Preparation method of oxidized graphene doped hollow fiber nanofiltration membrane

A technology of graphene and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of lack of foundation for wide application or industrialization, and no report or preparation of hollow fiber nanofiltration membranes. Problems such as cumbersome process, to achieve the effect of improving flux and pollution resistance, good wetting performance and surface activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

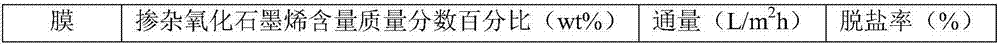

Embodiment 1

[0041] (1) Collect 10 hollow fiber ultrafiltration membranes (the ultrafiltration membrane material is polysulfone) with a length of 25cm into a bundle, put them into a component housing with a length of 20cm, and use epoxy AB glue after mixing thoroughly Carry out packaging, after the epoxy AB glue is cured, cut off the excess membrane wires at both ends of the shell, and prepare the membrane components for later use;

[0042] (2) Prepare respectively 0.4wt% piperazine, 0.2wt% sodium phosphate, 0.001wt% graphene oxide mixed solution as the water phase, and 0.3wt% trimesoyl chloride solution as the organic phase; the solvent of the organic phase solution is n-hexane Alkane; The solvent of the aqueous phase solution is pure water;

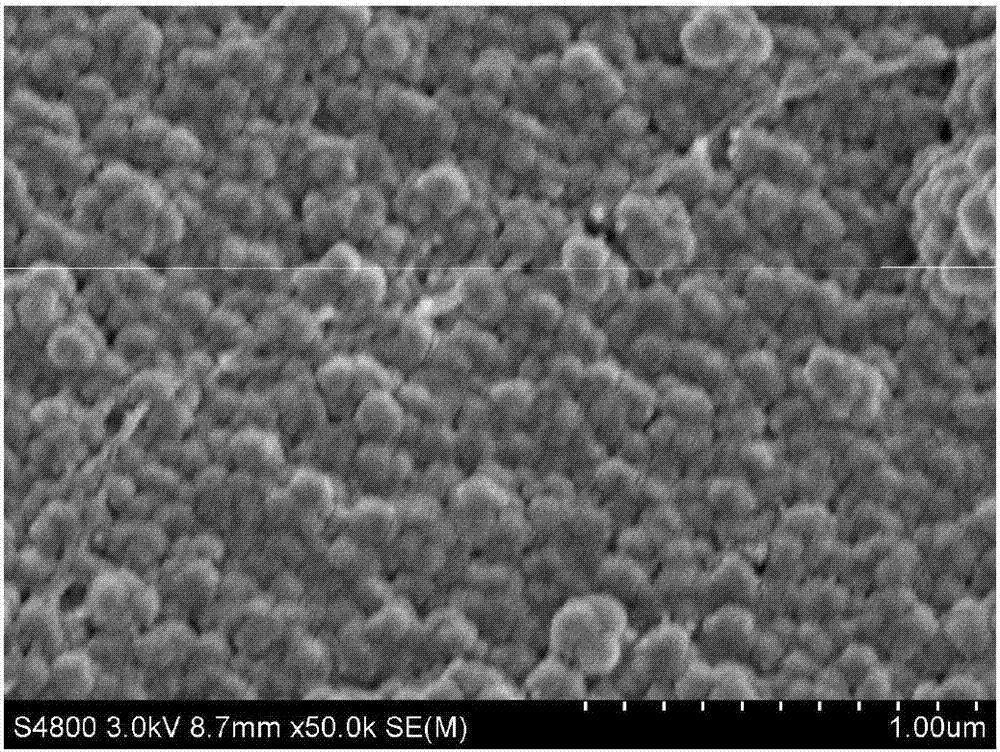

[0043] (3) Introduce the aqueous phase solution into the inner cavity of the hollow fiber basement membrane and discharge the air bubbles, fully immerse for 10 minutes, then remove the excess aqueous phase solution in the inner cavity of the membran...

Embodiment 2

[0045] (1) 30 hollow fiber ultrafiltration membranes with a length of 25cm (the ultrafiltration membrane material is polyvinylidene fluoride) are collected into a bundle, put into a module housing with a length of 20cm, and use epoxy resin after mixing thoroughly AB glue for packaging, after the epoxy AB glue is cured, cut off the excess membrane wires at both ends of the shell, and prepare the membrane assembly for later use;

[0046] (2) prepare respectively 0.4wt% p-phenylenediamine, 0.2wt% sodium phosphate, 0.005wt% graphene oxide mixed solution as the water phase, 0.3wt% trimesoyl chloride solution as the organic phase; the solvent of the organic phase solution It is n-hexane; the solvent of the aqueous phase solution is a mixed solution of pure water and ethanol (volume ratio is 9:1);

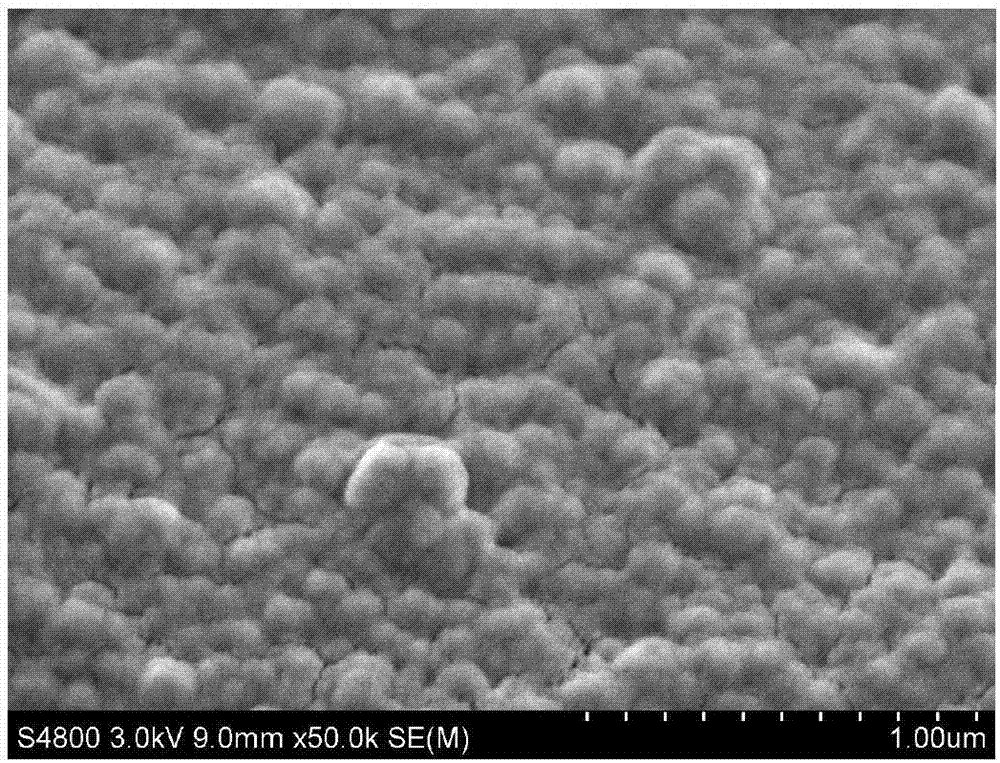

[0047] (3) Introduce the aqueous phase solution into the inner cavity of the hollow fiber basement membrane and discharge the air bubbles, fully immerse for 10 minutes, then remove the ex...

Embodiment 3

[0049](1) 80 hollow fiber ultrafiltration membranes (the ultrafiltration membrane material is polyvinyl chloride) that 80 lengths are 25cm are gathered into a bundle, and the length of packing into is 20cm in the module housing, and with epoxy AB after mixing thoroughly After the epoxy AB glue is cured, cut off the excess membrane wires at both ends of the shell, and prepare the membrane assembly for use;

[0050] (2) Prepare respectively 0.4wt% m-phenylenediamine, 0.2wt% sodium phosphate, 0.01wt% graphene oxide mixed solution as the water phase, and 0.3wt% trimesoyl chloride solution as the organic phase; the solvent of the organic phase solution It is n-hexane; the solvent of the aqueous phase solution is a mixed solution of pure water and ethanol (volume ratio is 8:2);

[0051] (3) Introduce the aqueous phase solution into the inner cavity of the hollow fiber basement membrane and discharge the air bubbles, fully immerse for 10 minutes, then remove the excess aqueous phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com