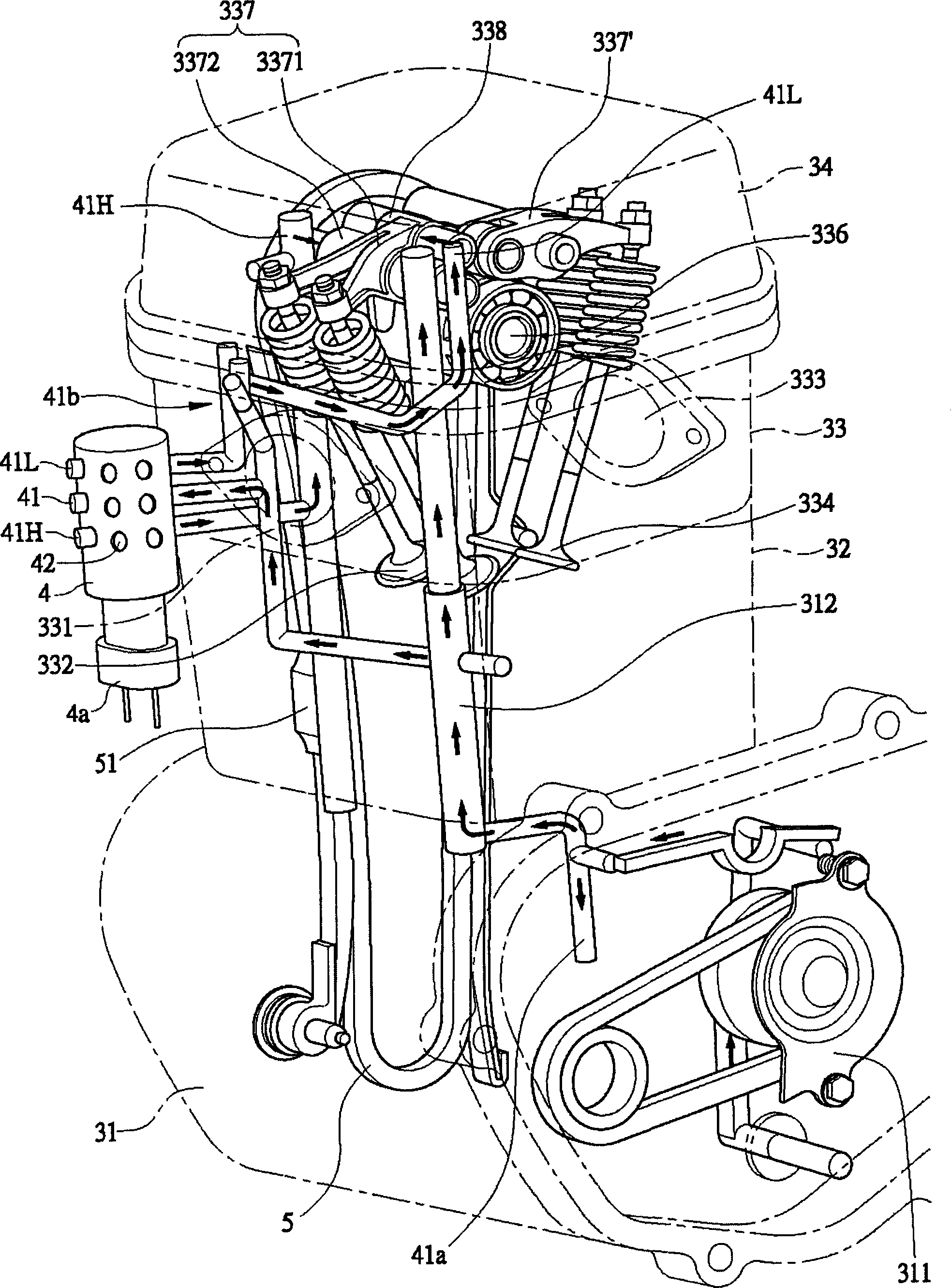

[0055] The engine 3 of the present invention is a swing engine 3 arranged on a scooter motorcycle in a substantially horizontal manner. First, see figure 2 As shown, the engine 3 of the present invention has a crankcase 31, a group of cylinder body 32 arranged on the crankcase 31, a group of cylinder head 33 and cylinder head cover 34 arranged on the cylinder body 32. Crankcase 31, inside is provided with a crankshaft 310, please cooperate image 3 Refer to, the crankcase 31 is provided with an oil pump 311, the oil pump 311 sends the oil to a main oil supply channel 312, and the main oil supply channel 312 is connected to the cylinder head after the crankcase 31 passes through the cylinder body 32. 33 oil control valve 4.

[0056] Cylinder body 32, this cylinder body 32 is connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com