Graphene-ionic liquid composite material and preparation method thereof, graphene-ionic liquid composite electrode and preparation method thereof, and electrochemical capacitor

A technology of ionic liquid and composite materials, which is applied in the field of graphene material synthesis, can solve the problems of restricting the energy density and power density, small specific capacity and electrical conductivity of electrochemical capacitors, and the decrease of the specific gravity of active materials, so as to achieve fast charge and discharge performance, High single-layer ratio, avoiding the effect of increasing the internal resistance of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

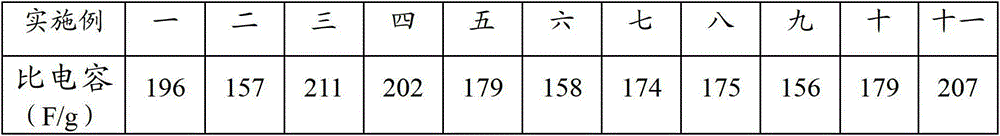

Examples

preparation example Construction

[0035] A method for preparing a graphene-ionic liquid composite material, comprising: mixing intercalated graphite and molten ionic liquid at a ratio of 1 g to 100 mL of solid-to-liquid ratio, stirring evenly and putting it into a microwave oven, and heating it at 1000 to 2000 W The power is peeled off for 10 to 100 minutes to obtain a graphene-ionic liquid composite material.

[0036]Graphite is a multilayer crystal structure with good stability. Although the bonding force between graphite layers is weak, it is almost impossible to completely peel off graphite crystal layers directly under the current technical conditions. The graphite is placed in the intercalation agent for electrolysis, and the ions in the electrolyte can enter the graphite layer, causing the expansion of the graphite interlayer distance, further weakening the bonding force between the graphite layers, and making an intercalated graphite that is easy to peel off. The intercalated graphite is prepared by th...

Embodiment 1

[0064] A kind of preparation method of graphene-ionic liquid composite material, comprises the steps:

[0065] (1) Use stainless steel sheet as the current collector, first take about 2g of natural phosphorus flake graphite and press it into a graphite sheet of 75mm×40mm×7mm as the working electrode, and use the lead plate as the counter electrode, Hg / Hg 2 SO 4 As a reference electrode; first pour formic acid into the electrolytic cell as the electrolyte, then place the reference electrode, working electrode and counter electrode in the electrolytic cell and completely soak in the electrolyte, at room temperature at 5mA / cm 2 The current density of the electrolysis reaction was 20 hours; after the electrolysis, the graphite flakes were taken out, and the volume of the graphite flakes could be seen to expand. Rinse the obtained graphite flakes twice with deionized water, then put them into a vacuum drying oven, and dry them at 60°C for 24 hours. , to obtain pure intercalated gr...

Embodiment 2

[0073] A kind of preparation method of graphene-ionic liquid composite material, comprises the steps:

[0074] (1) Use stainless steel sheet as the current collector, first take about 2g of artificial graphite and press it into a graphite sheet of 75mm×40mm×7mm as the working electrode, and use the lead plate as the counter electrode, Hg / Hg 2 SO 4 As a reference electrode; first pour acetic acid into the electrolytic cell as the electrolyte, then place the reference electrode, working electrode and counter electrode in the electrolytic cell and completely soak in the electrolyte, at room temperature at 20mA / cm 2 The current density of the electrolysis reaction was 1 hour; after the electrolysis, the graphite flakes were taken out, and the volume expansion of the graphite flakes could be seen, and the obtained graphite flakes were rinsed with deionized water for 3 times, then put into a vacuum drying oven, and dried at 70°C for 20 hours , to obtain pure intercalated graphite. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com