Preparation method of two-dimensional MoS2 nanosheet

A technology of nanosheets and large sheets, which is applied in the field of preparation of two-dimensional MoS2 nanosheets, can solve problems such as limited applications, and achieve the effects of ensuring electrical conductivity, controllable size of nanosheets, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

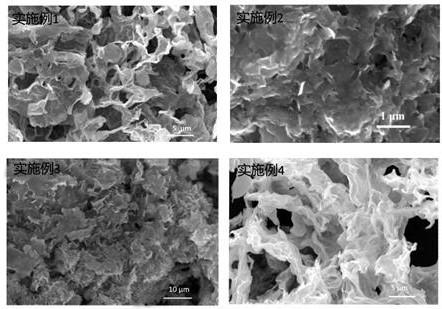

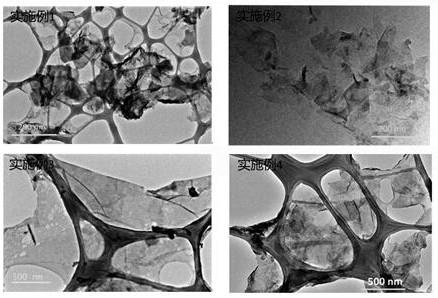

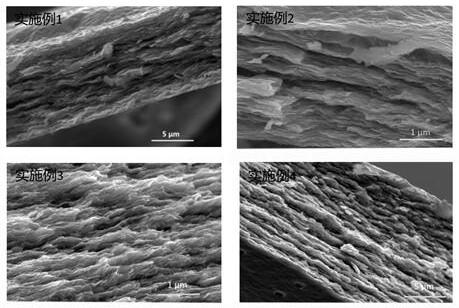

Embodiment 1

[0037] A two-dimensional MoS 2 A method for preparing nanosheets, comprising:

[0038] Step S1, first in an inert gas glove box, put 1 g MoS 2 polycrystalline powder (polycrystalline MoS 2 The particle size of the powder is 10-30 μm, the purity is greater than 99.95%), add 2.5 mol / L 40 ml n-butyllithium solution, seal and mix evenly in the reaction kettle;

[0039] Step S2, the above-mentioned reaction kettle for forming the mixed sample is reacted in a high-temperature incubator at 70°C for 12 h, and naturally cooled to room temperature after the reaction;

[0040]Step S3, after the reaction, clean the n-butyllithium solution remaining in the sample with clean n-hexane in an inert gas glove box to obtain a black lithium intercalation compound li X MoS 2 ;li X MoS 2 is a mixture, wherein the value of X is 1 to 3;

[0041] Step S4, after cleaning the lithium intercalation compound and vacuum drying to obtain li X MoS 2 The intercalation compound was added to deionized ...

Embodiment 2

[0055] The difference between this example and Example 1 lies in step S4: after the obtained large-diameter single-layer MoS 2 After nanosheets, continue to prepare small-diameter single-layer MoS by ultrasonic pulverization 2 Nanosheets; at the same time, by increasing the ultrasonic power to 250W and 50Hz to continue peeling, the control time is 2h to increase the peeling rate of nanosheets and obtain MoS with smaller sheet diameters 2 Nanosheets.

[0056] The specific process of centrifugation is as follows:

[0057] Step 1: Introduce the overflow tube into the centrifuge tube of the centrifugal separation device.

[0058] Step 2: Turn on the stirring device to provide centrifugal force, and the centrifuge tube is rotated and centrifuged at a speed of 4000-4500 r / min.

[0059] Step 3: Centrifuge for 30 minutes, and separate the heavy phase solid residue through the slag discharge pipe in the centrifuge tube. The solid substance separated in this step is a small single-la...

Embodiment 3

[0063] A two-dimensional SnS 2 A method for preparing nanosheets, comprising:

[0064] Step S1, first in an inert gas glove box, put 1 g SnS 2 Add polycrystalline powder (particle size 10-30 μm, purity greater than 99.95%) into 2.5mol / L 40 ml n-butyllithium solution, seal and mix evenly in the reactor;

[0065] Step S2, the above-mentioned reactor for forming the mixed sample was reacted in a high-temperature incubator at 90° C. for 12 h, and naturally cooled to room temperature after the reaction.

[0066] Step S3, after the reaction, clean the residual n-butyl lithium in the sample with clean n-hexane in an inert gas glove box, and the orange-yellow SnS 2 into a black lithium intercalation compound li X SnS 2 . li X SnS 2 It is a mixture, wherein the value of X is 1-3.

[0067] Step S4, after cleaning the lithium intercalation compound and vacuum drying to obtain li X SnS 2 Intercalation compounds, added to deionized water, SnS 2 The violent reaction between the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com