Method for preparing two-dimensional inorganic nanomaterial by mechanical force intercalation stripping

A two-dimensional nanomaterial, layer peeling technology, applied in vanadium oxide, tungsten oxide/tungsten hydroxide, manganese oxide/manganese hydroxide and other directions, to achieve the effect of shortened preparation time, high peeling efficiency and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

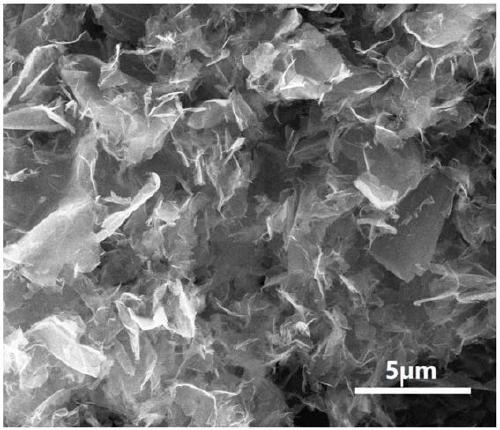

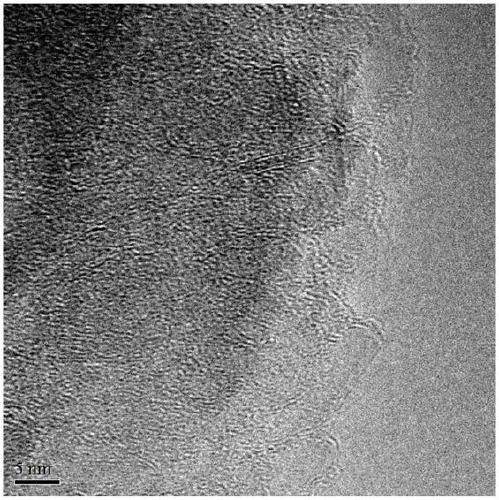

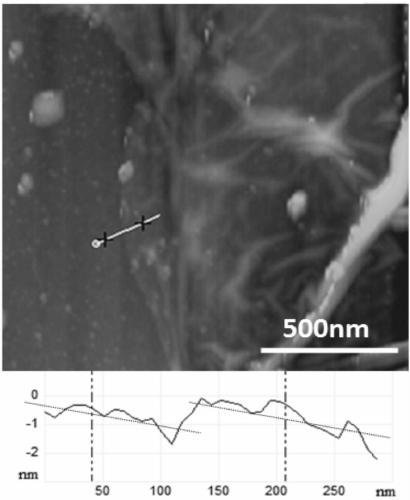

[0035] In this example, a 32-mesh artificially synthesized hexagonal boron nitride powder was used as a raw material to prepare two-dimensional boron nitride nanosheets. Mix lithium fluoride / sodium fluoride / potassium fluoride in a mass ratio of 3 / 1 / 6 to obtain a composite eutectic molten salt powder with a melting point of about 450°C. The hexagonal boron nitride powder and composite eutectic The molten salt powder is mixed evenly according to the mass ratio of 1:4, and then added to the stainless steel tank of the high-energy ball mill, and then stainless steel grinding balls with a diameter of 5mm are added, and the mass ratio of the grinding balls to the powder is 15:1. After sealing the tank body, carry out high-energy ball milling treatment, and the treatment time is 2 hours. After the ball milling process, spray water to the ball mill tank to cool to normal temperature. Open the ball mill tank, use a vibrating sieving machine to separate the ball powder, collect the obt...

Embodiment 2

[0037] In this example, 32-mesh natural molybdenum disulfide powder was used as raw material to prepare two-dimensional molybdenum sulfide nanosheets. Mix lithium fluoride / barium fluoride / potassium fluoride / sodium fluoride in a mass ratio of 45 / 2 / 41 / 12 to obtain a composite eutectic molten salt powder with a melting point of about 430°C. Molybdenum disulfide powder The body and the composite eutectic molten salt powder are mixed evenly according to the mass ratio of 1:6, then added to the agate tank of the high-energy ball mill, and then added with agate balls with a diameter of 10mm, the mass ratio of the balls to the powder is 8:1 . After sealing the tank body, carry out high-energy ball milling treatment, and the treatment time is 3 hours. After the ball milling process, spray water to the ball mill tank to cool to normal temperature. Open the ball mill tank, use a vibrating sieving machine to separate the ball powder, collect the resulting mixed powder, add deionized wat...

Embodiment 3

[0039]In this example, 32-mesh natural vermiculite powder was used as raw material to prepare two-dimensional silicate nanosheets. Mix lithium chloride / potassium fluoride in a mass ratio of 1 / 1 to obtain a composite eutectic molten salt powder with a melting point of about 490°C. Mix natural vermiculite powder and composite eutectic molten salt powder at a ratio of 1:8 After the mass ratio is mixed evenly, add it to the alumina tank of the high-energy ball mill, and then add alumina grinding balls with a diameter of 5mm. The mass ratio of the grinding balls to the powder is 6:1. After sealing the tank body, carry out high-energy ball milling treatment, and the treatment time is 1 hour. After the ball milling process, spray water to the ball mill tank to cool to normal temperature. Open the ball mill tank, use a vibrating sieving machine to separate the ball powder, collect the resulting mixed powder, add deionized water, and use a microporous filter membrane to repeatedly fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com