Patents

Literature

40results about How to "Improve stripping yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

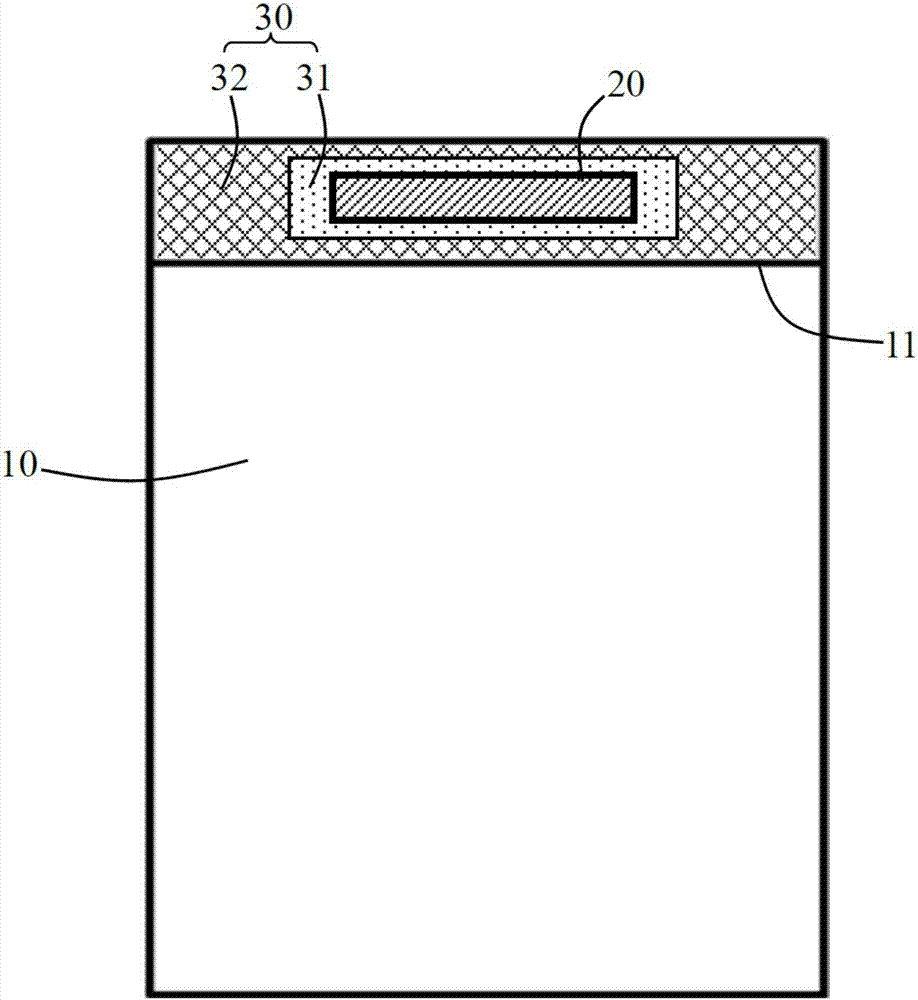

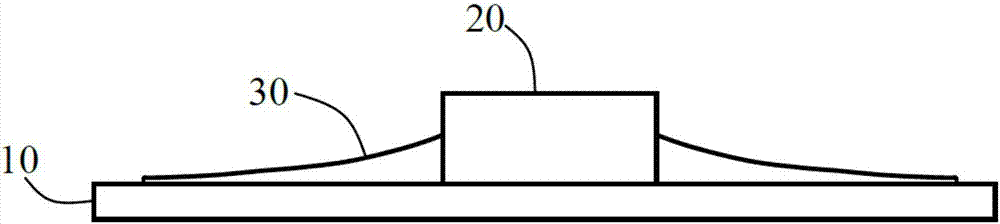

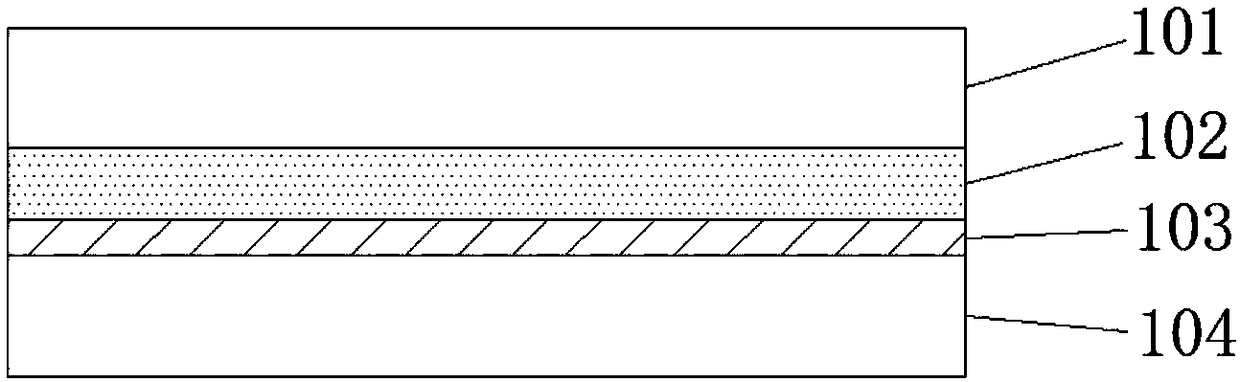

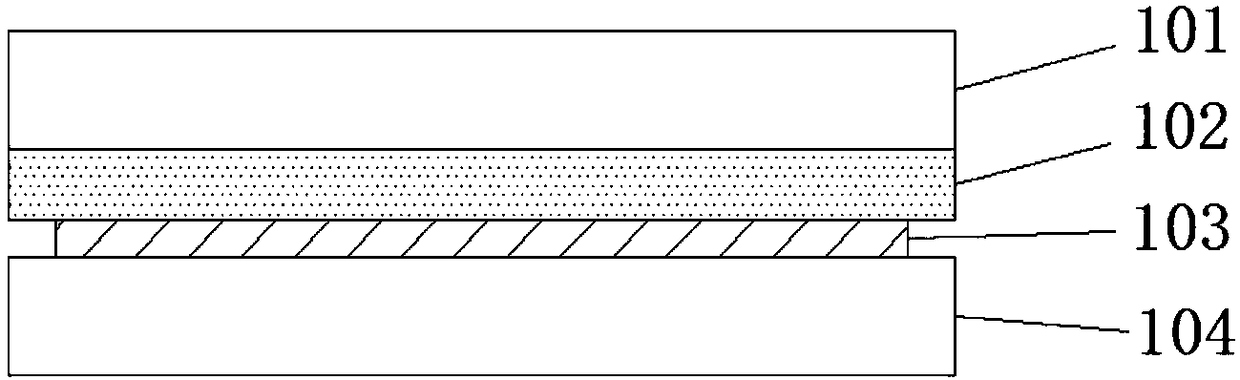

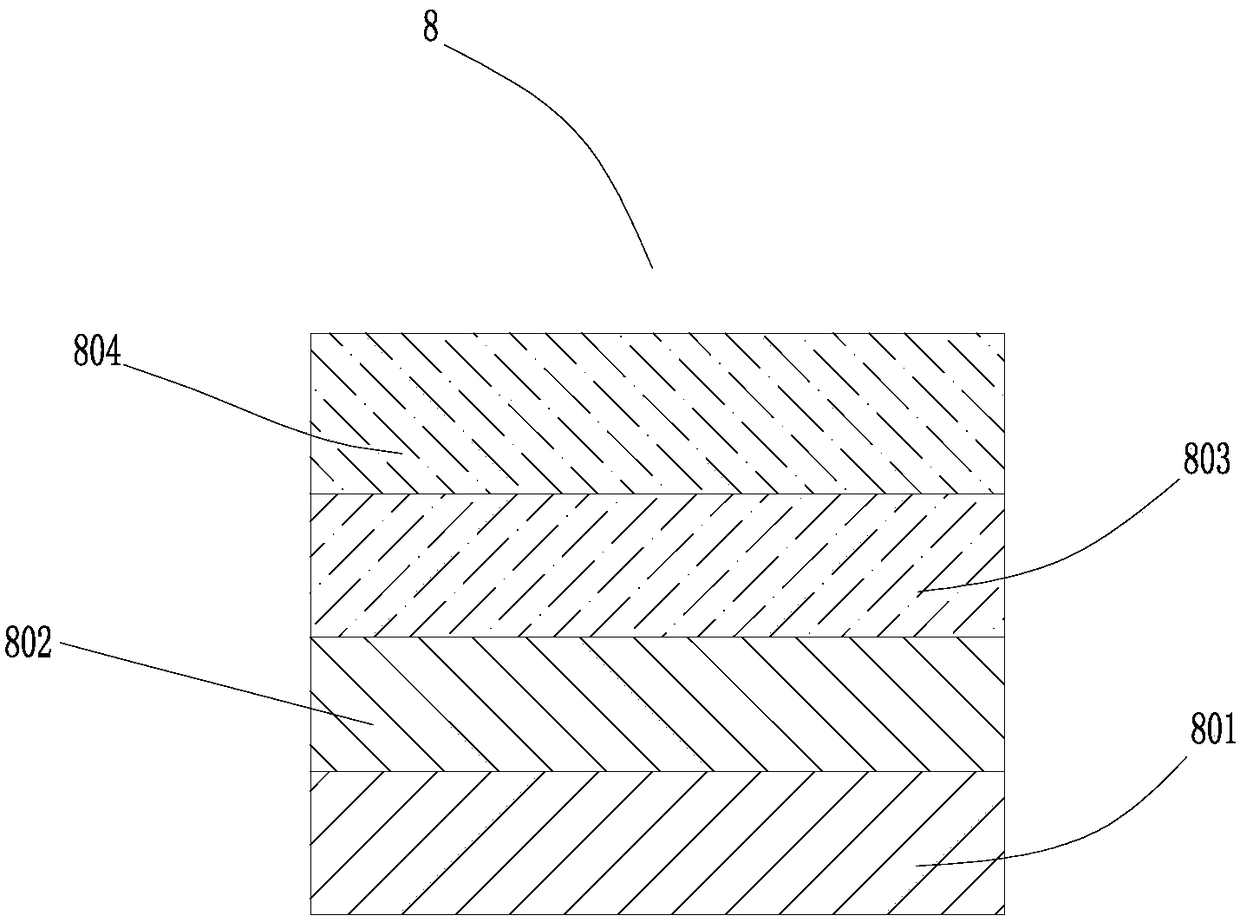

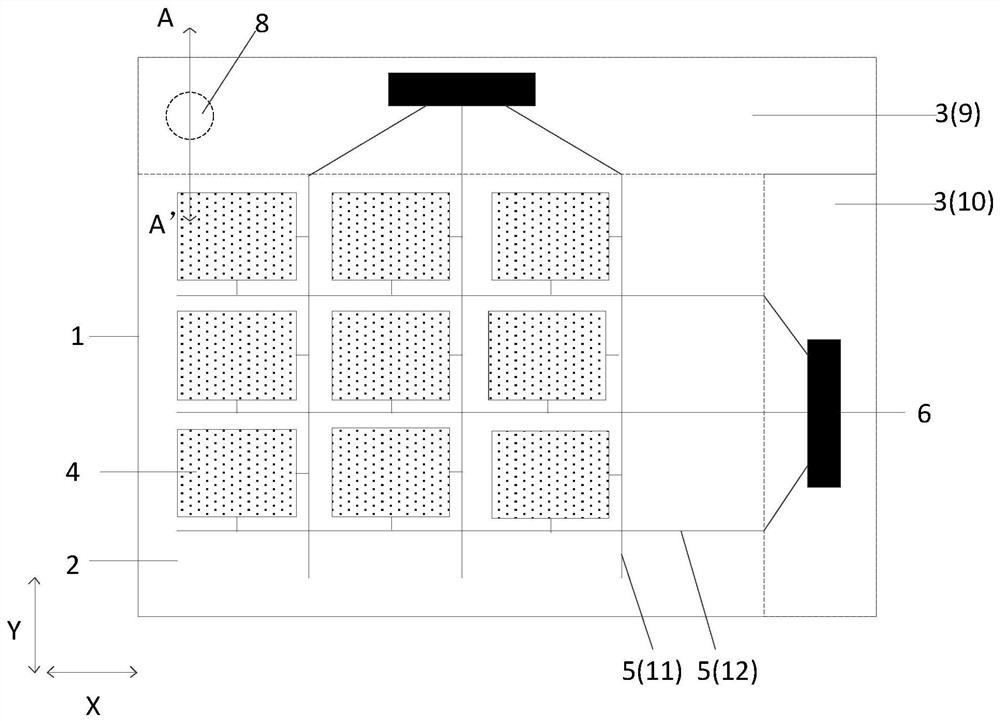

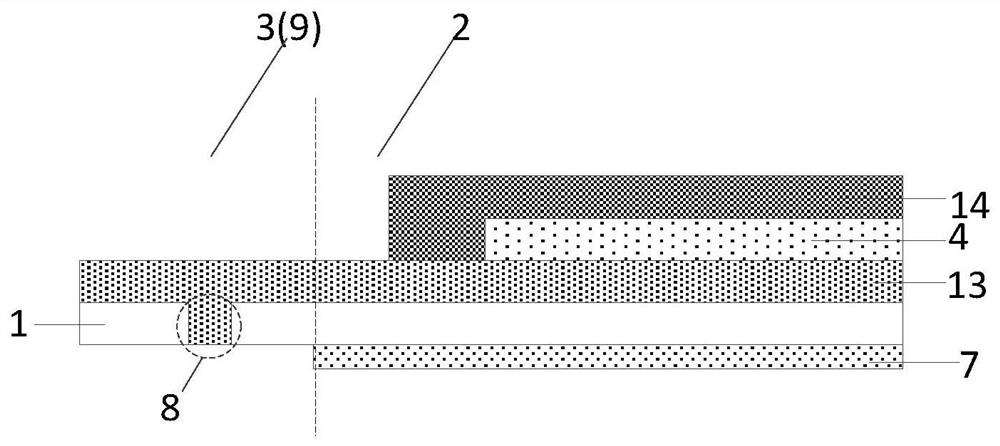

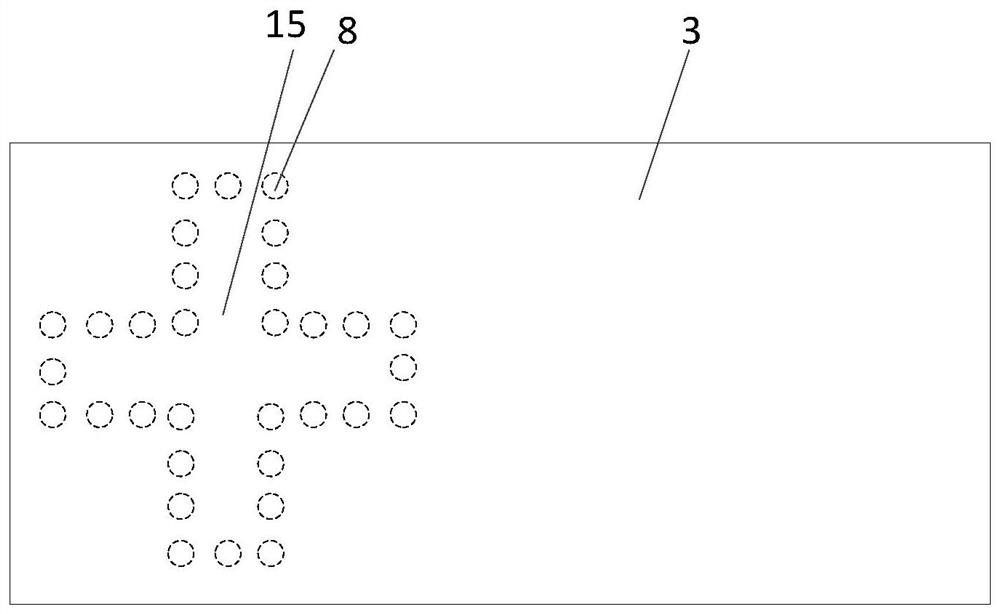

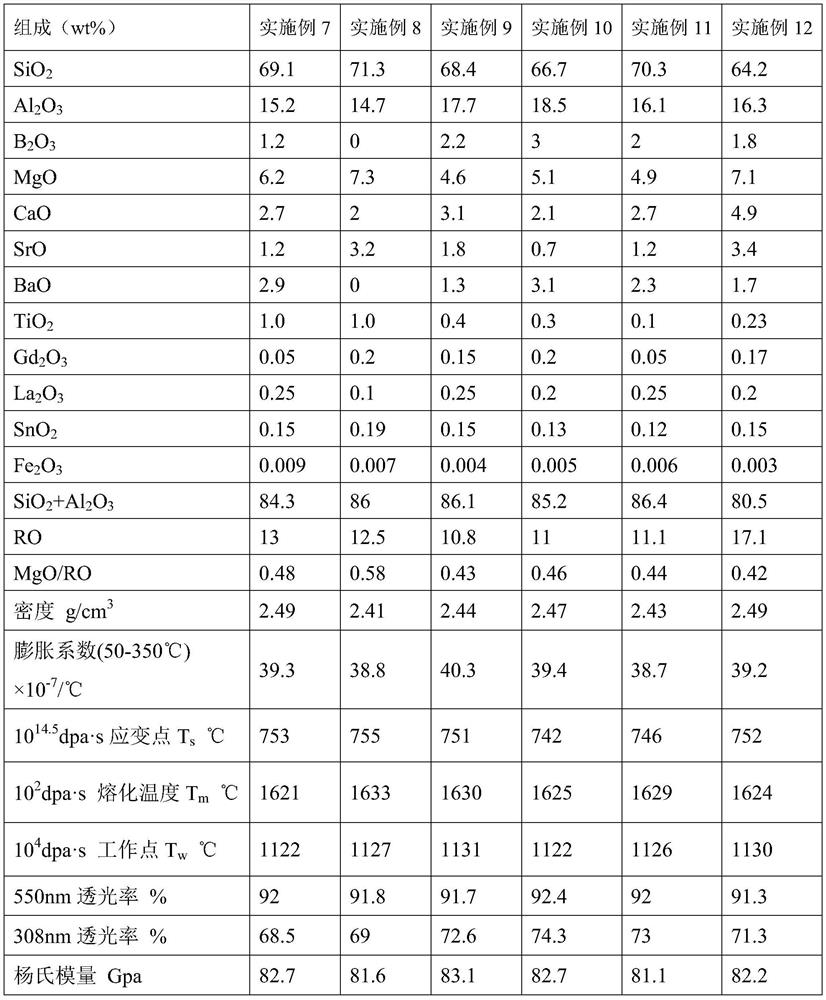

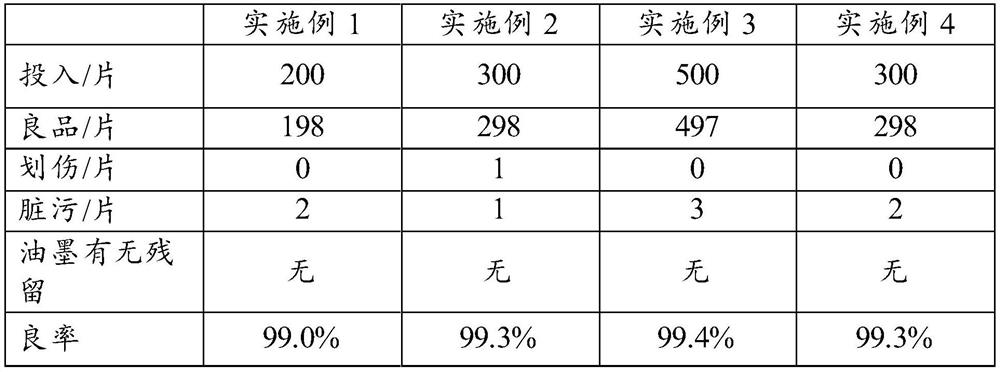

Display panel mother board and preparation method of display panel

ActiveCN106448473AGuaranteed performanceImprove stripping yieldFinal product manufacturePrinted circuitsComputer science

Owner:BOE TECH GRP CO LTD +1

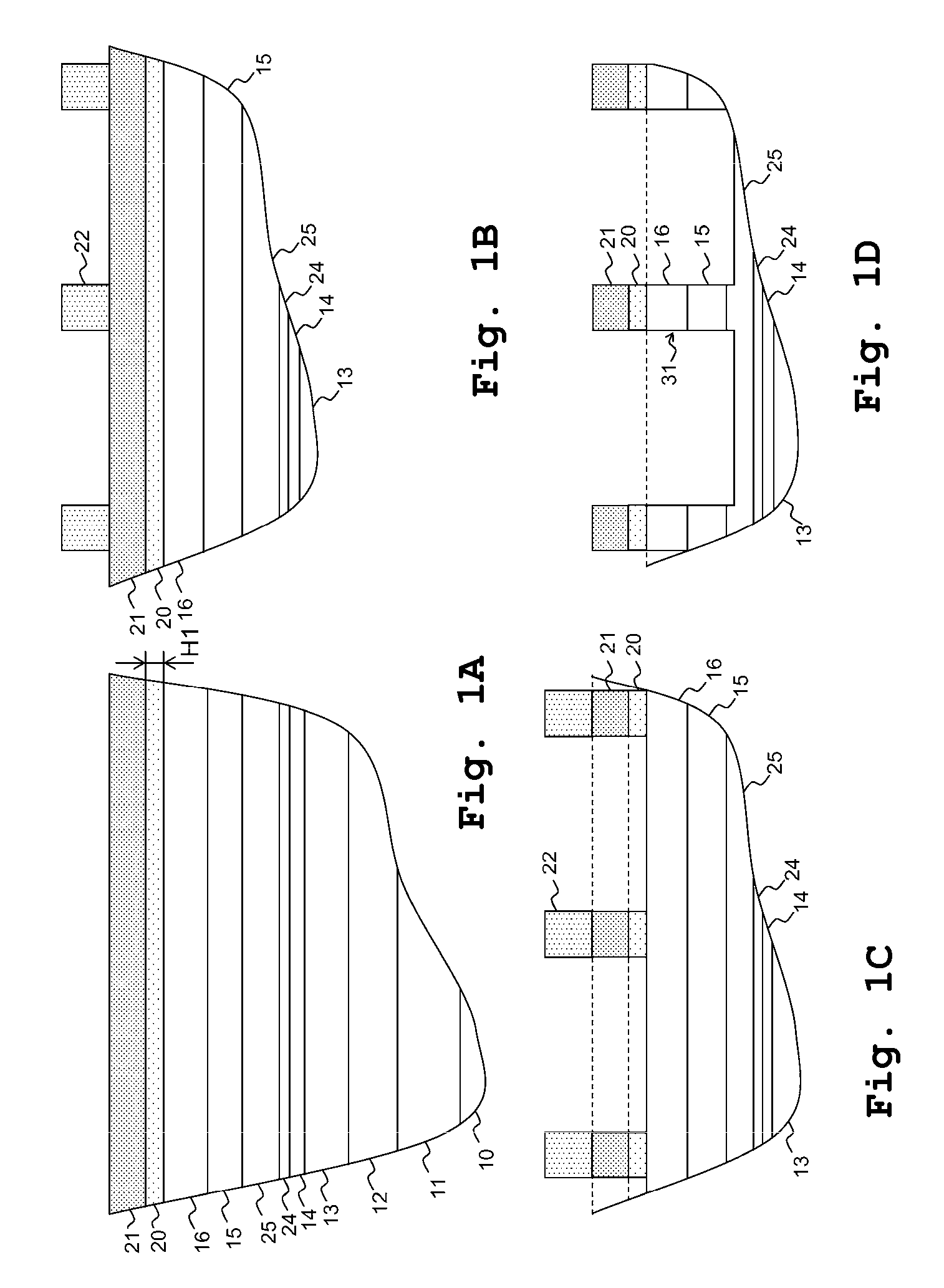

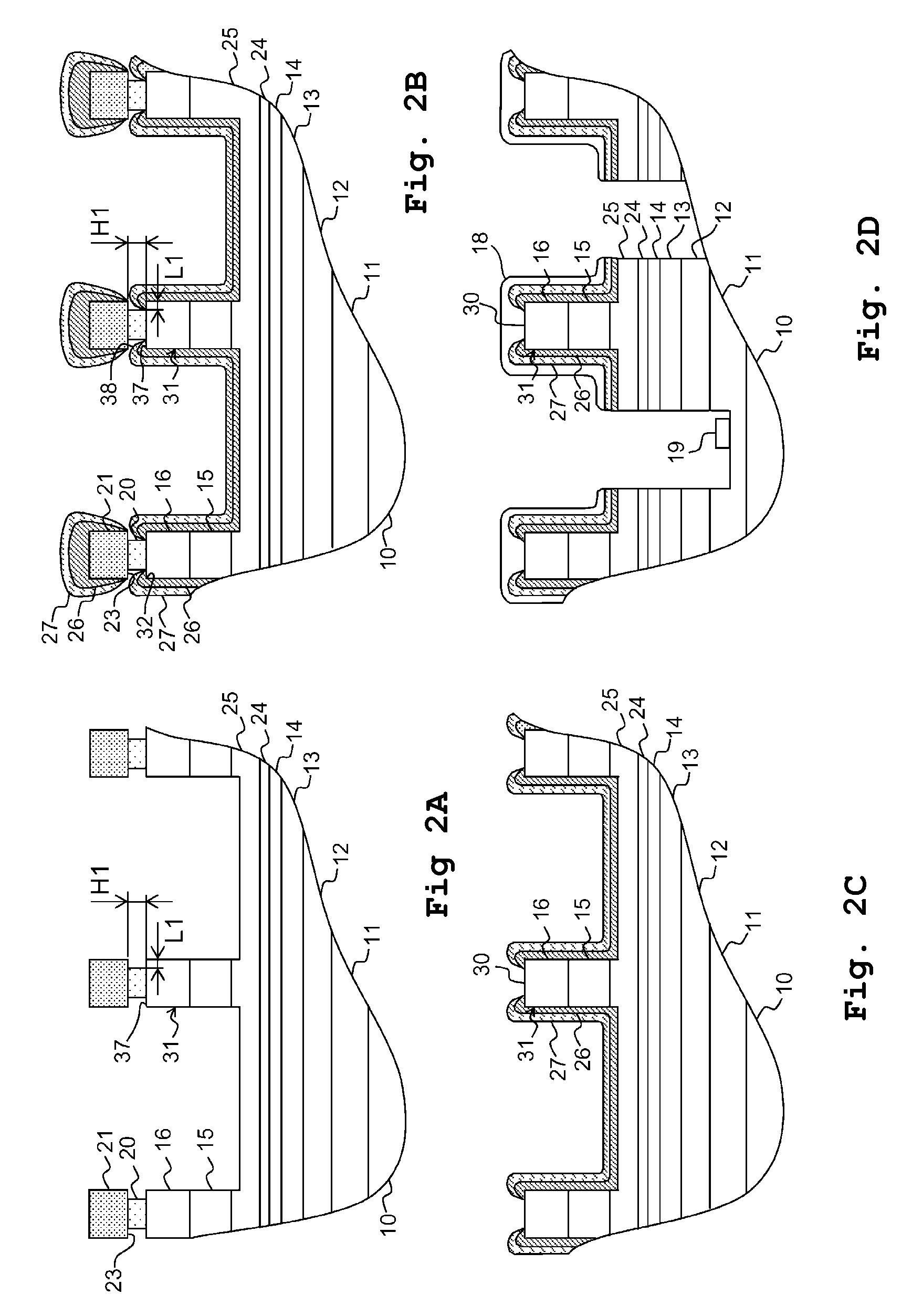

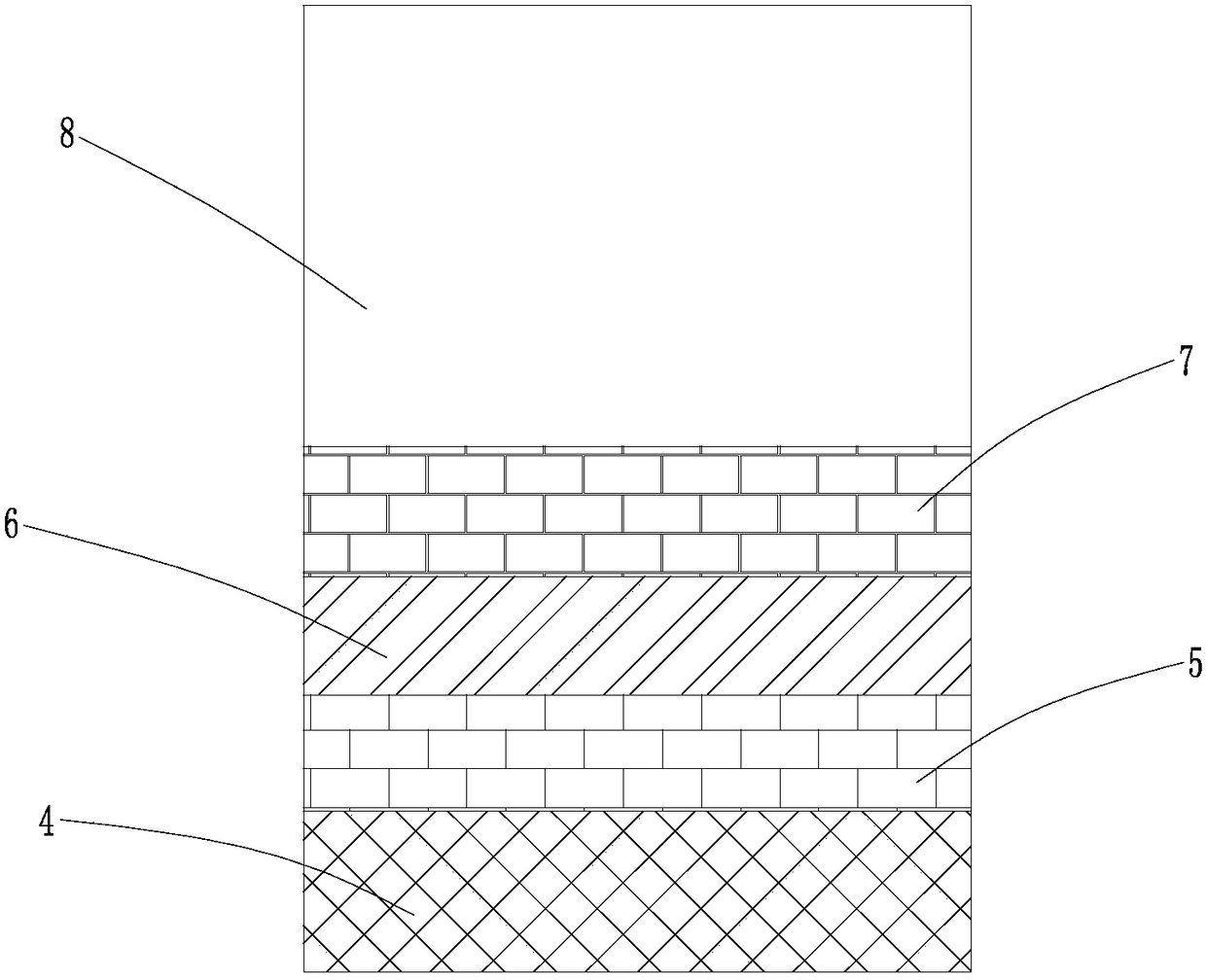

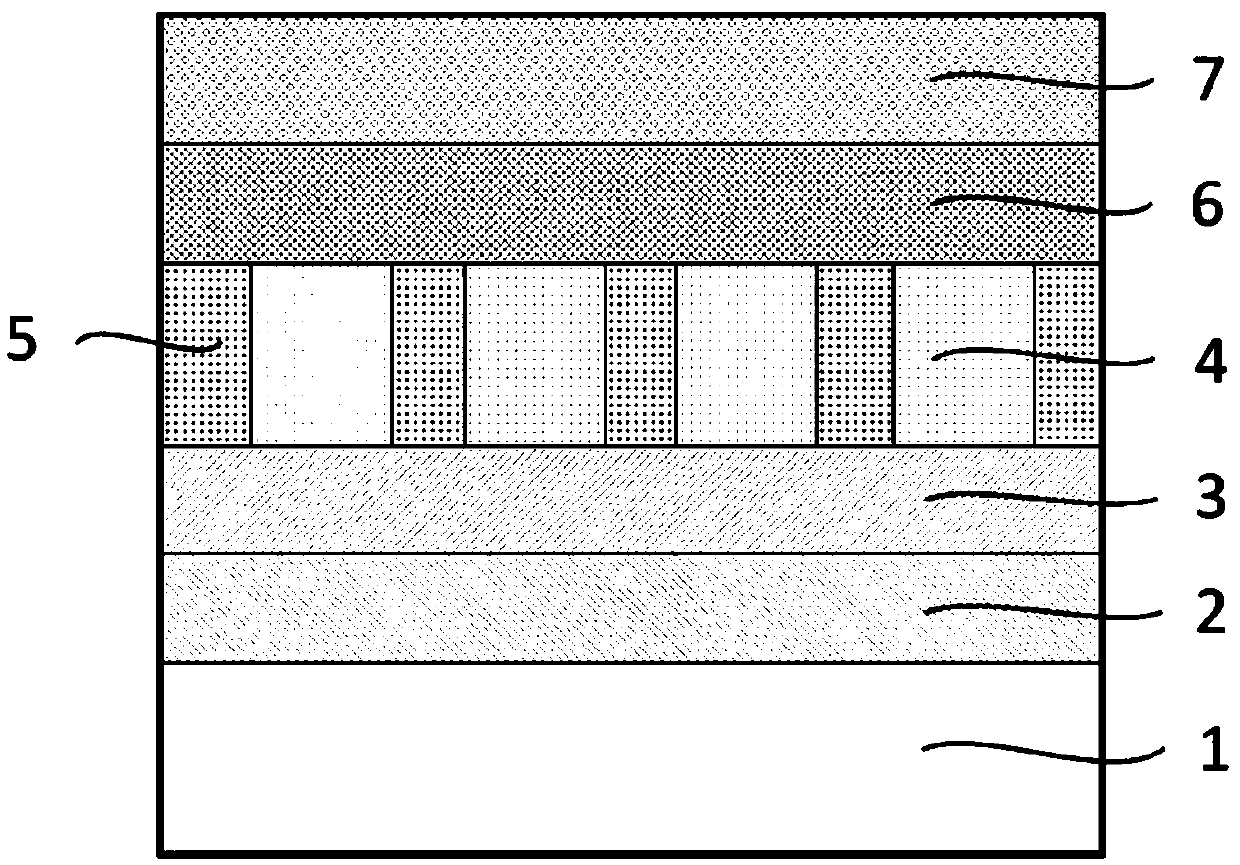

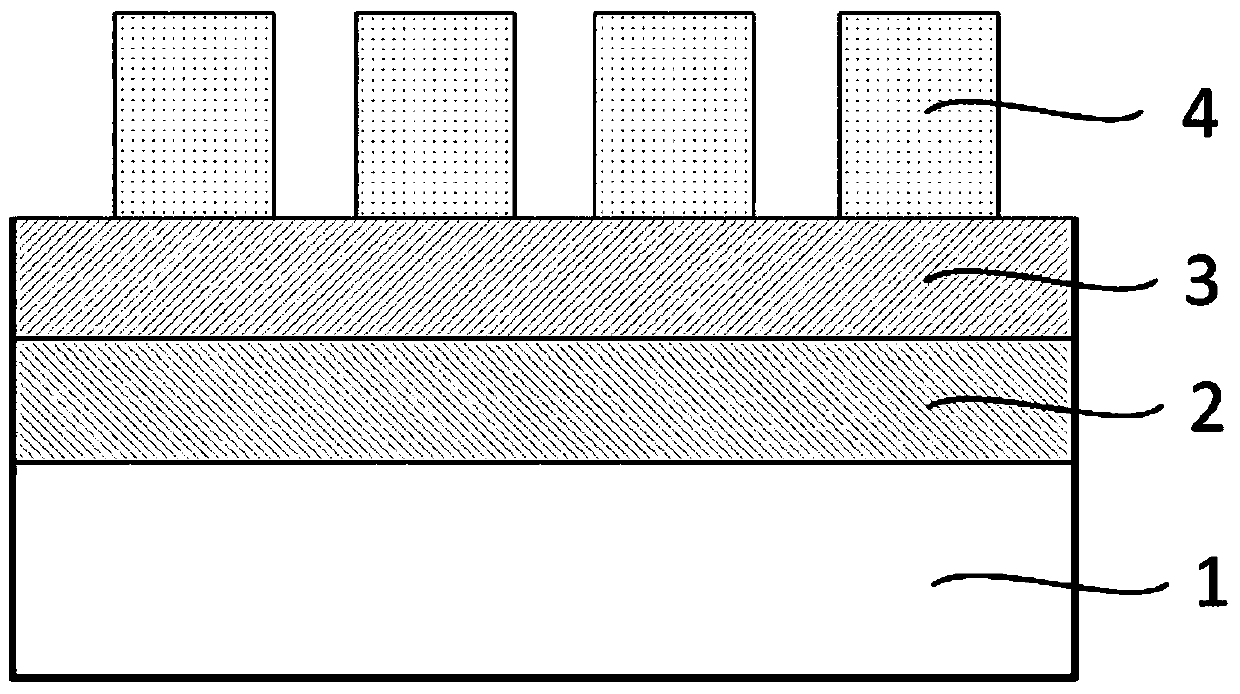

Light-emitting diode epitaxial wafer and preparation method thereof

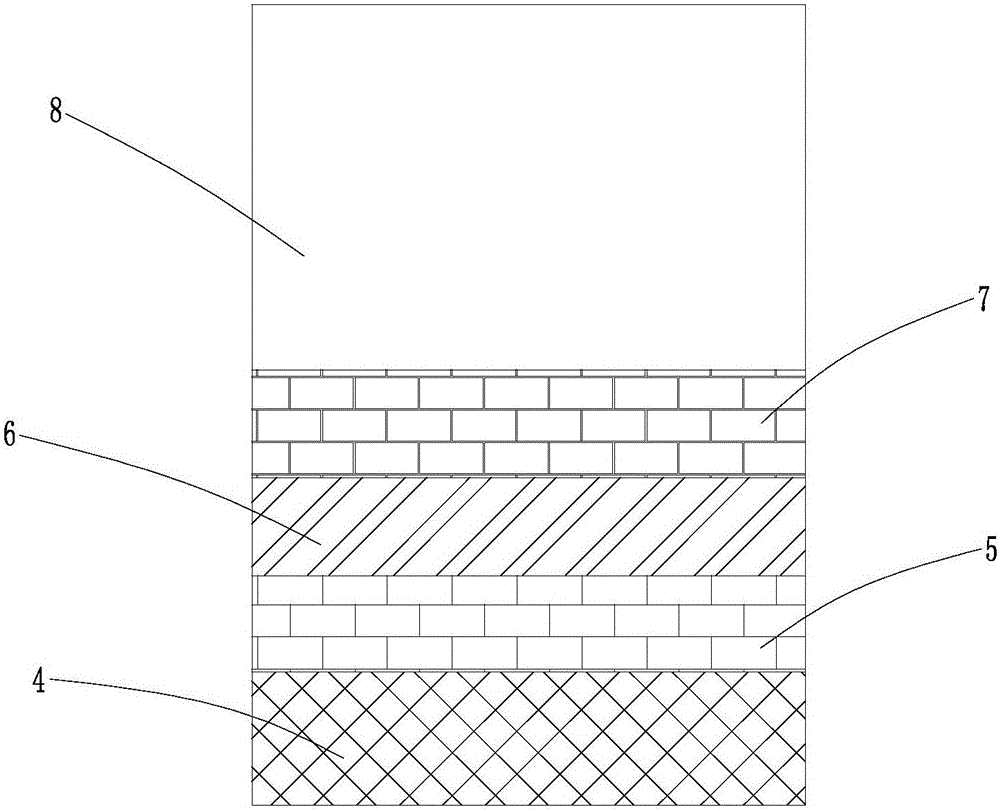

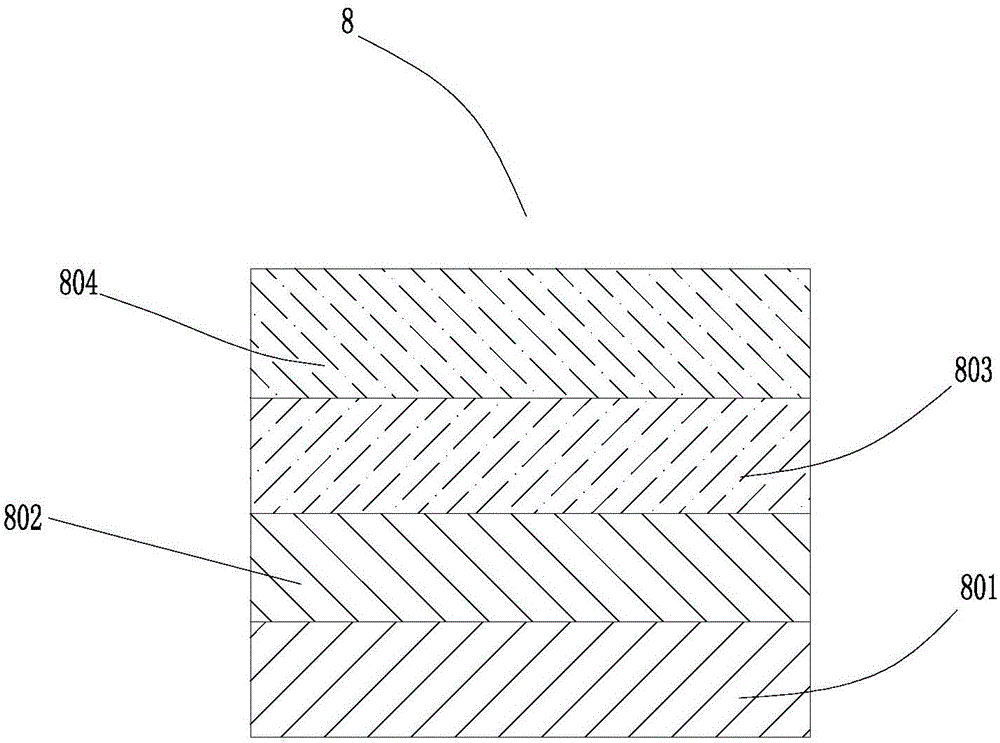

The invention discloses a light-emitting diode epitaxial wafer and a preparation method thereof, which belong to the photoelectric field. The epitaxial wafer comprises a first buffer layer, a graphene layer, a second buffer layer and an epitaxial structure layer from a substrate to a surface layer; and the epitaxial structure layer is composed of an N-type semiconductor layer, a multiple quantum well layer, a P-type electron blocking layer and a P-type semiconductor layer from the second buffer layer to the surface layer. In comparison with the traditional GaN-based epitaxial wafer structure, the graphene layer is added to enable the GaN-based epitaxial structure layer to be stripped from the substrate by using a mechanical mode, a laser device does not need to be adopted, and the stripping yield is improved; in comparison with other techniques of using a transfer mode to place the graphene layer on the substrate, the buffer layers exist between the graphene layer and the substrate for connection, and the problem of poor adhesion between the graphene layer and the substrate does not exist.

Owner:ELEC TECH OPTOELECTRONICS TECHWUHUCO

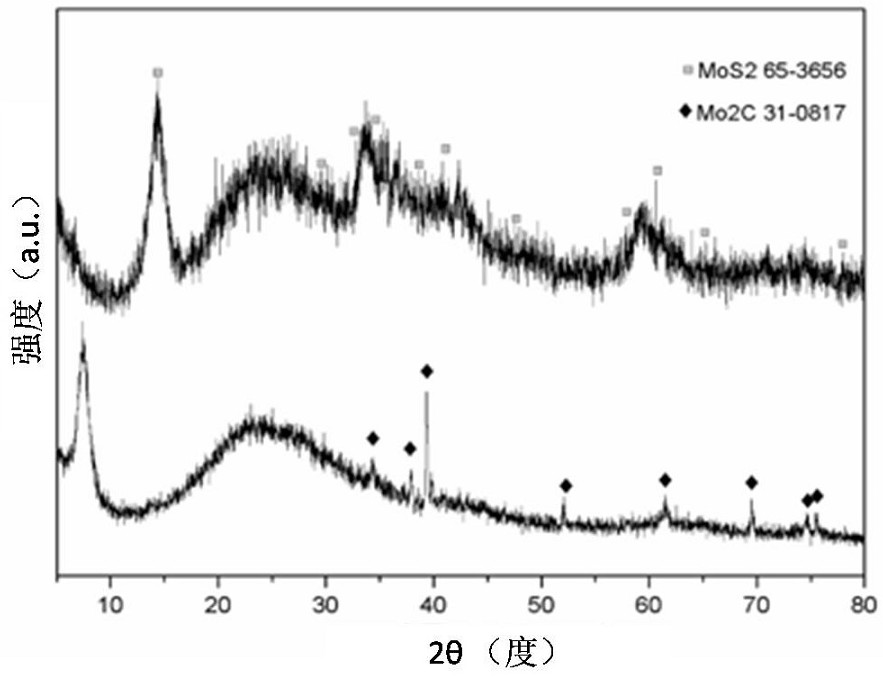

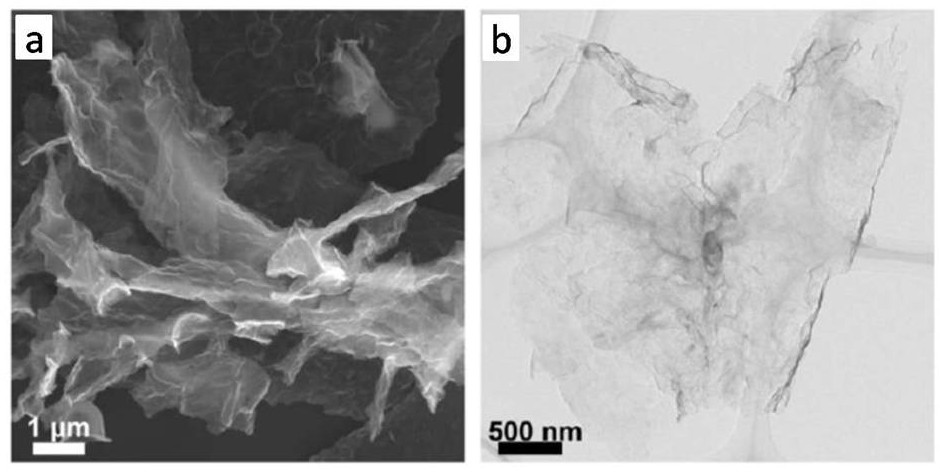

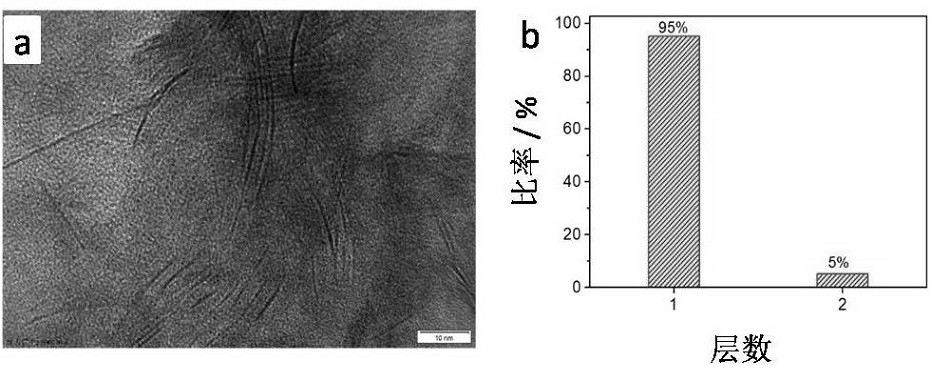

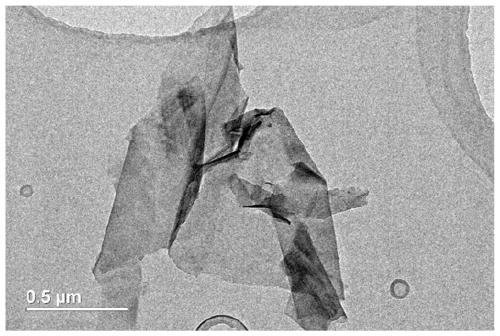

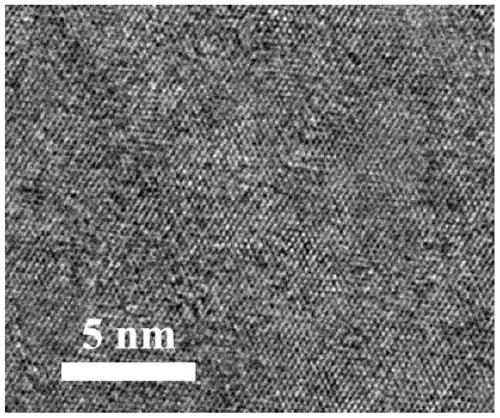

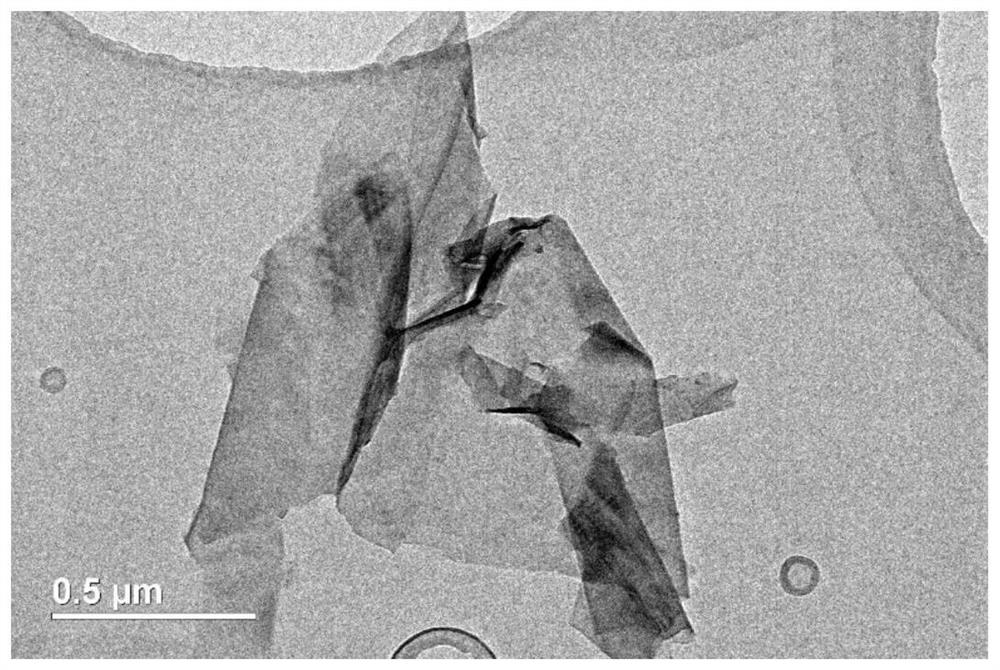

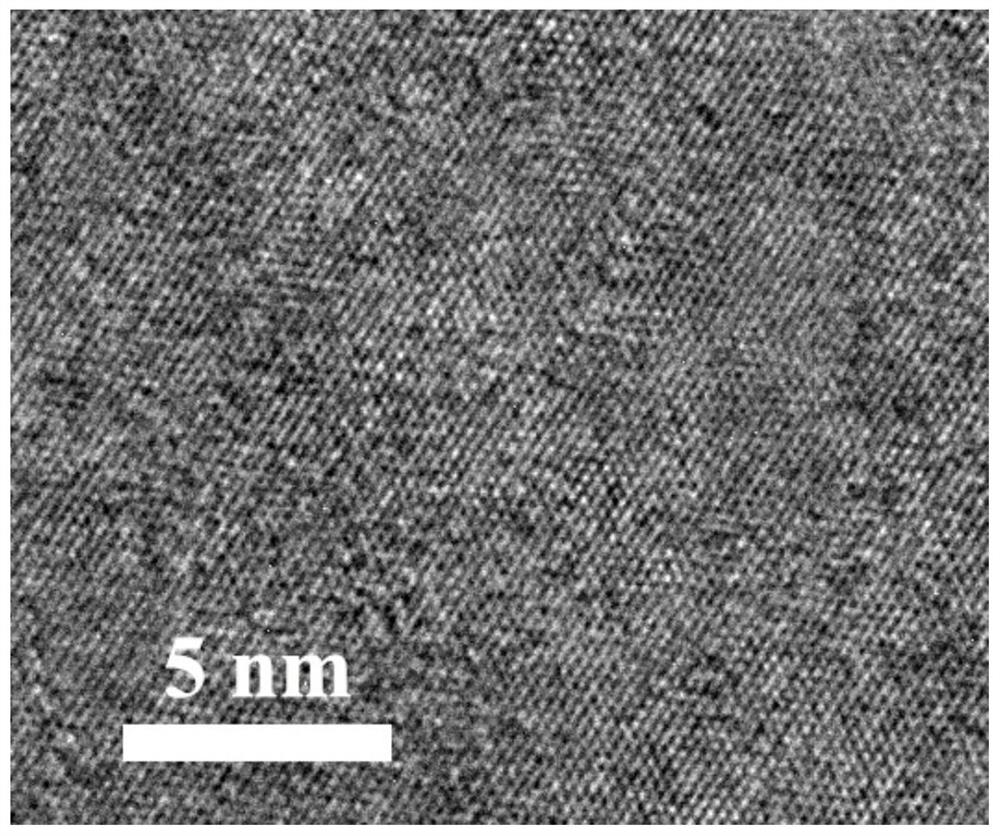

Synthesis method of two-dimensional transition metal chalcogenide

ActiveCN112678826AHigh yieldTopological transformation reaction heightMaterial nanotechnologyTitanium carbidePhysical chemistryReaction temperature

The invention discloses a synthesis method of a two-dimensional transition metal chalcogenide, which comprises the following steps: heating: heating a transition metal compound raw material to a reaction temperature in an inert gas environment; topological conversion reaction step: introducing a gas containing a chalcogen or a mixed gas of the gas containing the chalcogen and the gas containing the phosphorus, and maintaining the reaction temperature for a set period of time, so that the chalcogen, or the chalcogen and the phosphorus are subjected to a topological conversion reaction with the transition metal compound raw material, and generating the two-dimensional transition metal chalcogenide. The synthesis method has the advantages of high reaction degree, high yield, low energy consumption and high efficiency, the obtained two-dimensional transition metal chalcogenide is high in single-layer rate and narrow in layer number distribution, macro preparation can be realized, and the synthesis method has an excellent industrial application prospect.

Owner:济南三川新材料科技有限公司

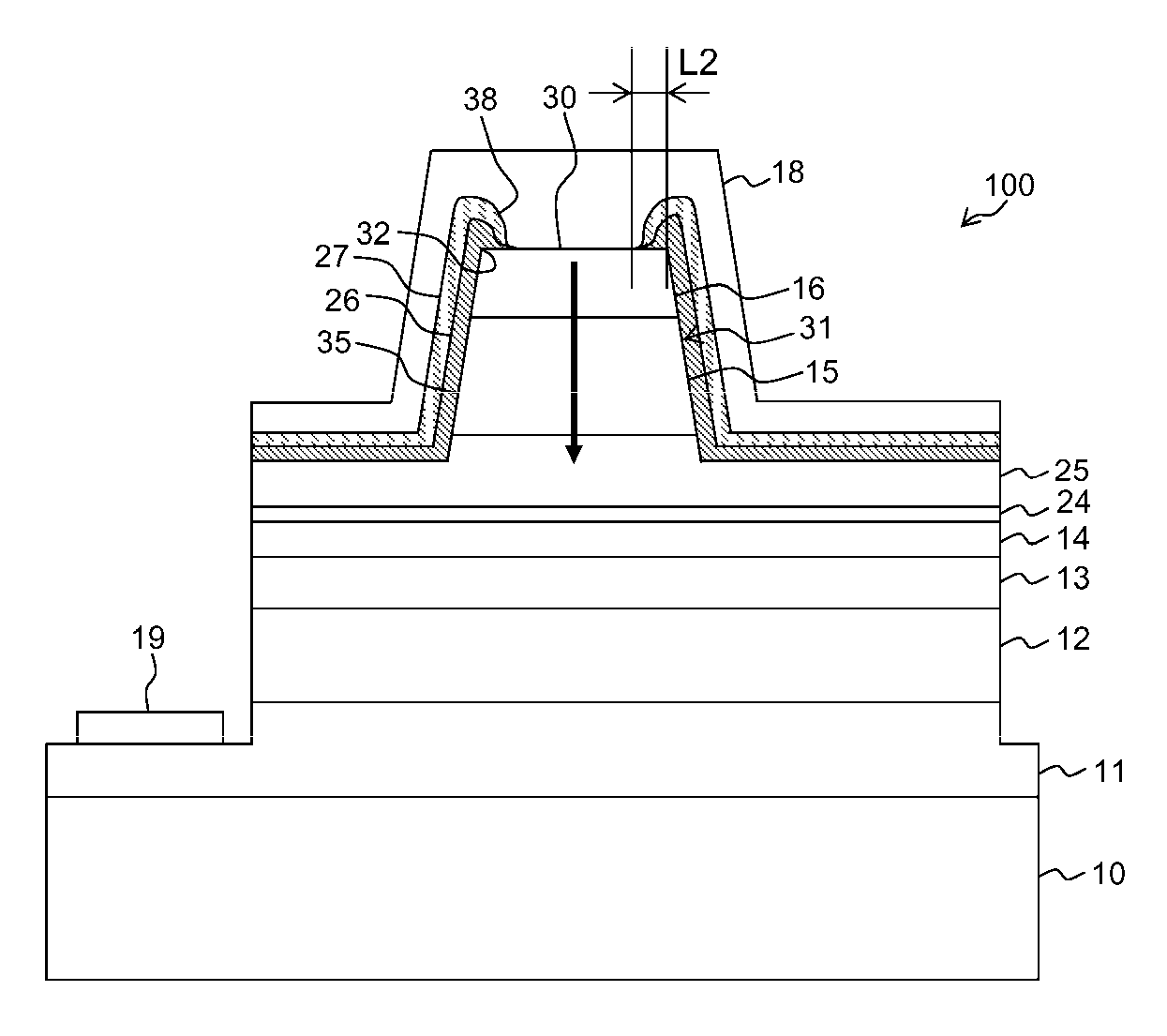

Semiconductor light-emitting device

InactiveUS7476903B2Improve adhesionImprove stripping yieldOptical wave guidanceLaser detailsLight emitting deviceNitride

Owner:ROHM CO LTD

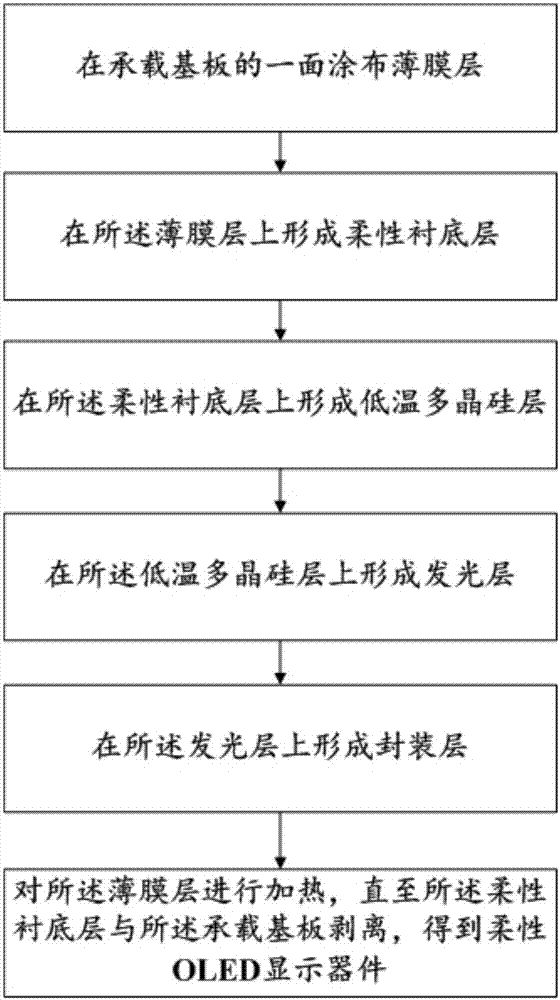

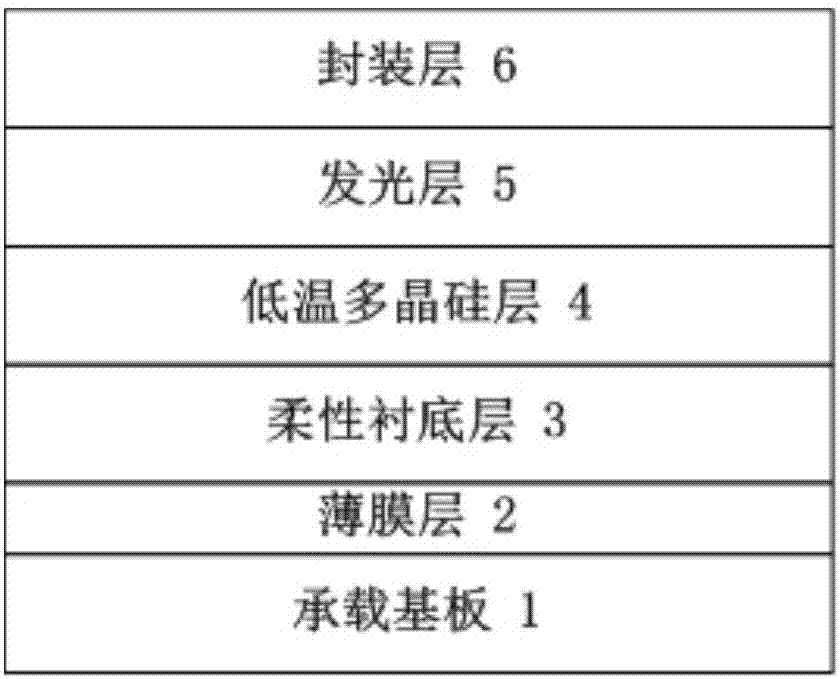

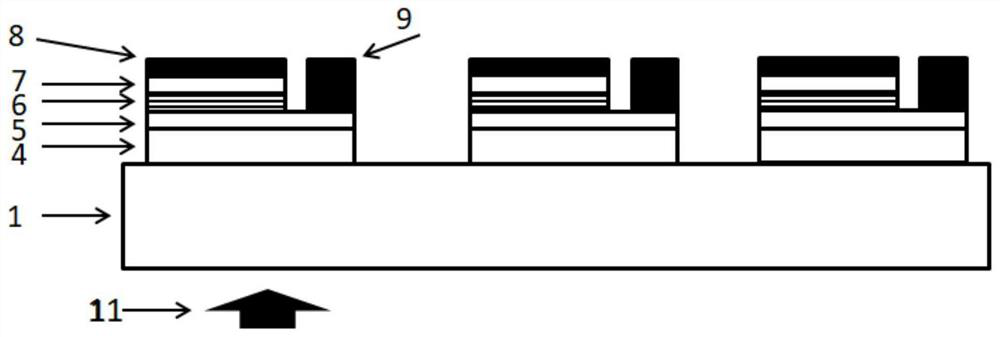

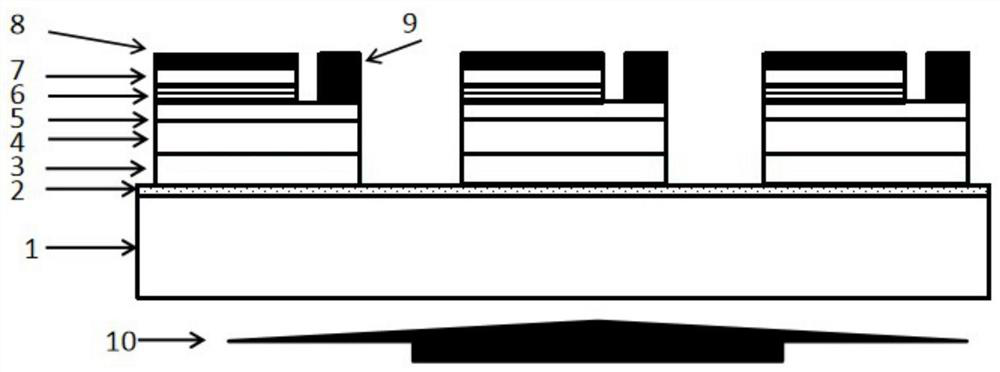

Flexible OLED display device stripping method and flexible OLED display device

ActiveCN107516666ALow melting pointImprove stripping yieldSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceParaffin oils

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Micro-LED chip preparation and substrate stripping method

The invention discloses a Micro-LED chip preparation and substrate stripping method in the field of photoelectric devices. The Micro-LED chip preparation and substrate stripping method comprises the following steps: 1, uniformly coating a transparent substrate with an ultraviolet adhesive; 2, growing an Al2O3 thin film and an LED thin film structure on the transparent substrate coated with the ultraviolet glue; 3, forming discrete Micro-LED structures on the Al2O3 thin film and the LED thin film structure; 4, irradiating the back surface of the transparent substrate by using an ultraviolet surface light source, desensitizing the ultraviolet glue between the transparent substrate and the Al2O3 film, and losing viscosity, thereby achieving the purpose of separating the Micro-LED structure from the transparent substrate, and forming the Micro-LED chip. According to the invention, the micro-LED chip substrate can be rapidly stripped, the working efficiency is high, the cost is low, and the yield is high.

Owner:NANJING RGB INFORMATION TECH CO LTD

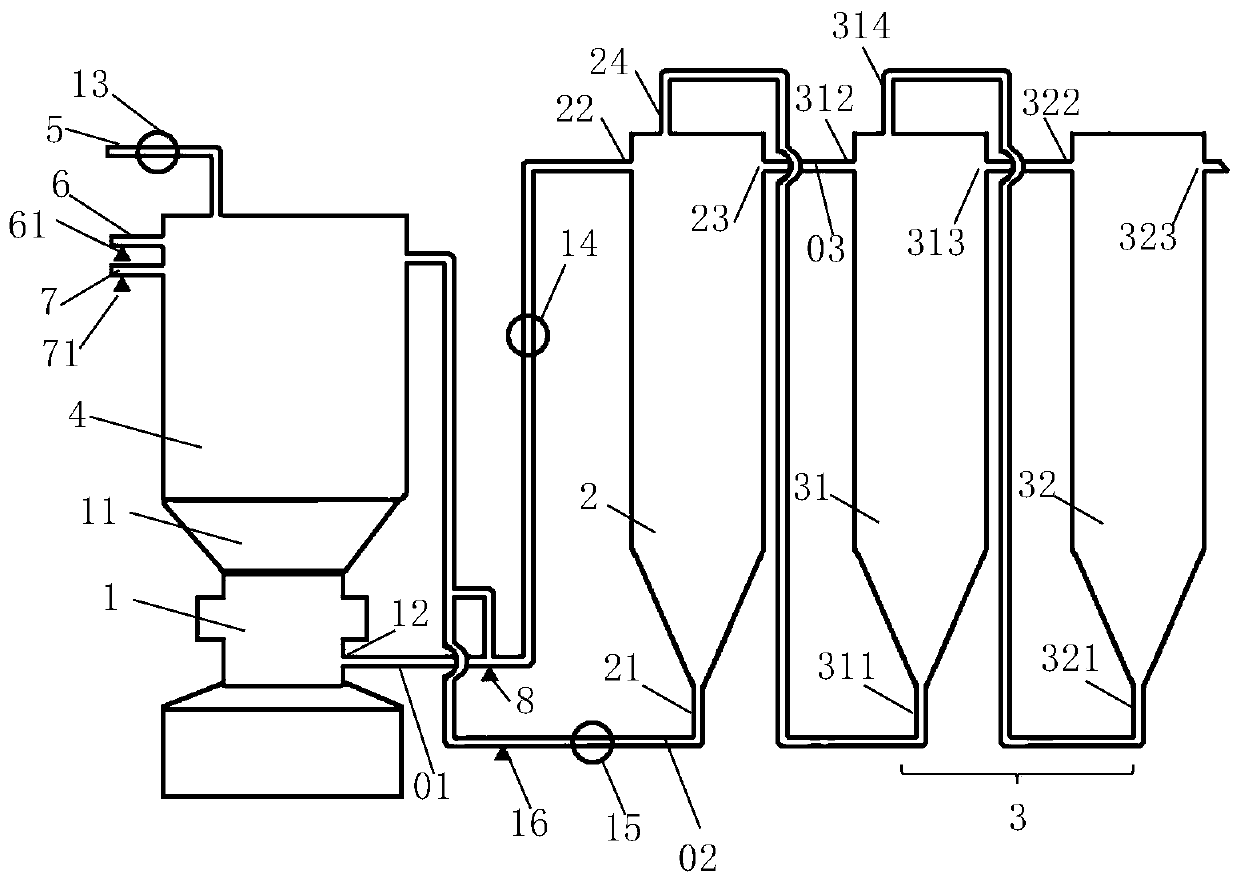

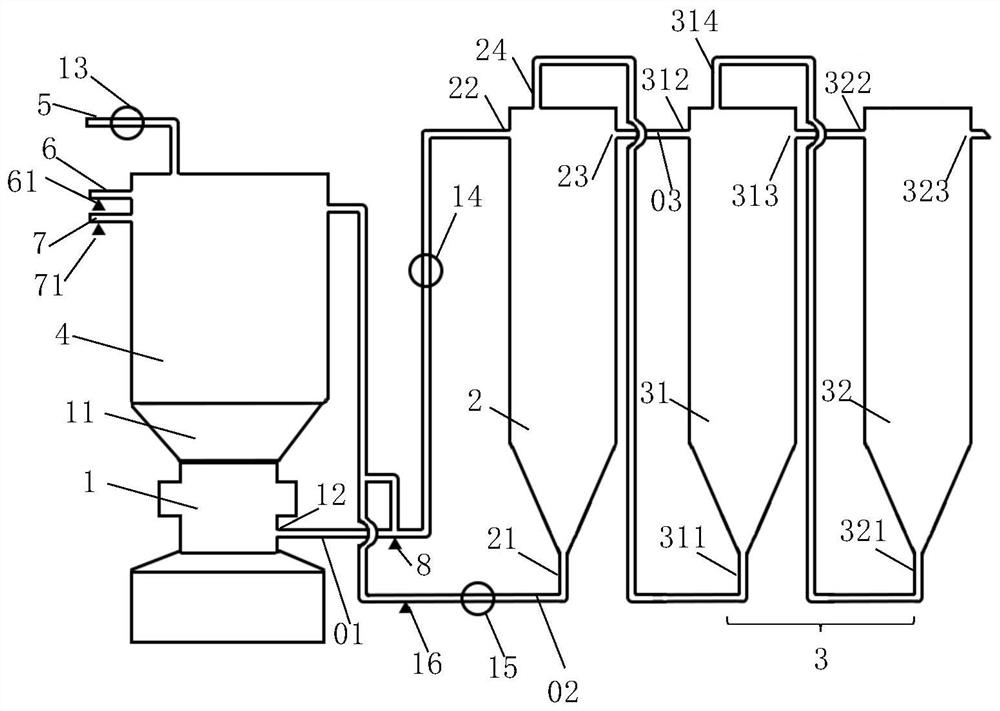

Method and equipment for peeling layered material and screening and separating two-dimensional nanosheets

ActiveCN110040728AImprove stripping yieldNarrow and single size rangeMaterial nanotechnologyGrapheneSolventLiquid phase

The invention discloses a method and equipment for peeling a layered material and screening and separating two-dimensional nanosheets. The layered material is of a lamellar structure, and is peeled toobtain the two-dimensional nanosheets. The method comprises the following steps: S1, mixing a layered material and a solvent; S2, adding the mixed solution into an emulsifying-dispersing machine forpeeling; S3, introducing the peeled mixed solution into a primary separator for separating to obtain a precipitate containing the non-peeled layered material and a liquid phase part containing two-dimensional nanosheets, carrying out a step S4 on the precipitate, and carrying out a step S5 on the liquid phase part; S4, mixing the precipitate and the solvent again for peeling, carrying out the stepS3 again after peeling, and repeatedly peeling the layered material; S5, conveying the liquid phase part into a secondary for screening and separating. By adopting the method and equipment, the layered material with the lamellar structure is peeled continuously and mechanically, and the two-dimensional nanosheets obtained by peeling are screened and separated, so that two-dimensional nanosheets with a narrow and single size range can be obtained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Bonding structure, flexible screen body with bonding structure and manufacturing method thereof

ActiveCN106997882AReduced risk of breakageImprove stripping yieldSemiconductor/solid-state device detailsSolid-state devicesStress concentrationEngineering

The invention discloses a flexible screen bonding area structure and a manufacturing method thereof. The flexible screen bonding area structure is provided with a flexible screen and a chip arranged on the surface of the flexible screen; the flexible screen is provided with a bonding area for bonding the chip; the bonding area is coated with a flexible protection layer; and the flexible protection layer surrounds the chip. In comparison with the prior art, through forming the flexible protection layer with a different hardness around the chip, the stress generated around the chip in the case of debonding can be greatly dispersed, hierarchy stress is formed, stress gathering at the position closely around the chip can be avoided, the risk that a line around the chip is pulled broken can be reduced, and the debonding yield of the flexible screen is finally improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

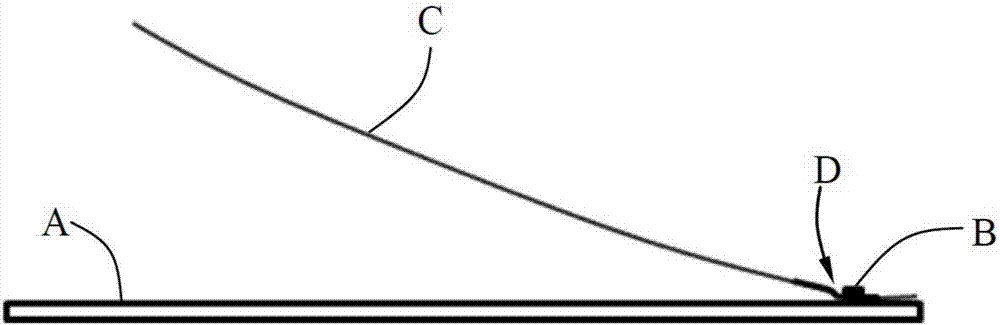

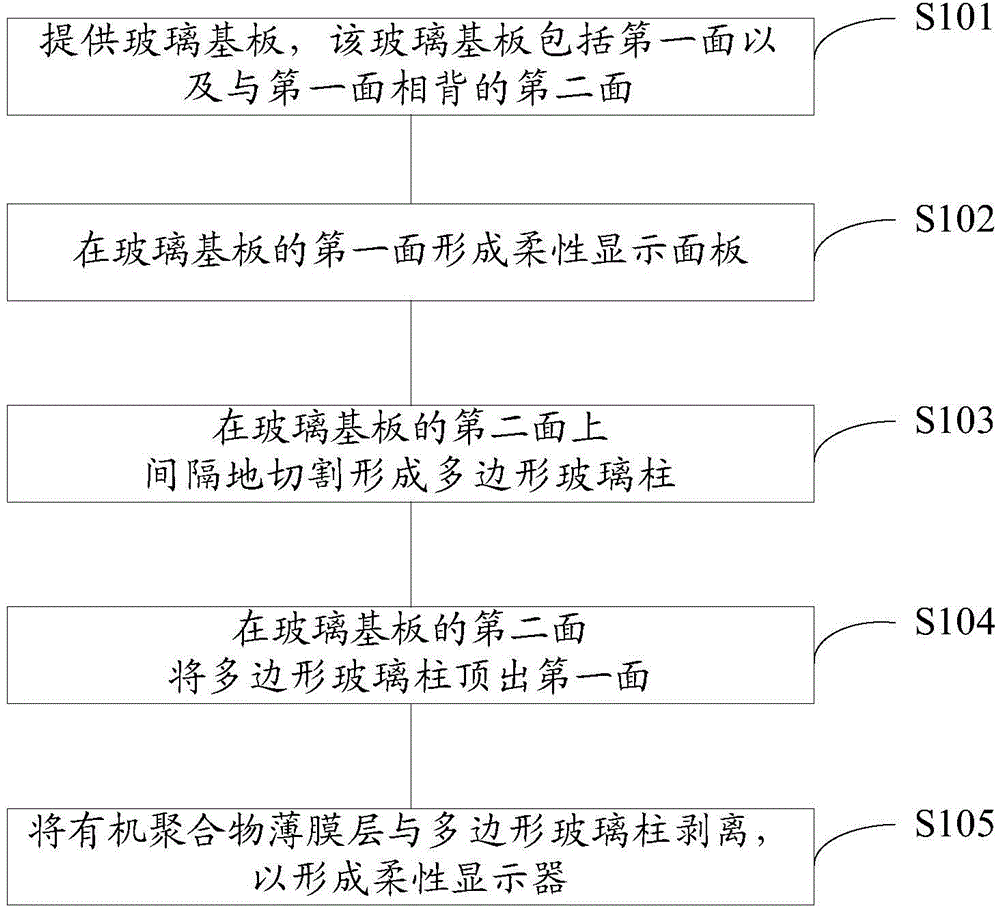

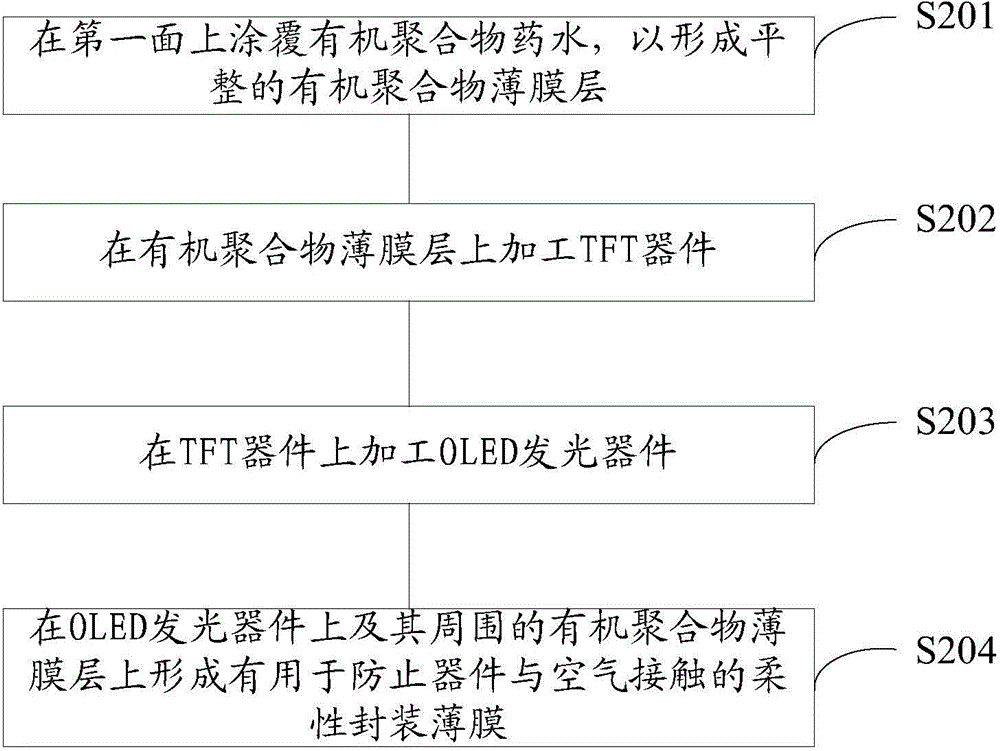

Method for preparing flexible display

ActiveCN105702879AImprove stripping yieldEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a method for preparing a flexible display, comprising the following steps: providing a glass substrate which consists of a first side and a second side opposite to the first side, and forming a flexible display panel on the first side; forming polygonal glass columns on the second side through cutting at intervals; pushing the polygonal glass columns out of the first side on the second side; and lifting off the flexible display panel from the polygonal glass columns to form the flexible display. According to the invention, the flexible display part is lifted off from the glass substrate through the polygonal glass columns formed on the glass substrate, and the flexible display is then lifted off from the polygonal glass columns, so that the flexible display can be well lifted off from the glass substrate. The lift-off method is simple to operate and low in cost, has no adverse effects on light-emitting devices, and can improve the yield of flexible display lift-off.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Semiconductor structure, preparation method thereof, self-supporting gallium nitride layer and preparation method thereof

PendingCN111223763ASelf-strippingQuality assuranceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureGallium nitride

The invention relates to a semiconductor structure, a preparation method thereof, a self-supporting gallium nitride layer and a preparation method thereof. The preparation method of the semiconductorstructure comprises the steps of providing a substrate; forming a nitride buffer layer on the substrate; and forming a multi-layer graphical mask layer on the nitride buffer layer, wherein materials of a bottom graphical mask layer in the multi-layer graphical mask layer comprise at least one of silicon-based oxide, silicon-based nitride, metal oxide and metal nitride, and the top graphical mask layer is a graphical metal mask layer. According to the invention, self-stripping of the gallium nitride layer formed on the multi-layer graphical mask layer is facilitated; the quality of the galliumnitride layer formed on the multi-layer graphical mask layer is ensured; and the problem of influence on the quality of the gallium nitride layer due to cracking caused by only partial stripping in the stripping process in stripping of the metal mask layer is solved.

Owner:镓特半导体科技(上海)有限公司

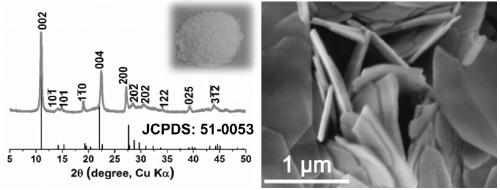

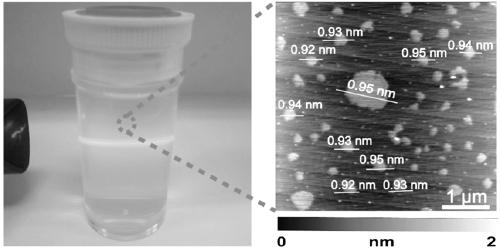

Preparation method of acid type niobium phosphate oxygen monoatomic layer sheet

The invention belongs to the technical field of chemical material synthesis, in particular to a preparation method of an acid type niobium phosphate oxygen monoatomic layer sheet. The method comprisesthe following steps: preparing acid type niobium phosphate oxygen precursor blocks with a chemical liquid phase synthesis method, and washing and drying the blocks to obtain powder; preparing the acid type niobium phosphate oxygen monoatomic layer sheet with an ultrasonic solvent assisted stripping method. The acid type niobium phosphate oxygen monoatomic layer sheet is uniform and stable ultrathin nanosheet colloid. The prepared acid type niobium phosphate oxygen monoatomic layer sheet has transverse dimension of tens of nanometers to hundreds of nanometers and thickness of about 1 nm, and can realize 10 mg / mL high-concentration stable dispersion in a water phase or an ethanol solvent. The synthesis and stripping yield realized with the method can be stably kept at 98% or higher. The method is simple, convenient, safe and efficient, and has potential value for application research of layered acid type phosphorus niobium oxygen in the fields of electrochemical energy storage, photoelectric conversion devices, chemical catalysis, electrocatalysis and the like.

Owner:FUDAN UNIV

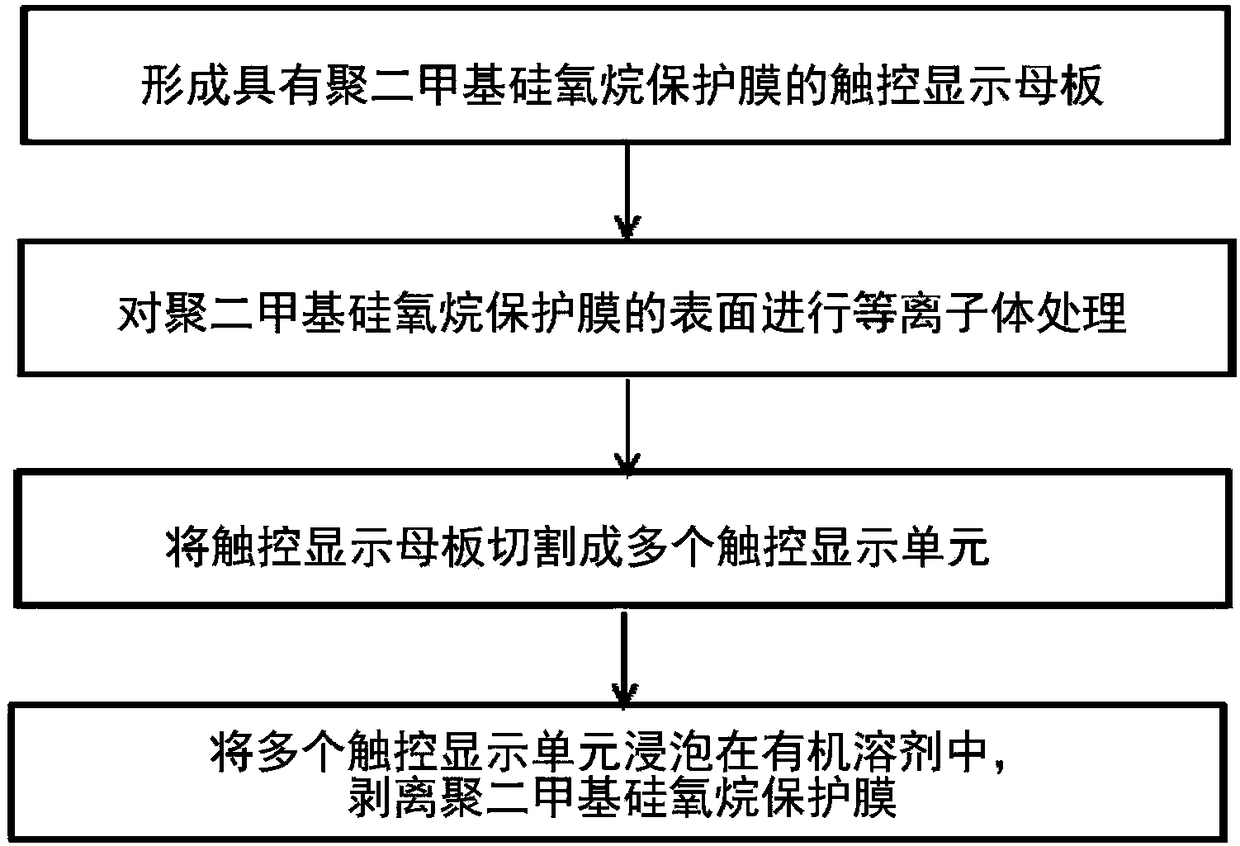

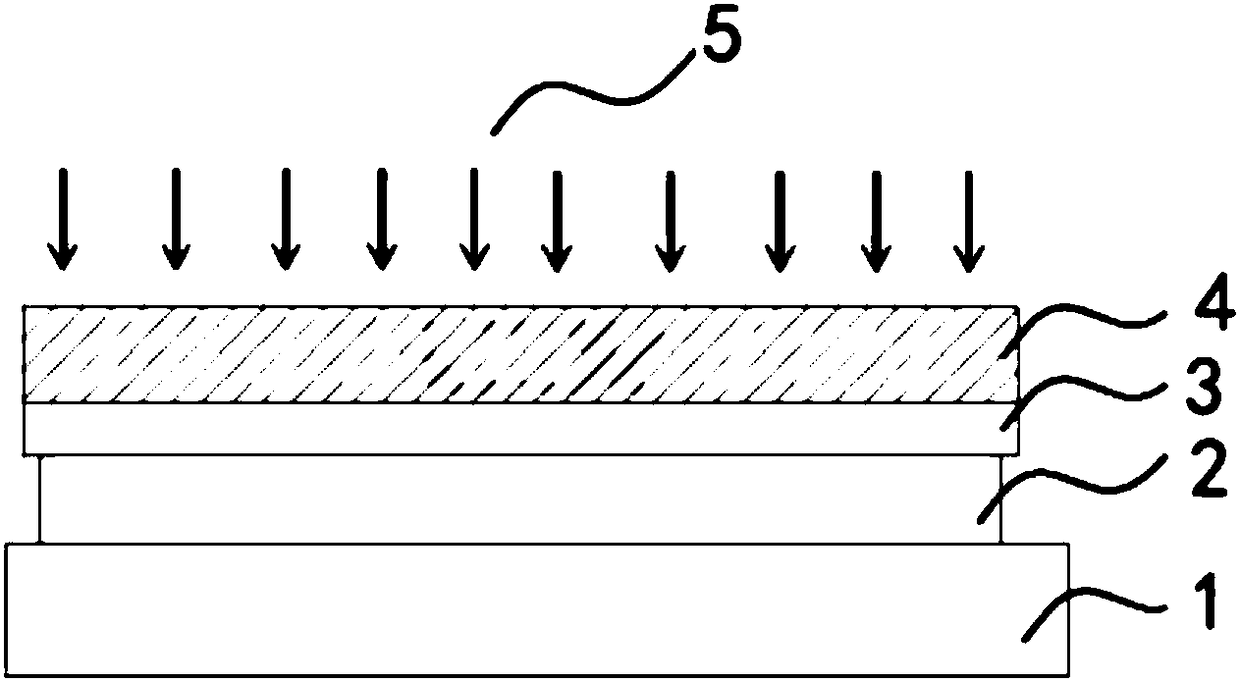

Forming method of touch display panel and touch display mother board

PendingCN108519833AReduce adhesionImprove stripping yieldNon-linear opticsInput/output processes for data processingPlasma treatmentPolydimethylsiloxane

The invention provides a forming method of a touch display panel and a touch display mother board. The forming method of the touch display panel comprises the steps that the touch display mother boardwith a polydimethylsiloxane protection film is formed, and the surface of the polydimethylsiloxane protection film is subjected to plasma treatment; the touch display mother board is cut into a plurality of touch display units; the touch display units are soaked in an organic solvent, and the polydimethylsiloxane protection film is stripped off. Polydimethylsiloxane subjected to plasma treatmentis adopted as a protection film of a touch sensor in the manufacturing process; the touch display units are soaked in the organic solvent in the stripping-off process, and therefore the adhesivity between the protection film and the touch sensor is reduced, so that the protection film is easy to strip off and free of residues, operation is easy, and the stripping-off yield is remarkably increased.

Owner:BOE TECH GRP CO LTD +1

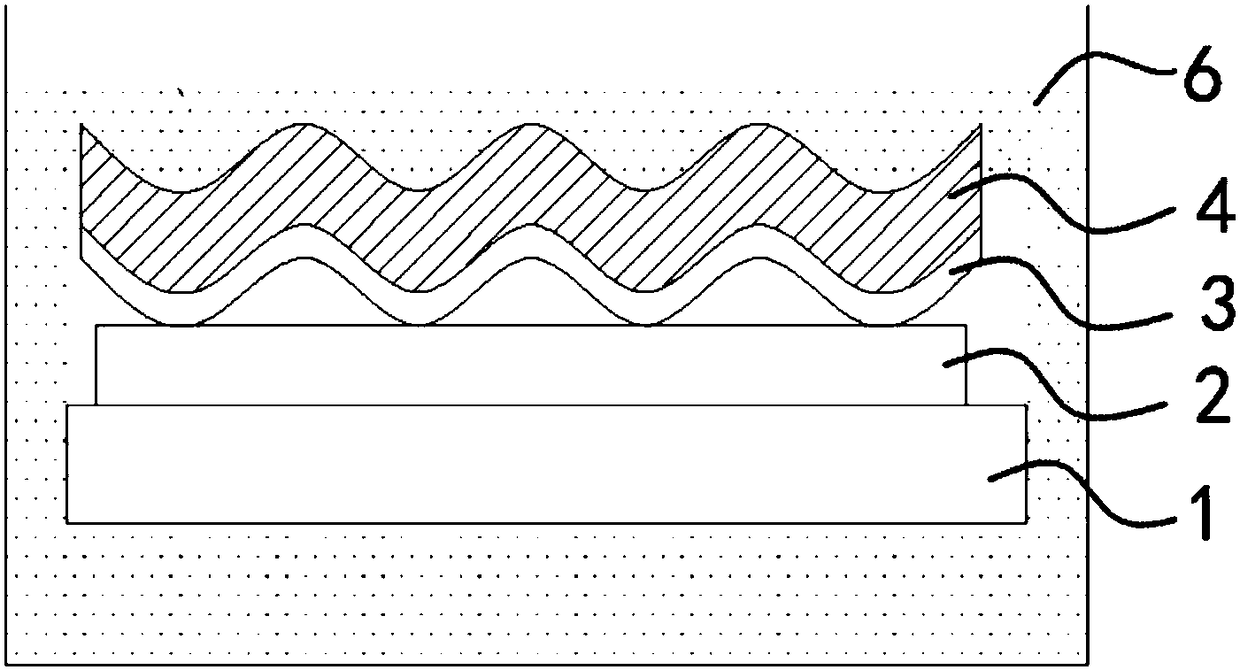

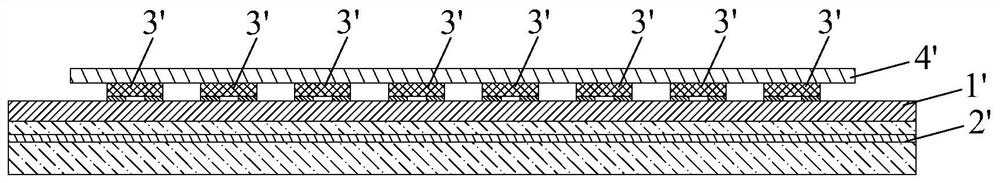

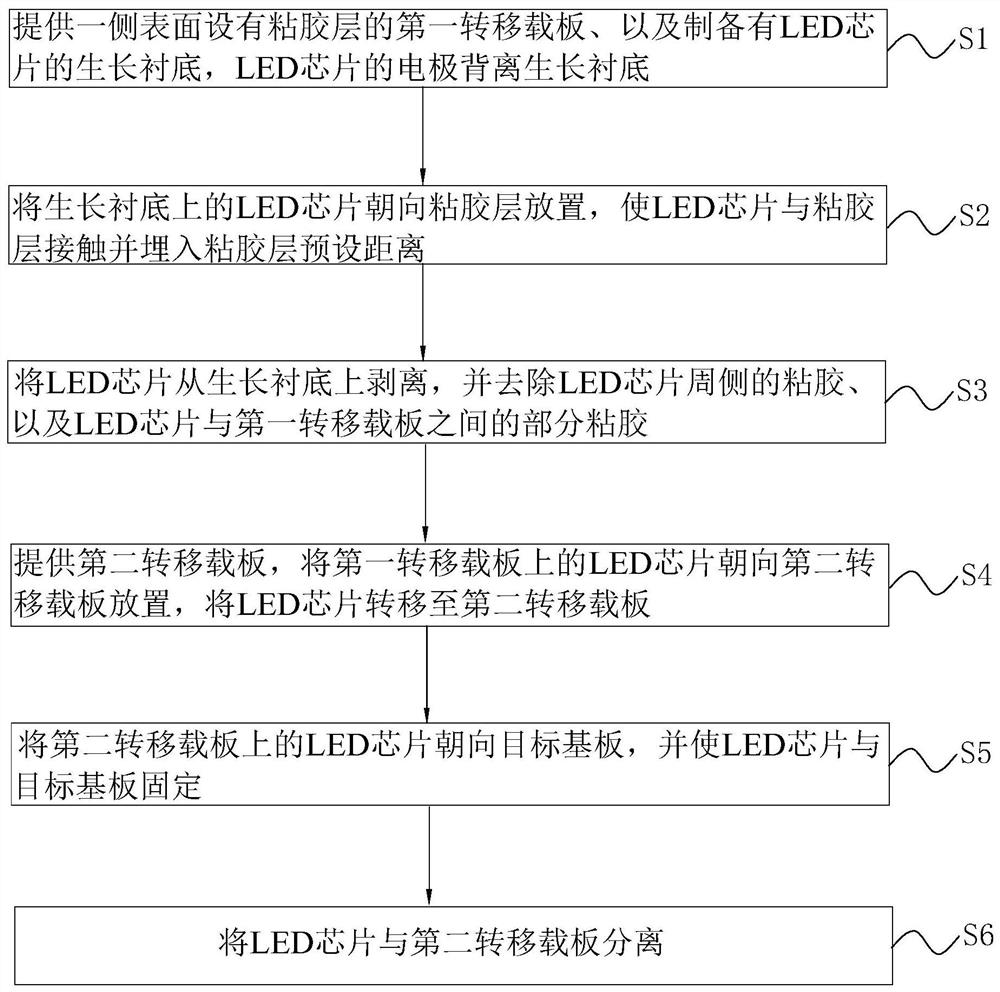

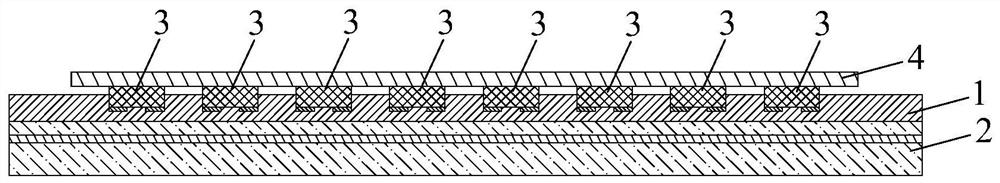

LED chip mass transfer method with high stripping yield and convenient film inversion

ActiveCN113611786AImprove stripping yieldEasy to pour filmSolid-state devicesSemiconductor/solid-state device manufacturingAdhesivePhysical chemistry

The invention discloses an LED chip mass transfer method with high stripping yield and convenient film inversion. According to the method, an LED chip is embedded into an adhesive layer of a first transfer support plate in the process of transferring the LED chip from a growth substrate to the first transfer support plate through a laser stripping mode; the LED chip is protected through the adhesive layer, so that the problem that when the LED chip is stripped from the growth substrate, the LED chip is broken is solved, and the transfer yield of the LED chip is improved; and on the basis, after the LED chip is stripped from the growth substrate, subsequent film inversion is carried out, and before the LED chip is transferred from the first transfer carrier plate to a second transfer carrier plate, part of the adhesive at the peripheral side of the LED chip and part of the adhesive between the LED chip and the first transfer carrier plate are removed, and only the rest part of the adhesive is adhered between the LED chip and the first transfer carrier plate, so that the LED chip can be conveniently separated from the first transfer carrier plate in the process of transferring the LED chip from the first transfer carrier plate to the second transfer carrier plate.

Owner:HCP TECH CO LTD

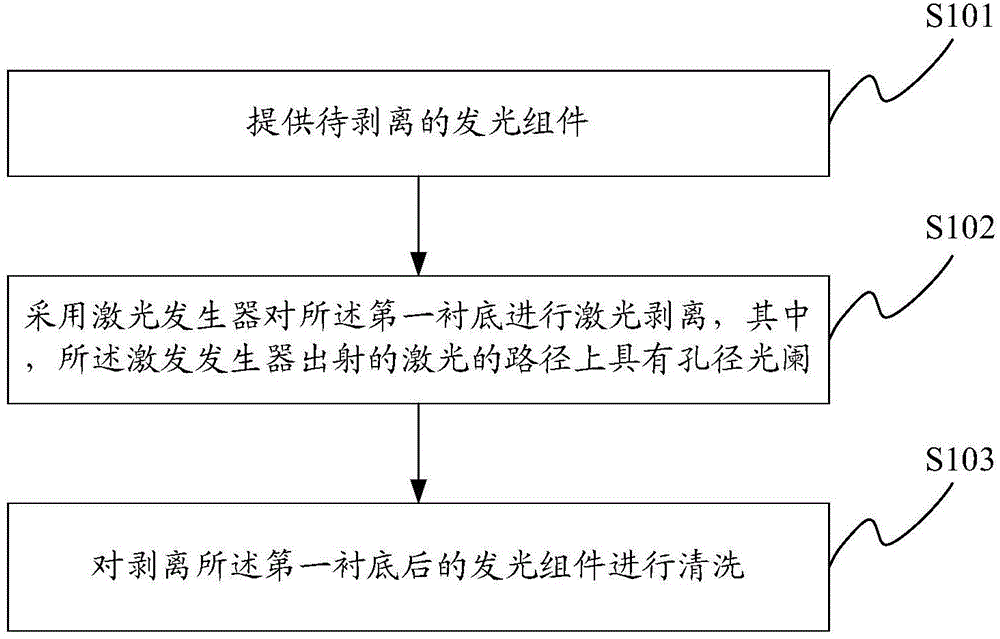

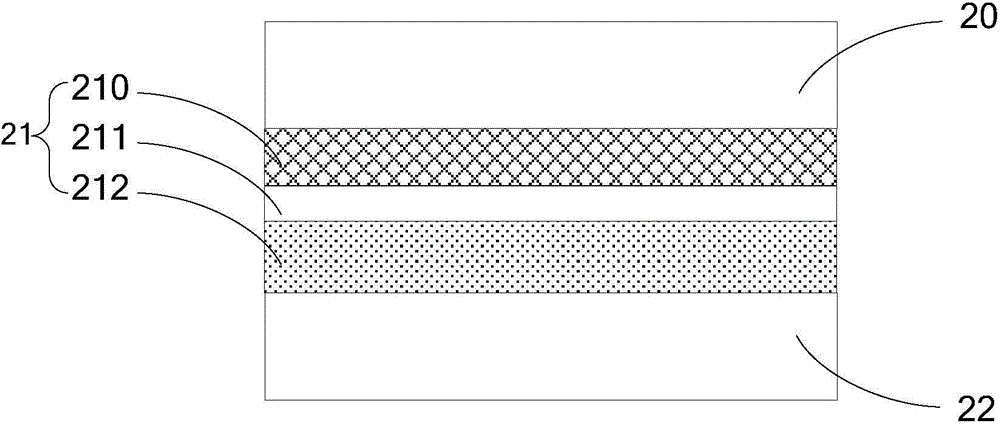

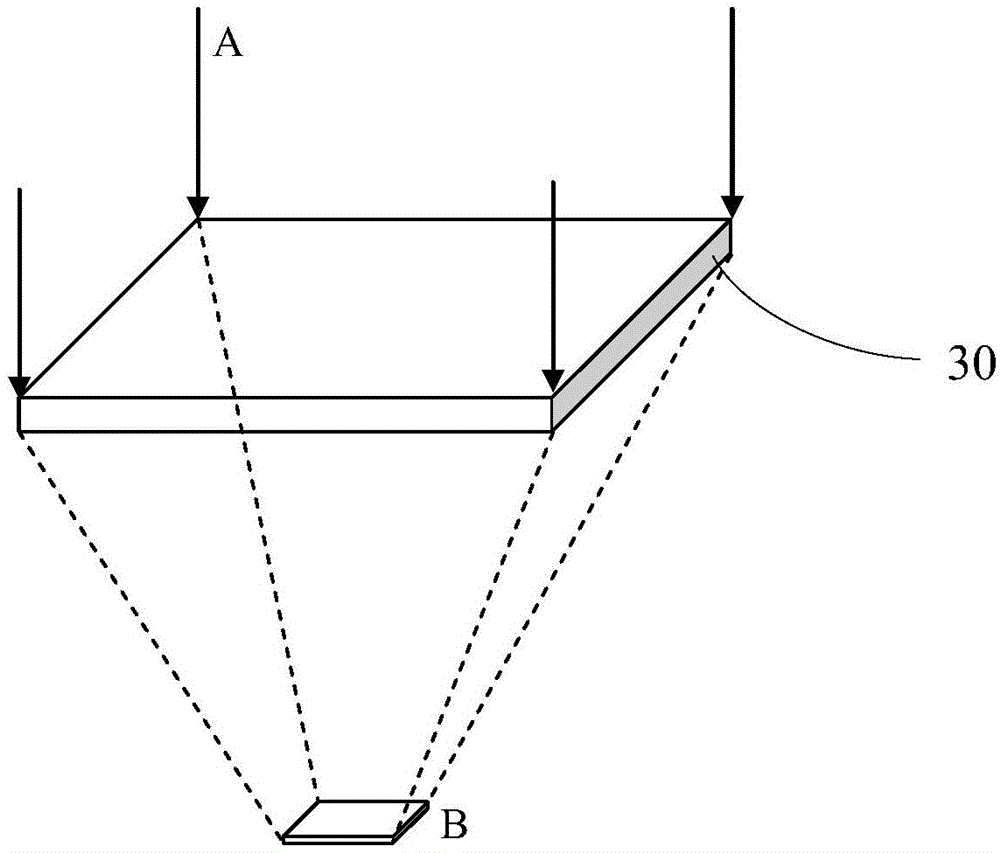

Method and apparatus of separating substrate from light emitting assembly

InactiveCN104979438AImprove stripping yieldLaser beam welding apparatusSemiconductor devicesLight spotGallium nitride

The invention provides a method and apparatus of separating a substrate from a light emitting assembly. The method includes the steps: providing a to-be-separated light emitting assembly, wherein the light emitting assembly includes a first substrate, a gallium nitride epitaxial layer arranged at one side of the first substrate, and a metal substrate, and the gallium nitride epitaxial layer includes an N-type gallium nitride layer, an active layer and a P-type gallium nitride layer; and adjusting utilizing a laser generator to separate the first substrate through laser, wherein an aperture diaphragm is arranged on the path of laser emitted from the generator so that light spots of the laser are adjusted in size through the aperture diaphragm. In this way, light spots as small as possible can be utilized to carry out separation through laser, so less nitrides will be produced locally, and the substrate separation yield rate can be improved.

Owner:FOSHAN NATIONSTAR SEMICON

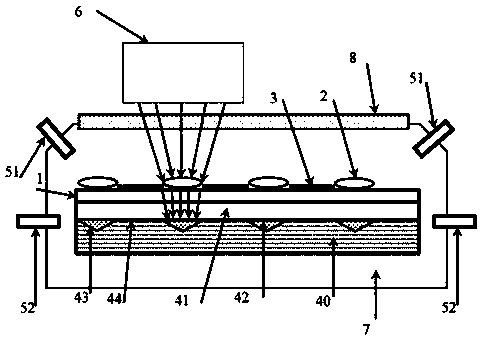

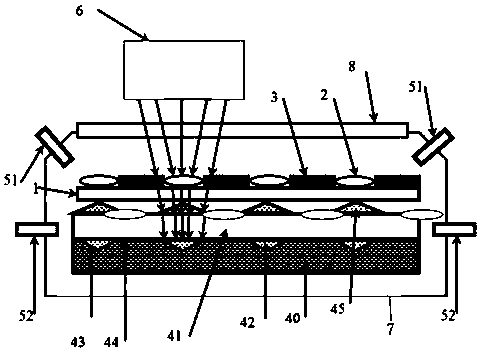

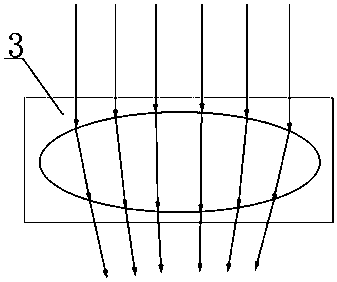

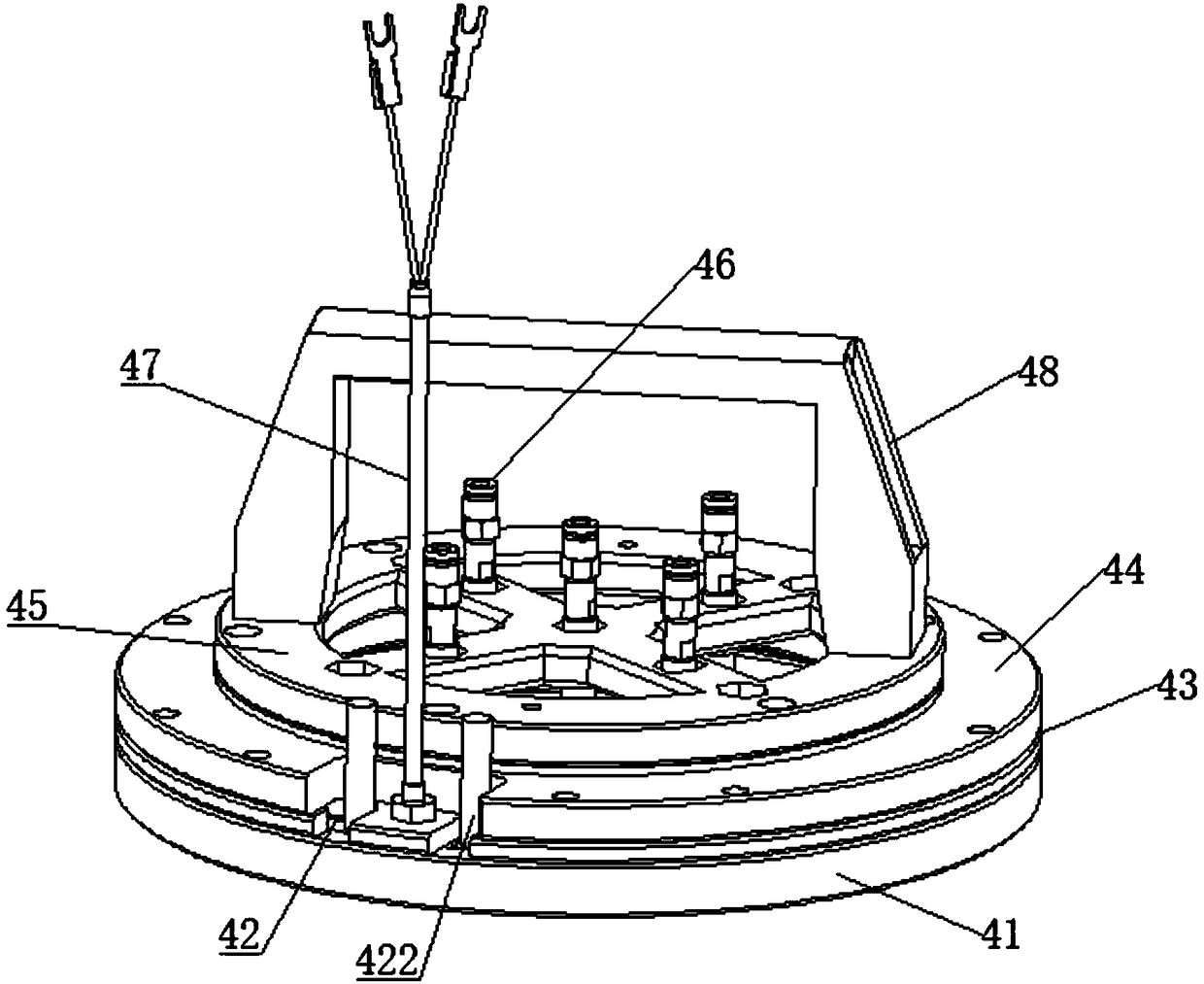

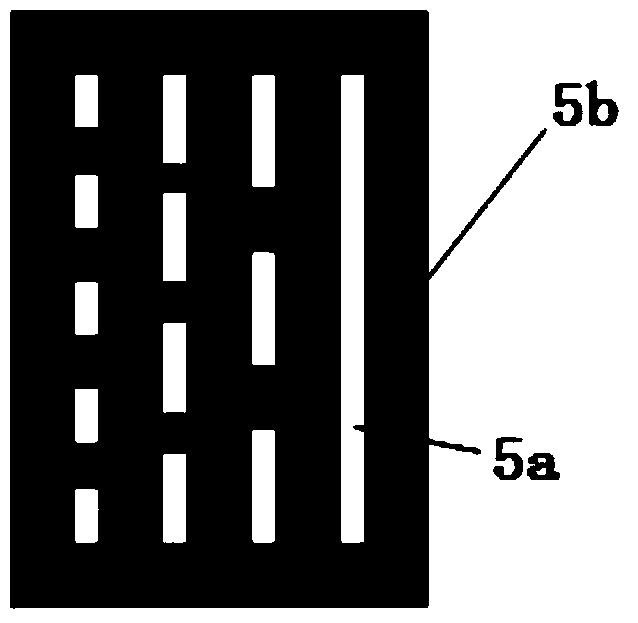

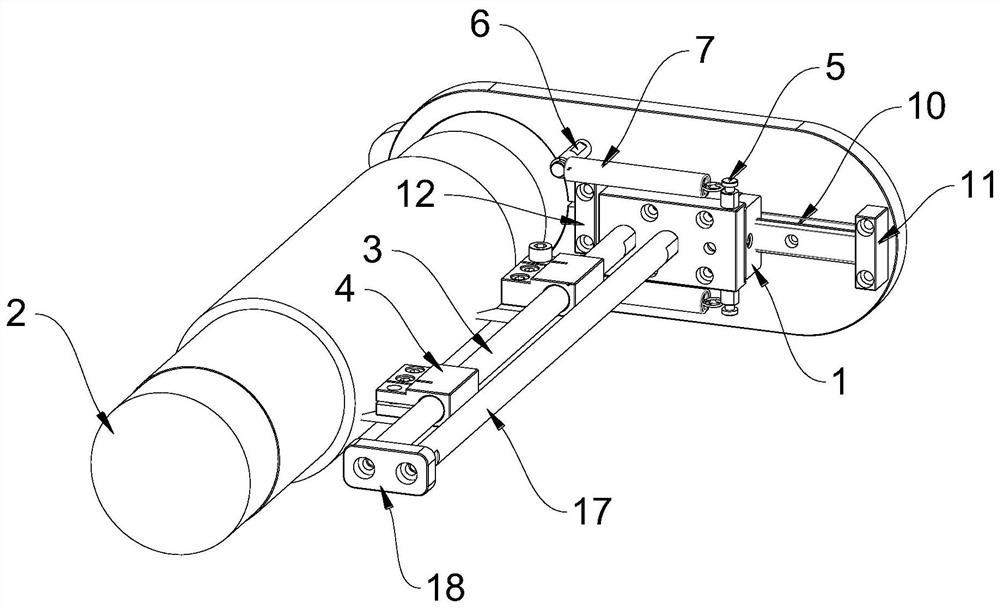

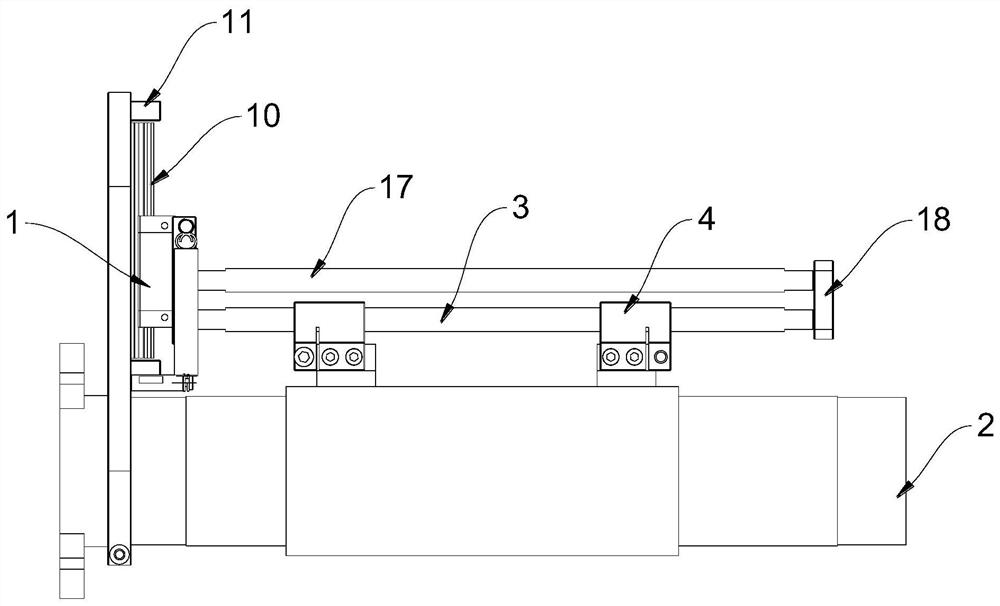

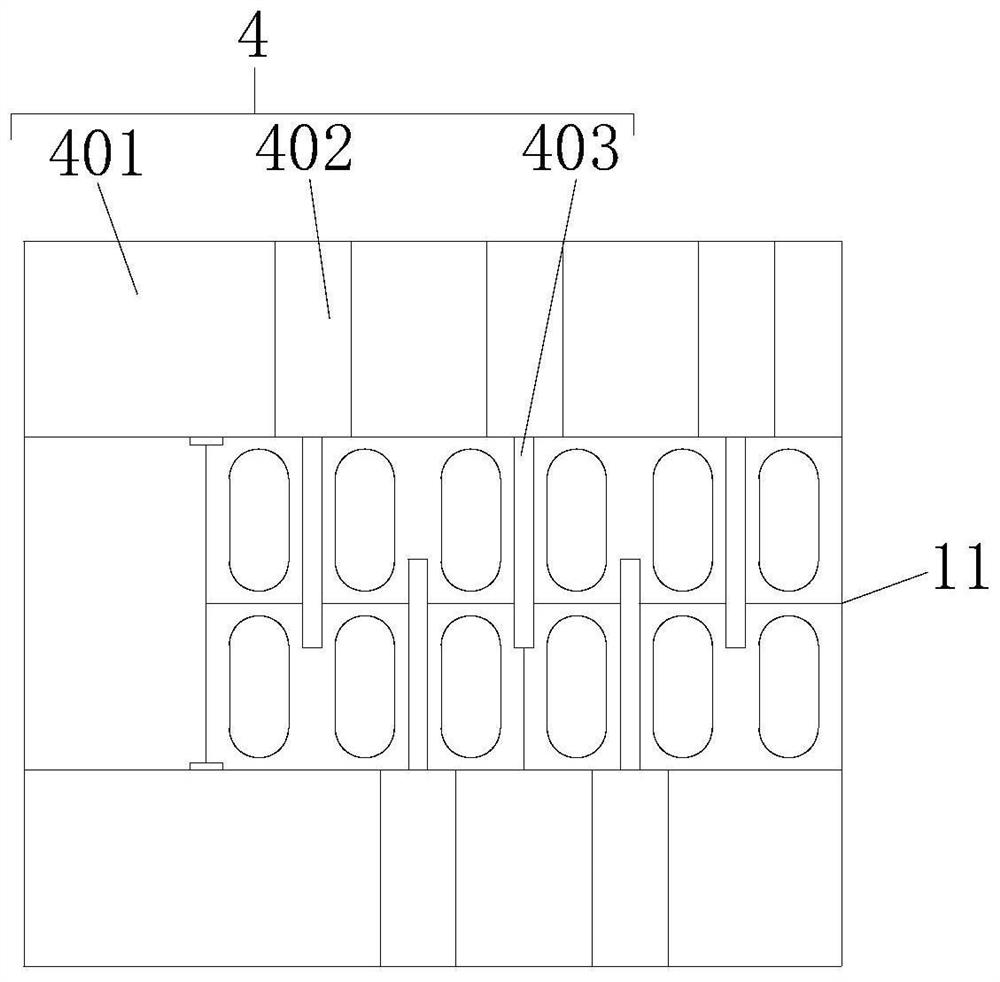

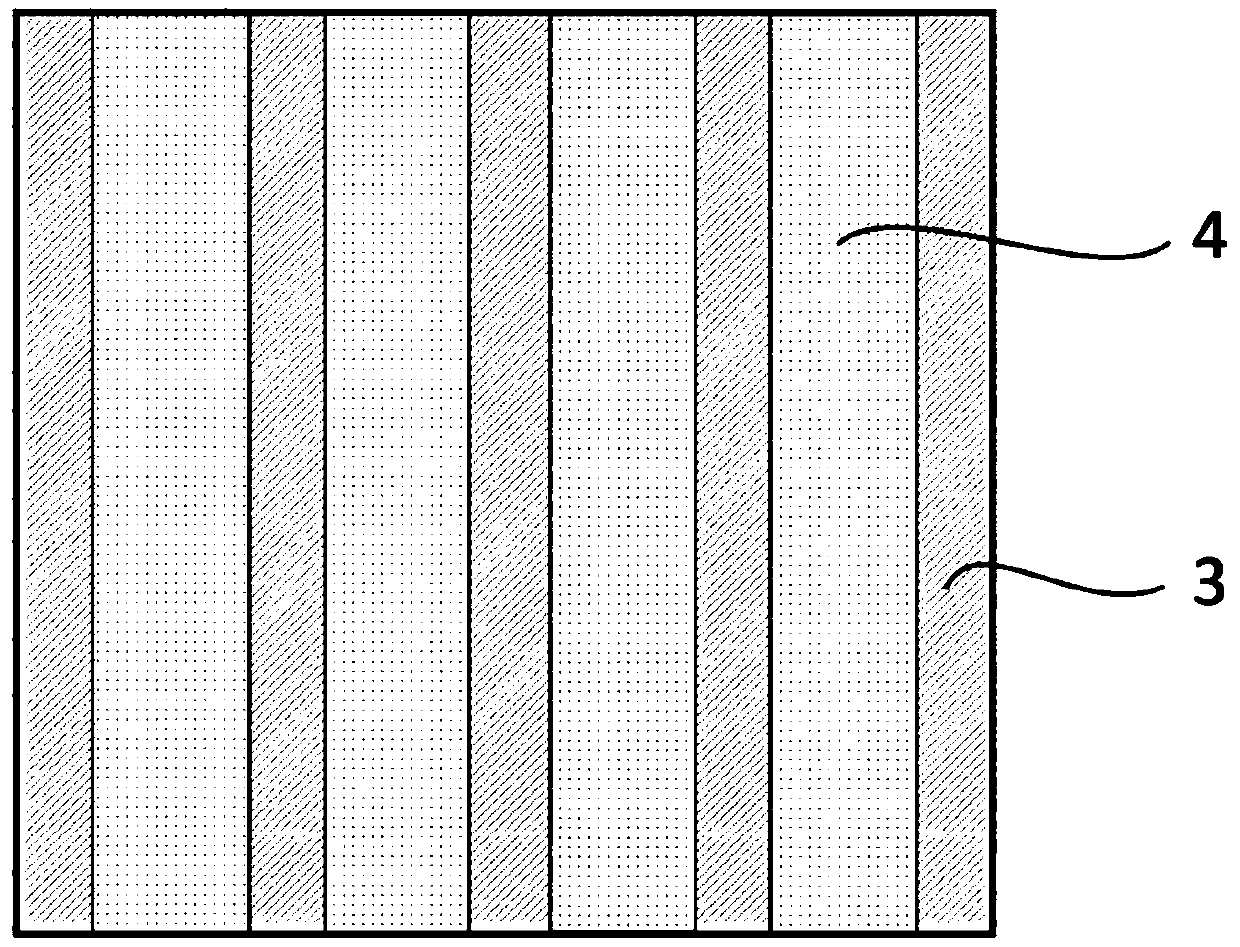

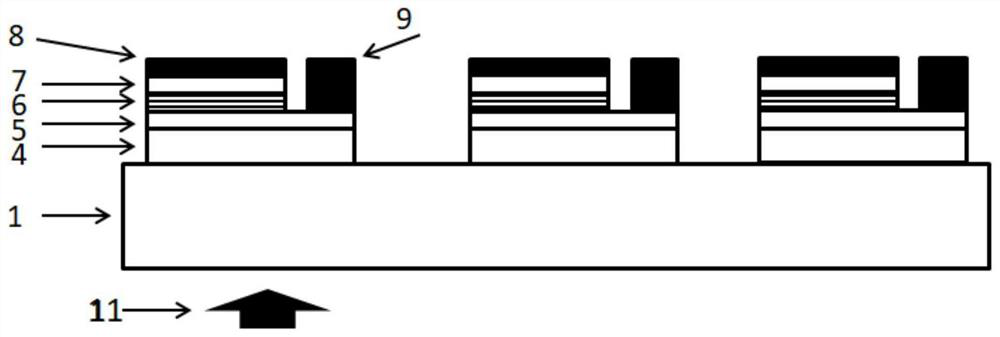

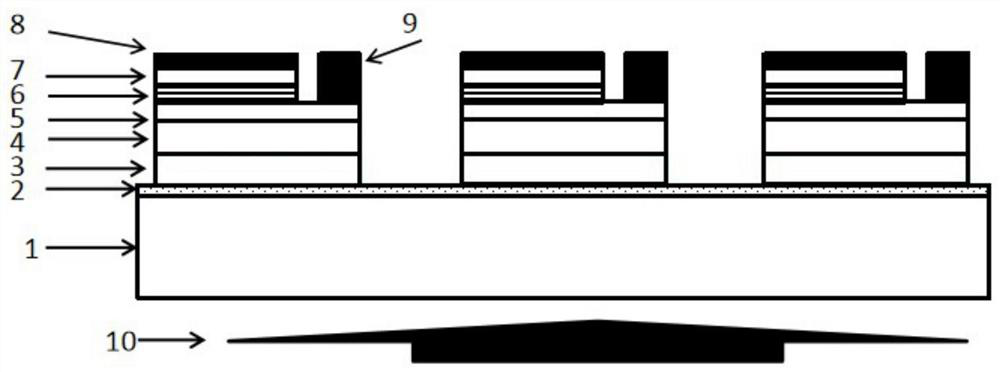

Graphical epitaxial structure laser lift-off device

PendingCN108538784AAchieve strippingIngenious designSemiconductor/solid-state device manufacturingSemiconductor lasersOptoelectronicsLight source

The present invention relates to a graphical epitaxial structure laser lift-off device. The device comprises a substrate, a shaping structure, a transmissivity regulation structure, a graphical epitaxial structure, gas transmission systems, an ultraviolet source, a lift-off chamber and a light-in window. Two sides of the lift-off chamber are respectively provided with the gas transmission systems,the light-in window is arranged on the lift-off chamber, the ultraviolet source is arranged above the outer side of the light-in window, the graphical epitaxial structure is arranged in the light-inwindow, the graphical epitaxial structure is provided with the substrate, the graphical epitaxial structure comprises an epitaxial structure, a sapphire substrate, graphical structures, inclined interfaces, planar interfaces, the plurality of graphical structures are uniformly arranged on the epitaxial structure, each graphical structure is one V-shaped slot structure formed by two inclined interfaces, and each planar interface is connected between each two adjacent graphical structures. The graphical epitaxial structure laser lift-off device is ingenious in design and convenient to operate, can achieve lift-off of the graphical substrate and can improve the lift-off yield.

Owner:NANTONG ZHONGTIE HUAYU ELECTRICS

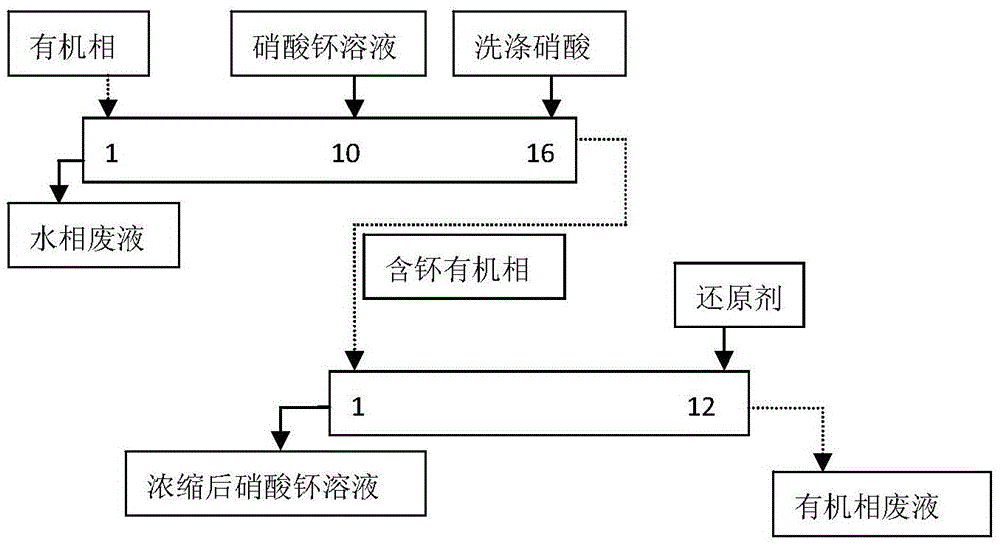

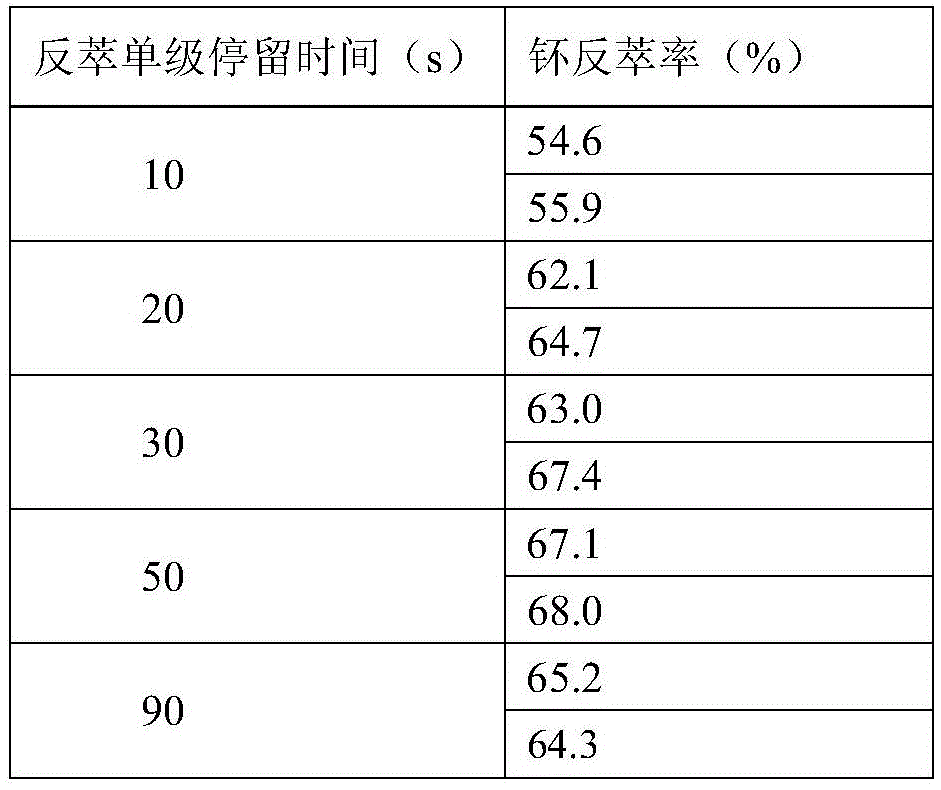

A method for purifying and concentrating plutonium

ActiveCN104004928BPurification and concentration achievedHigh yieldProcess efficiency improvementFuel reprocessingAfter treatment

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

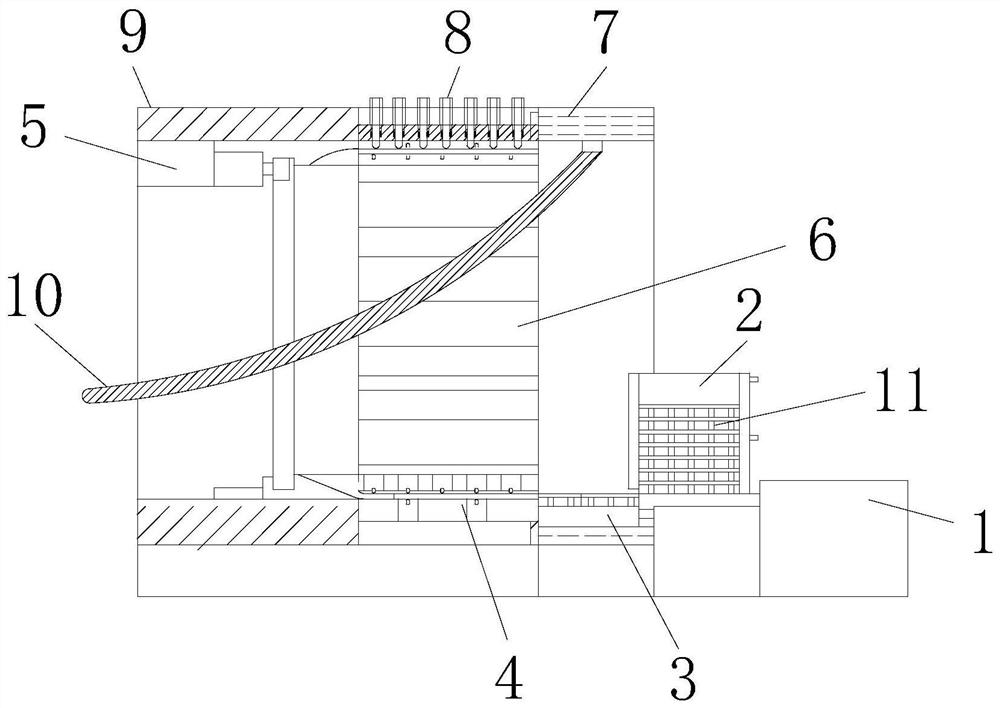

Vacuum heating system, and wafer stripping device and method

ActiveCN108346597AStripped completelyEasy to carrySemiconductor/solid-state device manufacturingLaser beam welding apparatusThermal insulationEngineering

The invention discloses a vacuum heating system, and a wafer stripping device and method. The vacuum heating system comprises a heating ring fixing plate, a heating ring, a thermal insulation plate, asuction nozzle fixing plate and a plurality of vacuum suction nozzles, wherein the heating ring fixing plate is in an annular shape and is provided with a circle of annular groove; the heating ring is in the annular shape and is arranged in the groove of the heating ring fixing plate; the thermal insulation plate is in the annular shape and is arranged above the heating ring; the suction nozzle fixing plate is arranged above the thermal insulation plate; and the plurality of vacuum suction nozzles are symmetrically and uniformly arranged on the suction nozzle fixing plate and are used for adsorbing a stripped wafer and removing the wafer. In the invention, through arranging the vacuum heating system, a bonding layer material can be heated in an area where the wafer is bonded and can be melted so that the wafer is completely stripped. Simultaneously, through the vacuum suction nozzles of the vacuum heating system, the stripped wafer can be adsorbed so that the wafer is convenient to carry, the wafer is prevented from be damaged and the yield rate of wafer stripping is increased.

Owner:深圳市大族半导体装备科技有限公司

Preparation method of graphene oxide

PendingCN114348998AImprove conversion rateEnsure Structural IntegrityCarbon compoundsIce waterPotassium permanganate

The invention provides a preparation method of graphene oxide, and belongs to the field of material preparation. The method comprises the following steps: (1) carrying out plasma sputtering on graphite to obtain modified graphite; (2) adding potassium permanganate into concentrated sulfuric acid, and uniformly mixing to obtain a mixture A; (3) adding the modified graphite in the step (1) into the mixture A to obtain a mixture B; (4) reacting the mixture B at 25-60 DEG C for 2-6 hours to obtain a mixture C; (5) adding the mixture C into ice water, adding hydrogen peroxide, and uniformly mixing; and (6) adding water into the product obtained in the step (5), and washing until the product is neutral, thereby obtaining the precipitate, namely the graphene oxide. The stripping yield of the graphene oxide reaches up to 95% or above, and the dosage of concentrated sulfuric acid and potassium permanganate is effectively reduced. The method is high in stripping yield, low in cost, small in danger, rapid and simple in reaction process and very suitable for large-scale industrial production.

Owner:无锡漆好环保新材料研究有限公司

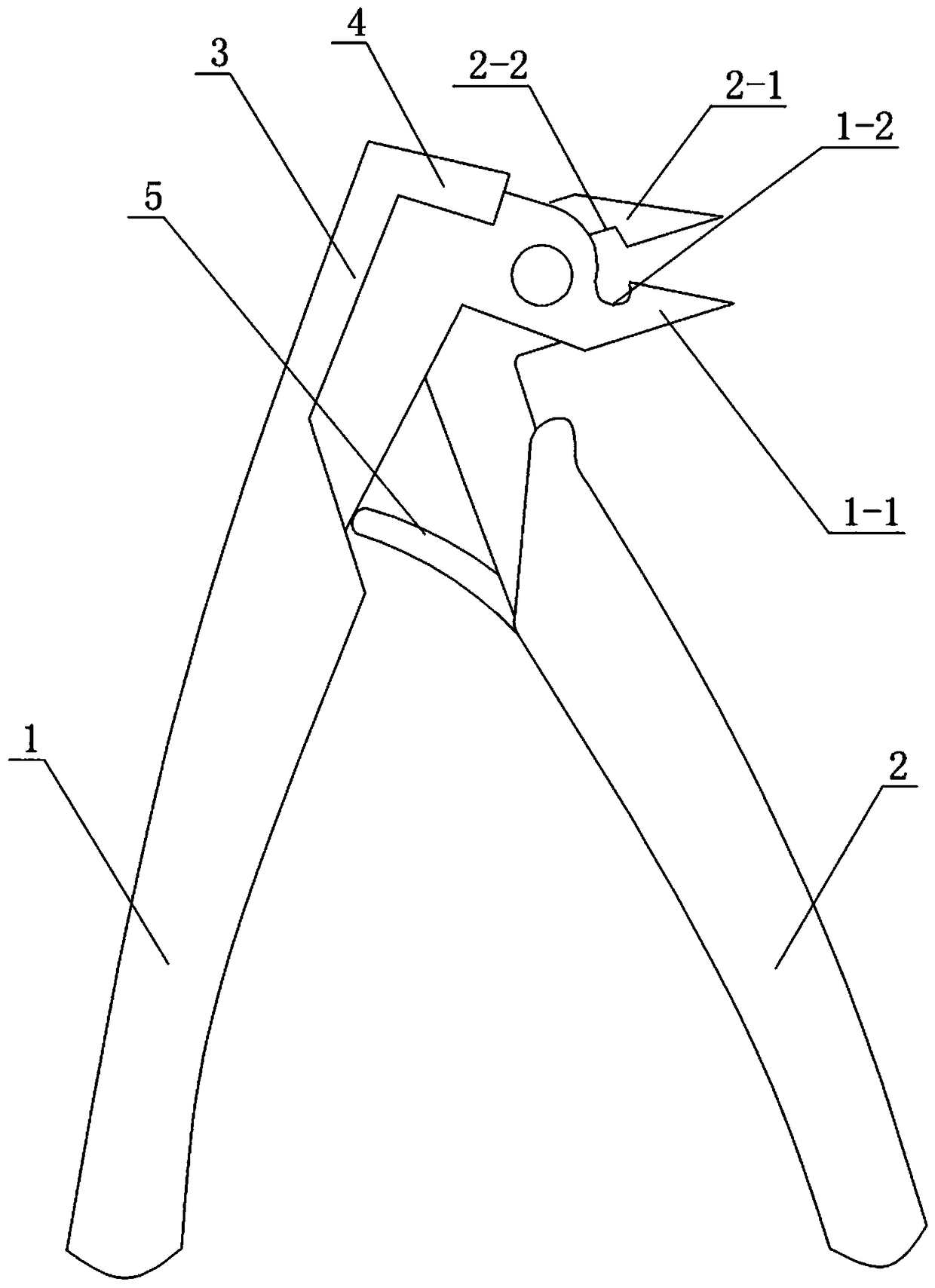

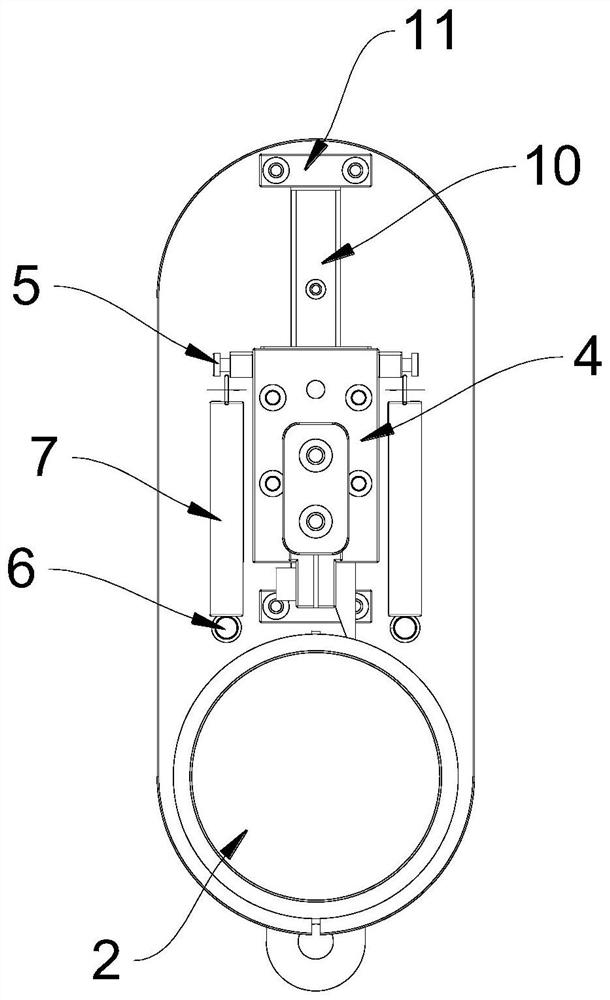

Fiber coating stripping device

InactiveCN108802903AVisualize the stripping processVisualizationOptical light guidesEngineeringMechanical engineering

The invention discloses a fiber coating stripping device comprising a first handle and a second handle that are hinged to each other. A first clamping head is arranged at the end portion of the firsthandle; a second clamping head is arranged at the end portion of the second handle; the first clamping head is perpendicular to the first handle; and the second clamping head is perpendicular to the second handle. The first clamping head and the second clamping head have pointed ends and matched cutting edges; a first groove and a second groove are formed at the parts, approaching a hinging point,of the inner sides of the first clamping head and the second clamping head; a pressing part connected with the first handle is arranged at the back of the first clamping head; and a hand protection part extends from the pressing part to the first clamping head. The fiber coating stripping device is based on the jaw design conforming to the human engineering and has advantages of labor saving andvisual peeling process and effect.

Owner:NANJING CHINA UNIV INTPROP CO LTD

A light-emitting diode epitaxial wafer and its preparation method

The invention discloses a light-emitting diode epitaxial wafer and a preparation method thereof, which belong to the photoelectric field. The epitaxial wafer comprises a first buffer layer, a graphene layer, a second buffer layer and an epitaxial structure layer from a substrate to a surface layer; and the epitaxial structure layer is composed of an N-type semiconductor layer, a multiple quantum well layer, a P-type electron blocking layer and a P-type semiconductor layer from the second buffer layer to the surface layer. In comparison with the traditional GaN-based epitaxial wafer structure, the graphene layer is added to enable the GaN-based epitaxial structure layer to be stripped from the substrate by using a mechanical mode, a laser device does not need to be adopted, and the stripping yield is improved; in comparison with other techniques of using a transfer mode to place the graphene layer on the substrate, the buffer layers exist between the graphene layer and the substrate for connection, and the problem of poor adhesion between the graphene layer and the substrate does not exist.

Owner:ELEC TECH OPTOELECTRONICS TECHWUHUCO

Method and equipment for exfoliating layered materials and separating two-dimensional nanosheets by size screening

ActiveCN110040728BImprove stripping yieldNarrow and single size rangeMaterial nanotechnologyGrapheneFluid phasePhysical chemistry

The invention discloses a method and equipment for peeling a layered material and screening and separating two-dimensional nanosheets. The layered material is of a lamellar structure, and is peeled toobtain the two-dimensional nanosheets. The method comprises the following steps: S1, mixing a layered material and a solvent; S2, adding the mixed solution into an emulsifying-dispersing machine forpeeling; S3, introducing the peeled mixed solution into a primary separator for separating to obtain a precipitate containing the non-peeled layered material and a liquid phase part containing two-dimensional nanosheets, carrying out a step S4 on the precipitate, and carrying out a step S5 on the liquid phase part; S4, mixing the precipitate and the solvent again for peeling, carrying out the stepS3 again after peeling, and repeatedly peeling the layered material; S5, conveying the liquid phase part into a secondary for screening and separating. By adopting the method and equipment, the layered material with the lamellar structure is peeled continuously and mechanically, and the two-dimensional nanosheets obtained by peeling are screened and separated, so that two-dimensional nanosheets with a narrow and single size range can be obtained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

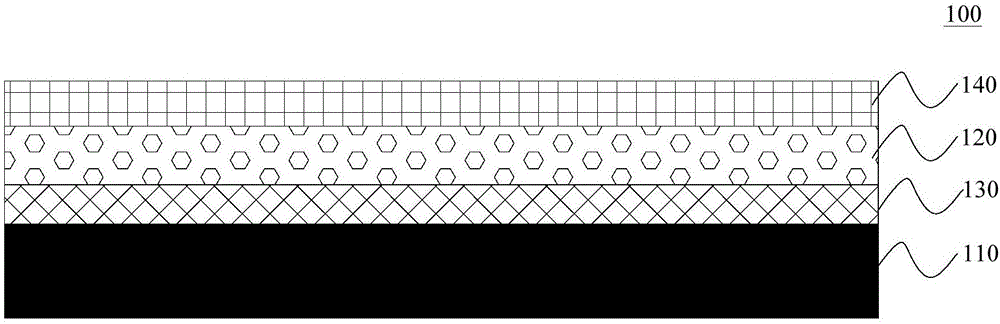

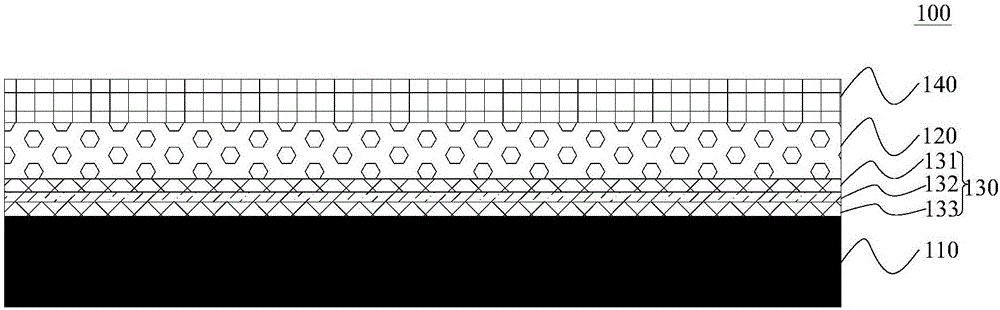

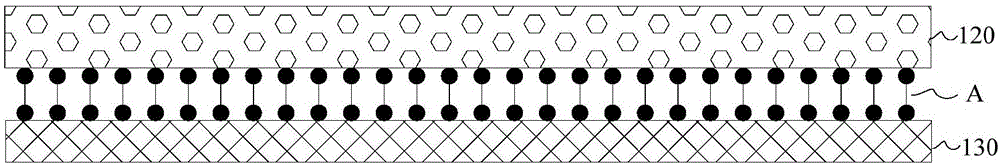

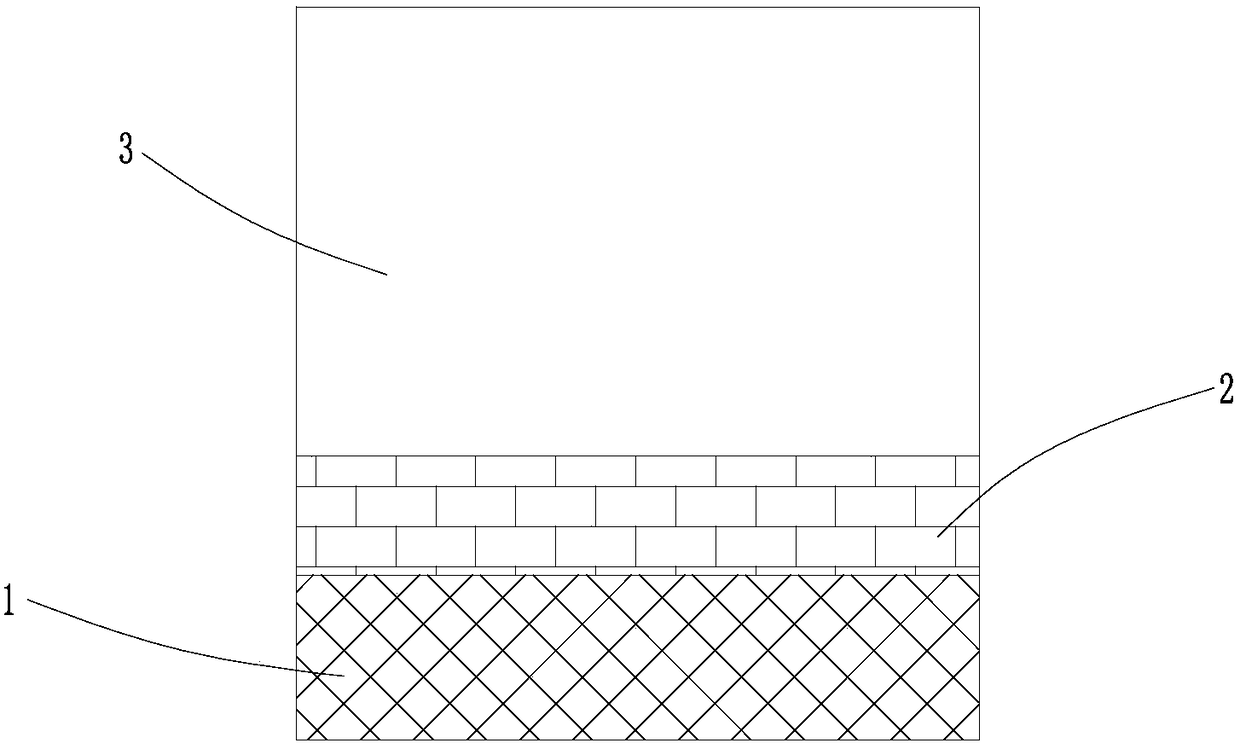

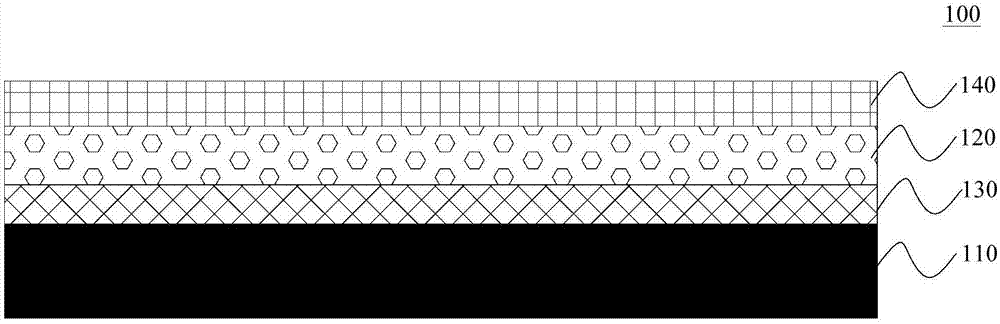

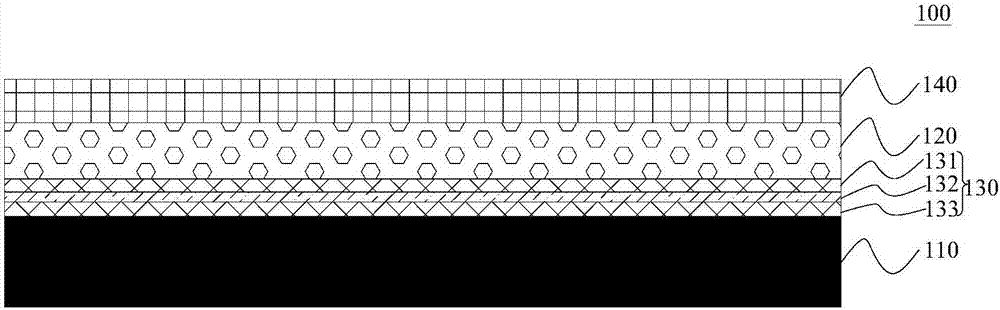

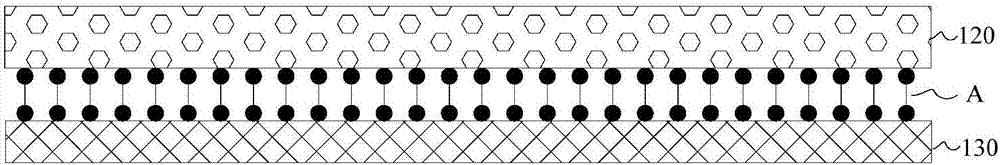

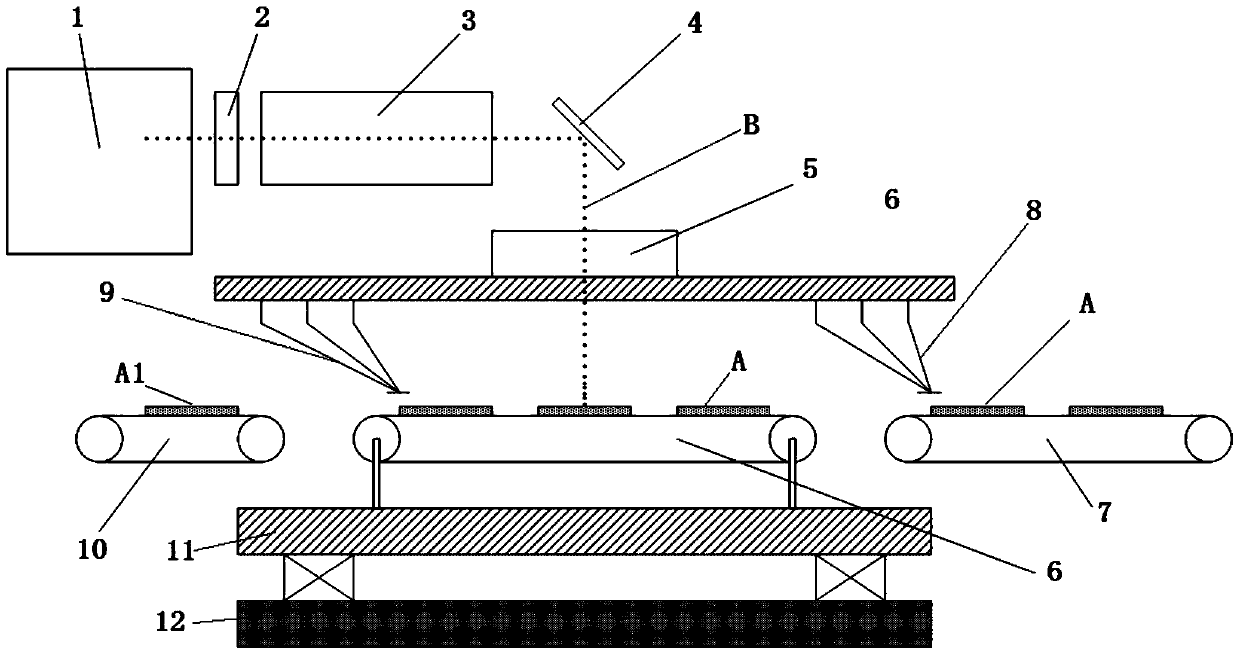

Motherboard of display panel and manufacturing method of display panel

ActiveCN106448473BGuaranteed performanceImprove stripping yieldFinal product manufacturePrinted circuitsEngineeringMotherboard

The invention discloses a display panel motherboard and a manufacturing method of the display panel, which belong to the field of display technology. The display panel motherboard includes a rigid substrate and a flexible substrate, and the display panel motherboard also includes a liquid affinity adjustable layer arranged between the rigid substrate and the flexible substrate, and the liquid affinity A degree-tunable layer bonds the flexible substrate to the rigid substrate. The adjustable liquid affinity layer provided on the motherboard of the display panel of the present invention can improve the peeling yield of the motherboard of the display panel.

Owner:BOE TECH GRP CO LTD +1

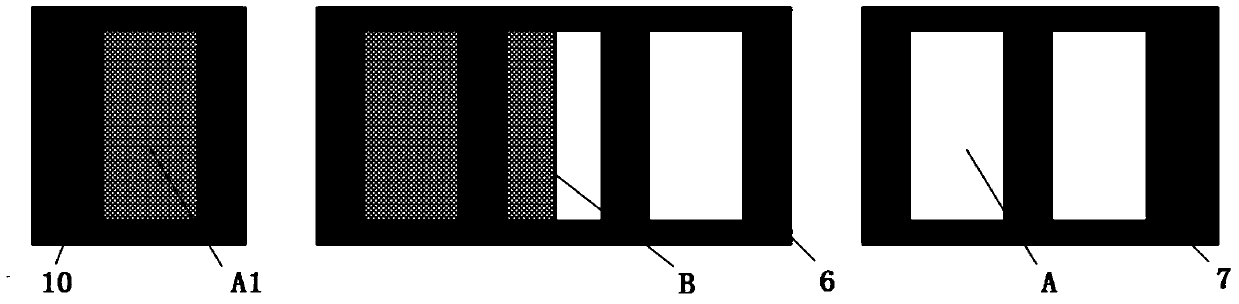

A kind of laser stripping device and method

ActiveCN107452898BEasy to useNot exposed to laser lightSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLarge screen

The invention discloses a laser peeling device and method, wherein the laser peeling device includes: a working conveyor belt for driving the display screen to be peeled to move on it, and the display screen to be peeled includes a glass substrate and a flexible display screen; The mask shielding device of the area and the light-shielding area, wherein the light-transmitting area is used to transmit a part of the laser beam and make it irradiate on the display screen to be peeled driven by the operation conveyor belt, so as to perform laser peeling on the display screen to be peeled off, In this way, a flexible display screen and a glass substrate separated from each other are obtained; and the light-shielding area is used to block the remaining part of the laser beam, so as to prevent the laser from irradiating areas other than the display screen to be peeled off on the operation conveyor belt. The laser stripping device and method of the present invention are compatible with large screens and small screens.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Bottom film stripping knife

PendingCN112874124AImprove separation efficiencyAvoid foamingLamination ancillary operationsLaminationEngineeringMechanical engineering

A bottom film stripping knife relates to the field of film stripping mechanisms. The bottom film stripping knife comprises a mounting base, a movable sliding rail and a stripping knife assembly, the mounting base is movably arranged on a machine table, and the moving direction of the mounting base is perpendicular to the central axis of a bottom film roller shaft; the movable sliding rail is arranged on the mounting base and is parallel to the bottom film roller shaft; and the stripping knife assembly is detachably arranged on the movable sliding rail and used for abutting against a bottom film so that the bottom film can be separated. According to the bottom film stripping knife, force can be applied to the separation position of the bottom film through external force limitation, so that belt films on the two sides can be more stably separated, in the separation process, due to the fact that the bottom film is subjected to external force, the phenomena of bubbling and wrinkling are effectively avoided, the rejection rate can be effectively reduced, and the yield of bottom film stripping is improved.

Owner:成都冠佳科技有限公司

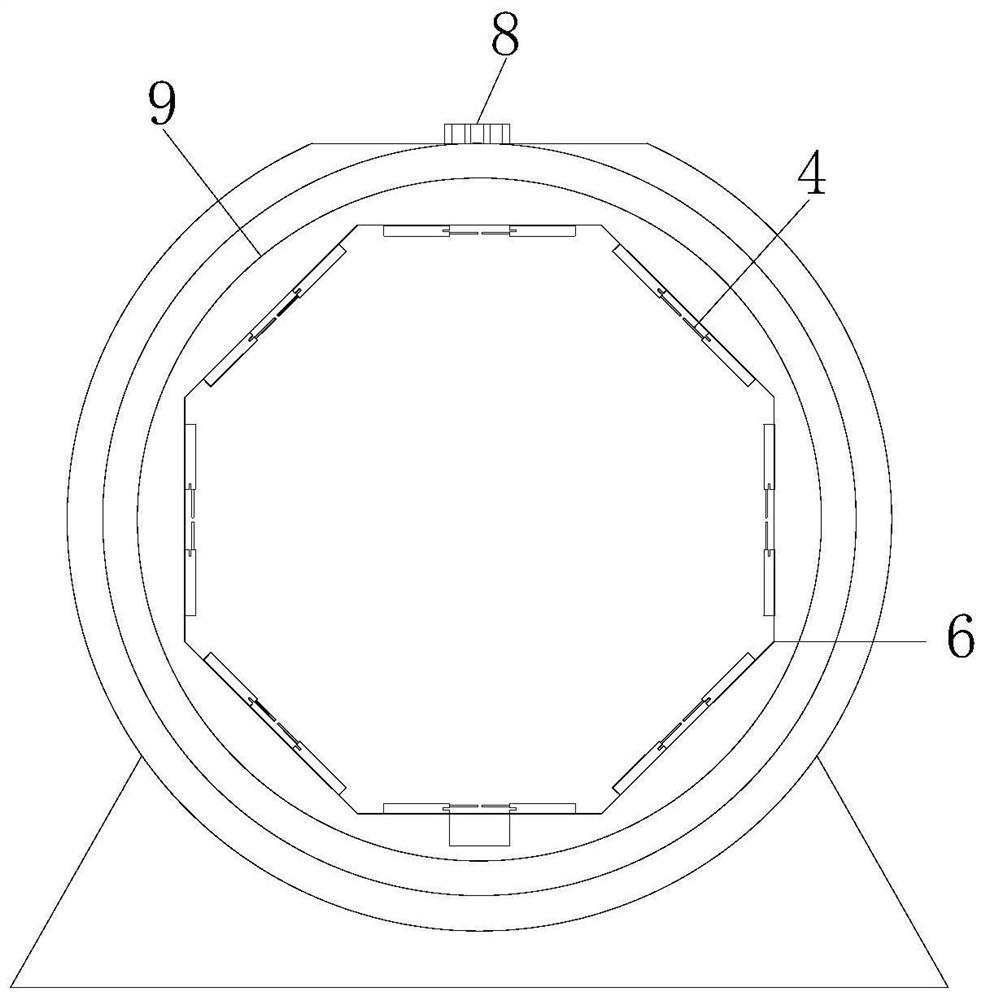

Medical medicine stripping machine and medicine stripping method

ActiveCN112874950AEliminate manual adjustmentImprove stripping yieldArticle unpackingMedicineElectric machinery

The invention discloses a medical medicine stripping machine and a medicine stripping method, and belongs to the technical field of medical instruments. The medical medicine stripping machine comprises a medicine tamping device and a medicine feeding mechanism. The medicine tamping device comprises a base plate, hole sites are formed in the base plate in an array mode, a medicine tamping rod and a micro motor are installed in each hole site, and the output end face of each micro motor and one end of the corresponding medicine tamping rod are both inclined planes. The medicine feeding mechanism is installed on the inner wall of a cylindrical shell, the medicine feeding mechanism comprises an annular cylinder, a conductive sliding ring, a driver and a clamping device, and the conductive sliding ring is electrically connected to the clamping device. A circle of the clamping device is installed in the annular cylinder, and the output end of the driver is connected with the annular cylinder. A mounting hole is formed in the shell wall of the cylindrical shell, the medicine tamping device is fixed in the mounting hole, a notch corresponding to the driver is formed in the annular cylinder, and when the annular cylinder rotates, the notch is intermittently communicated with the mounting hole. According to the medical medicine stripping machine and the medicine stripping method, medicine stripping is conducted in the mode that medicine plates are clamped and then tamps medicine on the front face, manual adjustment is avoided, and the medicine stripping yield is increased.

Owner:THE FIRST AFFILIATED HOSPITAL ZHEJIANG UNIV COLLEGE OF MEDICINE

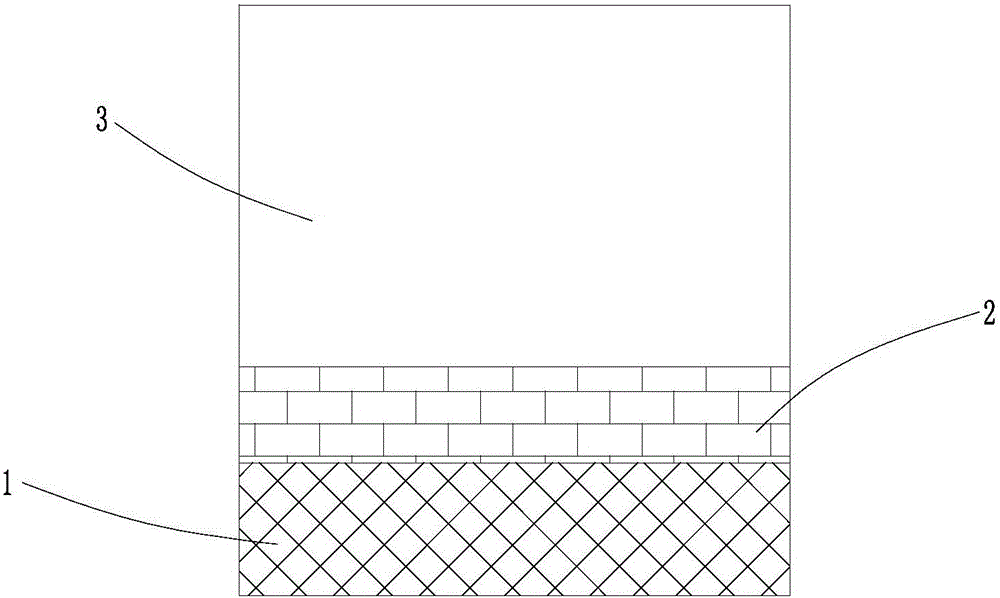

Line recognition module and preparation method thereof, and display device

PendingCN113161336AThere will be no change in viscosityAvoid peel damageSolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareDisplay device

The invention discloses a line recognition module and a preparation method thereof, and a display device, and aims to improve the stripping yield. The embodiment of the invention provides a line recognition module. The line recognition module comprises a flexible substrate which comprises a line recognition area and a binding area located outside the line recognition area; a plurality of line recognition units which are located on one side of the flexible substrate in the line recognition area; a plurality of signal lines which are located on the same side of the flexible substrate as the pattern recognition units and electrically connected with the pattern recognition units, each signal line extending to the binding area from the pattern recognition area; a driving chip which is bound with the signal line in the binding area; and an adhesive layer which is located on the side, away from the line recognition units, of the flexible substrate, the orthographic projection of the adhesive layer on the flexible substrate being not overlapped with the binding area.

Owner:BEIJING BOE SENSOR TECH CO LTD +1

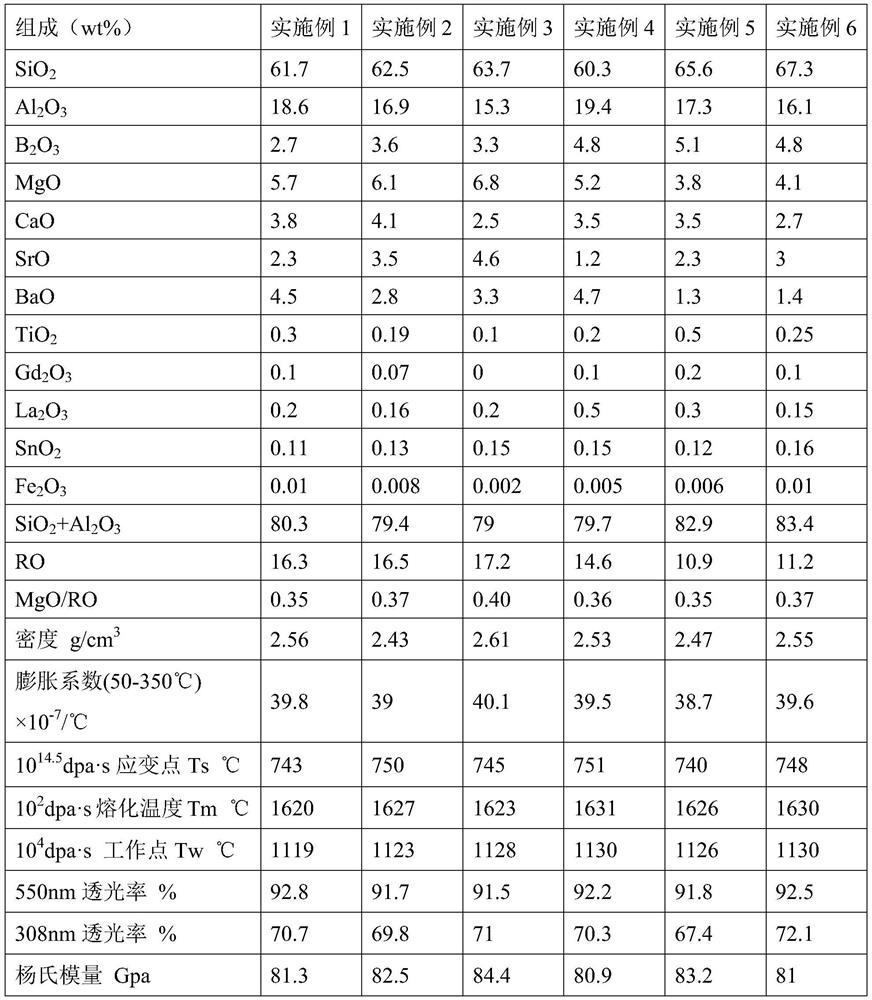

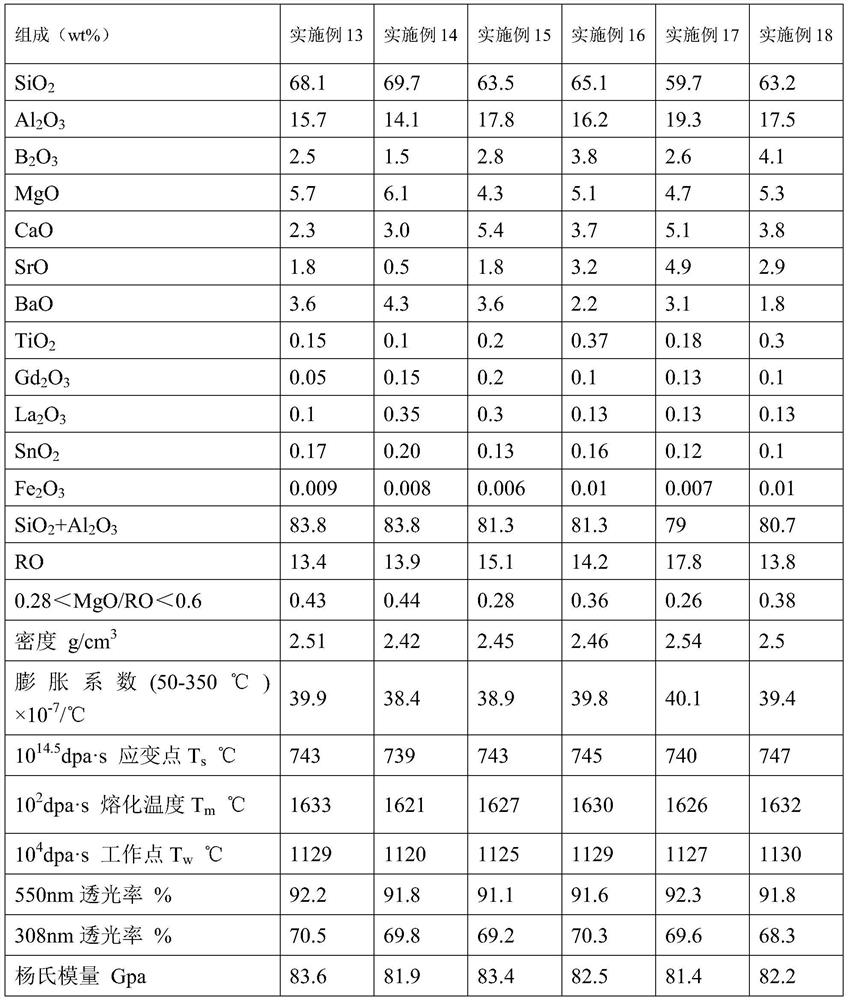

Aluminosilicate glass composition, aluminosilicate glass and its preparation method and application

The invention relates to the field of glass manufacturing, and discloses an aluminosilicate glass composition, aluminosilicate glass and a preparation method and application thereof. Based on the total weight of the aluminosilicate glass composition, the aluminosilicate glass composition contains 55-73wt% SiO 2 , 7‑28wt% Al 2 o 3 , 0‑8wt% of B 2 o 3 , 0.05‑4wt% TiO 2 , 2‑20wt% alkaline earth metal oxide RO, 0‑1wt% Gd 2 o 3 , 0‑2wt% La 2 o 3 and unavoidable impurities. The glass prepared by the invention has the characteristics of high thermal stability, high strain point, high UV 308nm transmittance, low thermal expansion coefficient and low static electricity, and is suitable for large-scale industrial production.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

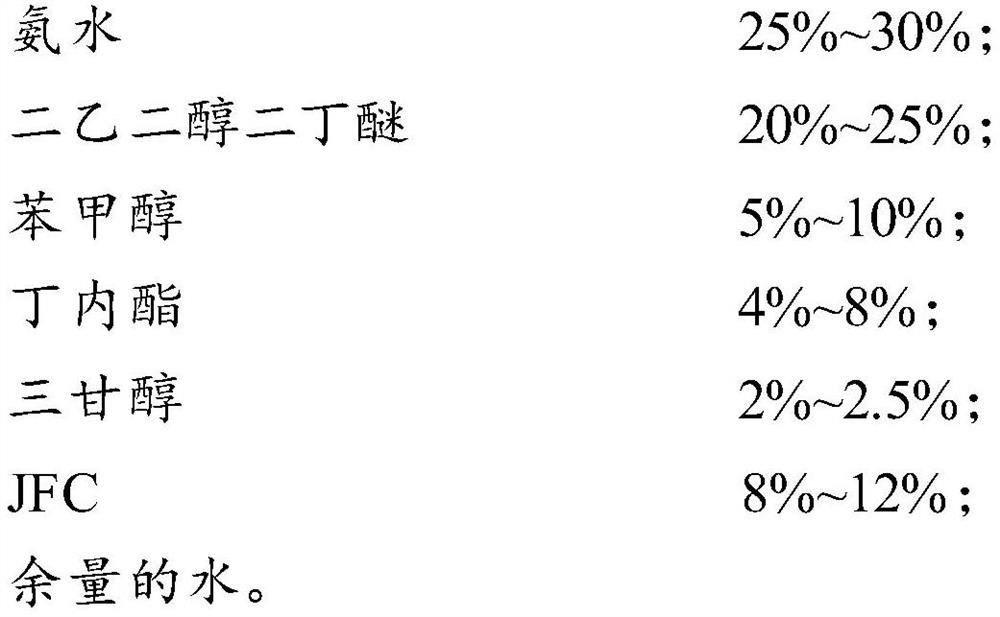

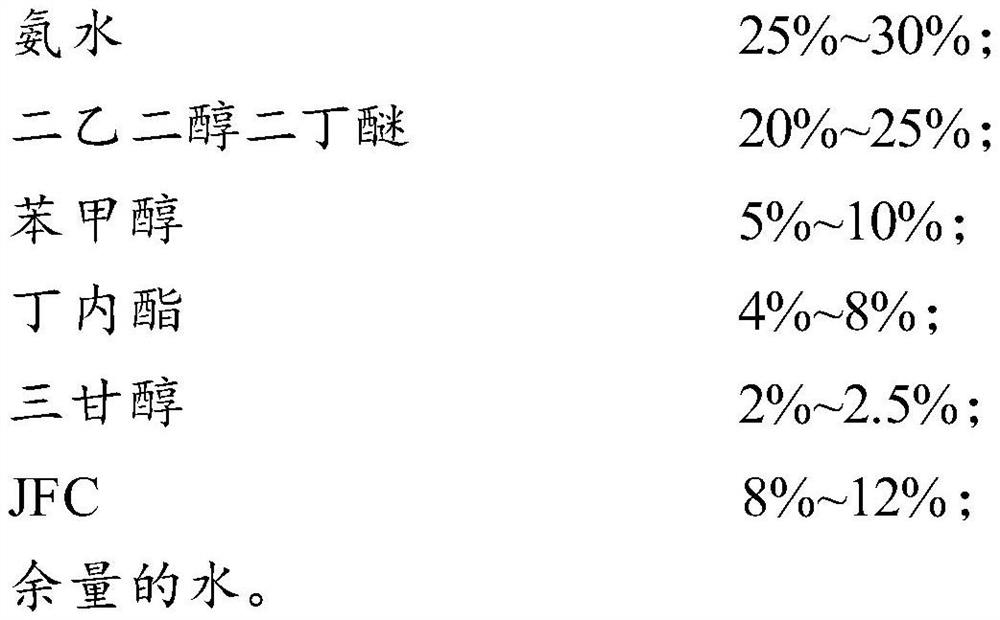

A kind of alkaline non-scratch stripping solution and stripping method

ActiveCN113004737BReduce rework costsReduce pollutionChemical paints/ink removersDiethylene glycolEnvironmental engineering

The invention provides an alkaline non-scratch deplating solution, which in mass percentage comprises: ammonia water 25%-30%; diethylene glycol dibutyl ether 20%-25%; benzyl alcohol 5%-10%; Butyrolactone 4% to 8%; triethylene glycol 2% to 2.5%; JFC 8% to 12%; the balance of water. The above-mentioned stripping solution provided by the present invention can strip the ink on the product without adding new scratches to the product during the stripping process, without regrinding. , reduce the company's rework cost, improve the secondary yield, and at the same time, the stripping time is short, and the stripping yield is high, which can effectively protect the product's appearance transparency and roughness. The de-plating solution is an environmentally friendly agent, does not cause damage to the human body and the environment, has little environmental pollution, and has high industrial application value.

Owner:LENS TECH CHANGSHA

A composite function p-type electrode of vertical structure deep ultraviolet LED and its preparation method

ActiveCN107634126BImprove adhesionStable supportMaterial nanotechnologySemiconductor devicesUltravioletEvaporation

Owner:XI AN JIAOTONG UNIV

A kind of micro-led chip preparation and substrate peeling method

ActiveCN113299804BImprove work efficiencyLow costSemiconductor devicesThin membraneMaterials science

The invention discloses a method for preparing a Micro-LED chip and peeling off a substrate in the field of optoelectronic devices. The Micro-LED chip preparation and substrate peeling method includes the following steps: step 1, uniformly coating UV glue on a transparent substrate; step 2, growing Al on the transparent substrate coated with UV glue 2 O 3 Thin film and LED thin film structure; step three, in Al 2 O 3 A discrete Micro-LED structure is formed on the thin film and the LED thin film structure; step 4, irradiating the back of the transparent substrate with an ultraviolet surface light source, the transparent substrate and the Al 2 O 3 The UV glue between the films is desensitized and loses its viscosity, so as to achieve the purpose of separating the Micro-LED structure from the transparent substrate, forming a Micro-LED chip. The invention can quickly realize the peeling of the Micro-LED chip substrate, has high work efficiency, low cost and high yield.

Owner:NANJING RGB INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com