Preparation method and application of graphene nano-materials and modified graphene nano-materials

A nanomaterial, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problem that the effect of concrete modification and enhancement is not obvious, the specific surface area and monolayer rate of graphene are not high, and the layer Difficulty filling interfunctional groups, etc., to achieve the effect of large surface modifiability, high specific surface area, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

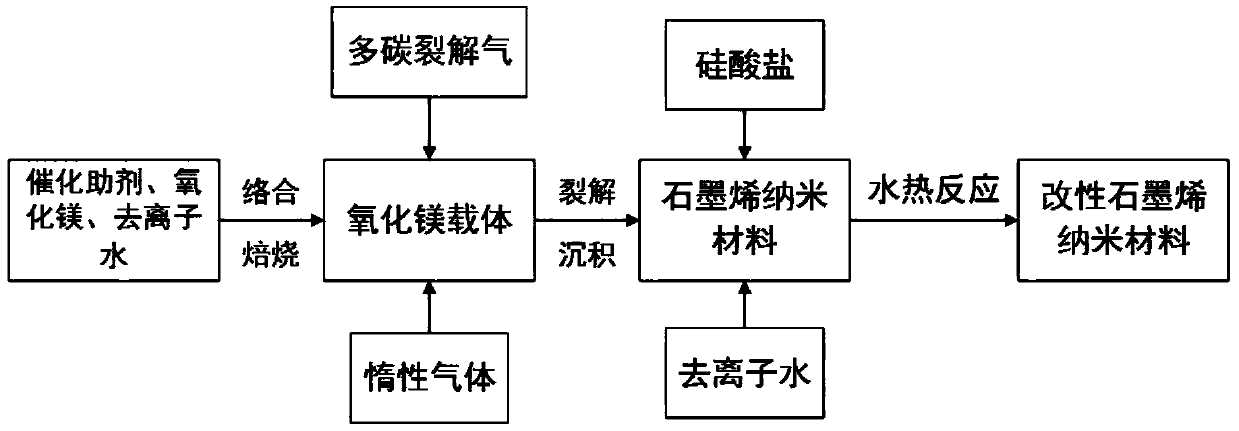

[0034] A preparation method of graphene nanomaterials, comprising the following steps:

[0035] 1) Catalyst promoter, magnesium oxide and deionized water complex reaction to obtain slurry, the slurry is spray granulated and dried and roasted to obtain a particle size of 10-100 μm and a specific surface area of 50-200m 2 / g of magnesium oxide carrier rich in active substances.

[0036] In the present invention, the catalytic promoter is any oxide or salt of metal copper, chromium, ruthenium, nickel, aluminum, palladium, zinc, and the type of salt includes chloride salt, nitrate, sulfate, hydroxide salt, etc. . As preferably, the catalyst promoter includes copper oxide, dichromium oxide, ruthenium oxide, nickel oxide, aluminum oxide, palladium oxide, zinc oxide, copper chloride, copper sulfate, copper hydroxide, chromium chloride, chromium nitrate, Ruthenium nitrate, nickel sulfate, nickel chloride, aluminum nitrate, aluminum hydroxide, palladium chloride, zinc chloride, zin...

Embodiment 1

[0061] The preparation method of the graphene nanomaterial of the present embodiment comprises the following steps:

[0062] 1) Put copper sulfate and nickel chloride at a mass ratio of 1:2, and magnesium oxide at a mass ratio of 1:80, and put them into a stirred reactor filled with deionized water, with a solid-to-liquid mass ratio of 1:20. Raise the temperature to 90°C, and conduct constant temperature complexation reaction for 5 hours to obtain a slurry, which is subjected to spray granulation, drying and roasting to obtain a particle size of 30-50 μm and a specific surface area of 140-160m 2 / g of magnesium oxide carrier rich in active substances;

[0063] 2) After the above-mentioned magnesia carrier rich in active substances is heated to 600°C under an inert gas atmosphere, the multi-carbon cracking gas containing methane, ethane, propane and n-butane is passed through, and the chemical vapor deposition (CVD) reaction is carried out for 1.5h , to obtain graphene nanom...

Embodiment 2

[0066] The preparation method of the graphene nanomaterial of the present embodiment comprises the following steps:

[0067] 1) Zinc oxide, ruthenium nitrate and magnesium oxide are put into a stirred reactor filled with deionized water at a mass ratio of 0.5:0.5:65. The solid-liquid mass ratio is 1:15. Combined reaction for 6h to obtain a slurry, the slurry is spray granulated and dried and roasted to obtain a particle size of 80-100μm and a specific surface area of 80-100m 2 / g of magnesium oxide carrier rich in active substances;

[0068] 2) After the above-mentioned magnesium oxide carrier rich in active substances is heated to 900°C under an inert gas atmosphere, the multi-carbon cracking gas containing methane, ethane, propane, propylene and n-butene is passed through to carry out chemical vapor deposition (CVD) reaction 3h, to obtain graphene nanomaterials.

[0069] Tested by methods such as BET, SEM and TEM, the specific surface area of the graphene nano material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com