Bottom film stripping knife

A technology of peeling knife and bottom film, which is applied in lamination, chemical instruments and methods, lamination auxiliary operation, etc., can solve the problems of raw material bottom film weight, easy foaming of materials, material waste, etc., to prevent foaming and Effects of wrinkling phenomenon, improvement of yield rate, and improvement of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

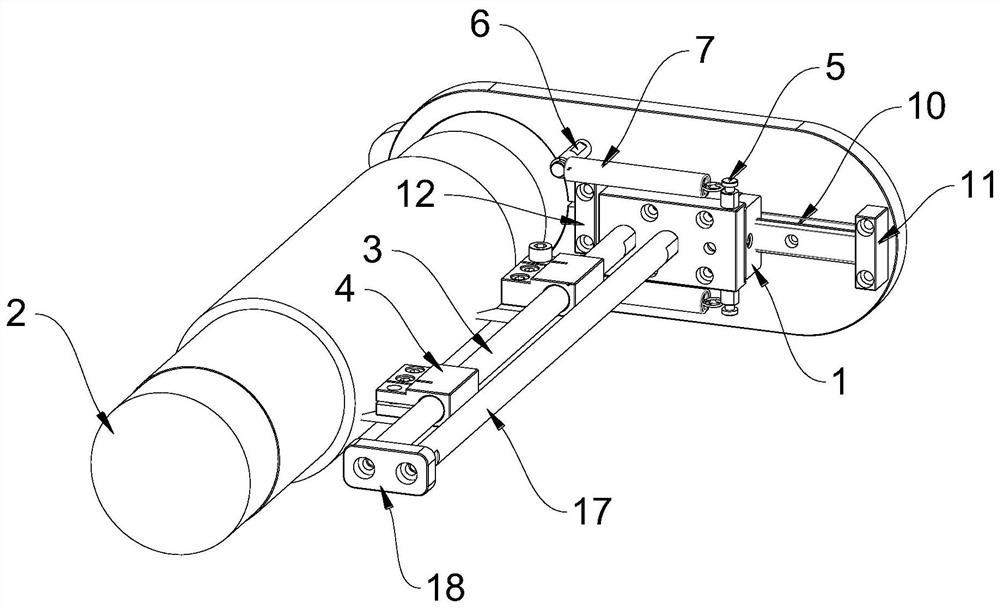

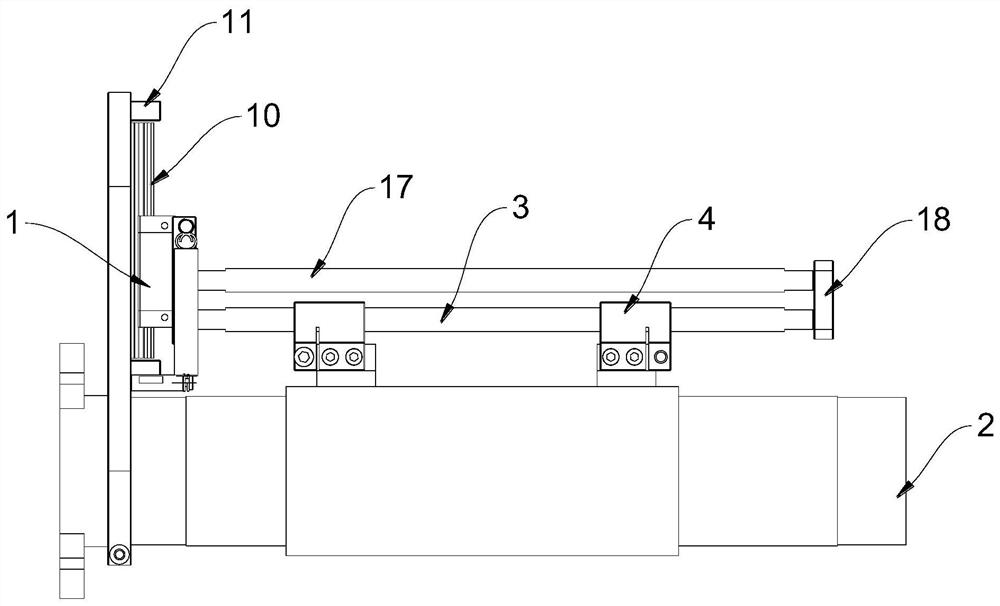

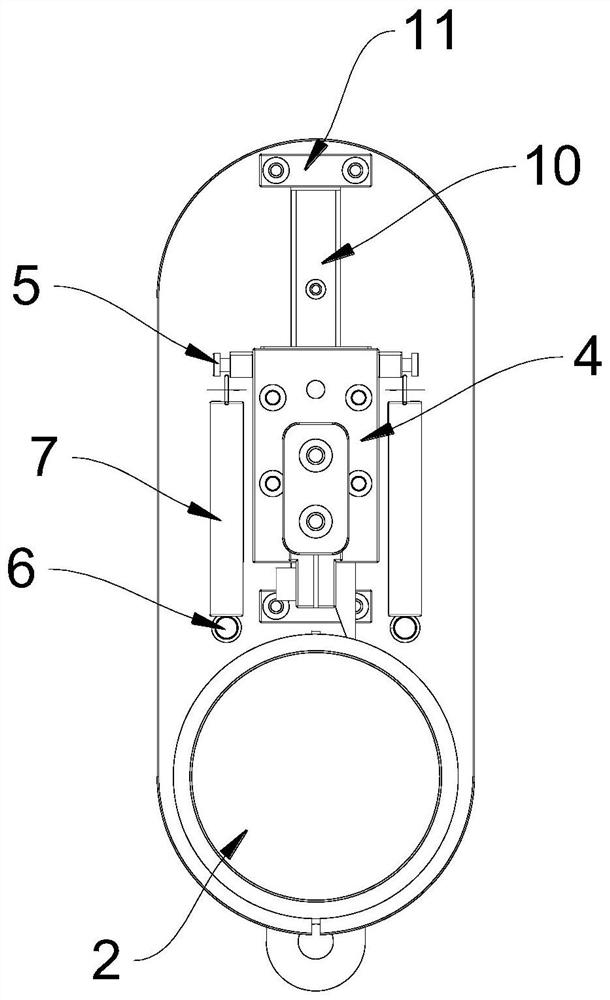

[0036] Please refer to Figure 1-6 , this embodiment provides a bottom film peeling knife, including: a mounting seat 1, a bottom film roller shaft 2, a moving slide rail 3, a stripping knife assembly 4, a first pull rod 5, a second pull rod 6, a tension spring 7, a pull ring 8. Limiting groove 9, linear slide rail 10, first limiting seat 11, second limiting seat 12, sliding through hole 13, locking bolt 14, installation groove 15, locking screw hole 16, support shaft 17 and Closing Block 18.

[0037] Mounting seat 1 is movable on the machine table, and its movement direction is perpendicular to the central axis of the bottom film roller shaft 2; the moving slide rail 3 is arranged on the mounting seat 1, and it is arranged parallel to the bottom film roller shaft 2; the peeling knife assembly 4 It is detachably arranged on the moving slide rail 3 and is used to press against the base film to separate the base film.

[0038] It should be noted that the bottom film roller sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com