A kind of alkaline non-scratch stripping solution and stripping method

A deplating solution and alkaline technology, applied in the field of alkaline non-scratch deplating solution and deplating, can solve the problems of poor penetration of deplating ink, fast chemical reaction, new scratches, etc., to protect the appearance transparency, Less environmental pollution, high yield rate of fading plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

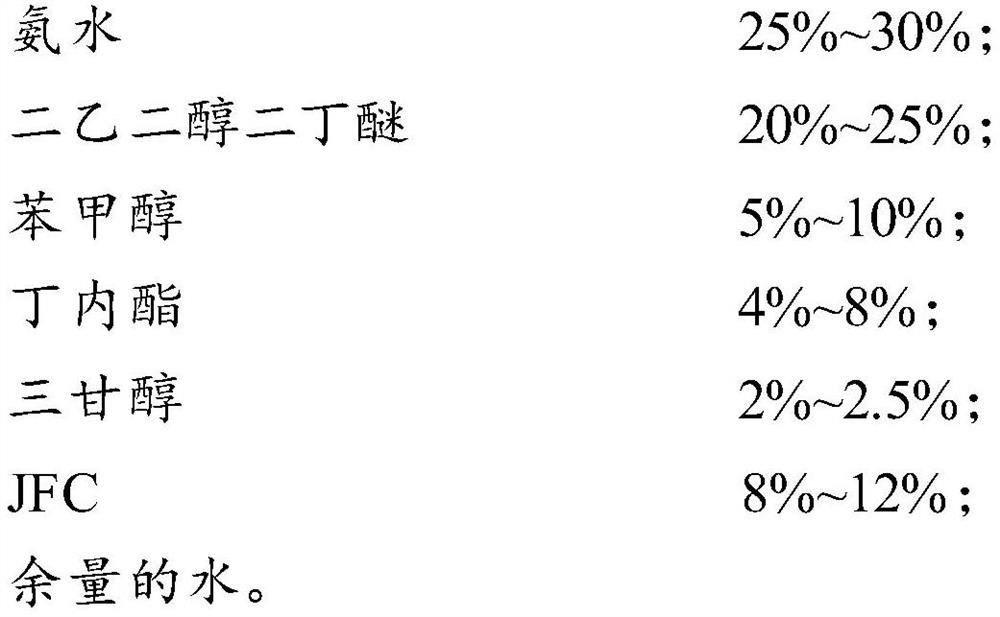

[0031] In terms of mass percentage, the ratio of the deplating agent is as follows: industrial ammonia 25%, diethylene glycol dibutyl ether 25%, benzyl alcohol 10%, butyrolactone 8%, triethylene glycol 2.5%, JFC 12%, the balance It is water; the deplating temperature is 95℃, and the deplating time is 2min. The parts were stripped to observe whether the stripping effect had any influence, and whether there was damage, bluing and fogging on the surface of the product. The results are shown in Table 1.

[0032] Wherein, the stripped parts in Examples 1-2 are glass sheets sprayed with AR protection oil on the surface; the stripped parts in Examples 3-4 are glass sheets with AR protection oil screen-printed on the surface.

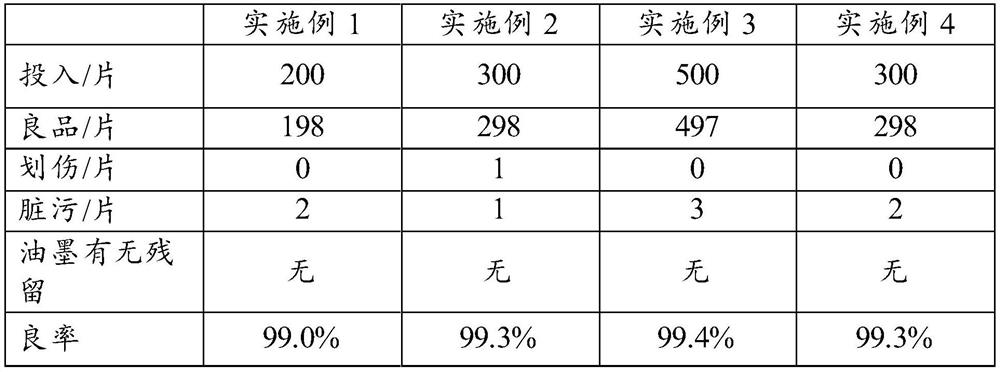

[0033] Table 1 Deplating results

[0034]

Embodiment 5~8

[0036] In terms of mass percentage, the ratio of the stripping agent is as follows: industrial ammonia 25%, diethylene glycol dibutyl ether 22%, benzyl alcohol 8%, butyrolactone 6%, triethylene glycol 2.0%, JFC 10%, the balance It is water; the deplating temperature is 95℃, and the deplating time is 3min. The parts were stripped to observe whether the stripping effect had any influence, whether there was any damage to the surface of the product, bluish and foggy. The results are shown in Table 2.

[0037] Among them, the stripped parts in Examples 5-6 are glass sheets sprayed with AR protection oil on the surface; the stripped parts in Examples 7-8 are glass sheets with AR protection oil silk-screened on the surface.

[0038] Table 2 Deplating results

[0039]

Embodiment 9~12

[0041] In terms of mass percentage, the ratio of the stripping agent is as follows: industrial ammonia 30%, diethylene glycol dibutyl ether 20%, benzyl alcohol 5%, butyrolactone 4%, triethylene glycol 2.0%, JFC 8%, the balance It is water; the deplating temperature is 95℃, and the deplating time is 4min. The parts are stripped to observe whether the stripping effect has any influence, whether there is damage to the product surface, bluish and foggy, and the results are shown in Table 3.

[0042] Among them, the stripped parts in Examples 9-10 are glass sheets sprayed with AR protection oil on the surface; the stripped parts in Examples 11-12 are glass sheets with AR protection oil screen printed on the surface.

[0043] Table 3 Deplating results

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com