Method for preparing graphene by alkali metal intercalation

A technology of alkali metals and graphene, applied in the direction of graphene, non-metallic elements, chemical instruments and methods, etc., can solve the problems of limiting the application field of graphene, increasing production costs, slow growth speed, etc., and achieves fast and efficient preparation methods, The effect of less pollution and high single-layer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

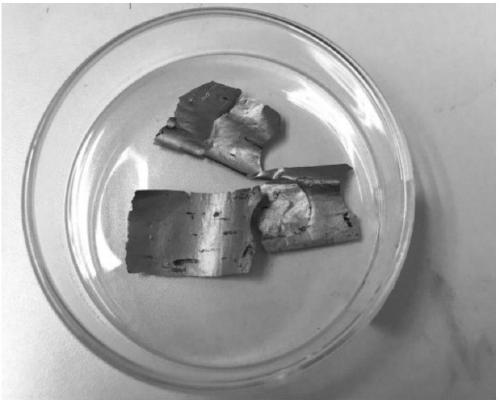

[0034] (1) Mix graphite powder and metal lithium in an inert environment of argon with a mass ratio of 6:1, first melt the lithium by heating, then add graphite powder and stir and mix until the graphite powder and metal lithium are evenly mixed and then place After being placed in an inert atmosphere for 24 hours, the above mixture turns golden yellow (attached figure 1 );

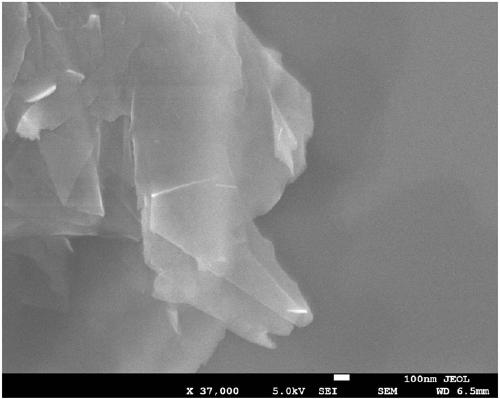

[0035] (2) Take the above golden composite material out of the inert environment and put it into ethanol (analytical pure), the intercalation metal reacts with ethanol quickly to generate gas, and the composite material expands rapidly and is dispersed in ethanol. After the reaction was completed, the solution was ultrasonically treated for one hour, then the solution was washed repeatedly, and the graphene material was obtained by suction filtration and separation.

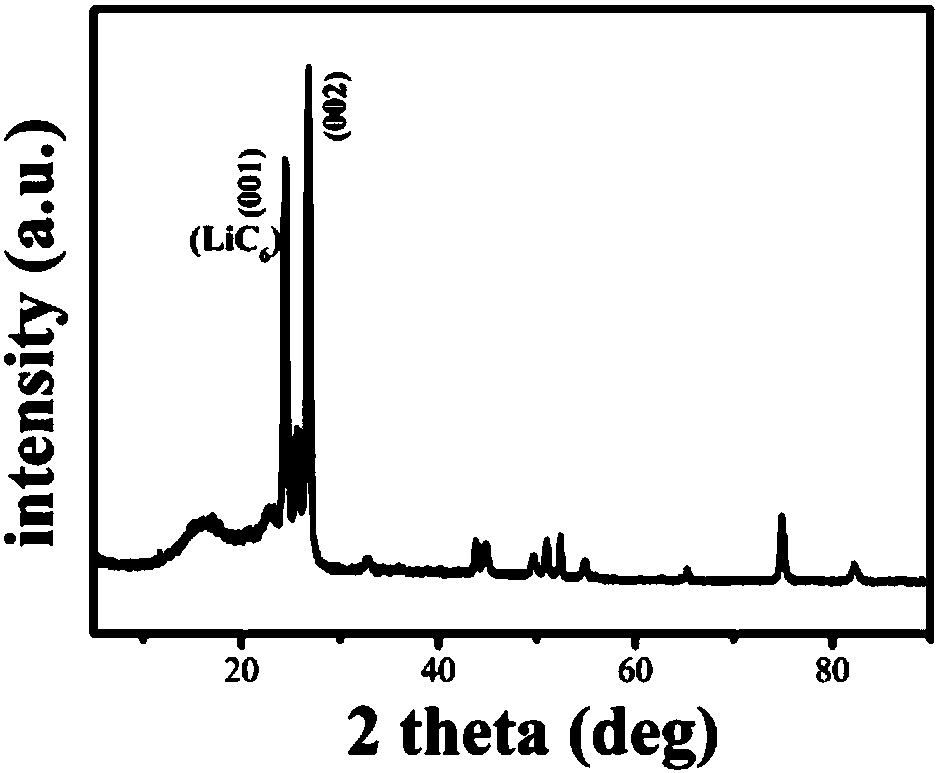

[0036] The XRD diffraction pattern of the material is attached figure 2 , analysis available golden material is alkali metal intercalate...

Embodiment 2

[0038] (1) Mix graphite flakes and lithium metal in an inert environment of argon with a mass ratio of 5:1, fold and roll repeatedly until the graphite flakes and lithium metal are evenly mixed and then placed in an inert atmosphere for 48 hours. The above mixture turns golden yellow;

[0039] (2) The above golden yellow composite material was taken out from the inert environment, and put into 0.1mol / L hydrochloric acid aqueous solution, the intercalation metal quickly reacted with the solution to generate gas, and the composite material rapidly expanded and dispersed in the hydrochloric acid aqueous solution. After the reaction was completed, the solution was ultrasonically treated for one hour, then the solution was washed repeatedly, and the graphene material was obtained by suction filtration and separation.

Embodiment 3

[0041] (1) Mix expanded graphite and metal lithium in an inert environment argon with a mass ratio of 3:1, fold and roll repeatedly until the flake graphite and metal lithium are evenly mixed and then placed in an inert atmosphere for 48 hours. The above mixture turns golden yellow;

[0042] (2) Take the above golden composite material out of the inert environment and put it into acetic acid (analytical pure), the intercalation metal reacts with acetic acid quickly to generate gas, and the composite material expands rapidly and is dispersed in acetic acid. After the reaction was completed, the solution was ultrasonically treated for one hour, then the solution was washed repeatedly, and the graphene material was obtained by suction filtration and separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com