Vertical structure LED blue light epitaxy preparation method

A vertical structure, blue light technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that cannot realize the original design intention and affect product performance, and achieve the effect of promoting uniform distribution of current, solving efficiency reduction, and increasing saturation threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

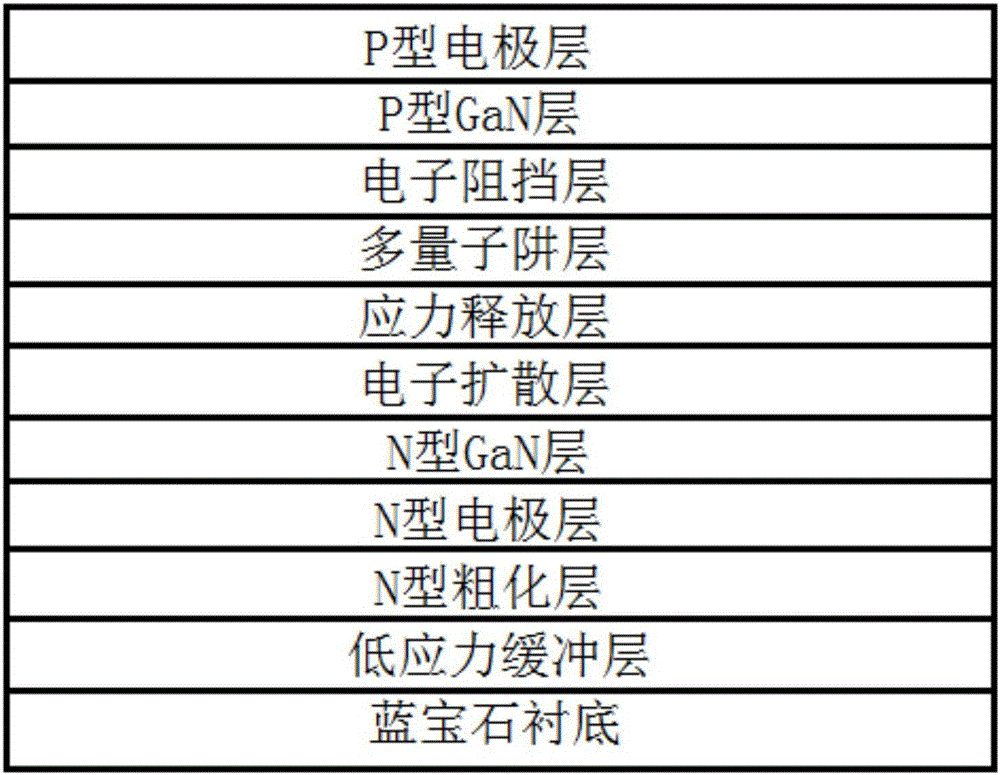

Image

Examples

Embodiment 1

[0063] A preparation method for vertical structure LED blue light epitaxy, comprising the following steps:

[0064] Step 1: Baking with N2 at a temperature of 1070°C and a pressure of 150 torr for 10 minutes, and nitriding the sapphire, SiC or Si substrate;

[0065] Step 2: Lower the temperature of the sapphire, SiC or Si substrate after nitriding in step 1 to 515°C and a pressure of 800 torr, then grow a low-stress buffer layer with a thickness of 0.8 μm on the substrate, then raise the temperature to 1030°C and a pressure of 400torr recrystallizes the low-stress buffer layer and re-grows a 0.8μm N-type roughening layer;

[0066] Step 3: Raise the temperature to 1070°C and the pressure is 200 torr to grow a light Si-doped N-type electrode layer with a thickness of 0.8 μm, and then grow a heavily Si-doped N-type GaN layer with a thickness of 1.8 μm;

[0067] Step 4: growing an n-GaN electron diffusion layer on the basis of the N-type GaN layer with a thickness of 80 nm; growi...

Embodiment 2

[0075] A preparation method for vertical structure LED blue light epitaxy, comprising the following steps:

[0076]Step 1: Bake the sapphire, SiC or Si substrate at a temperature of 1080 °C and a pressure of 150 torr for 20 minutes with N2;

[0077] Step 2: Cool down the sapphire, SiC or Si substrate after nitriding in Step 1 to 525°C and a pressure of 800torr, then grow a low-stress buffer layer with a thickness of 1μm on the substrate, then raise the temperature to 1040°C and a pressure of 400torr Recrystallize the low-stress buffer layer and re-grow a 0.9μm N-type roughening layer;

[0078] Step 3: Raise the temperature to 1080°C and the pressure is 200 torr to grow a light Si-doped N-type electrode layer with a thickness of 0.8 μm, and then grow a heavily Si-doped N-type GaN layer with a thickness of 2.1 μm;

[0079] Step 4: growing an n-GaN electron diffusion layer on the basis of the N-type GaN layer with a thickness of 100 nm; growing a stress release layer on the n-Ga...

Embodiment 3

[0087] A preparation method for vertical structure LED blue light epitaxy, comprising the following steps:

[0088] Step 1: Bake the sapphire, SiC or Si substrate at a temperature of 1090°C and a pressure of 150torr for 30min with N2;

[0089] Step 2: Cool down the sapphire, SiC or Si substrate after nitriding in step 1 to 535°C, and the pressure is 800torr, and then grow a low-stress buffer layer with a thickness of 1.2μm on the substrate, and then raise the temperature to 1050°C, and the pressure is 400torr recrystallizes the low-stress buffer layer and re-grows a 1μm N-type roughening layer;

[0090] Step 3: Raise the temperature to 1090°C and the pressure is 200 torr to grow a light Si-doped N-type electrode layer with a thickness of 1 μm, and then grow a heavily Si-doped N-type GaN layer with a thickness of 2.5 μm;

[0091] Step 4: growing an n-GaN electron diffusion layer on the basis of the N-type GaN layer with a thickness of 120 nm; growing a stress release layer on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com