Display panel mother board and preparation method of display panel

A technology for display panels and manufacturing methods, applied in the fields of final product manufacturing, sustainable manufacturing/processing, identification devices, etc., capable of solving deformation and damage of flexible substrates and display components, affecting the electrical performance of display components, and yield decline, etc. problems, to achieve the effect of ensuring the stripping yield, improving the stripping yield, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

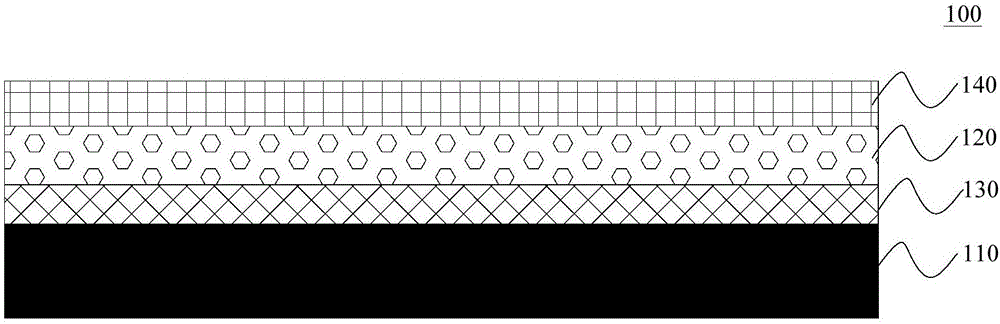

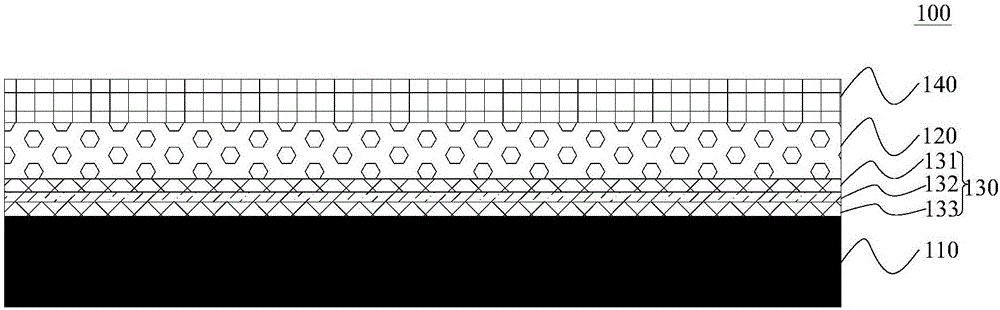

[0063] refer to figure 1 , the first aspect of the present invention relates to a display panel motherboard 100 . Wherein, the display panel motherboard 100 includes a rigid substrate 110 and a flexible substrate 120 , and the rigid substrate 110 is disposed opposite to the flexible substrate 120 .

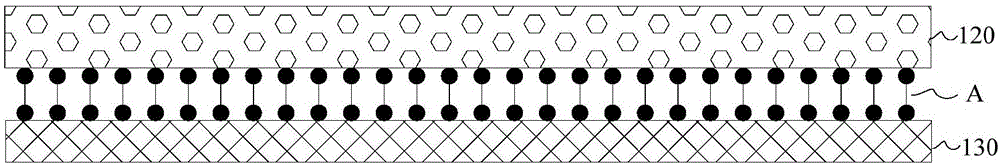

[0064] The display panel motherboard 100 also includes a liquid affinity adjustable layer 130 . Wherein, the liquid affinity adjustable layer 130 is arranged between the rigid substrate 110 and the flexible substrate 120 , and the liquid affinity adjustable layer 130 bonds the flexible substrate 120 to the rigid substrate 110 .

[0065] It should be noted that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com