Preparing method of graphene oxide

A graphene and graphite technology, which is applied in the field of graphene oxide preparation, can solve problems such as easy aggregation, low reactivity, and low graphene oxide monolayer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of graphene oxide, comprises the following steps:

[0029] A) Mix and react concentrated sulfuric acid, graphite and fuming nitric acid, then lower the temperature, add potassium permanganate, add water to quench the reaction after the mixed reaction, and finally add hydrogen peroxide to obtain graphene oxide.

[0030] Wherein, the graphite is preferably natural flake graphite; the particle size of the natural flake graphite is preferably 5-20 μm, more preferably 5-15 μm, more preferably 8-12 μm, most preferably 10 μm; the graphite and concentrated sulfuric acid The mass ratio of graphite is preferably 1:(60-80), more preferably 1:(65-75); in some embodiments provided by the present invention, the mass ratio of graphite to concentrated sulfuric acid is preferably 1:73.44; In other embodiments provided by the present invention, the mass ratio of graphite to concentrated sulfuric acid is preferably 1:68.85; the mass rati...

Embodiment 1

[0041] Disperse 20g (1.667mol) of natural flake graphite with a particle size of 10μm in 800ml of 98% concentrated sulfuric acid at room temperature, add 10ml of fuming nitric acid after stirring for 1 hour, and add 80g of permanganic acid to control the reaction temperature below 10°C after reacting for 14 hours Potassium, react at a constant temperature of 30°C for 72 hours. Use a constant pressure dropping funnel to control the temperature below 60°C and add 1.2L of high-purity water dropwise. Raise the temperature to 90°C to react for 2.5h, cool down to below 60°C, and add 40ml of hydrogen peroxide. After natural cooling, clean with ceramic membrane cleaning equipment, and obtain a single-layer graphene oxide solution after 20KHz ultrasound for 3 hours.

[0042] figure 1 It is a photo of the appearance of the graphene oxide solution obtained in Example 1.

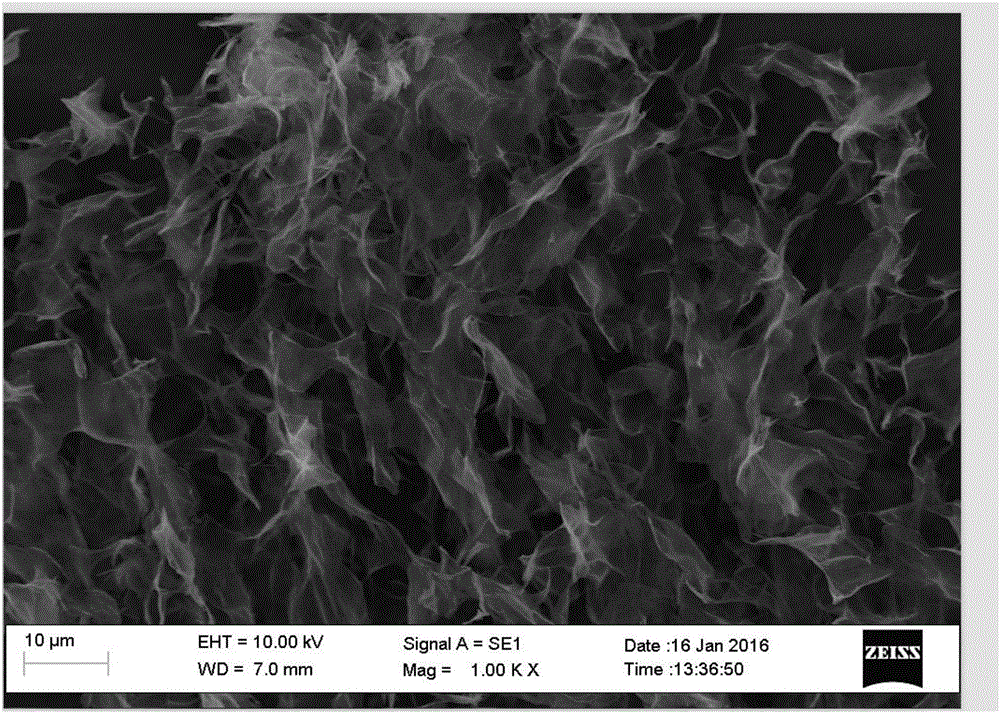

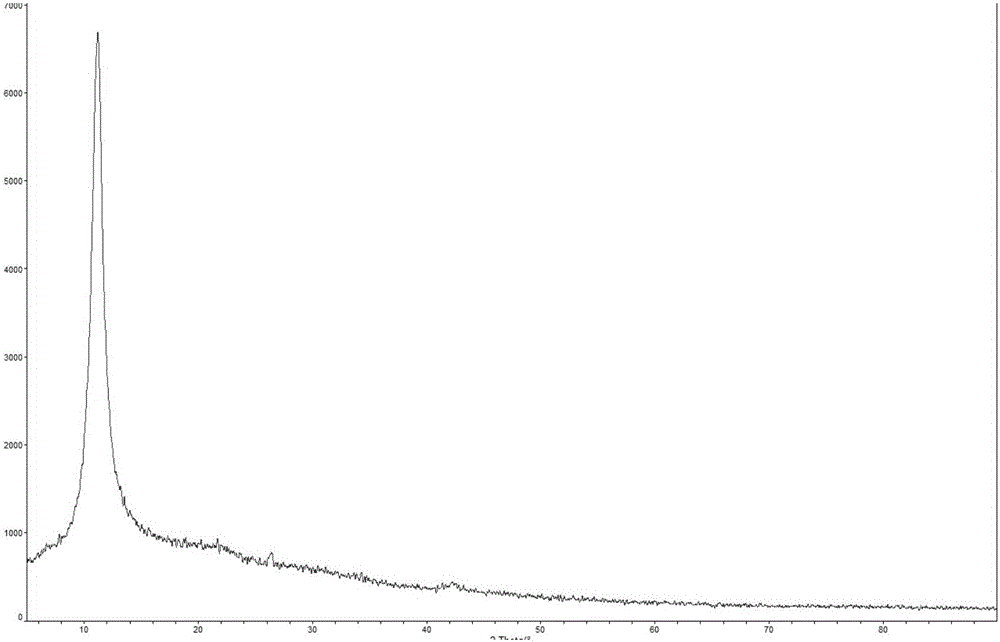

[0043] Utilize scanning electron microscope to analyze the graphene oxide obtained in embodiment 1, obtain its scann...

Embodiment 2

[0046] Disperse 60g (5mol) of natural flake graphite with a particle size of 10μm in 2.25L of 98% concentrated sulfuric acid at room temperature, add 30ml of fuming nitric acid after stirring for 1 hour, and add 240g of high manganese after 14 hours of reaction to control the reaction temperature below 10°C Potassium acid, react at a constant temperature of 30°C for 72 hours. Use a constant pressure dropping funnel to control the temperature below 60°C and add 2.25L of high-purity water dropwise. Raise the temperature to 90°C and react for 2.5 hours, then lower the temperature to below 60°C, and add 125ml of hydrogen peroxide. After natural cooling, clean with ceramic membrane cleaning equipment, and obtain a single-layer graphene oxide solution after 20KHz ultrasound for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com