Continuous production device for aminated graphene and method

A technology of aminated graphene and production methods, which is applied in the direction of chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems that remain in industrialized large-scale production, and achieve the improvement of reaction efficiency, equipment efficiency, The effect of small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

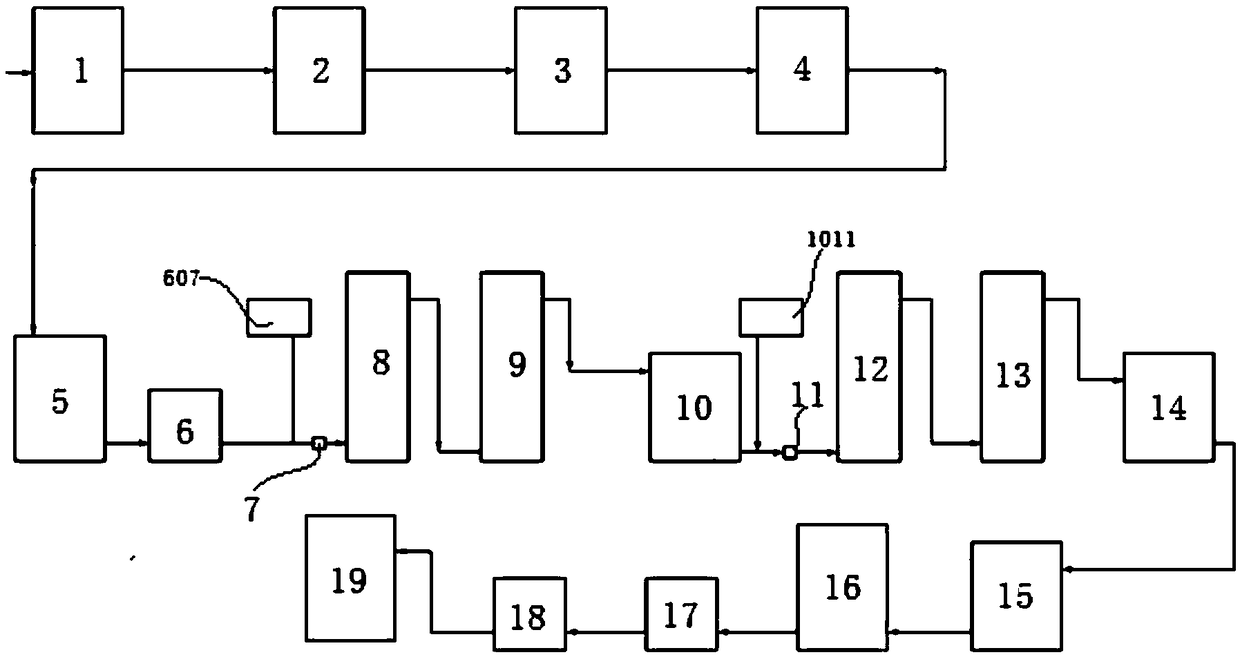

[0032] A kind of continuous production device of graphene amide of the present embodiment, such as figure 1 As shown, it includes acid treatment device 1, oxidation device 2, first washing suction filtration device 3, second washing suction filtration device 4, dispersion treatment device 5, first homogenization treatment device 6, first microreaction device connected in sequence 7. The first tubular reaction device 8, the second tubular reaction device 9, the first suction filtration and redispersion device 10, the second micro-reaction device 11, the third tubular reaction device 12, the fourth tubular reaction device 13, The second suction filtration and redispersion device 14, the third suction filtration and redispersion device 15, the first reaction product storage tank 16, the second homogenization treatment device 17, the third homogenization treatment device 18 and the second reaction product storage tank 19. A first raw material high-level addition device 607 is prov...

Embodiment 2

[0060] The present embodiment adopts the same device as in Example 1 to carry out the continuous production of graphene amide, which comprises the following steps:

[0061] Step 1, add 10kg of graphite powder to 10kg of dilute hydrochloric acid (mass fraction 15%), soak it at 20°C, and transport it to the oxidation device 2 at a speed of 100kg / h by a pump after 0.5h, and add it through an online addition system. 100kg main oxidant and 10kg co-oxidant, the main oxidant potassium perchlorate is added at a rate of 5kg / h, and the addition rate of the co-oxidant peroxyester is 2kg / h, and the temperature is controlled at 80 ° C. After 10 hours of reaction, it is pumped to the first washing pump. The filter device 3 is repeatedly washed with deionized water and suction filtered three times, and then N,N-dimethylformamide is added for dispersion, and the material is transported into the second washing and suction filter device 4 by a pump, and the N,N-di After methylformamide washing ...

Embodiment 3

[0072] The present embodiment adopts the same device as in Example 1 to carry out the continuous production of graphene amide, which comprises the following steps:

[0073] Step 1, 10kg graphite powder was added to 20kg oxalic acid, soaked at 10°C, transported to oxidation device 2 by a pump at a speed of 100kg / h after 2 hours, and 10kg main oxidant and 1kg pro-oxidant were added through the online addition system, The addition rate of the main oxidant potassium dichromate is 5kg / h, the addition rate of the auxiliary oxidant peroxycarbonate is 2kg / h, and the temperature is controlled at 60 ° C. Deionized water is repeatedly washed and suction filtered for three times, then N,N-dimethylformamide is added for dispersion, and the material is transported into the second washing and suction filtration device 4 by a pump, and washed with N,N-dimethylformamide , After three times of suction filtration, graphite oxide is dispersed in N,N-dimethylformamide to obtain graphite oxide slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com