Patents

Literature

43results about How to "Single layer rate is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method of graphene oxide

The invention provides a preparing method of graphene oxide. The preparing method includes the following steps that concentrated sulfuric acid, graphite and fuming nitric acid are mixed for reaction, the product is cooled, potassium permanganate is added and mixed for reaction, then water is added to quench the reaction, and finally hydrogen peroxide is added to obtain graphene oxide. Compared with the prior art, fuming nitric acid is used as intercalator, and obtained graphene oxide is high in monolayer rate.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

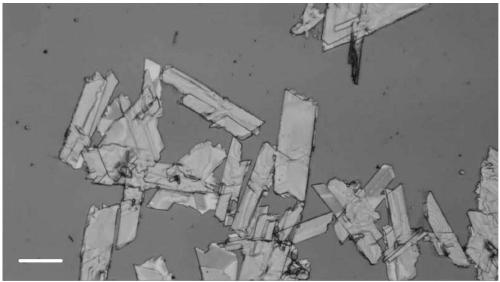

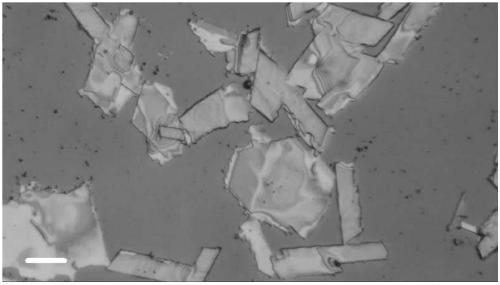

Method for preparing two-dimensional inorganic nanomaterial by mechanical force intercalation stripping

InactiveCN109250693AImprove stripping efficiencyShort manufacturing timeRare earth metal oxides/hydroxidesNitrogen compoundsHigh energyCrystal structure

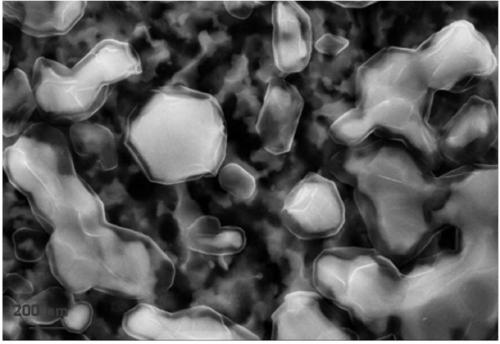

The invention relates to the technical field of inorganic nanomaterial preparation, and in particular, relates to a method for preparing a two-dimensional inorganic flaky nanomaterial by mechanical force intercalation stripping of a three-dimensional inorganic layered crystal material. With mixed metal halide as an intercalation and stripping medium, the purified layered inorganic crystal materialand the intercalation and stripping medium are subjected to solid-phase high-energy ball milling treatment together, mixed powder after ball milling treatment is washed with water to remove the intercalation and stripping medium, the three-dimensional layered material can be highly efficiently made into the corresponding two-dimensional flaky material. The method has universality for stripping ofthe inorganic non-metallic layered crystal material, has the advantages of simple preparation process, short production cycle, and high yield of the two-dimensional material, does not affect a crystal structure of the two-dimensional material, and the intercalation and stripping medium can be reused without causing environmental pollution.

Owner:深圳烯材科技有限公司

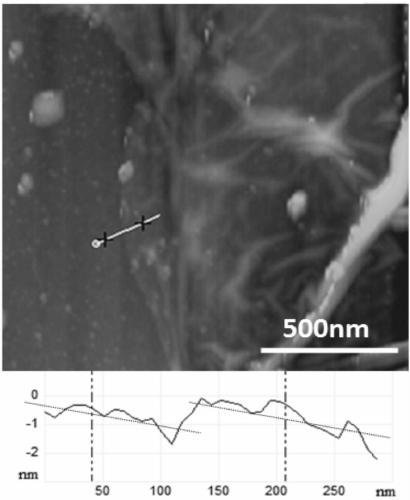

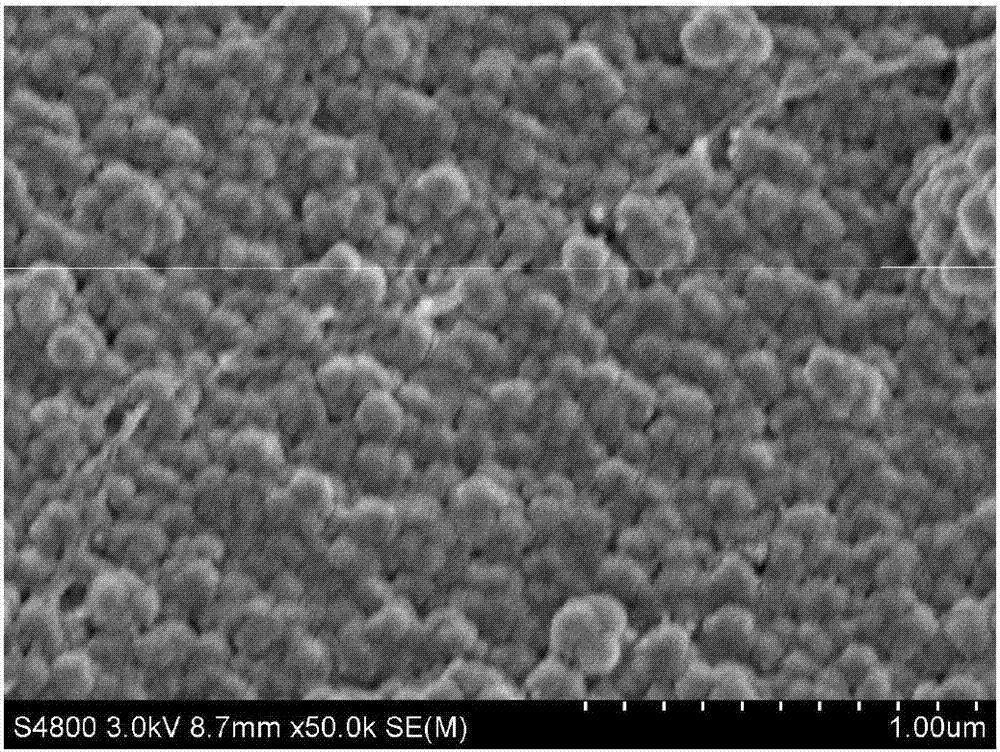

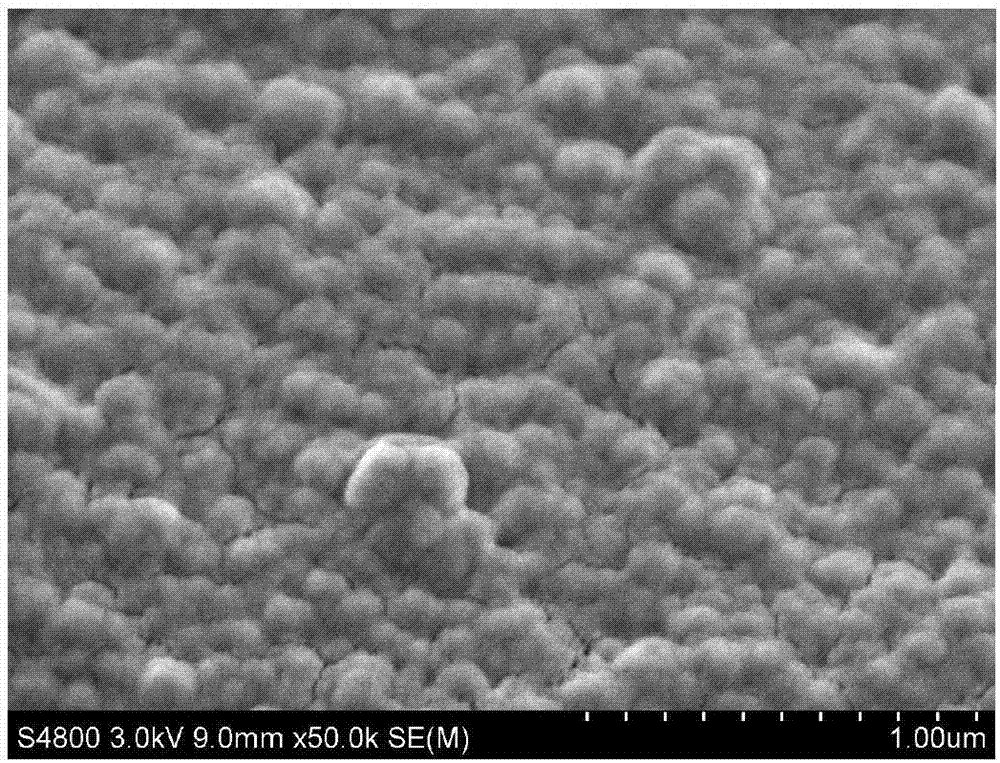

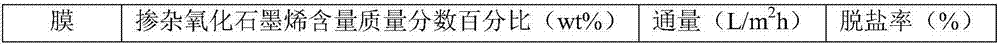

Preparation method of oxidized graphene doped hollow fiber nanofiltration membrane

InactiveCN106890570AHigh mechanical strengthExcellent salt rejectionReverse osmosisHollow fibreFiber

The invention provides a preparation method of an oxidized graphene doped hollow fiber nanofiltration membrane. The preparation method comprises the steps that a plurality of hollow fiber nanofiltration membrane serve as basic membranes to be packaged into a component shell to obtain a membrane component for usage; oxidized graphene, an active monomer and an acid absorbing agent are added into a solvent A for uniform ultrasonic mixing to obtain a solution A; multielementacyl chloride is dissolved in a solvent B to obtain a solution B; the solution A is introduced into the inner cavity of the hollow fiber nanofiltration membrane of the membrane component for full infiltration, the solution A is removed, drying is performed, the solvent B is introduced into the inner cavity of the membrane for interfacial polymerization reaction, then the solution B is removed, drying is performed, andpure-water rinsing and drying are performed to obtain the membrane. The oxidized graphene is added in the membrane preparation process and has the very good effect on the aspects of surface hydrophilicity improvement, membrane flux increase and pollution resistance. The product is good in mechanical strength andcontamination resistance and is higher than an oxidized-graphene-free pure polyamide nanofiltration membraneindesalting rate and water flux.

Owner:ZHEJIANG UNIV OF TECH

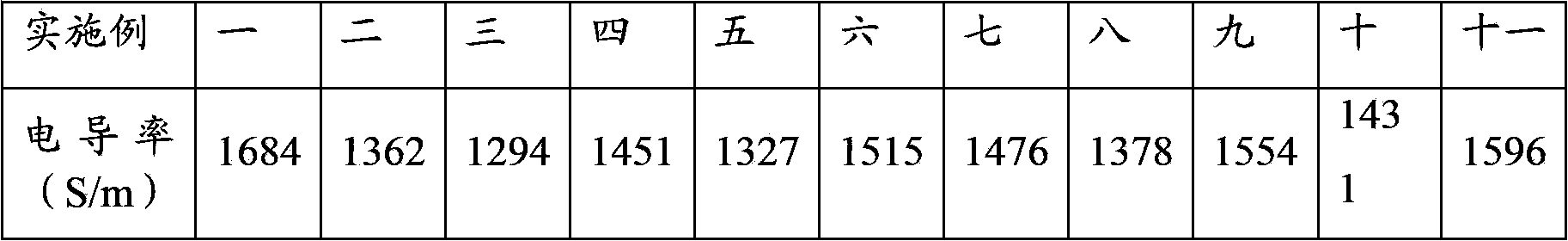

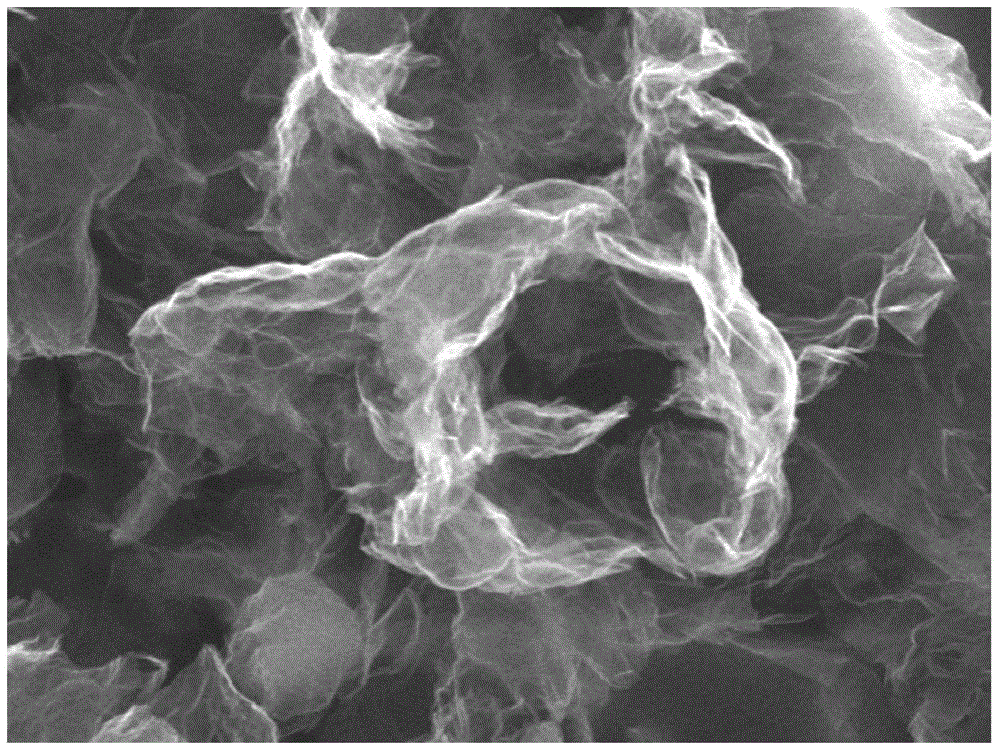

Preparation method for single-layer graphene dispersion liquid

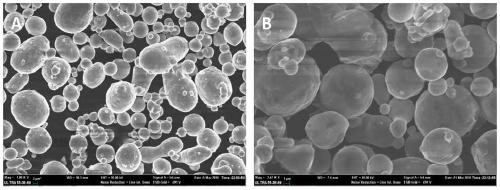

ActiveCN107857257AGood electrical and thermal conductivityAvoid reunionSingle layer grapheneSlurrySingle layer graphene

The invention provides a preparation method for single-layer graphene dispersion liquid. The preparation method comprises the following steps: providing natural crystalline flake graphite, carrying out oxidation treatment, and preparing oxide graphite slurry; adding deionized water into the oxide graphite slurry, breaking and stripping through a high-pressure homogenizer until graphene oxide of which the average thickness is 0.4-0.7nm and the average sheet diameter is 0.8-10mu m is obtained; after the graphene oxide is subjected to freeze drying, introducing nitrogen and hydrogen mixed gas tobe subjected to program temperature rise treatment, and then, cooling to room temperature to obtain single-layer graphene powder; putting the single-layer graphene powder in an atomizing stirrer, taking ethanol solution which contains dispersing agent as spray, carrying out spraying drying under the conditions that revolving speed is 300-1000rpm and temperature is 70-100 DEG C, and continuously stirring to obtain the modified single-layer graphene powder after the spraying drying is finished; dissolving the modified single-layer graphene powder into organic solvent to be subjected to ultrasonic dispersion treatment to obtain the single-layer graphene dispersion liquid.

Owner:YAHAM OPTOELECTRONICS CO LTD

Preparation method for preparing graphene dispersion liquid by electrochemical swelling

InactiveCN109553093AGood dispersionImprove production efficiencyGrapheneElectrolysisQuaternary ammonium cation

The invention belongs to the field of material preparation, and relates to a preparation method for preparing a graphene dispersion liquid by electrochemical swelling. The method comprises the following steps: (1) taking graphite sheets as a cathode and taking a graphite substrate as a cathode to carry out electrolysis on the electrodes in an electrolytic tank, wherein the electrolyte is an acetonitrile solution dissolved with a quaternary ammonium salt, and the concentration of the quaternary ammonium salt is 5-10 mg / mL; (2) rinsing the cathode by using a rinsing solution containing a dispersing agent, carrying out ultrasonic stripping on the solution subjected to rinsing to form a dispersion, then centrifuging the dispersion, washing the dispersion by using isopropyl alcohol to remove the excess dispersing agent; and (3) separating solid impurities to obtain the graphene dispersion liquid. According to the method, the graphene nanosheets are swelled and dispersed through an electrochemical method, quaternary ammonium salt cations are inserted into interlayers of the graphene, and then interlayer expansion is achieved, and preparation efficiency of the graphene dispersion liquid is improved.

Owner:厦门十一维科技有限公司

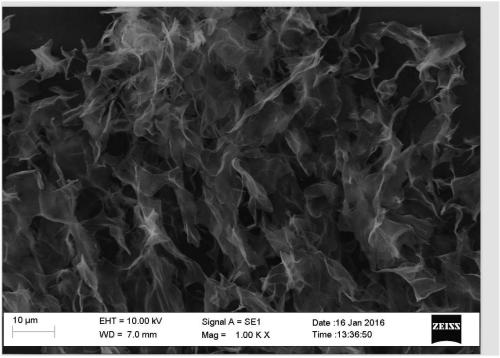

Graphene-ionic liquid composite material and preparation method thereof, combined electrode and preparation method thereof and electrochemical capacitor

InactiveCN103794371AImprove power densityFacilitate conductionElectrolytic capacitorsDispersityChloride

The invention discloses a preparation method of a graphene-ionic liquid composite material. The method comprises that: chloride intercalation graphite is taken to be added into the fused ionic liquid, the obtained mixed liquor after even stirring is placed in a constant parallel magnetic field to be centrifuged and supernatant is removed so that graphene is obtained; and the graphene is immersed into the ionic liquid again, filtering is performed and the filtered material is dried so that the graphene-ionic liquid composite material is obtained. The invention also discloses the graphene-ionic liquid composite material prepared via the aforementioned preparation method, a graphene-ionic liquid combined electrode prepared by the composite material and the preparation method thereof and an electrochemical capacitor prepared by the combined electrode. Defects of liable agglomeration and small specific area when the existing graphene acts as an electrode material independently can be overcome. Under the premise of not destroying the structure of the graphene, the graphene-ionic liquid composite material with high single-layer rate and great dispersity can be prepared so that preparation efficiency is high, cost is low and industrialization is easy to realize.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

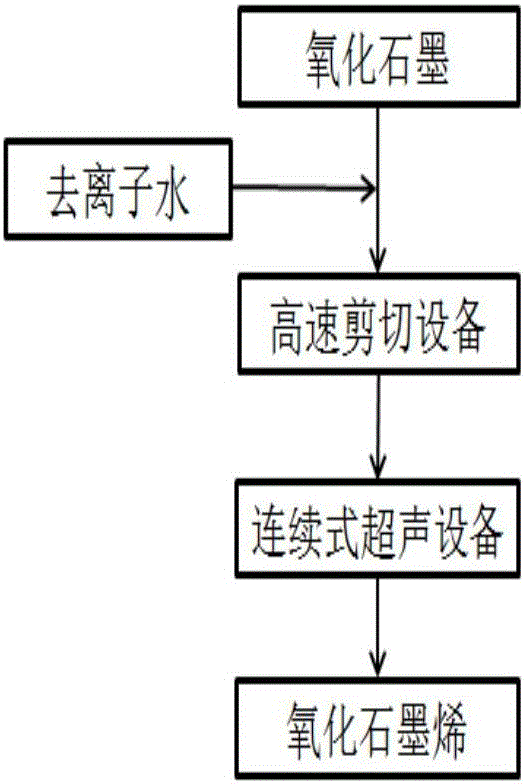

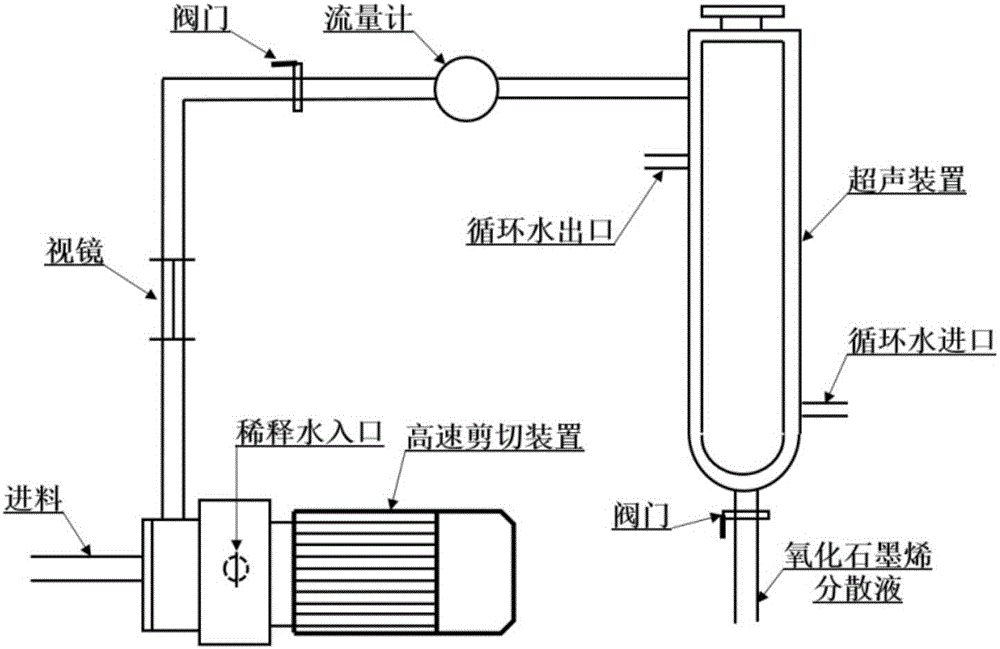

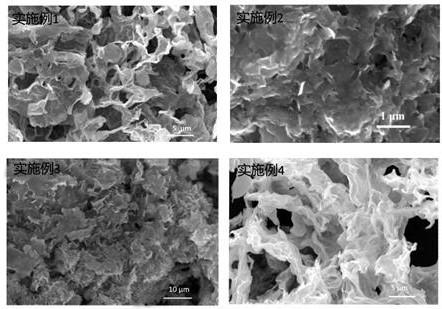

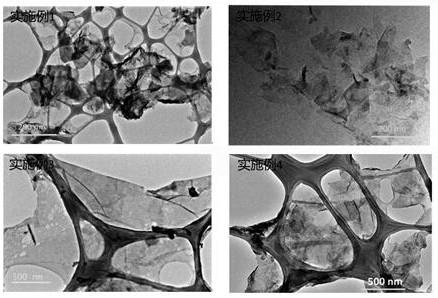

Method for large-scale, continuous and efficient graphite oxide stripping

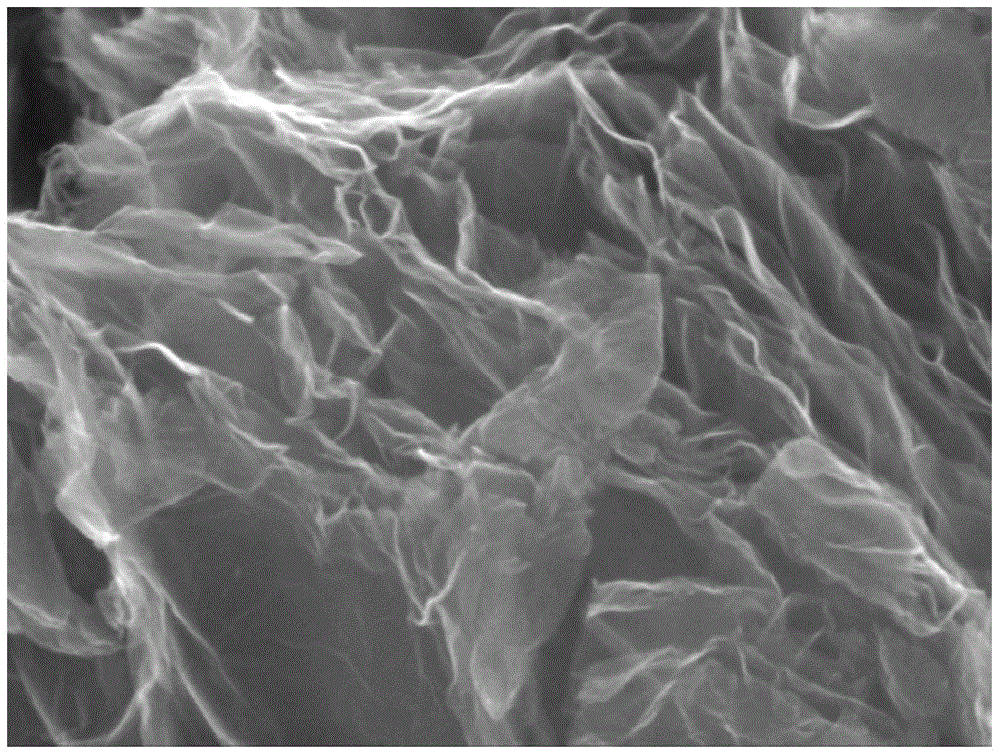

ActiveCN106219535ASingle layer rate is highIncrease concentrationSingle layer grapheneCvd grapheneGraphite oxide

The invention provides a method for large-scale, continuous and efficient graphite oxide stripping. The method comprises the following steps that purified and diluted graphite oxide dispersion liquid is delivered to a high-speed shear device, a high-speed water flow produced in the process of a high-speed mechanical shear method bumps and impacts graphite oxide to perform rapid macroscopic dispersion and partial stripping of graphite oxide; the graphite oxide dispersion liquid is introduced to a continuous ultrasonic device, the partially stripped graphite oxide having good macroscopic dispersion is rapidly stripped to obtain a single layer by virtue of a high-pressure and high-speed microjet produced by the ultrasonic cavitation effect in the process of an ultrasonic stripping method, and the microcosmic, uniformly dispersed and stable graphite oxide dispersion liquid is obtained. The method strengthens dispersion and stripping of the graphite oxide through a coupling shear field and an ultrasonic field, the obtained graphene oxide is high in single-layer rate, high in concentration and controllable in size, has the advantages of being continuous and rapid in production process, high in production efficiency, low in cost and the like and is suitable for large-scale production of graphite oxide and graphene.

Owner:NANJING UNIV OF TECH

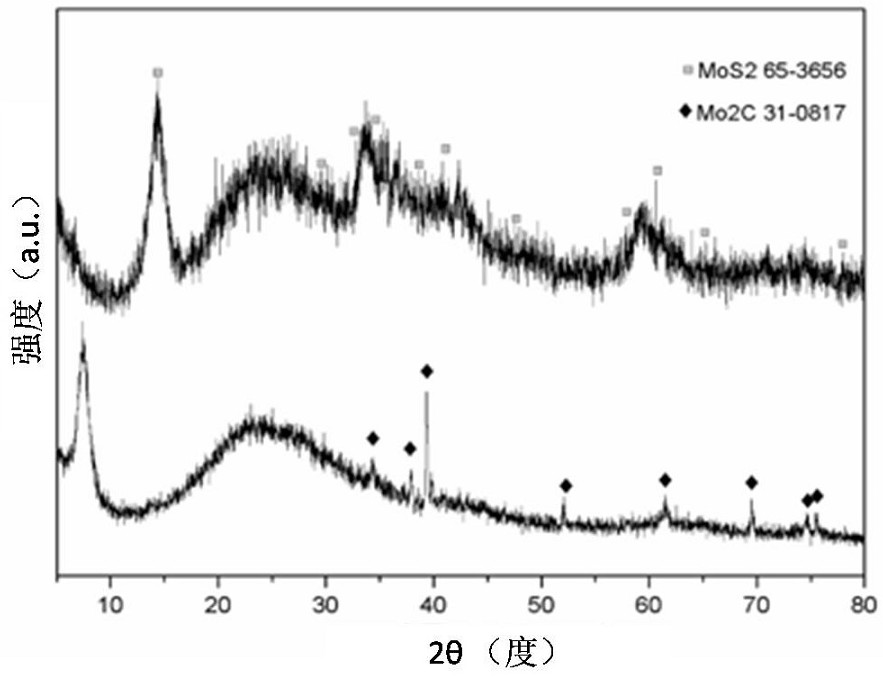

Preparation method of two-dimensional MoS2 nanosheet

InactiveCN110028103AGood size controlImprove stabilityMaterial nanotechnologyTin compoundsVacuum dryingAlkali metal

The invention discloses a preparation method of a two-dimensional MoS2 nanosheet, and belongs to the field of nano materials. The preparation method of the two-dimensional MoS2 nanosheet comprises thefollowing steps: adding a certain amount of molybdenum disulfide polycrystal or ground MoS2 polycrystal powder into a certain volume of strong-activity alkali metal organic reagent under the condition of inert gas in a glove box, placing a sealed reaction kettle into a constant-temperature heating box at the temperature of 30-150 DEG C, and carrying heat treatment for 2-100 h; and completing reaction to obtain a black intercalation compound, after vacuum drying, adding the obtained intercalation compound powder into deionized water, meanwhile, carrying out ultrasonic-assisted stripping to prepare a single-layer MoS2 nanosheet in a stripping manner, and then carrying out ultrasonic crushing or grinding treatment on the polycrystalline MoS2 powder according to different sheet diameter requirements to obtain the nanosheet which is high in single-layer rate and controllable in size. The specific surface area of an electrode material is increased, and the excellent conductivity of the electrode material is guaranteed.

Owner:南京倍格电子科技有限公司

Graphene/ionic liquid composite material and preparation method thereof, graphene/ionic liquid combined electrode and electrochemical capacitor

InactiveCN103794372AGood dispersionSingle layer rate is highElectrolytic capacitorsDispersityGraphite

The invention discloses a preparation method of a graphene / ionic liquid composite material. The method comprises that: chloride intercalation graphite is taken to be added into the fused ionic liquid, stripping is performed under the effect of an alternating electric field, the obtained mixed liquor is centrifuged and supernatant is removed so that graphene is obtained; and the graphene is immersed into the ionic liquid again, filtering is performed and the filtered material is dried so that the graphene / ionic liquid composite material is obtained. The invention also discloses the graphene / ionic liquid composite material prepared via the aforementioned preparation method, a graphene / ionic liquid combined electrode manufactured by the composite material and the preparation method thereof and an electrochemical capacitor manufactured by the combined electrode. Defects of liable agglomeration and small specific area when the existing graphene acts as an electrode material independently can be overcome. Under the premise of not destroying the structure of the graphene, the graphene / ionic liquid composite material with high single-layer rate and great dispersity can be prepared so that preparation efficiency is high, source of raw materials is wide, cost is low and industrialization is easy to realize.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

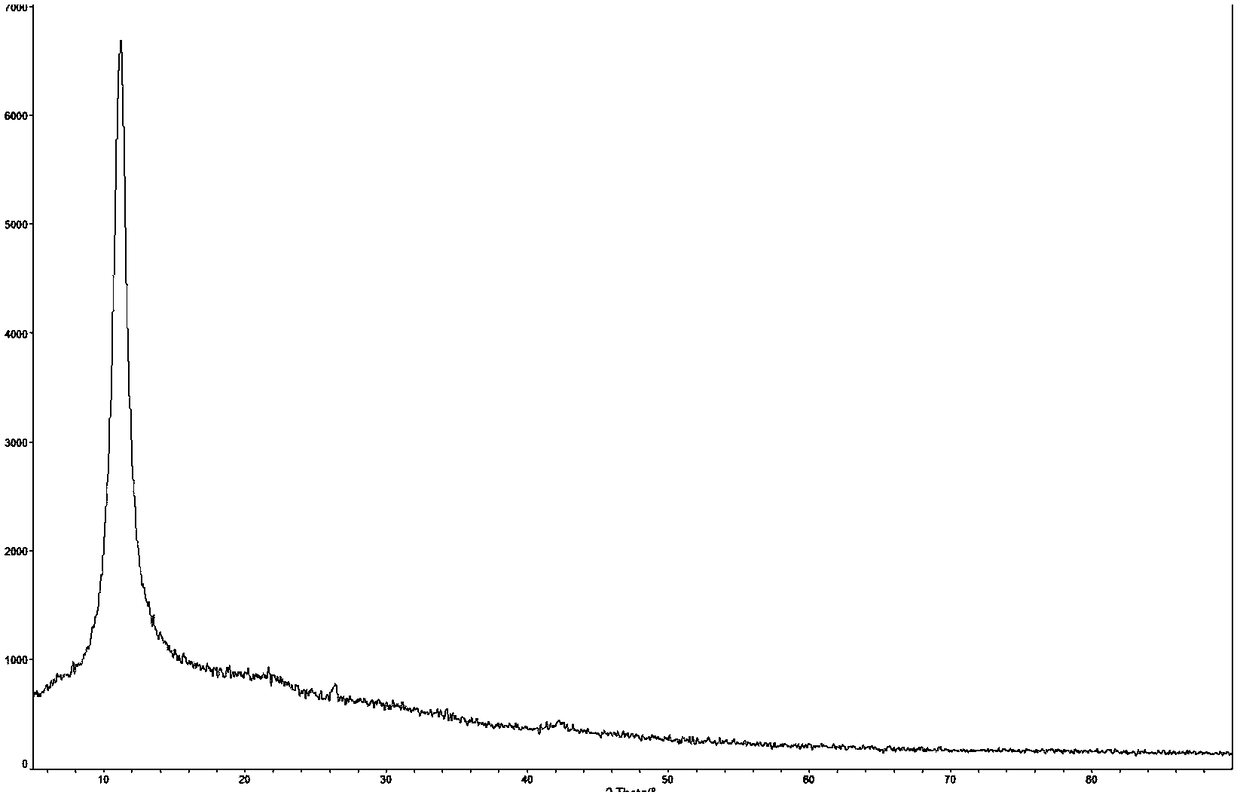

Preparation method of graphene oxide with hydrogen peroxide catalyst system

The invention belongs to the field of graphene technology, and particularly relates to a preparation method of graphene oxide. The preparation method particularly includes the steps: (1) raw materialpretreatment: uniformly mixing graphite and deionized water, adjusting the pH (potential of hydrogen) value of the system, and performing heating reaction to obtain acid mixed materials; (2) oxidization: cooling the acid mixed materials, and adding Fenton's reagents and deionized water to react mixture to obtain graphite oxide solution; (3) washing: centrifuging and washing the graphite oxide solution to reach neutral; (4) ultrasound: performing dilution, ultrasound and freeze drying on the solution acquired in the step (3) to obtain a graphene oxide product. The preparation method is simple to operate, mild in condition and free from pollution, and the prepared graphene oxide is high in monolayer rate.

Owner:嘉兴烯成新材料有限公司

Graphene-ionic liquid composite material and preparation method thereof, graphene-ionic liquid composite electrode and preparation method thereof, and electrochemical capacitor

InactiveCN104008886AComplete structureSingle layer rate is highHybrid capacitor electrodesHybrid/EDL manufactureIonCvd graphene

The invention discloses a preparation method of a graphene-ionic liquid composite material. The preparation method comprises mixing intercalated graphite with a molten ionic liquid in a solid-liquid ratio of 1g:10-100mL, stirring the mixture uniformly, and then putting the mixture into a microwave oven for stripping for 10 to 100 minutes with power being 1,000 to 2,000w, and obtaining the graphene-ionic liquid composite material. The invention further discloses the graphene-ionic liquid composite material made by using the preparation method, a graphene-ionic liquid composite electrode including the graphene-ionic liquid composite material, a preparation method of the graphene-ionic liquid composite electrode, and an electrochemical capacitor. The graphene-ionic liquid composite material which is intact in laminated structure, high in single layer rate and good in dispersibility is made by placing the intercalated graphite into the ionic liquid for microwave stripping. The prepared composite electrode does not need to use an adhesive or to prepare a current collector, and therefore the internal resistance of the electrode and the contact resistance are reduced, and the power density and energy density of the electrochemical capacitor are improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Synthesis method of two-dimensional transition metal chalcogenide

ActiveCN112678826AHigh yieldTopological transformation reaction heightMaterial nanotechnologyTitanium carbidePhysical chemistryReaction temperature

The invention discloses a synthesis method of a two-dimensional transition metal chalcogenide, which comprises the following steps: heating: heating a transition metal compound raw material to a reaction temperature in an inert gas environment; topological conversion reaction step: introducing a gas containing a chalcogen or a mixed gas of the gas containing the chalcogen and the gas containing the phosphorus, and maintaining the reaction temperature for a set period of time, so that the chalcogen, or the chalcogen and the phosphorus are subjected to a topological conversion reaction with the transition metal compound raw material, and generating the two-dimensional transition metal chalcogenide. The synthesis method has the advantages of high reaction degree, high yield, low energy consumption and high efficiency, the obtained two-dimensional transition metal chalcogenide is high in single-layer rate and narrow in layer number distribution, macro preparation can be realized, and the synthesis method has an excellent industrial application prospect.

Owner:济南三川新材料科技有限公司

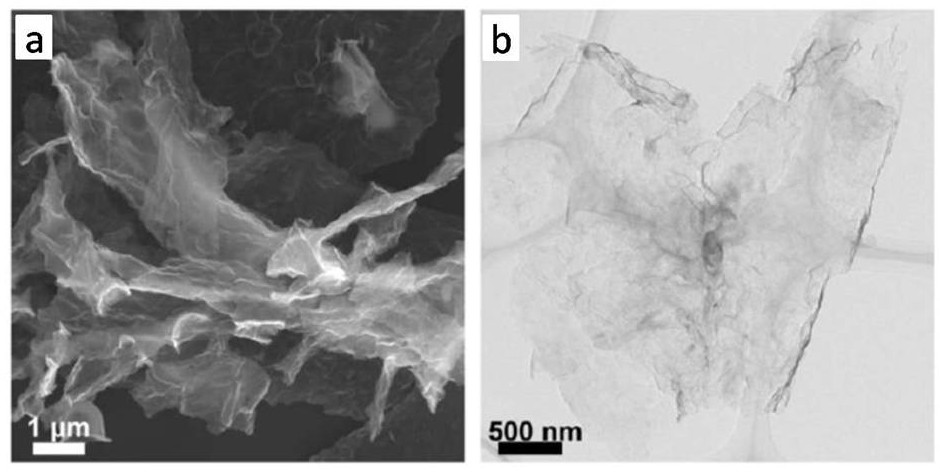

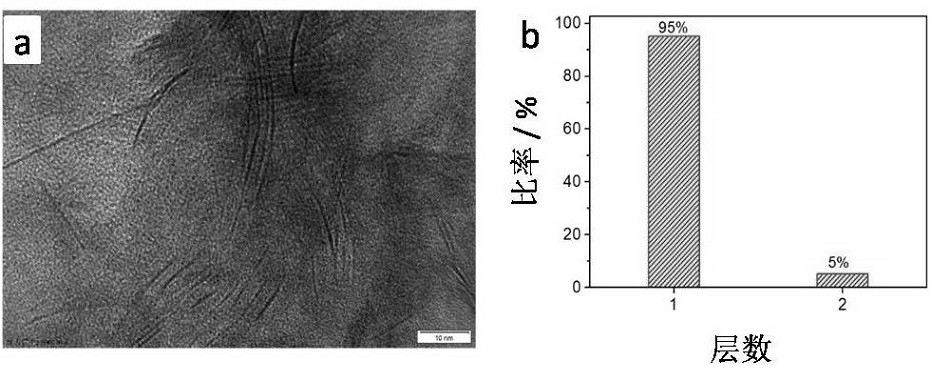

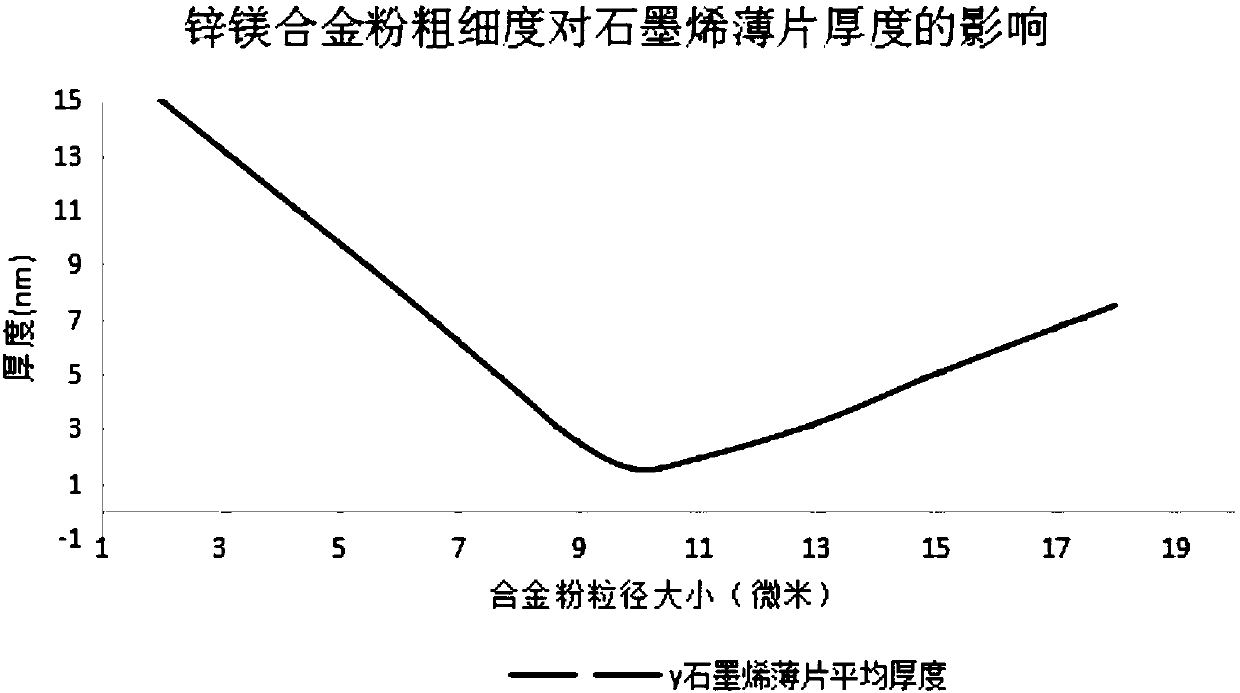

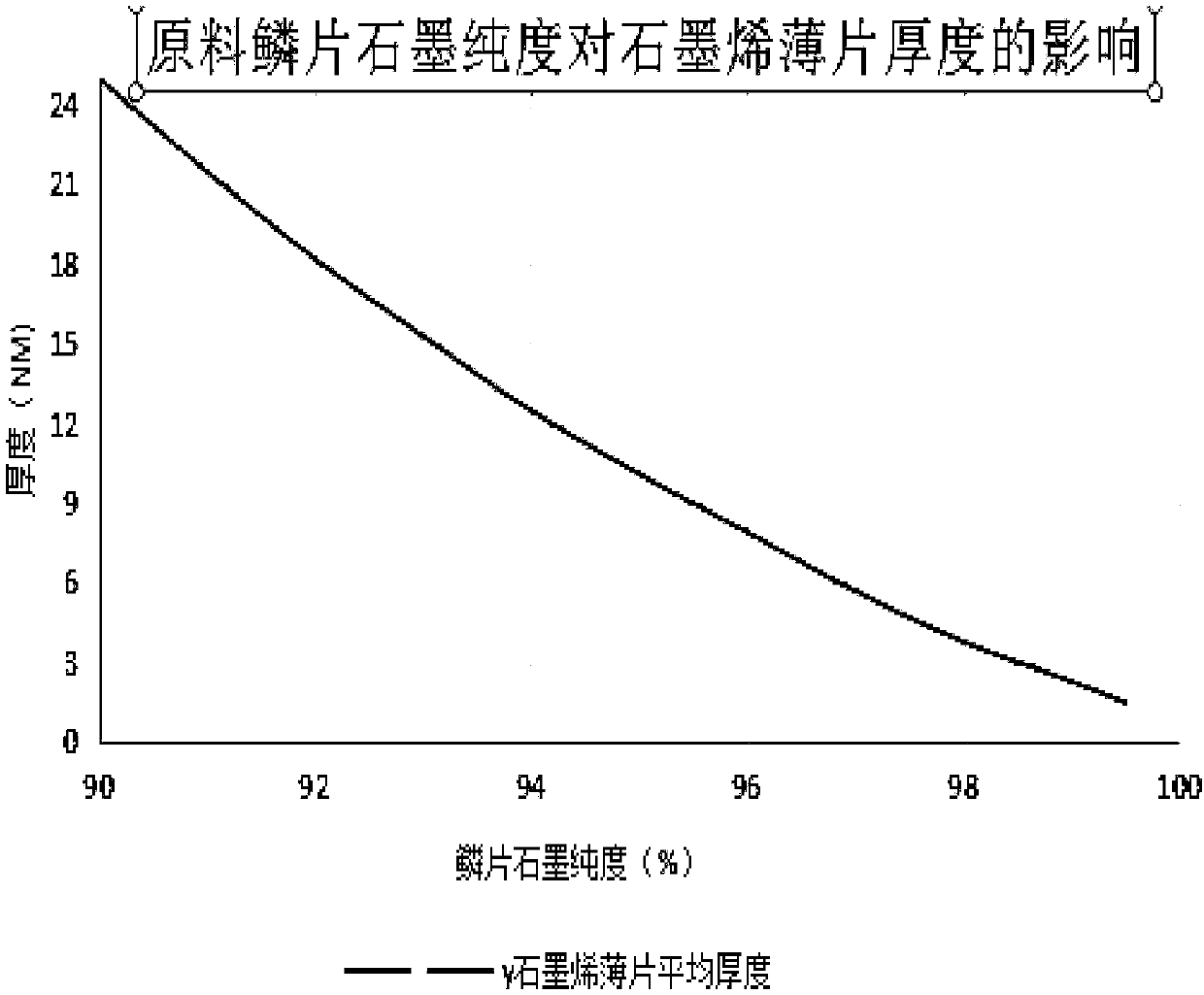

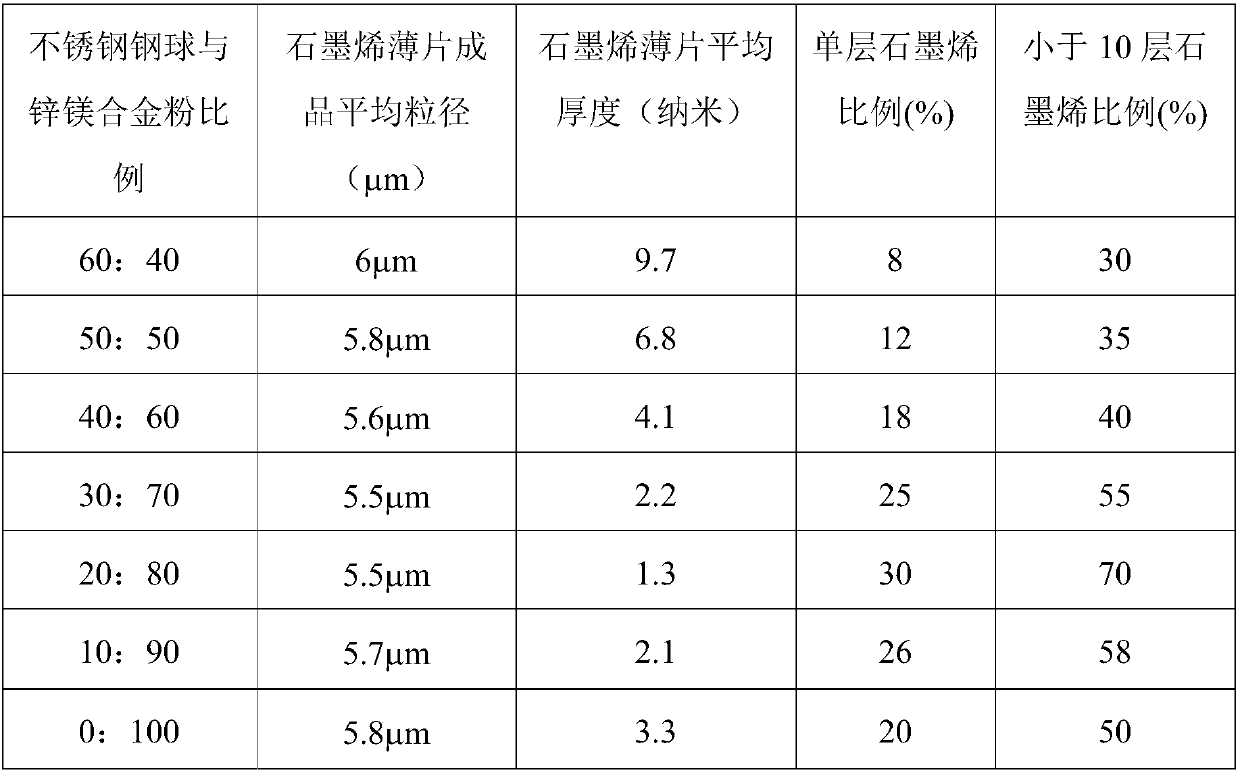

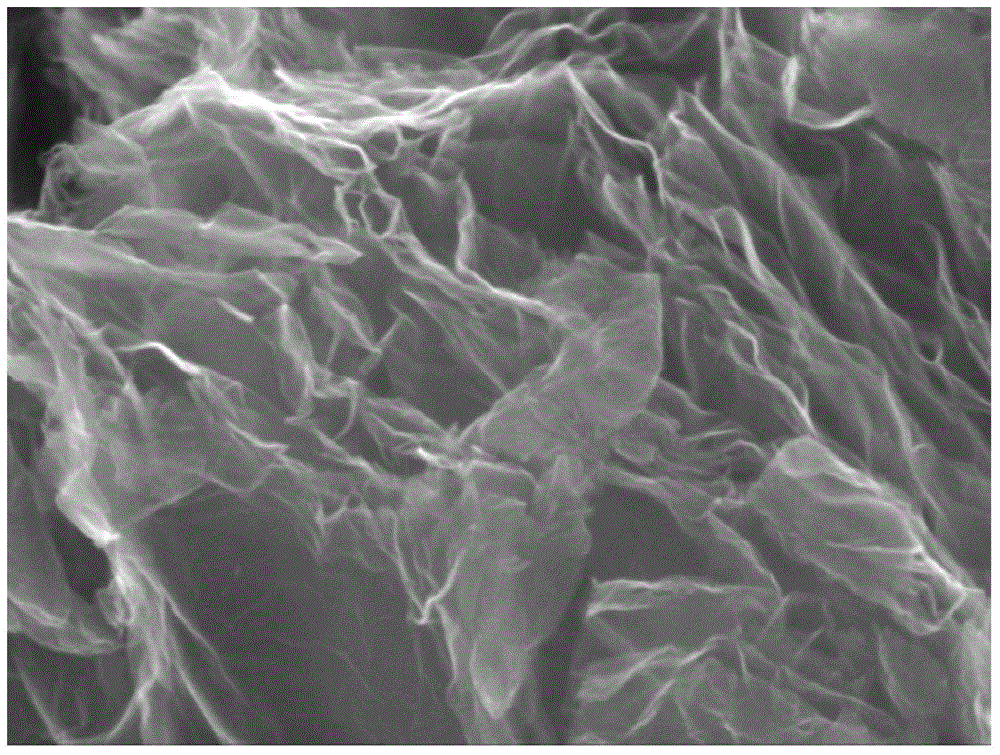

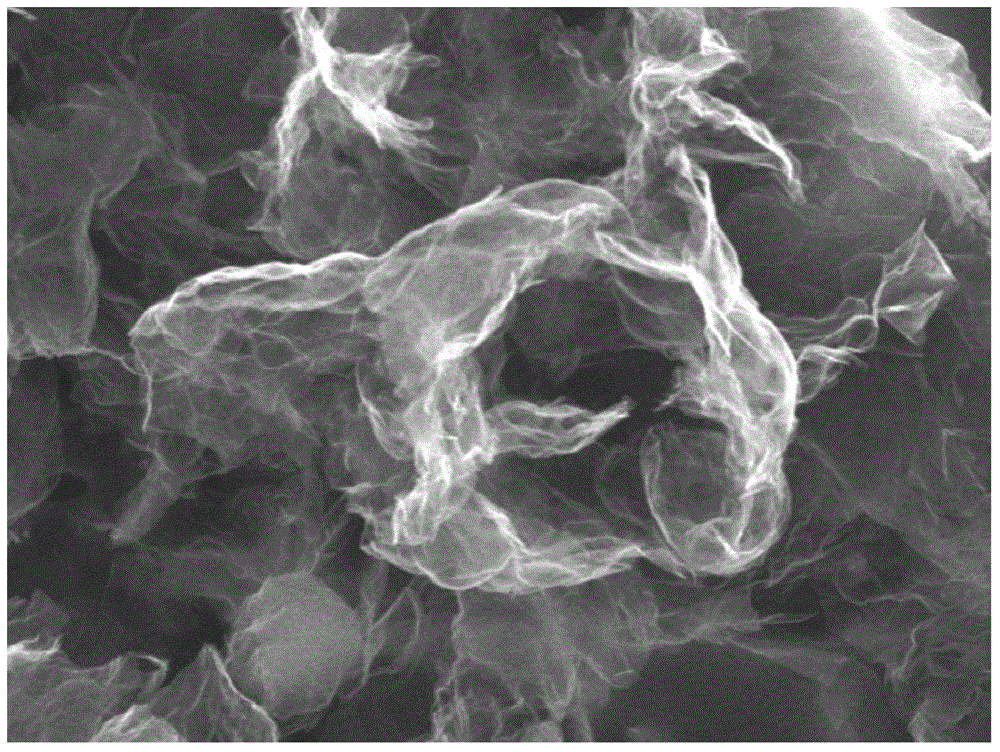

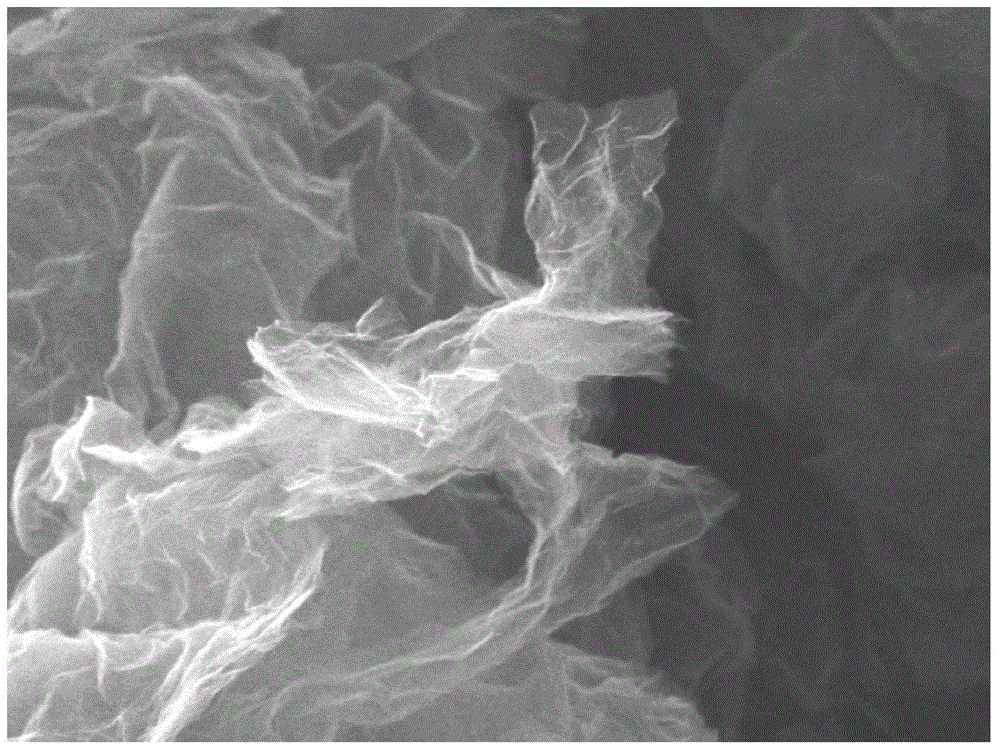

Graphene physical stripping production method and graphene produced through method

The invention provides a graphene physical stripping production method and a graphene produced through the method. The method comprises the steps that high-purity flaky graphite is used as a raw material for producing graphene, steel balls and zinc-magnesium alloy powder is used as a ball-milling stripping medium, and the flaky graphite and the ball-milling stripping medium are put into a ball grinding mill and are subjected to ball-milling stripping under nitrogen protection; after completion of stripping, graphene flakes subjected to ball-milling stripping are separated out through air classification under inert gas shielding. The whole production process is easy to operate and free of generation of pollutants.

Owner:李文辉

Method for quickly preparing high-performance graphene

The invention discloses a method for quickly preparing high-performance graphene. The method comprises the steps of putting graphite oxide into a reactor, vacuumizing the reactor, treating the graphite oxide by three-stage gradient microwave radiation, and peeling off the graphite oxide expanded with heat, thus obtaining high-performance graphene. The method has the advantages of high production efficiency, low production cost, high safety and reliability in the operation process and high product quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of single-layer graphene pyridine solution

InactiveCN103723710AEvenly dispersedSingle layer rate is highCarbon compoundsPotassium nitrateInorganic salts

The invention discloses a preparation method of a single-layer graphene pyridine solution. According to the method, natural graphite, calcium nitrate, potassium nitrate, concentrated sulfuric acid and potassium permanganate are mixed and processed to obtain a graphite oxide solution, after the graphite oxide solution is prepared into an aqueous single-layer graphene oxide solution, hydrobromic acid is added for a reaction, an aqueous single-layer graphene solution is obtained, then pyridine is added into the aqueous graphene solution, and extraction and reduced pressure distillation are performed through an inorganic salt saturated solution to obtain the graphene pyridine solution. According to the method, the single-layer graphene pyridine solution with high single layer rate, high compositing feature and uniform dispersion is prepared finally after multiple times of ultrasonic stripping.

Owner:北京纳新天地科技发展有限公司

Continuous production device for aminated graphene and method

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

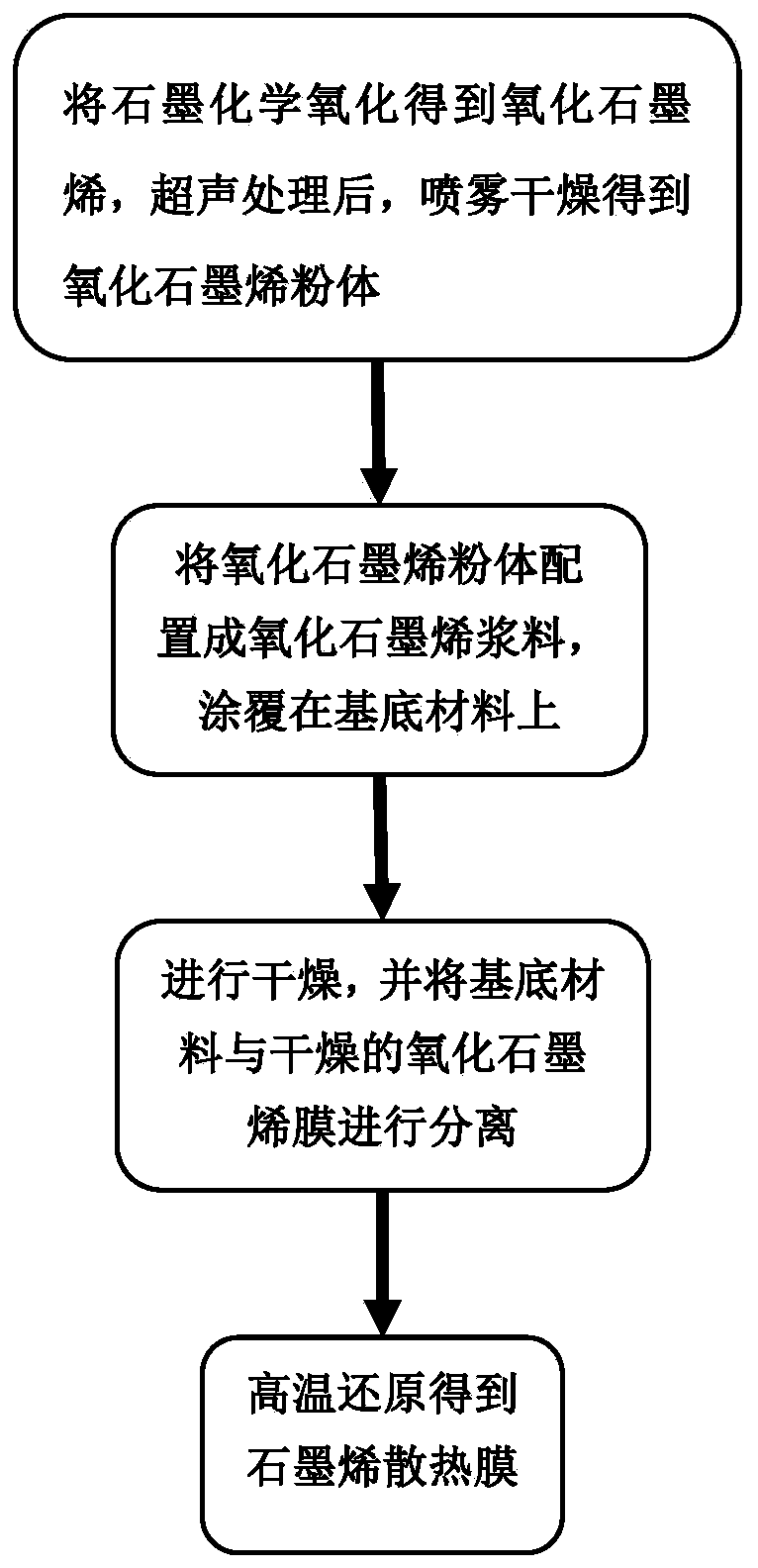

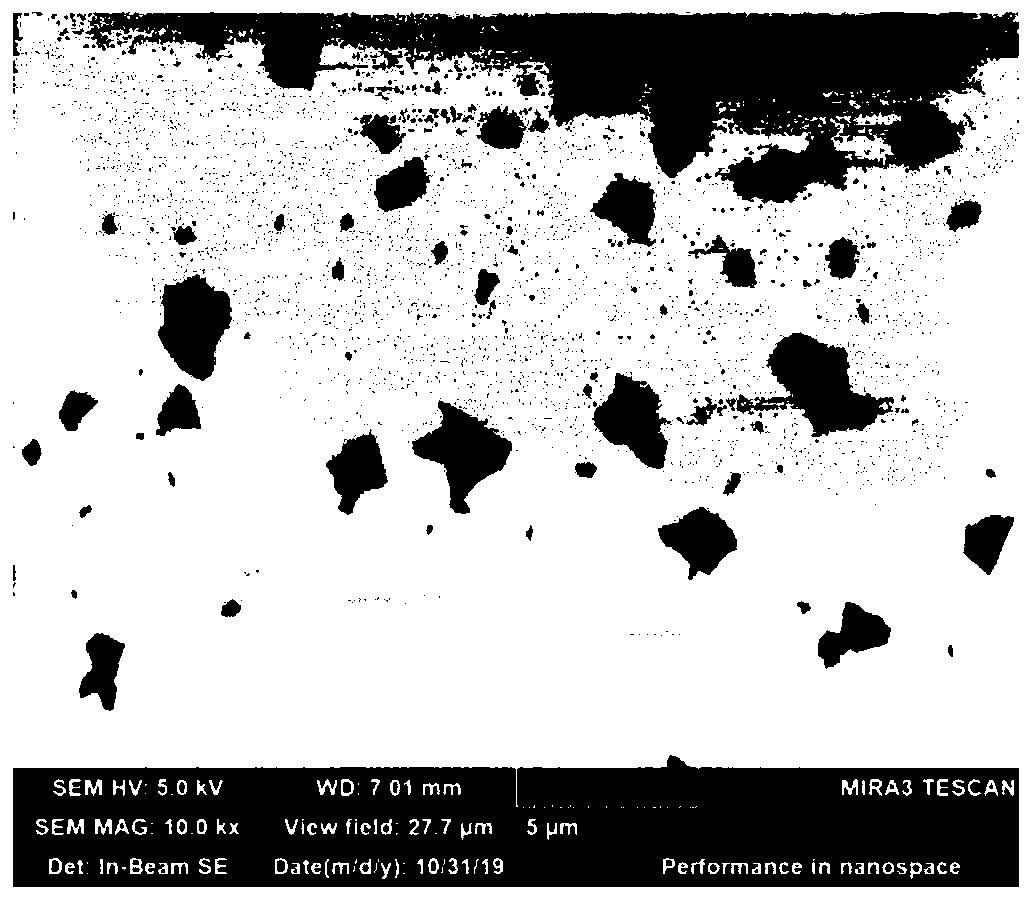

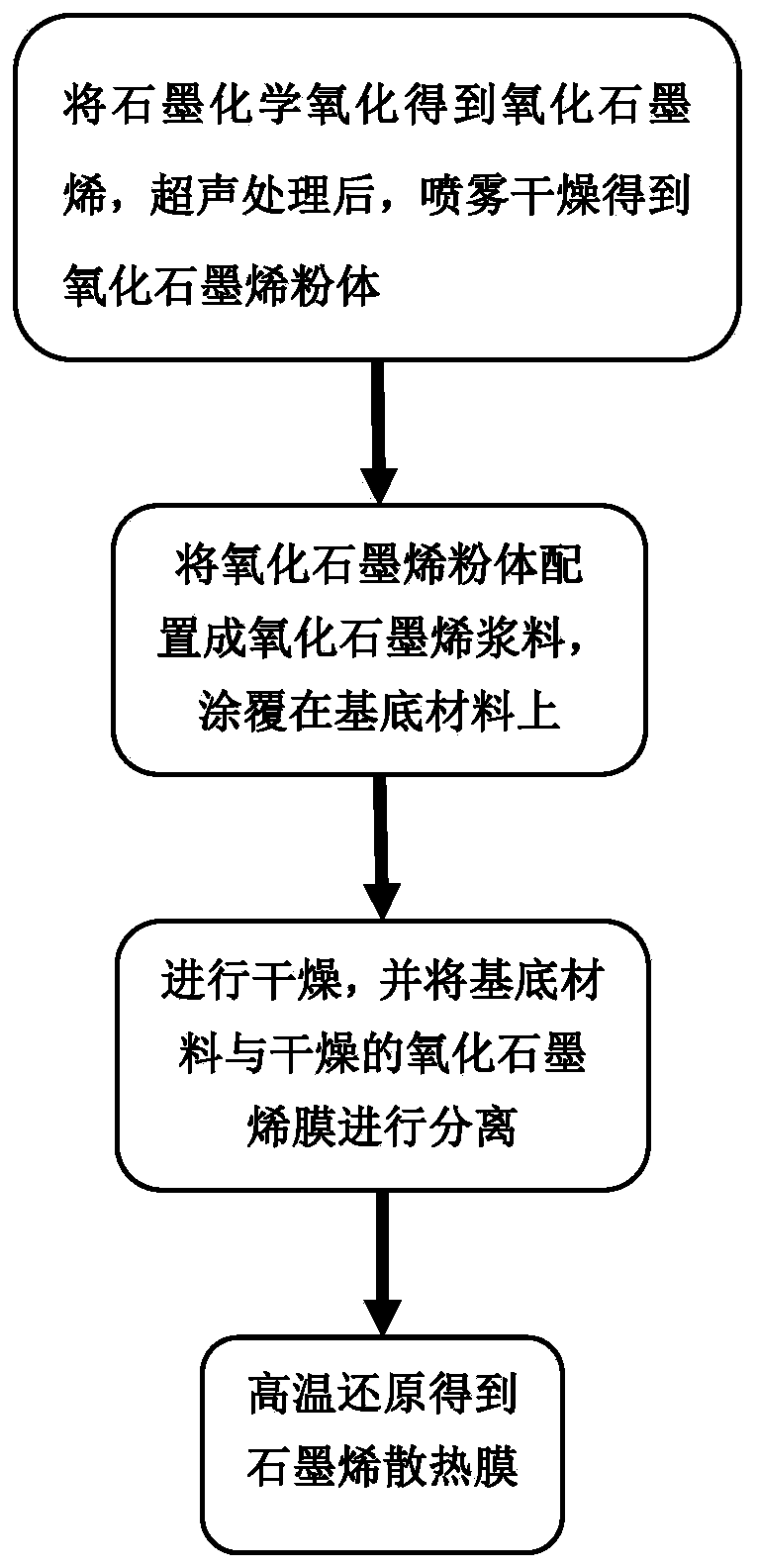

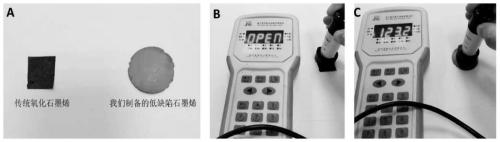

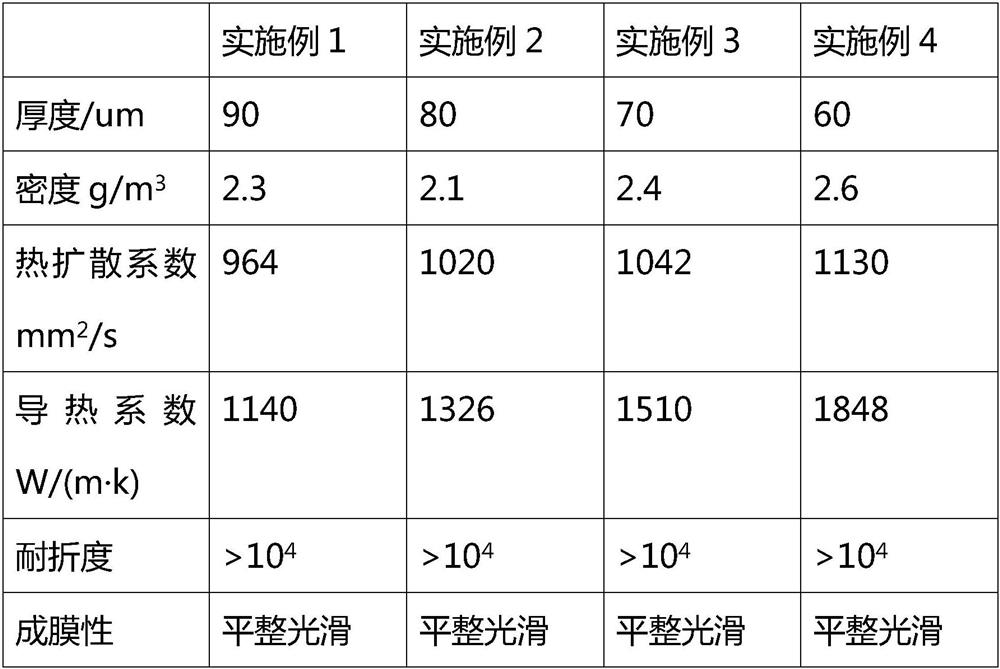

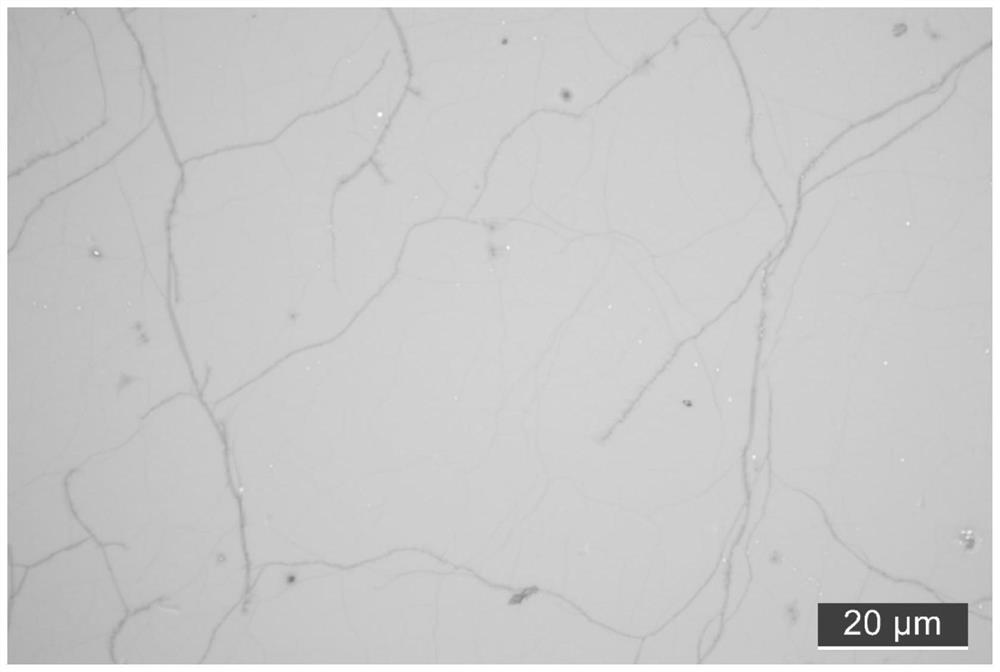

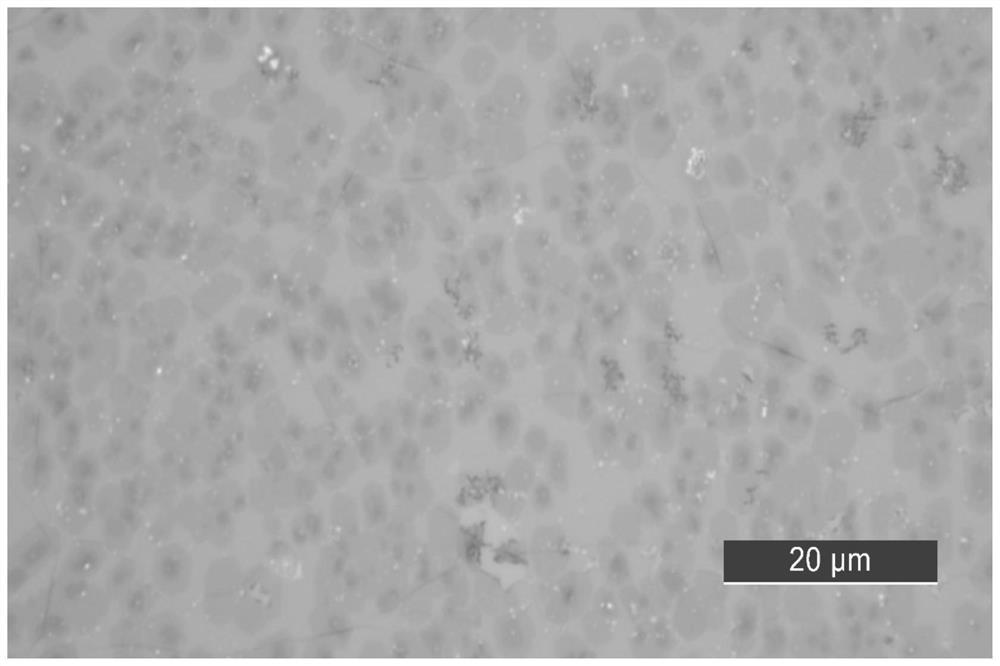

Graphene heat dissipation film and preparation method thereof

PendingCN111137878AImprove thermal conductivityWide variety of sourcesGrapheneModifications by conduction heat transferSlurrySpray dried

The invention relates to a graphene heat dissipation film and a preparation method thereof, the graphene heat dissipation film is only composed of graphene, and the graphene is obtained by high temperature reduction of graphene oxide obtained by ultrasonic treatment after chemical oxidation of graphite with bismuthate under a strong acid condition. The preparation method comprises the following steps: S1, chemically oxidizing crystalline flake graphite by using bismuthate under a strong acid condition, washing the product until the pH value is 5-7, carrying out ultrasonic treatment to obtain agraphene oxide aqueous dispersion liquid, and carrying out spray drying to obtain graphene oxide powder; S2, preparing the graphene oxide powder into slurry, and coating a substrate material with thegraphene oxide slurry; s3, drying the substrate material coated with the graphene oxide slurry, and separating the substrate material from the dried graphene oxide film; and S4, performing high-temperature reduction on the dried graphene oxide film to obtain the graphene heat dissipation film. The graphene heat dissipation film provided by the invention has the characteristics of low cost and good heat dissipation performance, and can be suitable for 5G mobile phones.

Owner:中科悦达(上海)材料科技有限公司

Preparation method of low-defect graphene coated aluminum powder particles

ActiveCN110449574AReduce the degree of oxidationImprove conductivityTransportation and packagingMetal-working apparatusAlloyMicroparticle

The invention provides a preparation method of low-defect graphene coated aluminum powder particles. The preparation method comprises the following steps that 1) graphite is taken as an electrode, metal platinum is taken as a counter electrode, the electrode is inserted into an electrolyte aqueous solution and is connected to positive and negative electrodes of a direct current power supply, voltage is applied, current is introduced, and the graphite is expanded and dispersed in an electrolyte solution; 2) the collected expanded graphite powder is washed with water to remove electrolyte components, and then is dispersed in an organic solution, and ultrasonic treatment is carried out to obtain a graphene uniform dispersion liquid; and 3) aluminum powder or aluminum alloy powder is added into the graphene dispersion liquid, stirred and mixed, and then filtered and dried to obtain the composite aluminum powder material coated with the graphene coated aluminum powder. The graphene in the prepared graphene aluminum powder composite material is tightly adsorbed on the surface of the aluminum powder particles, the graphene oxidation degree is low, the structure and the chemical defects are few, and the electric conductivity and the heat conductivity of the composite material are high.

Owner:上海世系新材料有限公司

High-energy catalytic physical stripping preparation method of graphene

The invention relates to a high-energy catalytic physical stripping preparation method of graphene, relates to the technical field of graphene materials, and solves the problem that a conventional physical stripping method is high in cost and not easy to be mass-produced. The method specifically comprises the following steps: performing preliminary infiltration on pure water, performing first high-energy ultrasonic preliminary stripping, adding SiC for ball milling, then performing second high-energy catalysis for stripping, classifying graphene flakes by gas flow classification and spray-drying to obtain the graphene; by infiltration, ultrasonic treatment, SiC ball milling, addition of a surfactant and the secondary high-energy ultrasonic treatment, the graphene is stripped layer by layer, the process is mild, and basically no crushing and wear phenomena occur; the prepared graphene crystal lattice structure is complete and processed by a physical stripping method, the graphene flakesare present in a completely powdery form, the storage and use environments are not restricted, and the industrial production cost is relatively low, thereby facilitating the wider application of graphene in various industries.

Owner:大同墨西科技有限责任公司

A preparation method of single-layer porous graphene reinforced carbon fiber fishing rod

The invention discloses a preparation method of a single-layer porous graphene enhanced carbon fiber fishing rod, and belongs to the technical field of high polymer materials. The preparation method is characterized by comprising the steps that expanded graphite is separated into graphene microfilm dispersible fluid at first, the graphene microfilm dispersible fluid is subjected to spray drying toform graphene microfilm powder, the powder is oxidized and subjected to microwave treatment in NMP dispersion fluid to prepare a single-layer porous graphene precursor, the precursor is activated through strong base, and single-layer porous graphene with many holes and the large hole diameter is obtained and compounded with carbon fiber to obtain a carbon fiber cloth material, and finally the material is cut and rolled to form the fishing rod. The carbon fiber can be easily wrapped by the single-layer porous graphene, an enough channel is provided for circulation of resin between the carbon fiber cloth, an organic whole with good continuity is formed between the graphene and the carbon fiber and between the carbon fiber, so that the stretching bending strength of the carbon fiber fishingrod is greatly improved, and the fishing weight of the fishing rod is remarkably improved.

Owner:陈川莲 +2

A kind of preparation method of graphene oxide

The invention provides a method for preparing graphene oxide, comprising the following steps: A) mixing concentrated sulfuric acid, graphite and fuming nitric acid, then cooling the temperature, adding potassium permanganate, adding water after the mixing reaction to quench the reaction, and finally adding Hydrogen peroxide to obtain graphene oxide. Compared with the prior art, the present invention adopts fuming nitric acid as the intercalating agent, so that the obtained graphene oxide monolayer rate is higher.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Graphene/ionic liquid composite material and preparation method thereof, combined electrode and preparation method thereof and electrochemical capacitor

The invention discloses a preparation method of a graphene / ionic liquid composite material. The method comprises that: chloride intercalation graphite is taken to be added into the fused ionic liquid, ultrasonic stripping is performed for 0.5-24 hours and then the obtained mixed liquor is placed in a constant electric field to be centrifuged, and supernatant is removed so that graphene is obtained; and the graphene is immersed into the ionic liquid again, the ionic liquid is removed via filtering and the filtered material is dried so that the graphene / ionic liquid composite material is obtained. The invention also discloses the graphene / ionic liquid composite material prepared via the aforementioned preparation method, a graphene / ionic liquid combined electrode manufactured by the composite material and the preparation method thereof and an electrochemical capacitor manufactured by the combined electrode. Defects of liable agglomeration and small specific area when the existing graphene acts as an electrode material independently can be overcome. Under the premise of not destroying the structure of the graphene, the graphene / ionic liquid composite material with high single-layer rate and great dispersity can be prepared so that preparation efficiency is high, cost is low and industrialization is easy to realize.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparing graphene oxide by using a Fenton reagent

The invention belongs to the technical field of graphene, and in particular relates to a method for preparing graphene oxide. The method for preparing graphene oxide by using a Fenton reagent providedby the invention comprises the following specific steps: (1) pretreatment of raw materials: after uniformly mixing graphite and an aqueous solution, adjusting the pH value of the system, and heatingto obtain an acidic mixture; (2) oxidation: after cooling the acidic mixture, adding theFenton reagent and the aqueous solution for reaction, so as to obtain a graphite oxide solution; (3) washing with water: centrifuging, washing the graphite oxide solution until that the solution is neutral; (4) superultrasound: diluting the solution obtained in the step (3), then being subjected to superultrasound, and freezeing and drying to obtain a graphene oxide product. The preparation method of the graphene oxide according toprovided by the invention is simple in operation, mild in condition and non-pollution, and the prepared graphene oxide has a high single layer rate.

Owner:嘉兴烯成新材料有限公司

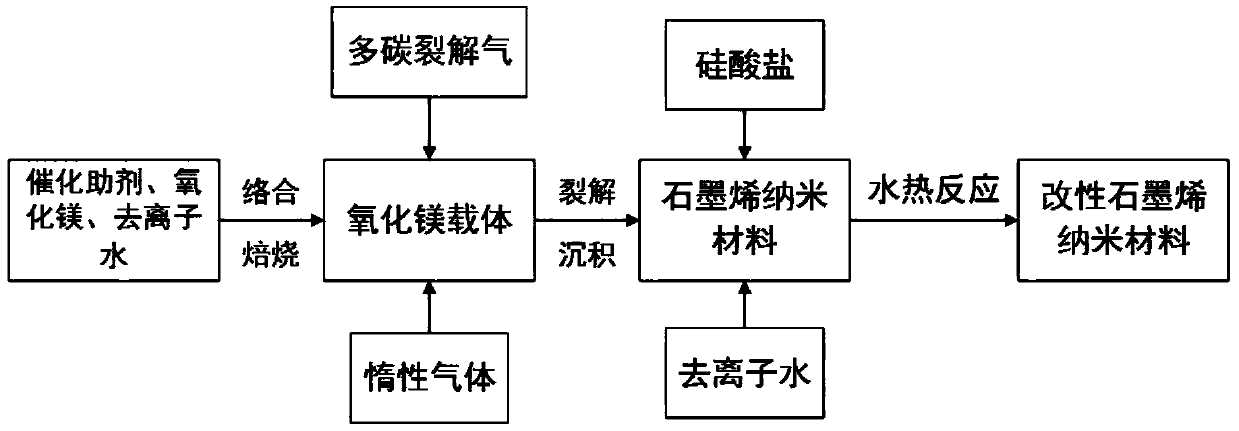

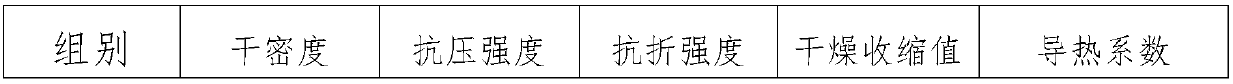

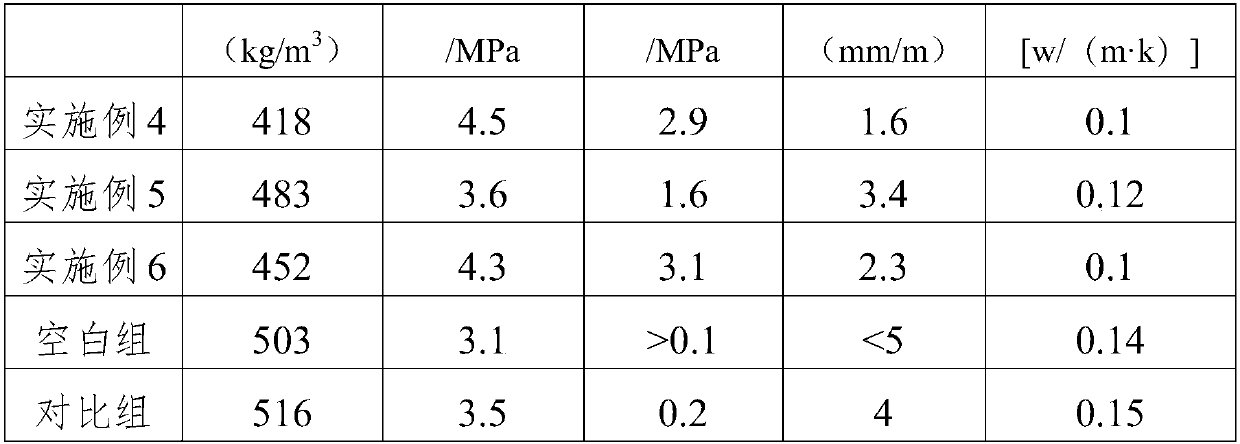

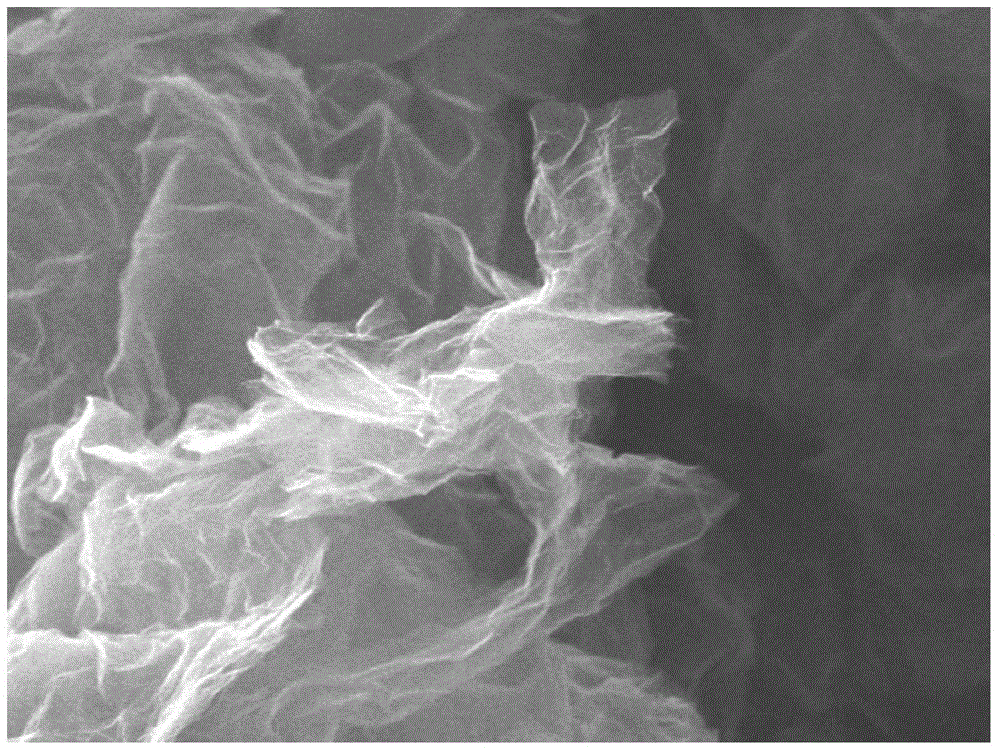

Preparation method and application of graphene nano-materials and modified graphene nano-materials

InactiveCN109665517ASingle layer rate is highLarge specific surface areaSingle layer grapheneSlurryMaterials science

An embodiment of the invention discloses a preparation method and an application of graphene nano-materials and modified graphene nano-materials, and belongs to the technical field of graphene nano-materials. The preparation method of the graphene nano-materials includes the following steps: 1) a slurry is obtained by the complexation reaction of catalytic agent, magnesium oxide and deionized water, and a magnesium oxide carrier rich in active substances is obtained by spray granulation and dry roasting of the slurry; 2) the magnesium oxide carrier rich in active substances is heated to 600 to900 DEG C in an inert gas atmosphere, a mult-carbon pyrolysis gas is introduced, and the graphene nano-materials is obtained by the chemical vapor deposition reaction. The modified graphene nano-materials prepared by the hydrothermal reaction of graphene nano-materials with high monolayer rate and high specific surface area and silicate is added to concrete, which significantly improves the strength, toughness, water resistance and other properties of concrete, and accordingly has broad development prospect.

Owner:河北北方国能科技有限公司

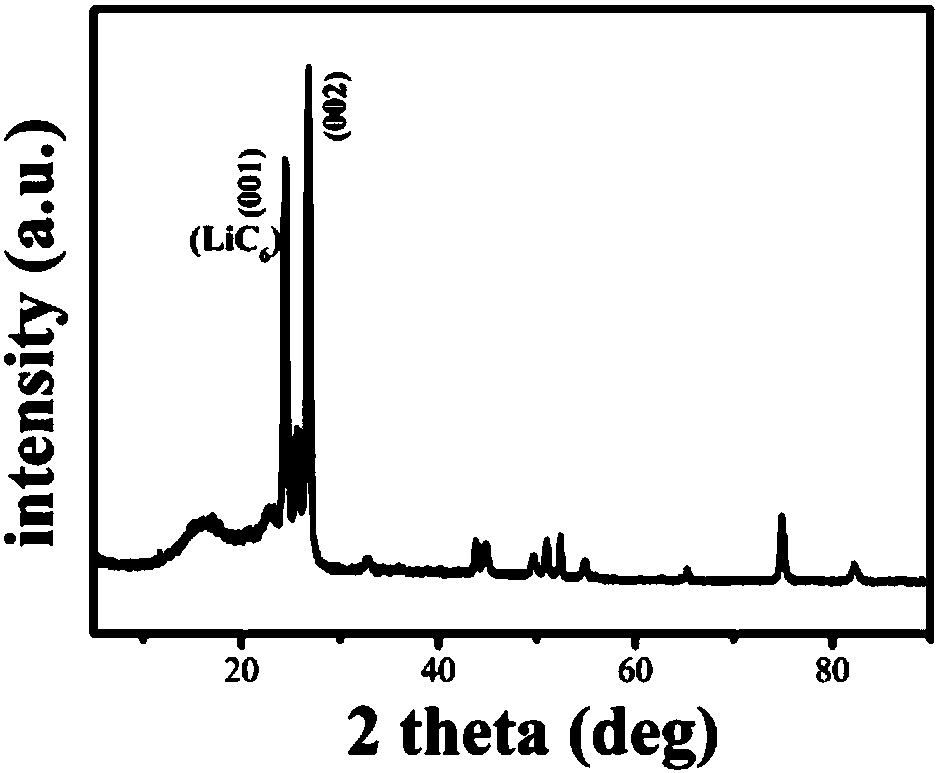

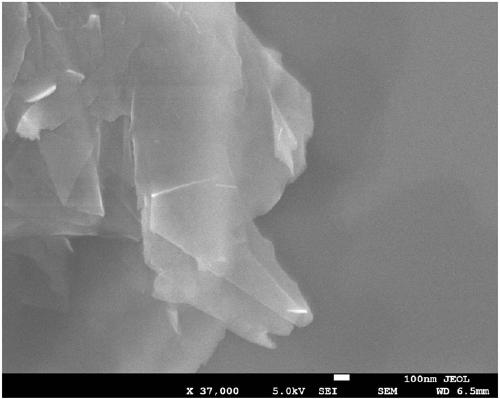

Method for preparing graphene by alkali metal intercalation

The invention provides a method for preparing graphene by alkali metal intercalation. The method comprises the following steps that (1) in an inert environment, a graphene material is mixed with alkali metal to obtain an evenly-mixed graphene carbon material-alkali metal composite material, still standing is conducted in the inert environment, and thus metal intercalation reaction is produced; and(2) the obtained composite material is put in a liquid medium reacting with the composite material to react, an intercalation object is removed, and the graphene material is obtained through vibration, washing and separating. The invention further provides the graphene prepared through the method. According to the preparation method of the high-quality graphene, a golden yellow composite materialobtained through lithium or other highly-reactive alkali metal mixed and reacted with the graphene material is adopted to serve as a precursor, the later stage preparation process of the graphene canbe conducted under condition of room temperature, air and the like, and the method is suitable for large-scale preparation of the graphene.

Owner:BEIHANG UNIV

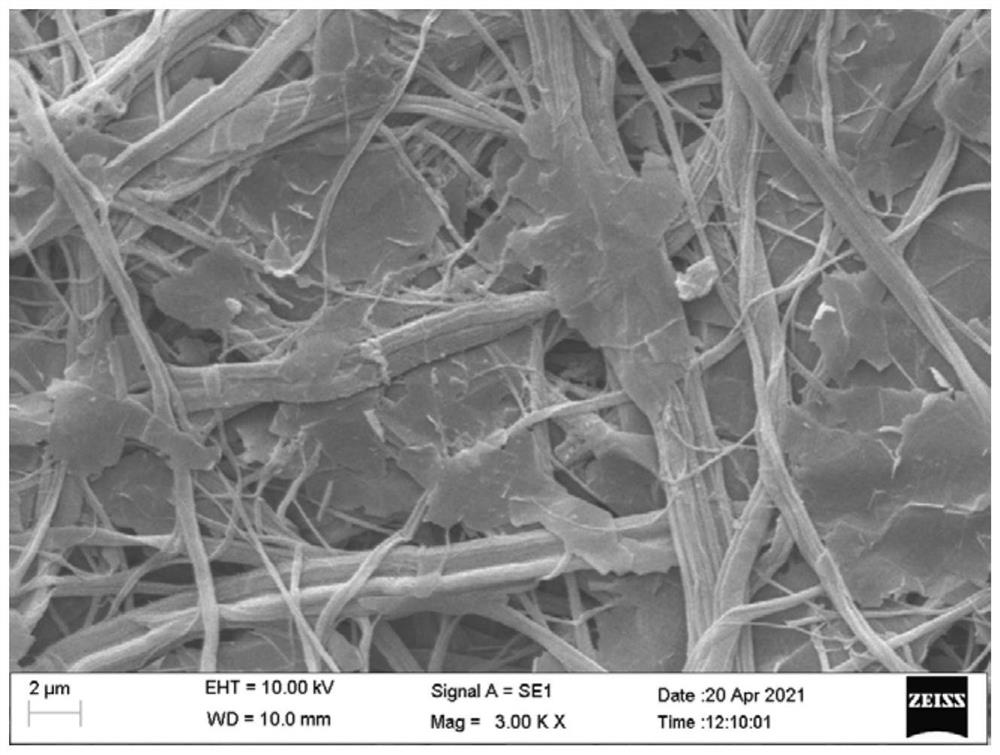

High-thermal-conductivity graphene film and preparation method thereof

The invention discloses a high-thermal-conductivity graphene film and a preparation method thereof, and belongs to the technical field of thermal conductive materials. The graphene oxide adopted by the invention can be uniformly dispersed in water. The preparation method comprises the following steps: mixing graphene oxide and fibers, grinding, permeating the graphene oxide into the fibers, firmly combining the graphene oxide with the fibers, adding a certain amount of a binder into the mixed slurry of the graphene oxide and the fibers, and carrying out vacuum filtration to obtain a graphene oxide film; and performing high-temperature carbonization and graphitization in the later stage to obtain the graphene heat-conducting film with high heat conductivity and high flexibility. The graphene heat-conducting film can be prepared through a simple preparation process, and the preparation method is low in cost, controllable in thickness, simple to operate, high in production efficiency and suitable for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

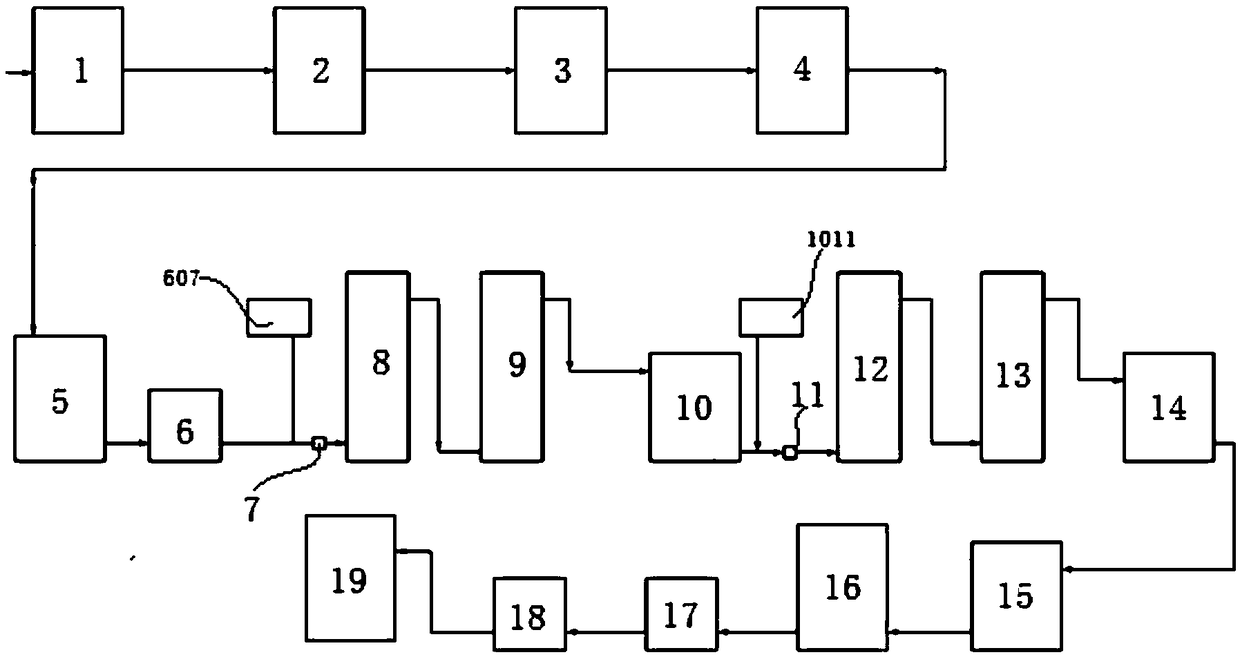

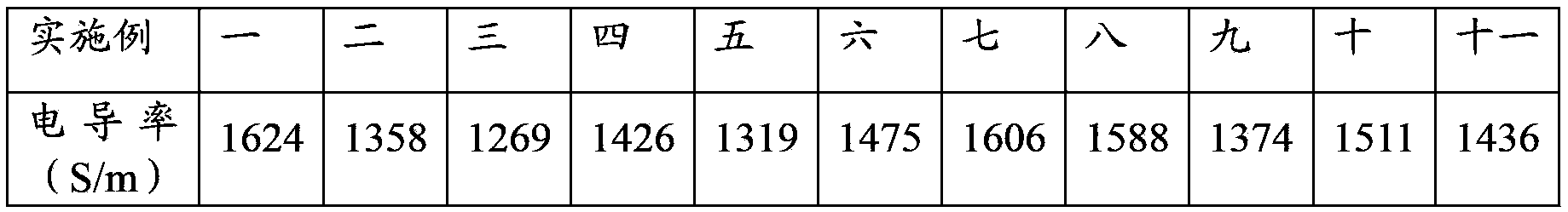

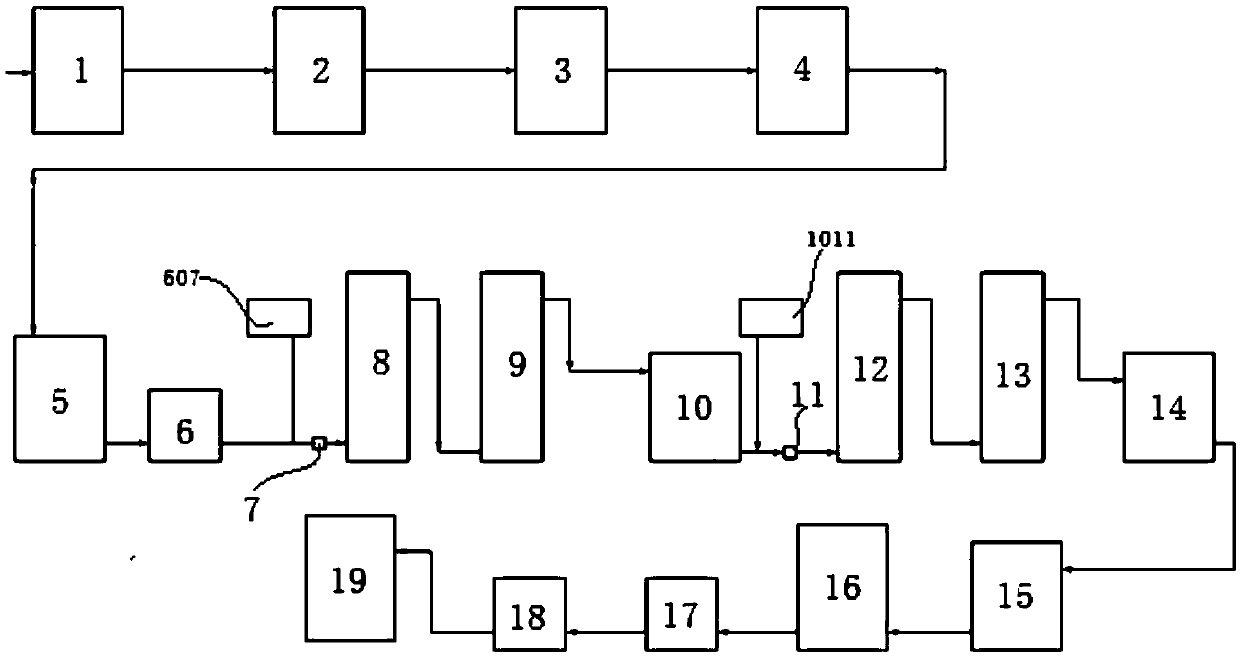

A continuous production device and method for aminated graphene

The invention discloses a continuous production device for aminated graphene and a method and belongs to the technical field of graphene preparation. The continuous production device comprises an acidtreatment device, an oxidation device, a first washing suction filtration device, a second washing suction filtration device, a dispersion treatment device, a first homogenization treatment device, afirst micro-reaction device, a first tubular reaction device, a second tubular reaction device, a first suction filtration and dispersion device, a second micro-reaction device, a third tubular reaction device, a fourth tubular reaction device, a second suction filtration and dispersion device, a third suction filtration and dispersion device, a first reaction product storage tank, a second homogenization treatment device, a third homogenization treatment device and a second reaction product storage tank; a static mixer is arranged inside a material conveying tube. Modified aminated grapheneproduced by using the device is small in piece size, narrow in piece diameter distribution, high in single layer rate, free of pollution in a production process, and a raw material base is provided for on-scale application of the aminated graphene.

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

Graphene oxide pre-dispersion mixing process in banbury production process

The invention relates to a pre-dispersion and mixing process for graphene oxide in the process of internal mixing. The pre-dispersion and mixing process is characterized by comprising the following steps: (1) dissolving graphene oxide in water so as to obtain an aqueous graphene oxide solution with a mass percentage concentration of 0.2 to 0.3%; (2) subjecting the aqueous graphene oxide solution to ultrasonic treatment for 1 to 2 h, wherein ultrasonic power is 500 to 1500 W; and (3) carrying out multi-stage mixing on a tabletted rubber compound, wherein the surface of the rubber compound is uniformly covered with the aqueous graphene oxide solution before each stage of mixing, and blow-drying by a drying system and blanking are carried out before mixing. The aqueous graphene oxide solution is maintained neutral. In the step (3), the surface of the rubber compound is uniformly covered with the aqueous graphene oxide solution in such a manner that the rubber compound is immersed in the aqueous graphene oxide solution treated in the step (2). The process provided by the invention can greatly improve the dispersity of graphene oxide in a mixed rubber compound, so dispersion of graphene oxide in the mixed rubber compound is greatly improved.

Owner:JIANGSU GENERAL SCI TECH

Graphene film growth substrate and preparation method and application thereof

ActiveCN114604860AAvoid the effects of growthSingle layer rate is highGrapheneCarbon impuritiesThin membrane

The invention relates to a graphene film growth substrate and a preparation method and application thereof. The preparation method of the graphene film growth substrate comprises the following steps: providing a copper foil substrate, wherein the copper foil substrate is provided with a first surface and a second surface opposite to the first surface; performing protective film pasting treatment on the first surface, and performing oxidation treatment on the second surface to prepare an intermediate I; and removing the protective film to expose the first surface. The method is simple to operate, can reduce the content of carbon impurities in the substrate, remarkably improves the single-layer rate of graphene, can be carried out in a roll-to-roll manner on a large scale, can remarkably improve the production efficiency of the copper foil substrate of the substrate, can be used for preparing the copper foil substrate on a large scale, and is combined with a preparation method of a large-scale graphene film, so that the production cost is reduced. And the production efficiency of the graphene film is improved.

Owner:北京石墨烯技术研究院有限公司

A method for rapidly preparing high-performance graphene

The invention discloses a method for quickly preparing high-performance graphene. The method comprises the steps of putting graphite oxide into a reactor, vacuumizing the reactor, treating the graphite oxide by three-stage gradient microwave radiation, and peeling off the graphite oxide expanded with heat, thus obtaining high-performance graphene. The method has the advantages of high production efficiency, low production cost, high safety and reliability in the operation process and high product quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com