Graphene/ionic liquid composite material and preparation method thereof, combined electrode and preparation method thereof and electrochemical capacitor

A technology of ionic liquids and composite materials, which is applied in the field of graphene material synthesis, can solve the problems of restricting the energy density and power density, small specific capacity and conductivity of electrochemical capacitors, and the decrease of the specific gravity of active materials, so as to avoid internal resistance and activity Effects of reduction in material specific gravity, high monolayer ratio, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

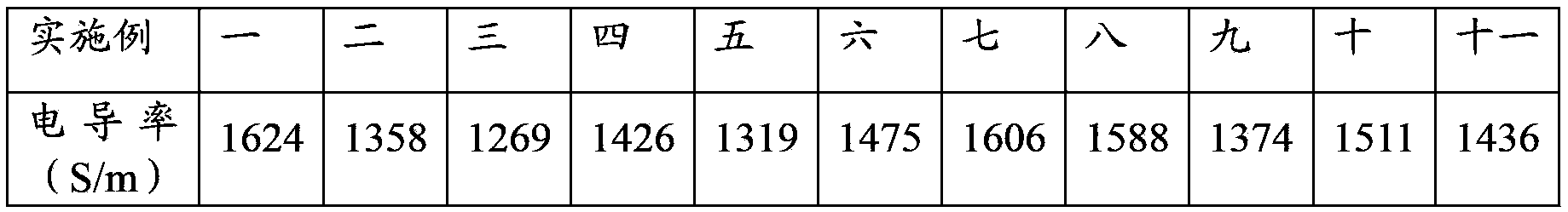

Examples

preparation example Construction

[0036] A preparation method of graphene / ionic liquid composite material, comprising:

[0037] Take chloride-intercalated graphite, add it into the molten ionic liquid according to the ratio of solid-liquid ratio of 1g: 10-100mL, and ultrasonically strip it for 0.5-24 hours to obtain a mixture of graphene, ionic liquid and chloride;

[0038] Place the mixed solution in an environment with an electric field strength of 100-1000 V / m and a vertical direction of the electric field, centrifuge at a speed of 1000-5000 r / min for 1-10 minutes, remove the supernatant, and obtain graphene ;

[0039] The graphene is immersed in the ionic liquid again for 10 to 24 hours, filtered to remove the ionic liquid, and the filtrate is dried to obtain a graphene / ionic liquid composite material.

[0040] The graphite is natural phosphorus flake graphite or artificial graphite.

[0041] The chloride intercalation agent is at least one of ferric chloride, nickel chloride, copper chloride, cobalt chl...

Embodiment 1

[0061] A kind of preparation method of graphene / ionic liquid composite material, comprises the following steps:

[0062] (1) Mix natural graphite and ferric chloride according to the mass ratio of 1:0.8, mix them evenly and put them into a quartz tube, seal the quartz tube and put the quartz tube into a high-temperature furnace, raise the temperature to 460°C, and keep warm for 2 Hours, after the reaction is finished, cool to room temperature, pour the reactant into deionized water and rinse once, then filter the filter residue and put it in a vacuum drying oven to dry at 80°C for 6 hours to obtain pure ferric chloride intercalated graphite;

[0063] (2) Select 1-ethyl-3-methylimidazolium bromide (EtMeImBr) as the ionic liquid, melt it in a beaker to obtain 1L of EtMeImBr solvent, maintain the temperature of EtMeImBr solvent at 150°C, add 100g of the above pure Ferric chloride intercalated graphite, after stirring evenly, put the beaker into an ultrasonic instrument with a pow...

Embodiment 2

[0073] A kind of preparation method of graphene / ionic liquid composite material, comprises the following steps:

[0074] (1) Mix artificial graphite and copper chloride according to the mass ratio of 1:0.9, mix them evenly, put them into a quartz tank, seal the quartz tank, put the quartz tank into a high-temperature furnace, raise the temperature to 500°C, and keep warm for 3 Hours, after the reaction is finished, cool to room temperature, pour the reactant into deionized water and rinse once, then filter the filter residue and put it in a vacuum drying oven to dry at 90°C for 5 hours to obtain pure copper chloride intercalated graphite;

[0075] (2) Select 1-ethyl-3-methylimidazolium chloride salt (EtMeImCl) as the ionic liquid, melt it in a beaker to obtain 10L of EtMeImCl solvent, maintain the temperature of EtMeImCl solvent at 180°C, add 100g of the above pure Copper chloride intercalated graphite, after stirring evenly, put the beaker into a 500W ultrasonic instrument, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com