Graphene physical stripping production method and graphene produced through method

A technology of physical exfoliation and production methods, applied in the field of graphene, can solve the problems of unfavorable graphene popularization, high production cost, high production difficulty, etc., and achieve the effects of low production cost, long service life and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

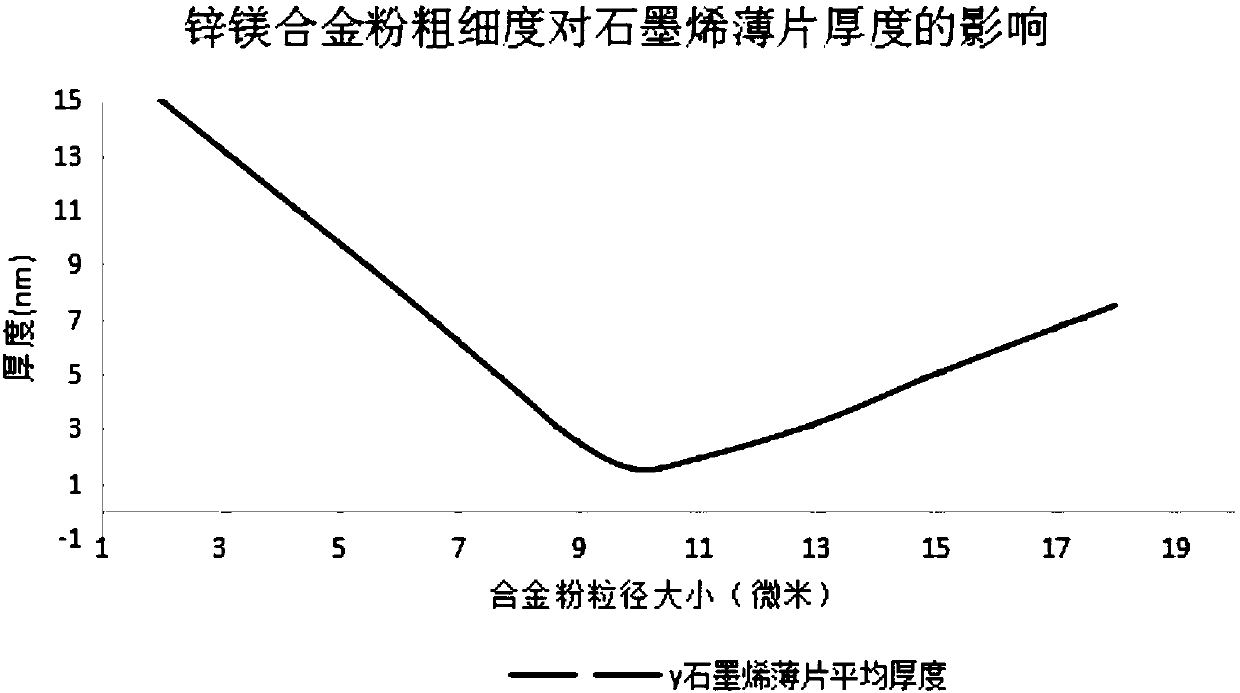

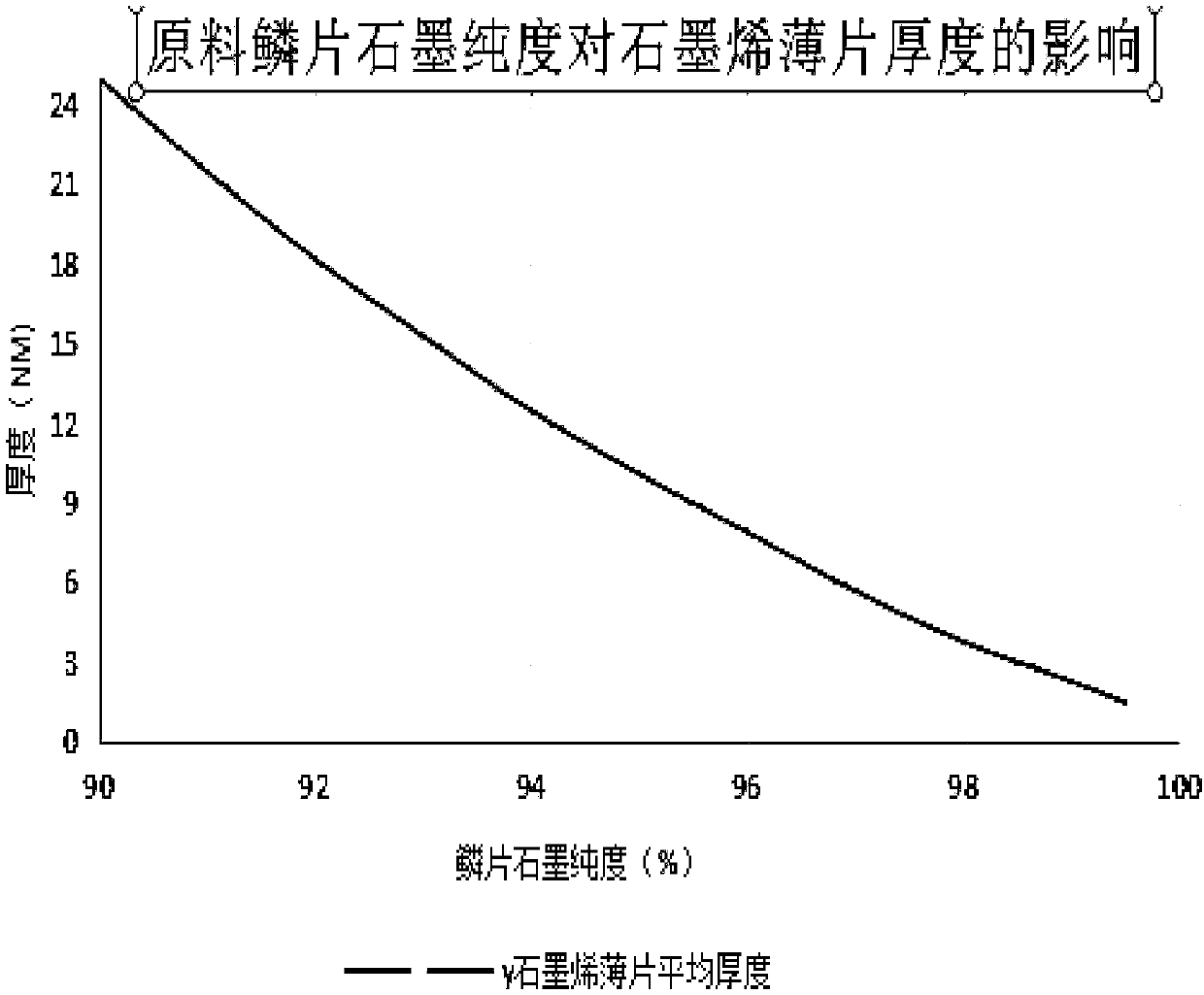

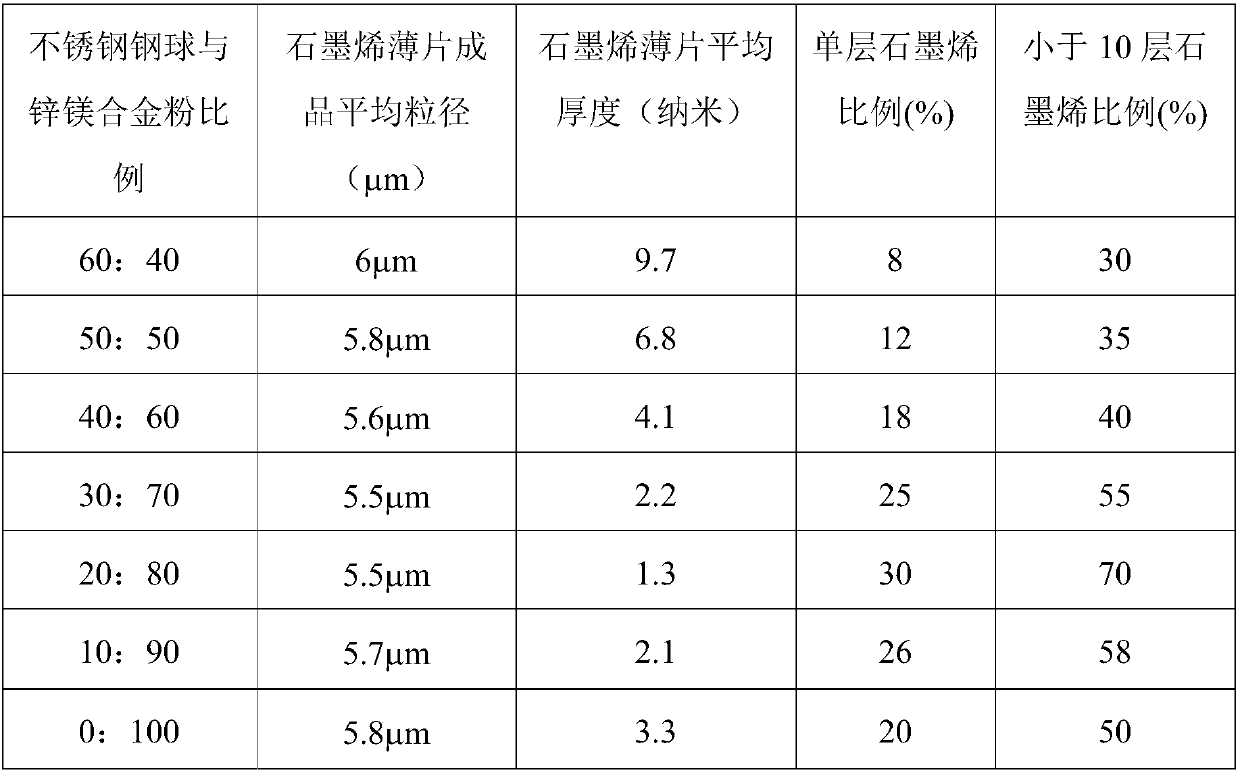

[0025] The average particle size D50 is 6-8 μm, D10099.5% flake graphite, spherical zinc-magnesium alloy powder from 9 μm-11 μm (in zinc-magnesium alloy, zinc content 70wt%, magnesium content 30wt%) Add the ball milling medium composed of stainless steel balls with a diameter of 0.6mm-0.8mm into the ball mill. The weight ratio of stainless steel balls and zinc-magnesium alloy powder is shown in Table 1 below. The sum of the ball and the zinc-magnesium alloy powder) is 4.5%, the speed of the ball mill is 50-55 rpm, the temperature is 120-150°C, the ball mill stripping is carried out in a nitrogen atmosphere with an oxygen content of less than 0.8%, and the nitrogen pressure is 6-10kPa , The ball milling stripping time is 200-300 hours. After the ball milling stripping, the graphene flakes after ball milling stripping are separated by airflow classification under the protection of inert gas, and then accurately classified by airflow for many times. The classification system is a ...

Embodiment 2

[0030] Exfoliate flake graphite with average particle size D50 of 6-8μm, D10099.5%, spherical zinc-magnesium alloy powder of 9μm-11μm and stainless steel ball with diameter of 0.6mm-0.8mm The medium is added into the ball mill, wherein relative to the total weight of the ball milling medium, the weight of the steel ball is 20%, the weight of the zinc-magnesium alloy powder is 80%, and the ratio of zinc and magnesium in the zinc-magnesium alloy powder is: the mass ratio of zinc is 70%, The mass ratio of magnesium is 30%.

[0031] The weight of flaky graphite and the weight ratio of ball milling exfoliation medium (the sum of steel ball and zinc-magnesium alloy powder) are as shown in Table 2. The rotating speed of ball mill is 50-55 rev / min, temperature 120-150 ℃, ball mill exfoliation is in atmospheric oxygen It is carried out in a nitrogen atmosphere with a content of less than 0.8%, the nitrogen pressure is 6-10kPa, and the ball milling stripping time is 200-300 hours. After...

Embodiment 3

[0036]The ball milling medium consists of flake graphite with an average particle size D50 of 6-8 μm, D10099.5%, spherical zinc-magnesium alloy powder of 9 μm-11 μm and stainless steel balls with a diameter of 0.6mm-0.8mm Add it into the ball mill, wherein, relative to the total weight of the ball milling medium, the weight of the steel ball is 20%, the weight of the zinc-magnesium alloy powder is 80%, and the mass ratio of zinc and magnesium in the zinc-magnesium alloy powder is shown in Table 3 below. The weight of the graphite is about 4.5% of the ball milling exfoliation medium (the sum of steel balls and zinc-magnesium alloy powder), the speed of the ball mill is 50-55 rpm, and the temperature is 120-150°C. % nitrogen atmosphere, the nitrogen pressure is 6-10kPa, the ball milling stripping time is 200-300 hours, after the ball milling stripping is completed, the graphene flakes after the ball milling stripping are separated by airflow classification under the protection of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com