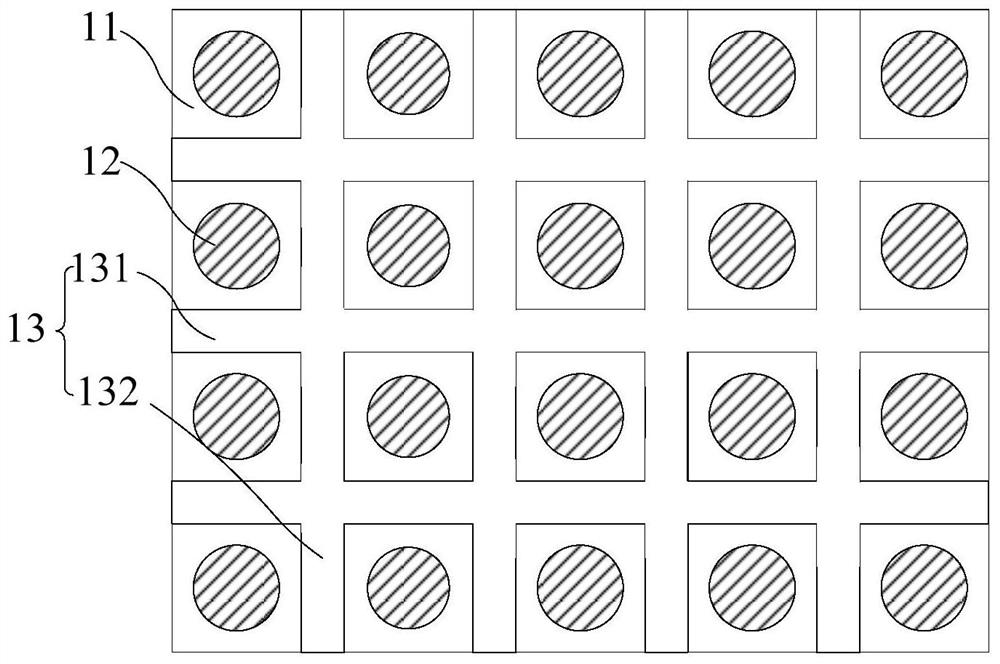

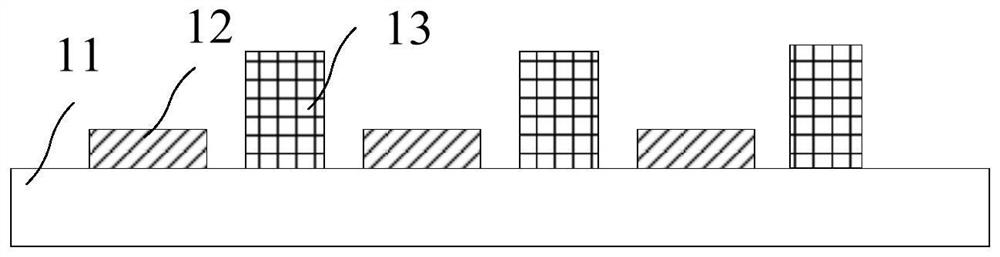

Micro light-emitting diode array substrate and micro light-emitting diode transfer method

A technology for micro-light-emitting diodes and array substrates, which can be applied to electrical components, electrical solid-state devices, circuits, etc., and can solve problems such as decreased adhesion, swelling, and unfavorable Micro-LED transfer yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

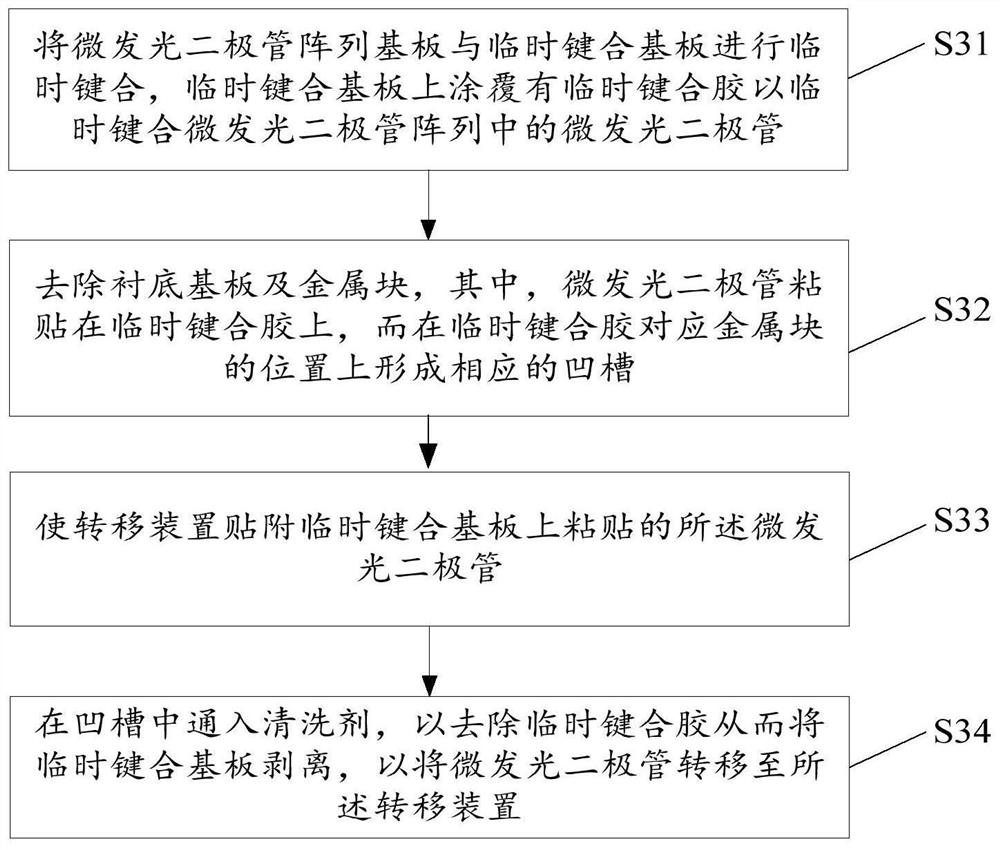

[0020] In the transfer process of transferring micro-light-emitting diodes in batches with polydimethylsiloxane (PDMS) transfer heads, it is necessary to use PDMS transfer heads to pick up micro-light-emitting diodes from the surface of the temporary bonding adhesive. The commonly used temporary bonding adhesive materials are based on the material Properties can be divided into thermoplastic, UV-sensitive and so on. For thermoplastic temporary bonding substrates, the glue can be changed from solid to liquid by heating, so as to realize the pick-up of micro light-emitting diodes by the PDMS transfer head, but the general process temperature is above 150°C, which will affect the properties of the PDMS transfer head . One of the alternatives is to soak in the cleaning solution of the temporary bonding glue after the PDMS transfer head and the temporary bonding substrate are bonded. After the temporary bonding glue dissolves, the micro-LEDs will stay on the PDMS transfer head. . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com