Preparation method for preparing graphene dispersion liquid by electrochemical swelling

A graphene dispersion, electrochemical technology, applied in graphene, nano-carbon and other directions, can solve the problems of long electrolysis time, inability to effectively improve the graphene monolayer rate, uncontrollable graphene sheet layers and thickness, etc. Achieve the effect of speeding up dispersion, reducing the difficulty of peeling, and improving the single-layer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use a double-electrode electrochemical cell for intercalation reaction, take 40mL of tetraethylammonium bromide / acetonitrile solution with a concentration of 8mg / mL as the electrolyte, fix 1.0g of graphite sheets on the copper wires with conductive copper strips, and apply 12V Voltage for electrolysis reaction for 1.0h, rinsed with 0.2mol / mL PVP / DMF solution for 0.5h, ultrasonicated the rinsed graphene solution for 5min, and then centrifuged the dispersion at 1000rpm / min for 0.5h , and then washed twice with isopropanol IPA to remove the PVP in the solution. The graphene dispersion was centrifuged again for 3 min at a centrifugation speed of 1000 rpm / min, and then the precipitate IPA was removed from the graphene solution to obtain a graphene dispersion.

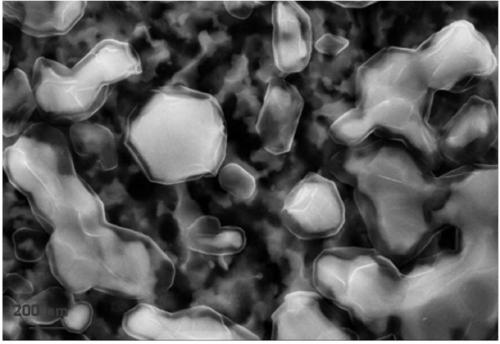

[0032] The entire process of the method takes about 2.5 hours, which is at least 58 hours shorter than the traditional method, and greatly improves the dispersion efficiency of the graphene nanosheets. Characterize t...

Embodiment 2

[0034] A two-electrode electrochemical cell was used for intercalation reaction, and 40 mL of tetrapropylammonium bromide / acetonitrile solution with a concentration of 5 mg / mL was used as the electrolyte, and 2.0 g of graphene nanosheets were respectively fixed on copper wires with conductive copper strips. Apply a voltage of 5V to carry out the electrolysis reaction for 0.5h, rinse with 0.1mol / mL PVP / DMF solution for 0.5h, and ultrasonicate the rinsed graphene solution for 5min, then centrifuge the dispersion at a centrifugal speed of 1000rpm / min for 0.5 After h, wash twice with isopropanol IPA to remove PVP in the solution. The graphene dispersion was centrifuged again for 2 min at a centrifugation speed of 1000 rpm / min, and then the precipitate IPA was removed from the graphene solution to obtain a graphene dispersion.

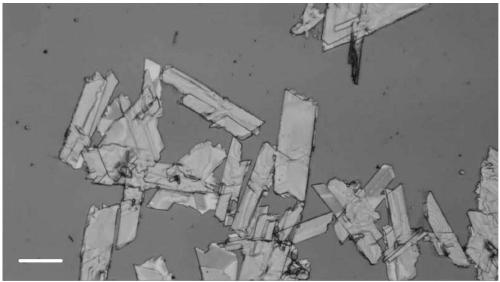

[0035] The entire process of this method takes about 2.5 hours, which is the same as that of Example 1, and shortens nearly 58 hours compared to the tradit...

Embodiment 3

[0037] A two-electrode electrochemical cell is used for intercalation reaction. Take 40mL of electrolyte, the concentration of tetrabutylammonium bromide in the acetonitrile solution is 5mg / mL, and the concentration of tetradecylammonium bromide is 5mg / mL. Graphene nanosheets were fixed on copper wires, applied a voltage of 15V for electrolysis for 2.5h, rinsed with 0.5mol / mL PVP / DMF solution for 1.0h, ultrasonicated the rinsed graphene solution for 10min, and then centrifuged After the dispersion was centrifuged at 1000 rpm / min for 1.0 h, it was washed twice with isopropanol IPA to remove PVP in the solution. The graphene dispersion was centrifuged again for 5 min at a centrifugation speed of 1000 rpm / min, and then the precipitate IPA was removed from the graphene solution to obtain a graphene dispersion.

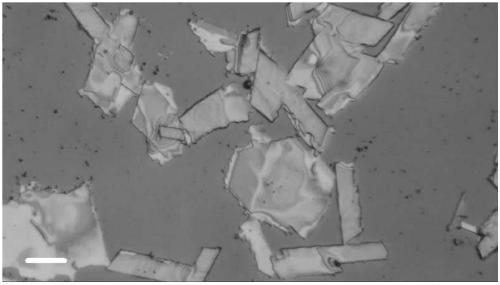

[0038] The entire process of this method takes about 3.5 hours, which is also shortened by nearly 58 hours compared with the traditional method, and greatly improves the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com