Patents

Literature

47results about How to "Wide range of reaction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

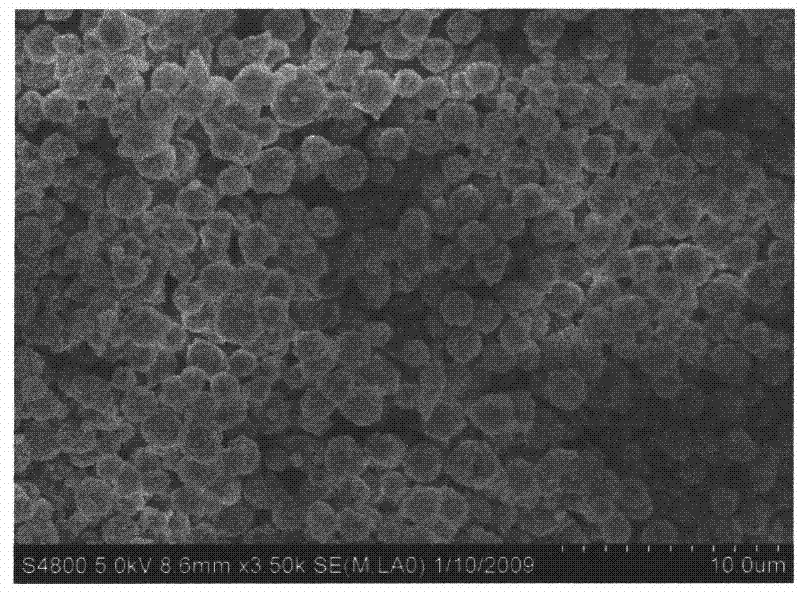

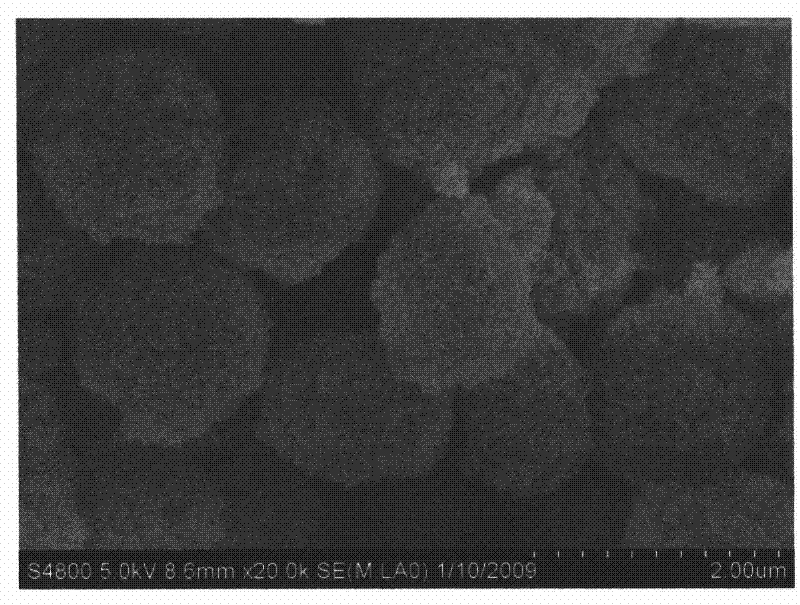

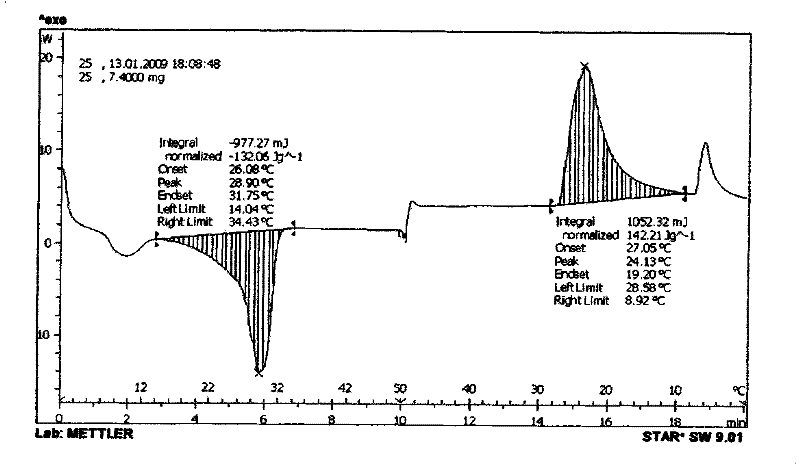

Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

InactiveCN101530772ALess light fastnessSmall smellHeat-exchange elementsMicroballoon preparationPolymer chemistryPhase-change material

A preparing method for phase transited stored energy microcapsule covered with an organic polymer material adopts the following steps: (1) mixing the 10 weight organic phase transited material and 0.5-2.5 weight nonionic surfactant under the condition of heating and blending; (2) picking the organic polymer material monomer A, B 2-3 weight to add to 40-60 weight water, blending and mixing as the water phase; (3) adding the oil phase to the water phase, blending the material as the creaming liquid at 30-50 centigrade, adding the free radical to the initiator for the poly-reaction 1-8h at 35-90 centigrade; then adjusting the low temperature as blending the material and adding the cross linker, filtering, washing and drying to obtain the finished products. The organic polymer material achieves the phase transited capsule envelopment via the creaming polymer reaction of the wall material; the microcapsule is the spherical; the granule is distributed evenly; the polymer wall material has a stable intensity, great tightness and great mechanical performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

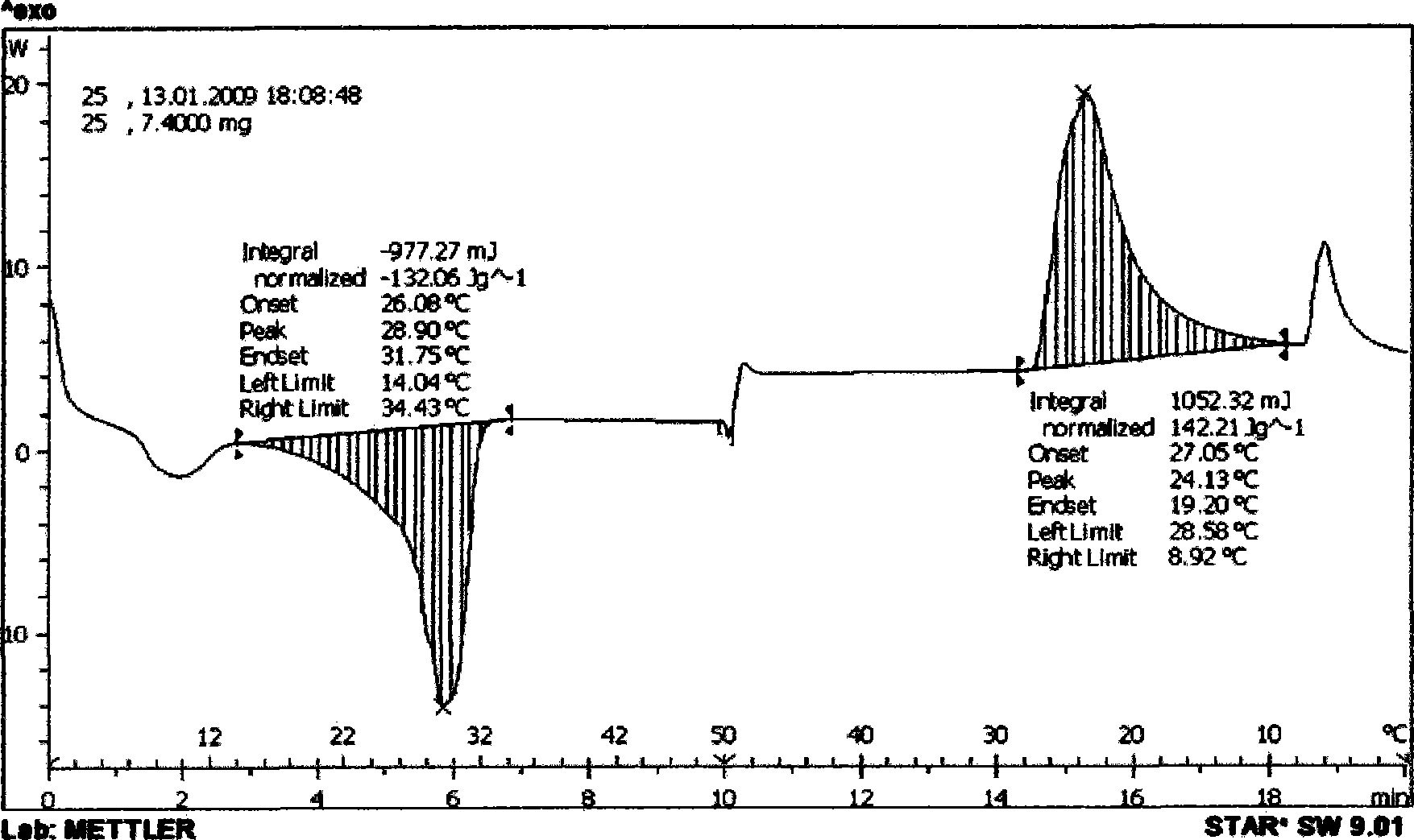

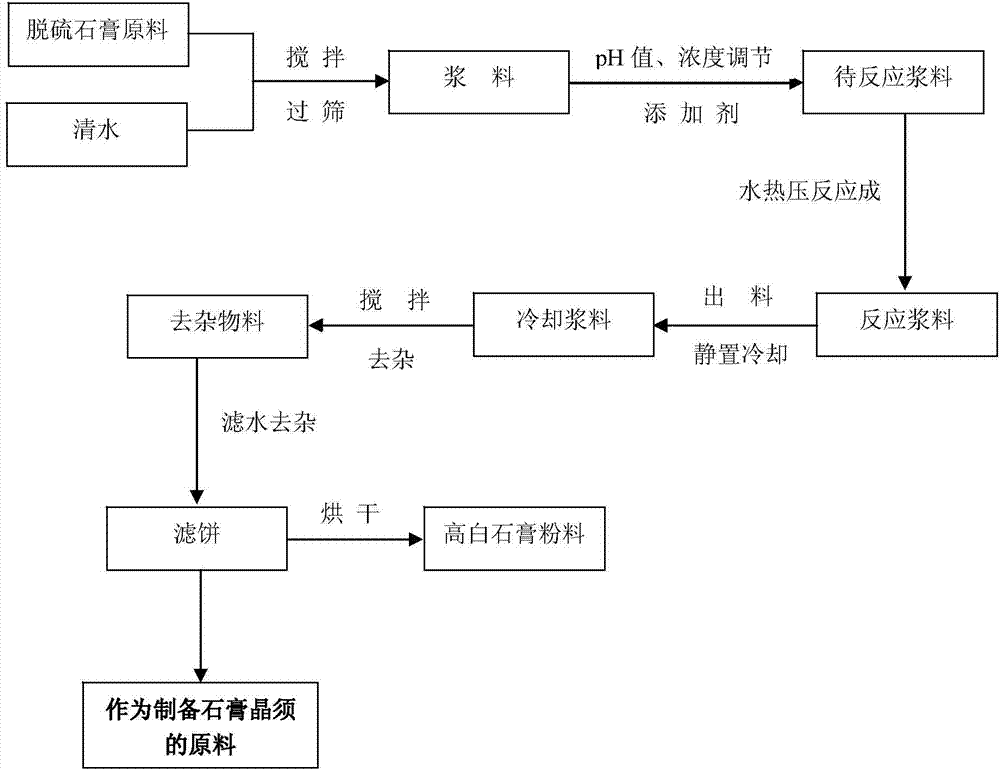

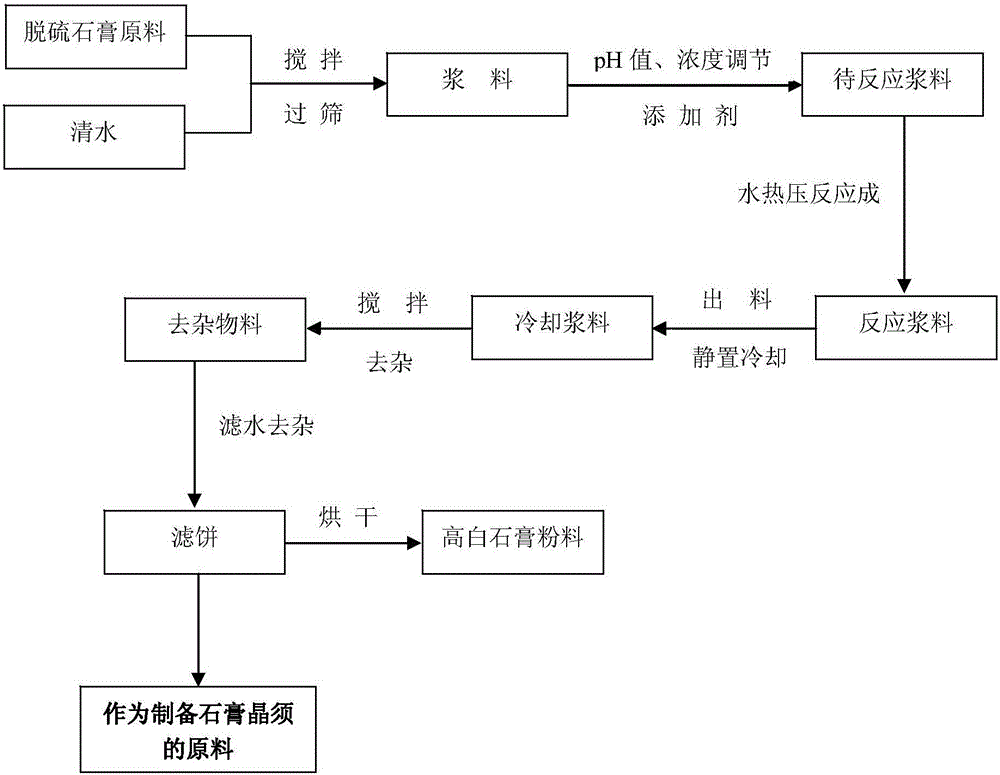

Method for removing impurities from desulphurization gypsum of power plant

The invention relates to a method for removing impurities from desulphurization gypsum of a power plant. The invention adopts a reversible conversion principle that dihydrate gypsum can be rapidly dissolved, re-crystallized and converted into alpha-hemihydrate gypsum under the conditions that temperature is higher than or equal to 120 DEG C, pressure is higher than or equal to 0.15MPa, a pH value is 2.5-7 and an additive exists, and the alpha-hemihydrate gypsum can be also rapidly converted into dihydrate gypsum when being cooled in a water environment. The method for removing the impurities from the desulphurization gypsum of the power plant comprises the following steps: sieving a raw material for filtering out large-particle impurities; preparing reaction slurry, and carrying out water type hot pressing reaction, so that dihydrate gypsum is rapidly converted into alpha-hemihydrate gypsum; standing, and cooling, wherein alpha-hemihydrate gypsum in the slurry is converted into relatively large dihydrate gypsum particles; removing impurities to obtain a relatively pure gypsum material; carrying out water filtration to further remove small impurity particles and harmful soluble salt in gypsum; and obtaining slurry and a wet body or drying to obtain powder according to follow-up needs. The method for removing the impurities from the desulphurization gypsum of the power plant can be taken as a gypsum raw material purification process in preparation of calcium sulphate whiskers by virtue of the desulphurization gypsum, and can also be taken as a method for producing high-whiteness gypsum. The method for removing the impurities from the desulphurization gypsum of the power plant is simple, efficient and easy for mass production.

Owner:ROAD ENVIRONMENT TECH

Production method of inorganic nanometer light response type self-cleaning polyester fiber

InactiveCN102560724AConsiderable value-addedImprove efficacyFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a production method of inorganic nanometer light response type self-cleaning polyester fiber, comprising the following steps of: firstly specially producing visible light response type photochemical catalyst and easily-dispersed functional self-cleaning master batch, mixing the specially-produced functional master batch with polyester chip, and producing the inorganic nanometer light response type self-cleaning polyester fiber by a polyester fiber production technology. On the premise that the physical and chemical properties and the spinnability of the conventional fiber are not changed, the inorganic nanometer light response type self-cleaning polyester fiber has the characteristics such as bacteriostasis, air cleaning, self-cleaning function of easily desorbing greasy dirt, wide reaction condition, economical efficiency and the comprehensive treatment on pollutants. The various textiles made from the fiber, such as curtains, tablecloth, sofas, bedclothes and clothes, just like automatically running air cleaners, can be widely used in places such as bedrooms, hotel rooms, hospital wards, office, shopping malls, restaurants, indoor recreation grounds, etc.

Owner:SHANGHAI DEFULUN CHEM FIBER

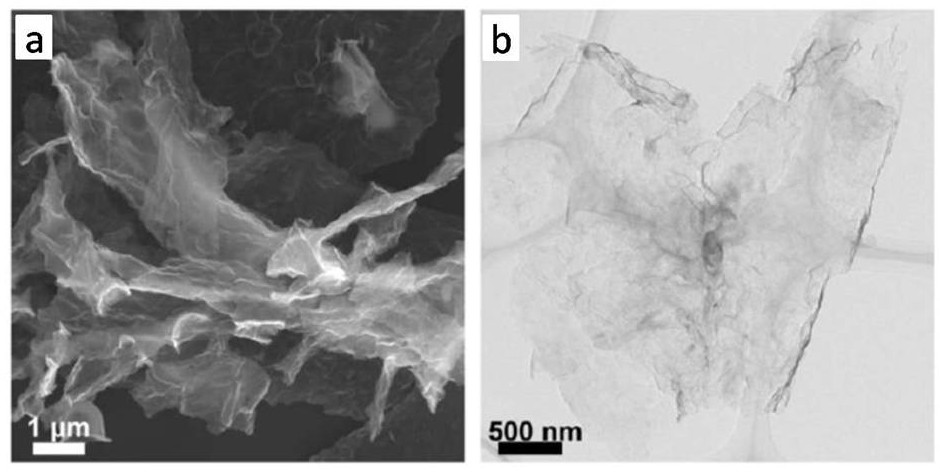

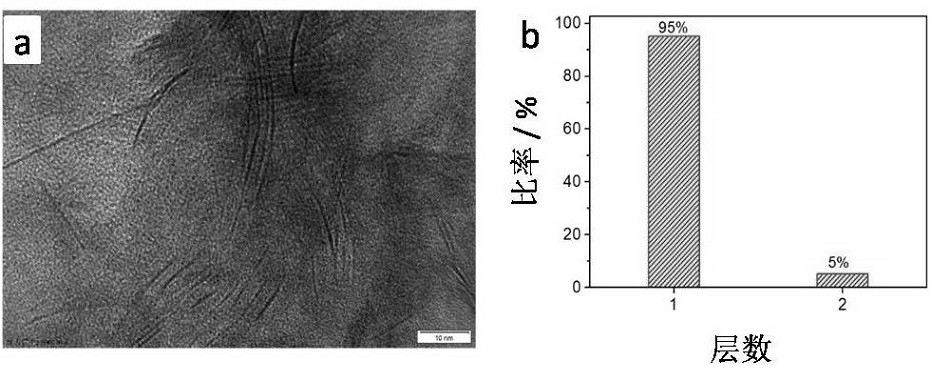

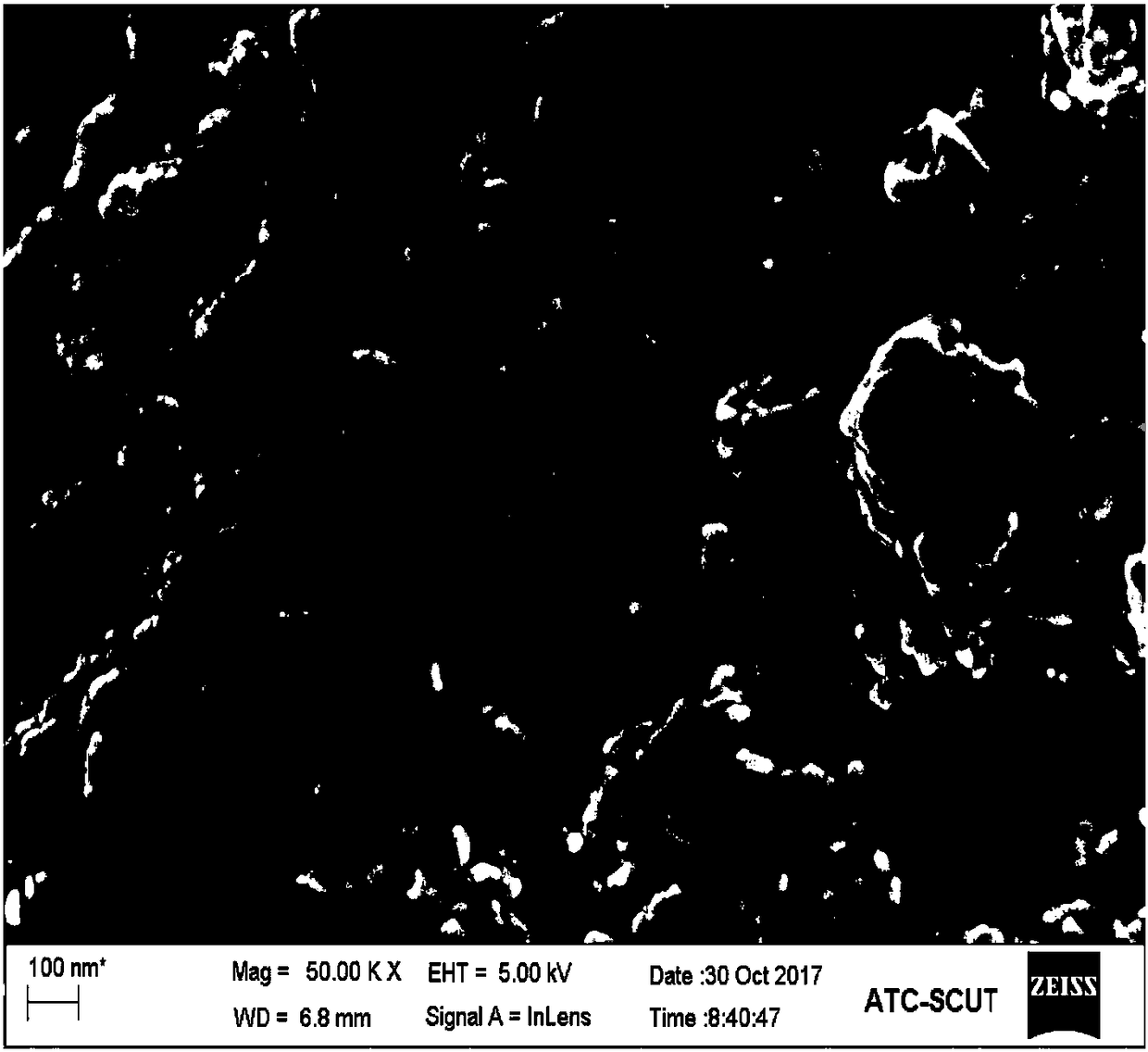

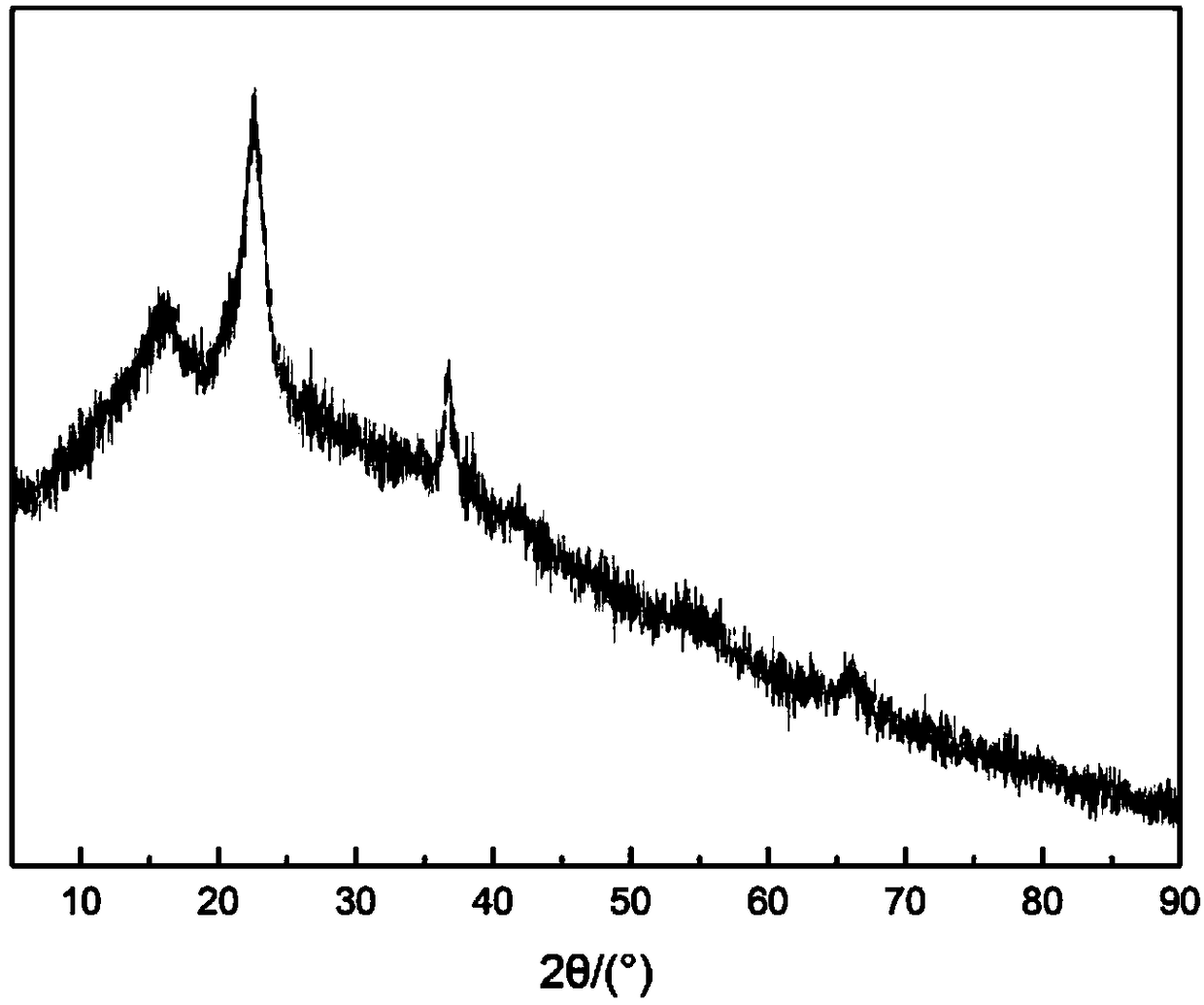

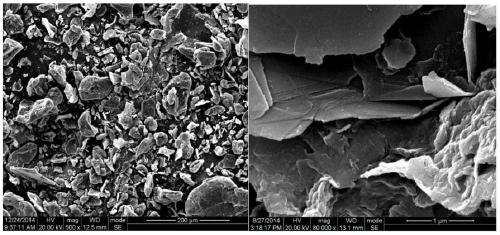

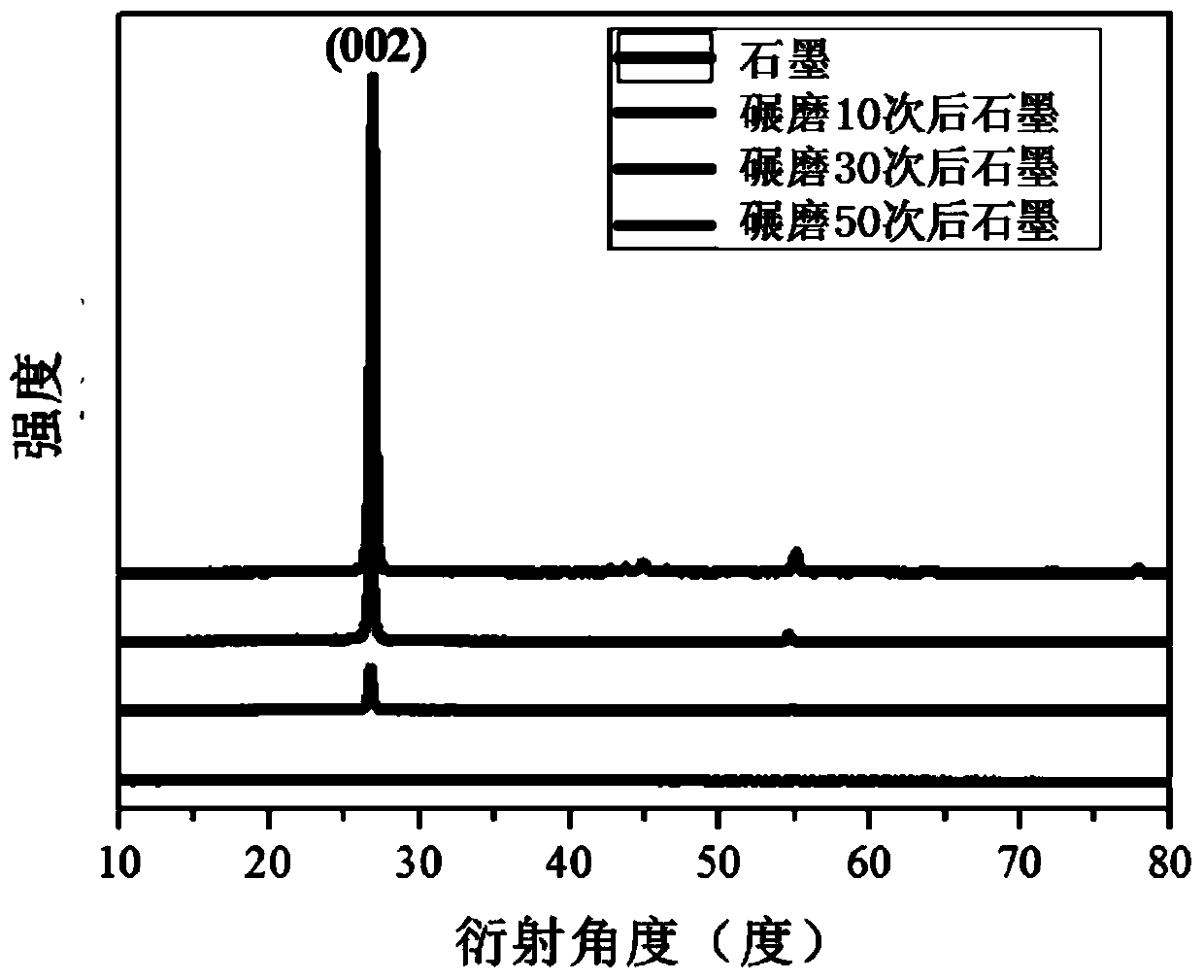

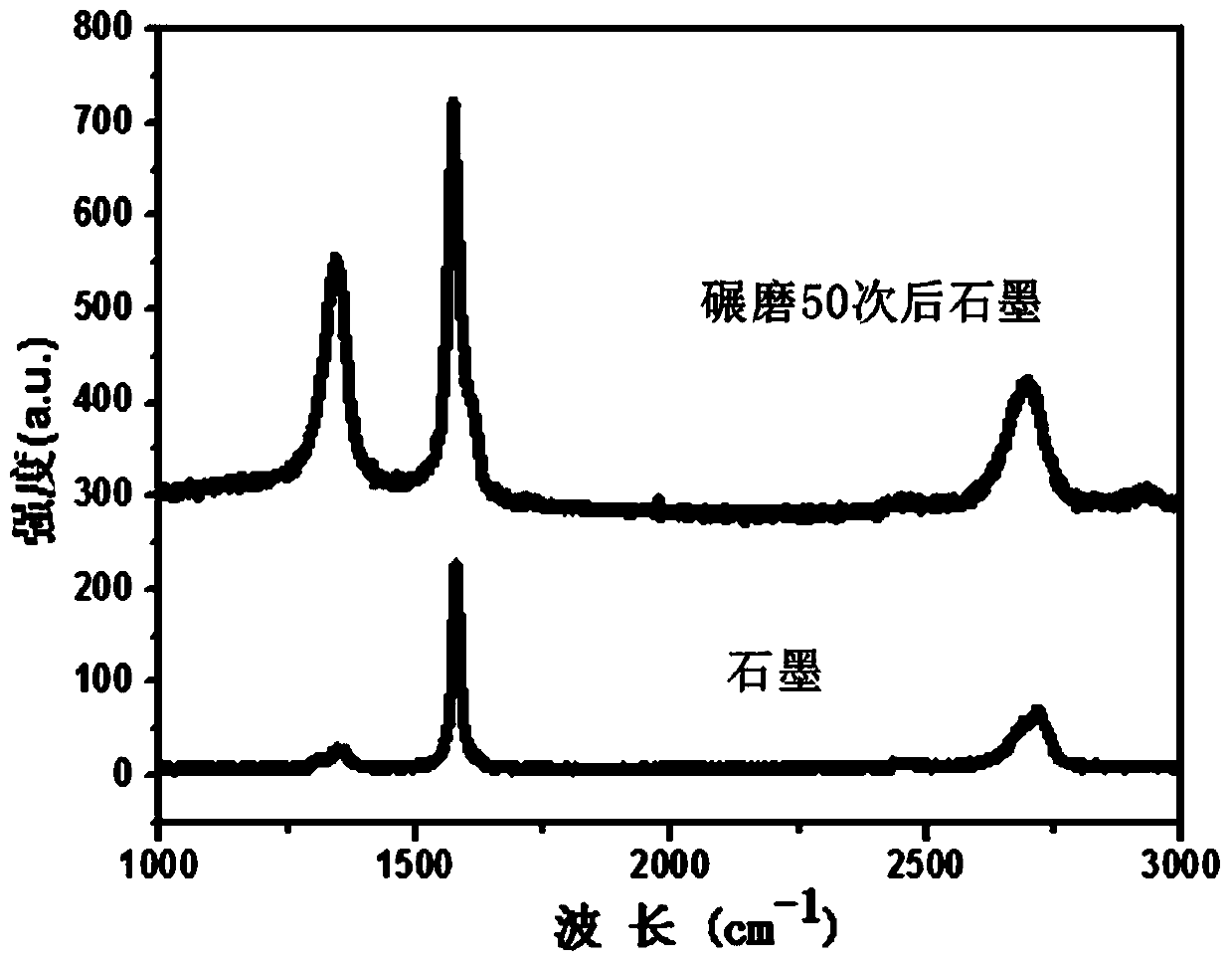

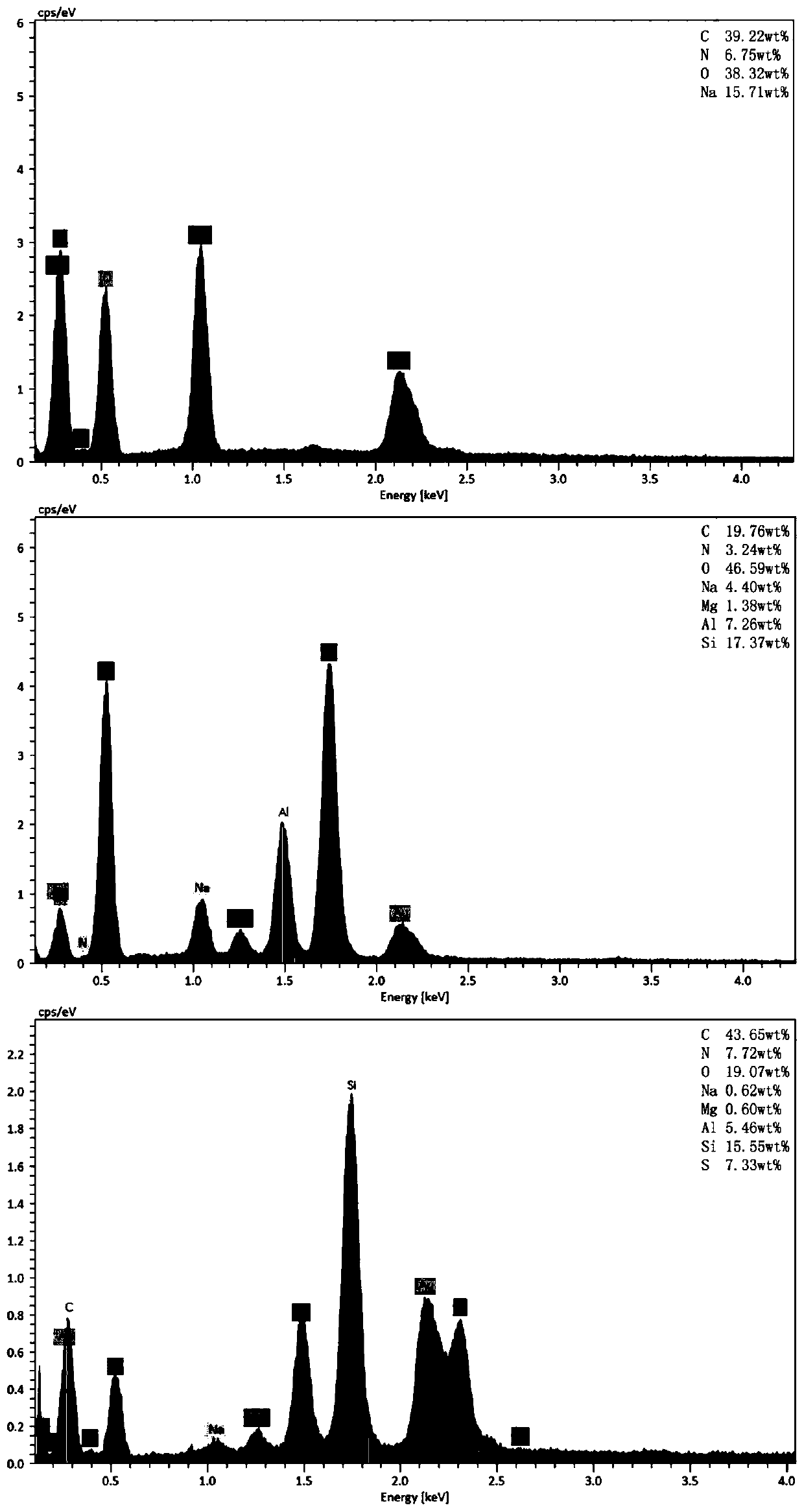

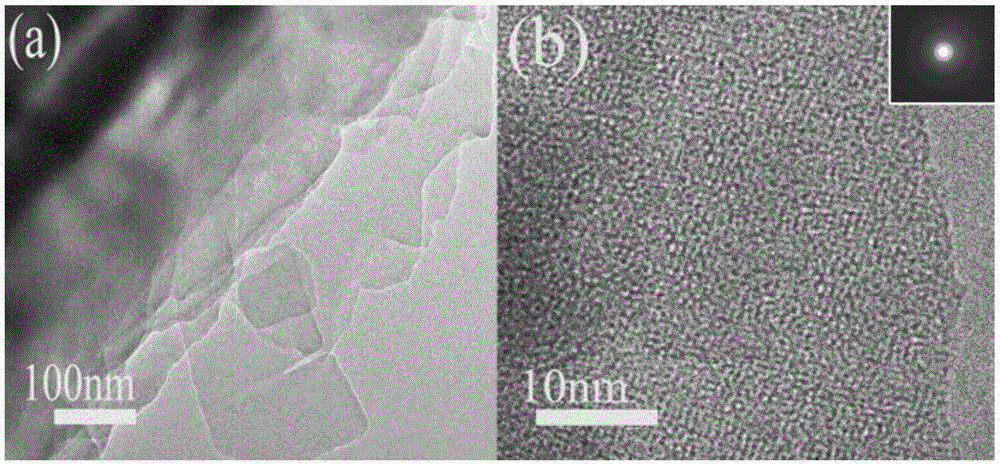

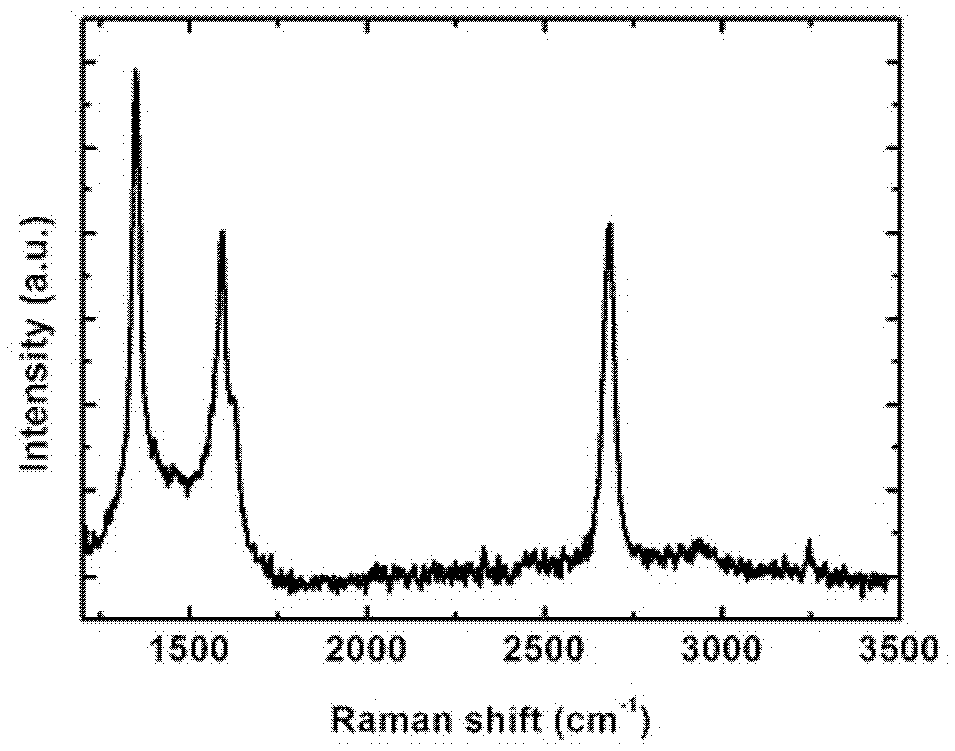

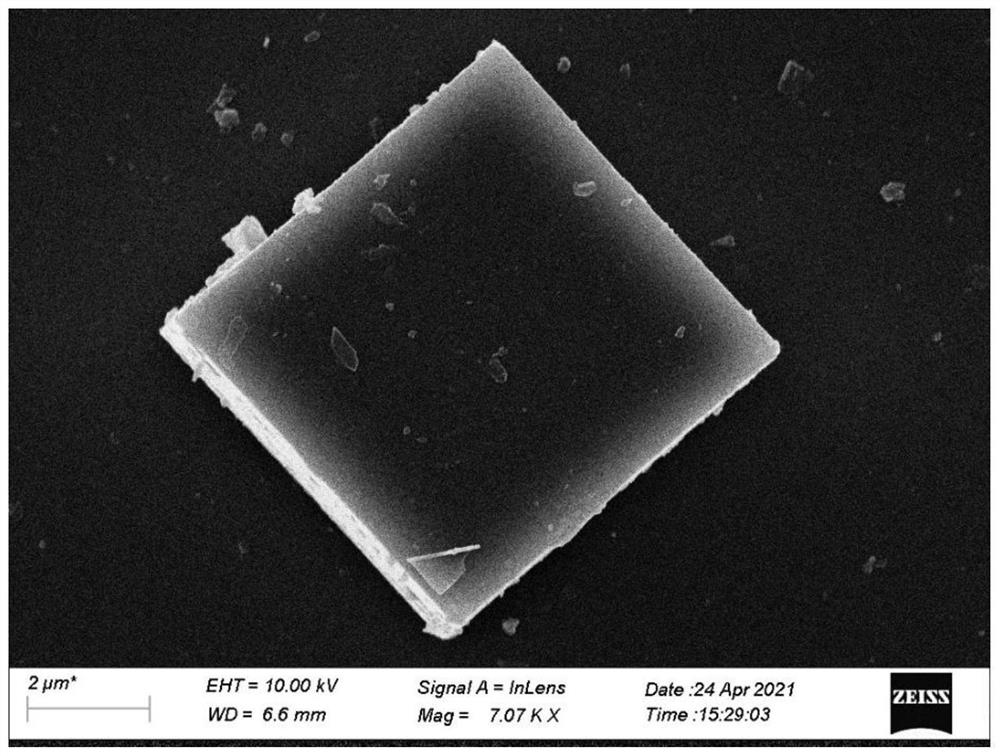

Graphene material based on solid state mechanochemical reactor and preparation method of graphene material

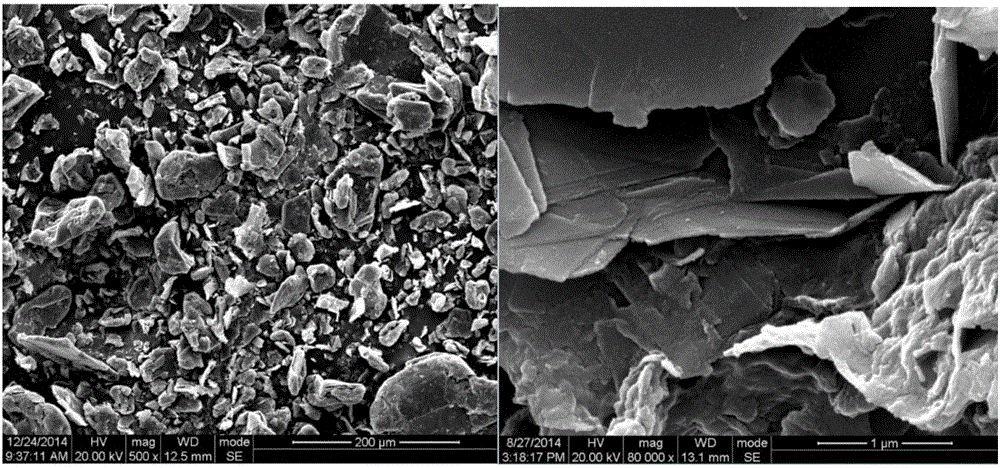

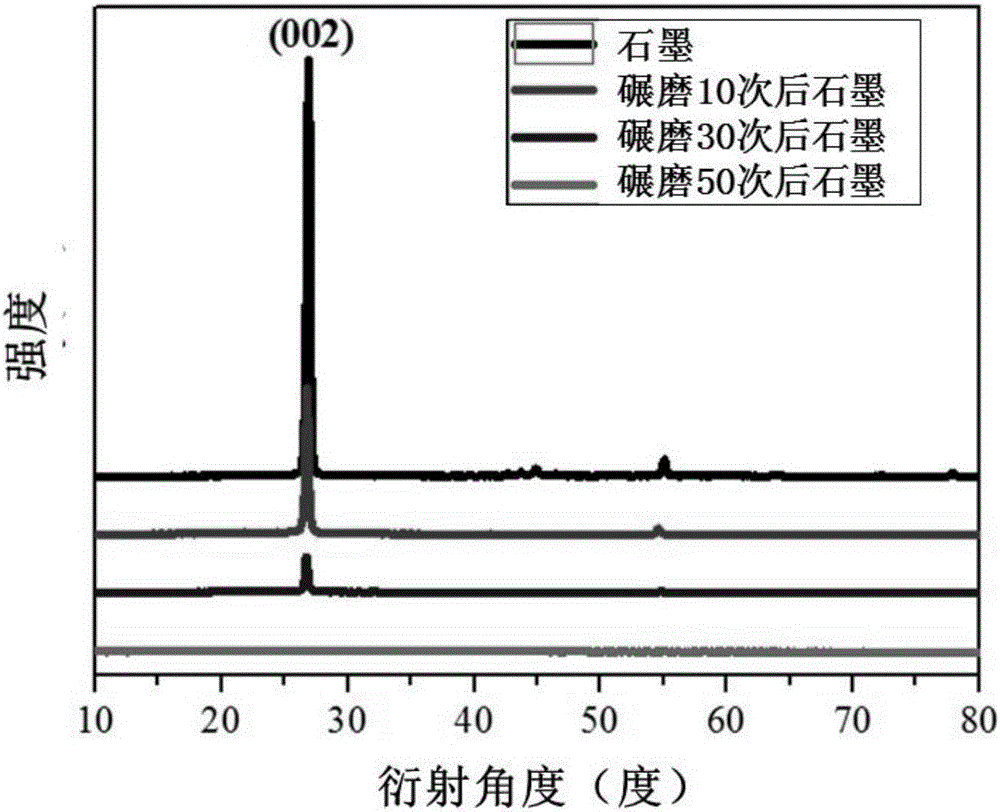

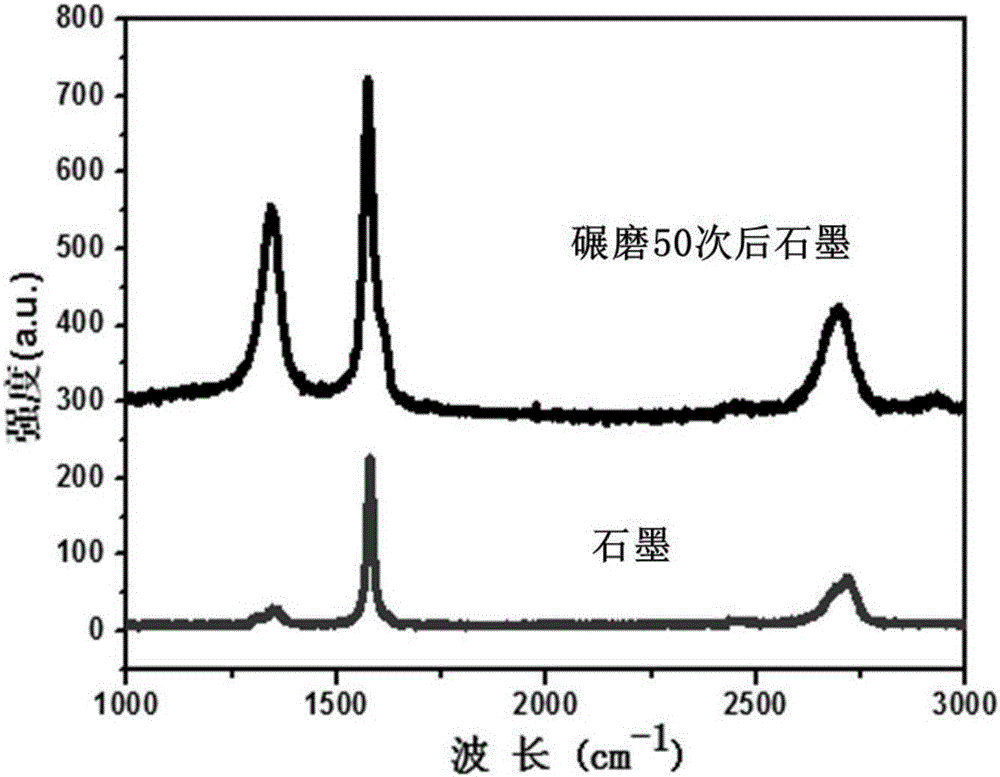

The invention belongs to the technical field of graphene preparation, and in particular relates to a graphene material based on a solid state mechanochemical reactor and a preparation method of the graphene material. According to the technical scheme of the invention, a three-dimensional strong shearing structure of the solid state mechanochemical reactor is utilized, a grinding aid is introduced in the graphite grinding process, the grinding aid and the graphite can be subjected to intense mutual friction caused by three-dimensional shearing force initialized by the three-dimensional shearing structure, then graphite can be peeled, and thus single-layer or small-layer graphene can be prepared. The preparation method comprises the following steps of: respectively drying graphite and the grinding aid, adding into a mixing machine, uniformly mixing, transferring into the solid state mechanochemical reactor for grinding, removing the grinding aid and impurity ions, and drying at 60-90 DEG C, thereby obtaining the high-performance graphene material of which the layer number is smaller than 8 and substrate defects are slightly caused. The novel preparation method of the graphene material provided by the invention has the characteristics of simplicity, high efficiency, cleanliness and low cost, the prepared graphene material has small substrate defects, and surface functionalization of graphene can be achieved at one step.

Owner:SICHUAN UNIV

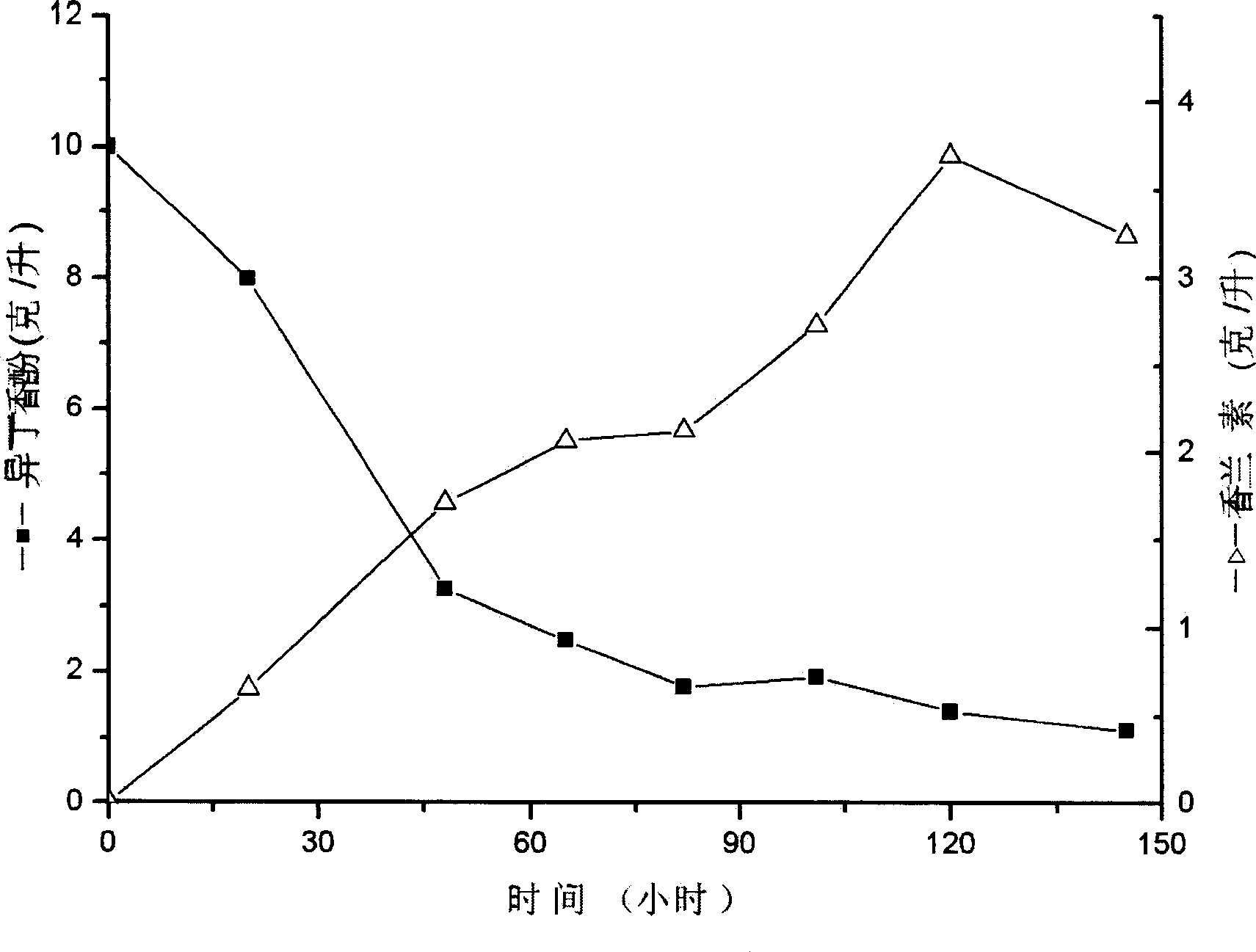

Bacillus pumilus and application of the same in producing natural vanillin by biologically converting iso-eugenol

ActiveCN101078005AWide variety of sourcesLow priceBacteriaMicroorganism based processesBiotechnologyHigh concentration

The invention discloses Bacillus pumilis and its application of biotransformation of iso-eugenol into natural vanillin. The name of bacterial stripe is Bacillus pumilus S-1, preserved in China Center for Type Culture Collection on 3rd, January, 2006 and its serial number is CCTCC M 205165. The procedure of transforming iso-eugenol into natural vanillin includes: (1)cultivation, (2)preparation of seed culture fluid, (3)culture of transforming cell, (4) transformation.The invention exists in field of biology and technology. It can improve the transformating rate of vanillin with high concentration, solving problems of low concentration and low yield of vanillin by biological method.

Owner:SHANGHAI KAIXIN BIOTECH +2

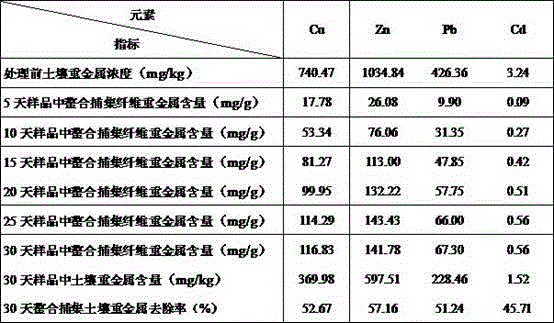

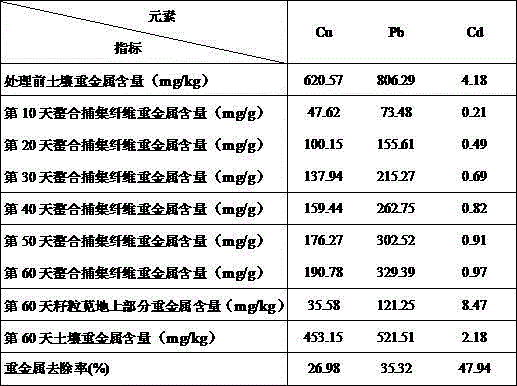

In-situ capturing treatment method for soil heavy metal pollution

ActiveCN105689371AImprove capture capacityProcessing speedContaminated soil reclamationHigh concentrationHeavy metal chelation

The invention discloses an in-situ capturing treatment method for soil heavy metal pollution. The method comprises the steps of 1 deep ploughing and cleaning-up of soil, 2 burying of chelating capturing materials, 3 dry and wet adjustment, 4 soil heavy metal activation, 5 removing of the chelating capturing materials, 6 activating and recycling of the chelating capturing materials, 7 soil microelement supplementing and the like. According to the method, the chelating capturing materials are used for effectively removing water-soluble heavy metal, exchangeable heavy metal and part of carbonate-exchangeable heavy metal in soil, and the main route of soil heavy metal environmental risk transfer is effectively interdicted. The heavy metal chelating capturing materials adopted in the method can effectively treat trace metal pollution, high-concentration heavy metal pollution and multi-metal combined pollution, and the chelating capturing materials obtained after treatment can be activated and recycled. In addition, the method has the beneficial effects of being easy to operate, capable of being used in combination with other restoring methods easily, good in treatment effect, low in cost, free of secondary environmental risks and the like.

Owner:SHENZHEN DUOYUAN TUOZHAN ENVIRONMENTAL PROTECTION TECH CO LTD

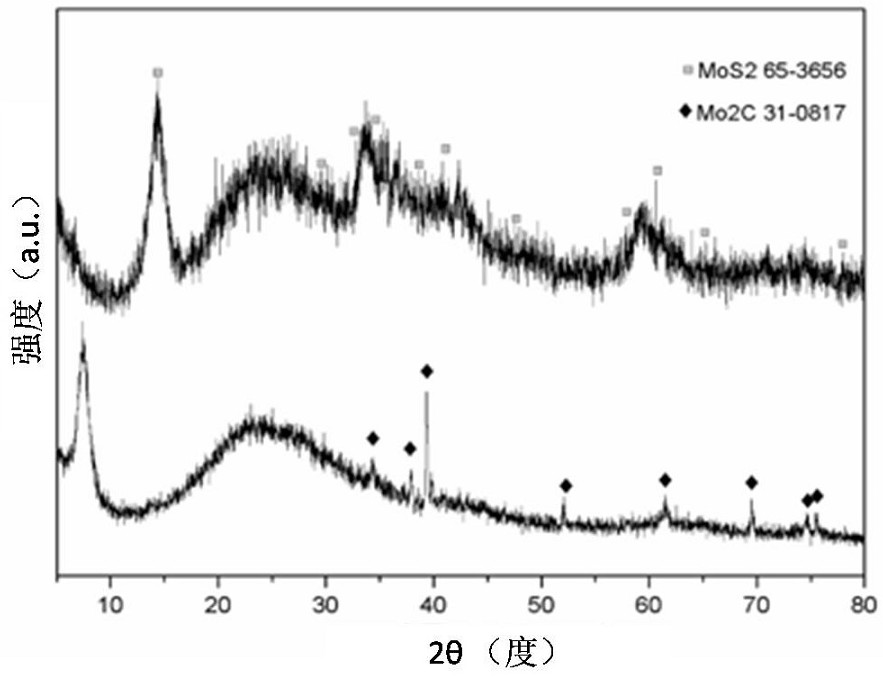

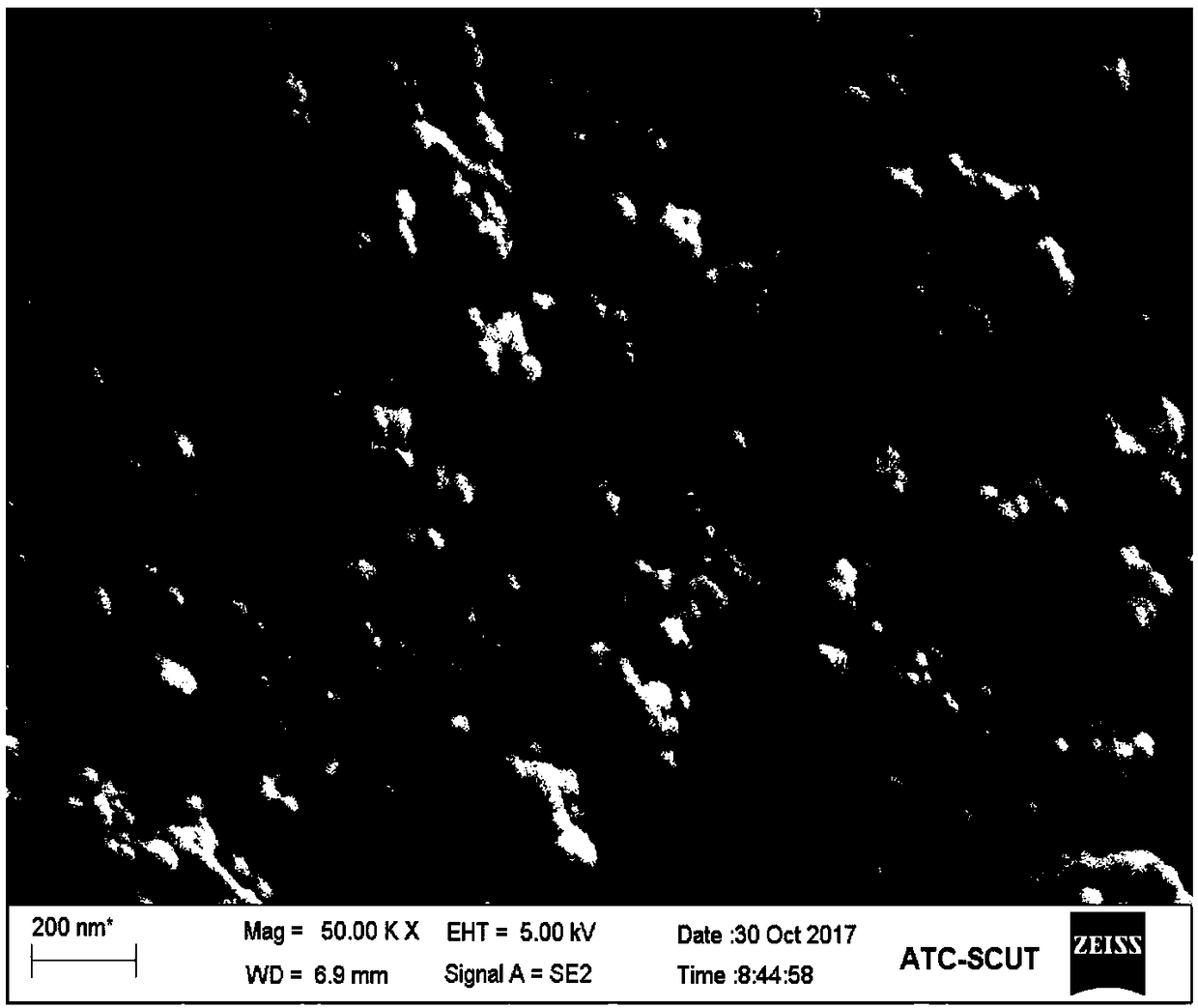

Synthesis method of two-dimensional transition metal chalcogenide

ActiveCN112678826AHigh yieldTopological transformation reaction heightMaterial nanotechnologyTitanium carbidePhysical chemistryReaction temperature

The invention discloses a synthesis method of a two-dimensional transition metal chalcogenide, which comprises the following steps: heating: heating a transition metal compound raw material to a reaction temperature in an inert gas environment; topological conversion reaction step: introducing a gas containing a chalcogen or a mixed gas of the gas containing the chalcogen and the gas containing the phosphorus, and maintaining the reaction temperature for a set period of time, so that the chalcogen, or the chalcogen and the phosphorus are subjected to a topological conversion reaction with the transition metal compound raw material, and generating the two-dimensional transition metal chalcogenide. The synthesis method has the advantages of high reaction degree, high yield, low energy consumption and high efficiency, the obtained two-dimensional transition metal chalcogenide is high in single-layer rate and narrow in layer number distribution, macro preparation can be realized, and the synthesis method has an excellent industrial application prospect.

Owner:济南三川新材料科技有限公司

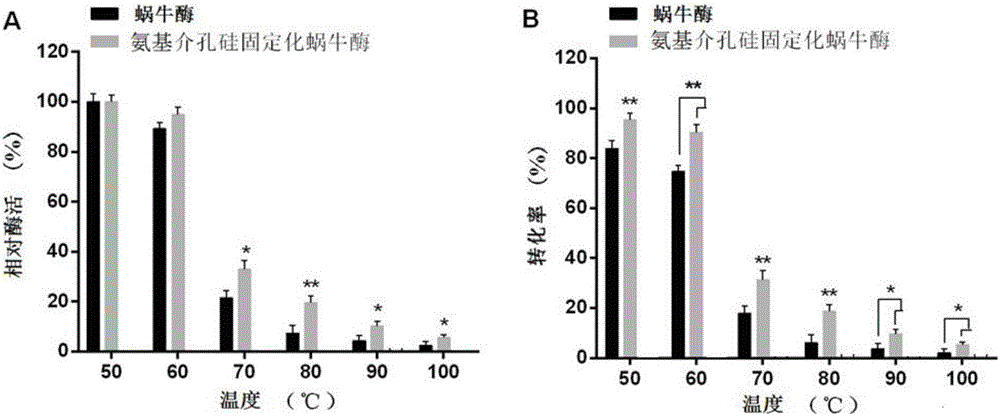

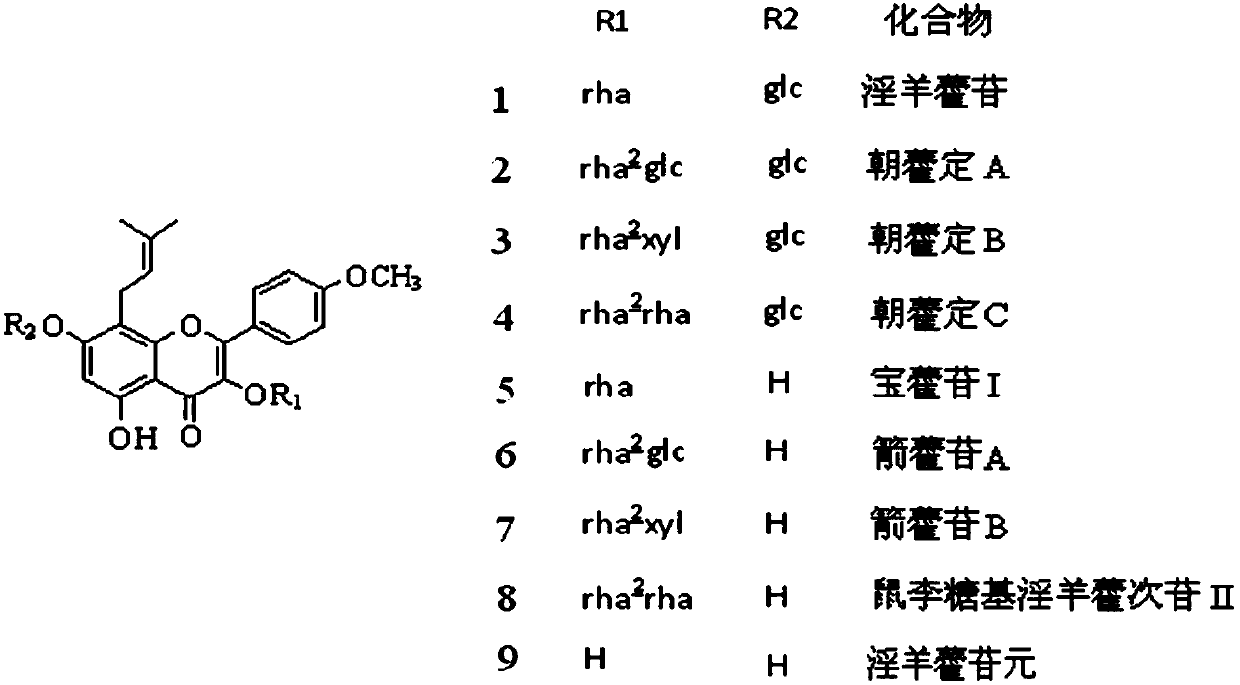

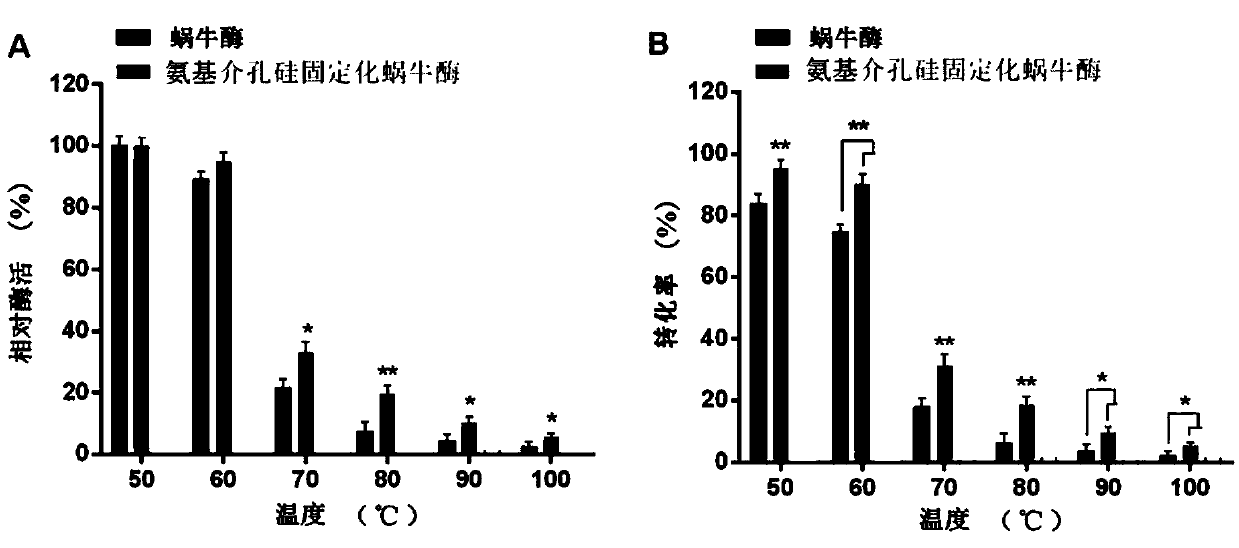

Herba epimedii total flavonoid enzymatic product and preparing method and application thereof

ActiveCN106420880AImprove binding efficiencyImprove the conversion rate of enzymatic hydrolysisAntineoplastic agentsPlant ingredientsHelicaseCervical cancer

The invention relates to a herba epimedii total flavonoid enzymatic product. Herba epimedii total flavonoid is generated through immobilized helicase, and the enzymatic product has higher antineoplastic activity than the herba epimedii total flavonoid archetype and free enzyme enzymatic product and has high oral absorptivity. The invention further discloses a preparing method of the enzymatic product. The immobilized enzyme is used for enzymolysis of herba epimedii total flavonoid, selected helicase is high in combining efficiency with a fixed carrier and high in stability, the enzymolysis conversion rate is large, the immobilized enzyme can be used circularly, resources can be saved, and green production is achieved. The invention further relates to application of the enzymatic product in antitumous effect, and the herba epimedii total flavonoid enzymatic product obtained through the technical scheme has a remarkable anti-proliferative effect on the human lung cancer cell A549, liver cancer HepG2 cell, breast cancer MCF-7 cell, cervical cancer Hela cell and can be used for treating the lung cancer, liver cancer, breast cancer and cervical cancer.

Owner:JIANGSU PROVINCE INST OF TRADITIONAL CHINESE MEDICINE

A method of extracting taurine from scallop skirt

InactiveCN105523966APromote dissolutionMild sourceOrganic chemistryOrganic compound preparationCavitationSolvent

A method of extracting taurine from scallop skirt is provided. The method adopts scallop skirt leftovers as raw materials, and prepares the taurine by steps of cleaning, homogenizing, ultrasonic enzymolysis, enzyme deactivation, decoloring, concentration, cooling and crystallization. The method combines ultrasonic smashing and stepped enzymolysis to prepare the taurine. Cavitation effects and mechanical functions of ultrasonic waves in an extracting solvent can effectively smash cells so that effective components are in an isolated state and are dissolved into the extracting solvent, and can accelerate molecule movements of the extracting solvent so that the extracting solvent and the taurine molecules are brought into rapid contact, dissolved and mixed with each other, taurine digestion is facilitated and the extracting efficiency is increased. The method is mild in reaction conditions, wide in raw material sources, low in cost and simple in operation, can be used for industrial production and has high economic value.

Owner:广西钦州市绿源天然食品加工有限公司

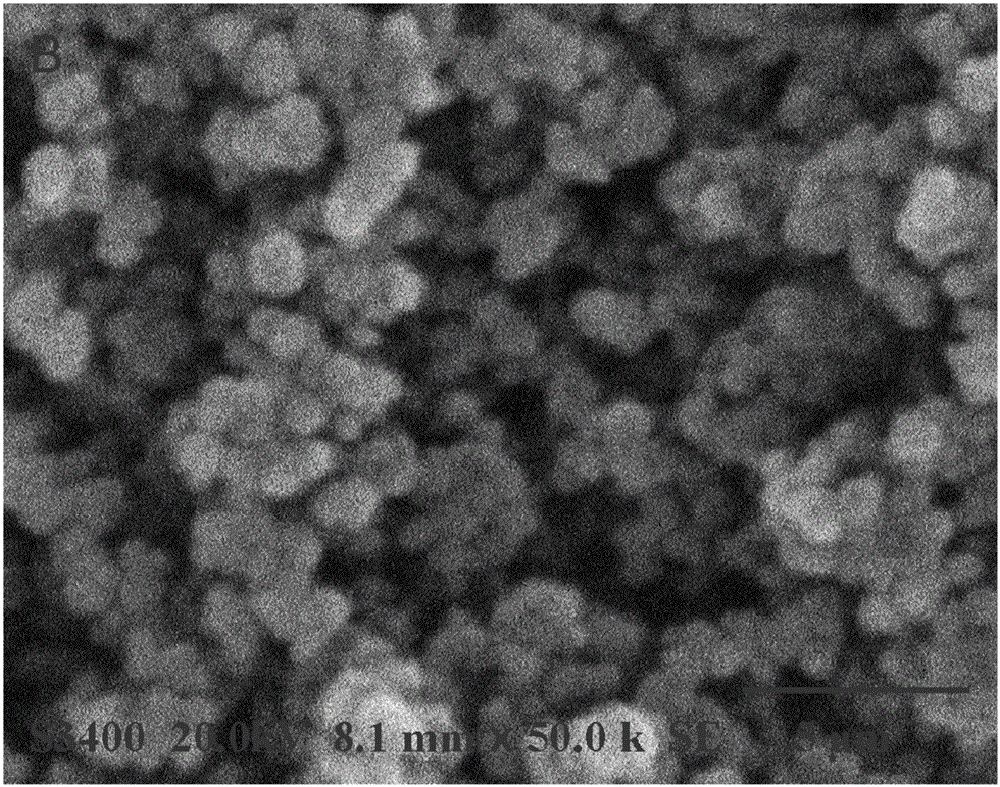

Fiber/nano manganese dioxide composite material and preparation method and application thereof

ActiveCN108176412AUniform particle size distributionSimple conditions of useOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberManganese

The invention discloses a fiber / nano manganese dioxide composite material and a preparation method and an application thereof. The method comprises the following steps: 1) pretreatment of a fibrous raw material: performing selective oxidation treatment on the fibrous raw material, and washing the fibrous raw material to a neutral state to obtain oxidized fibre; and 2) preparation of the compositematerial: processed the oxidized fiber through dilute acid treatment and washing the material to the neutral state, mixing the material and a Mn2+solution and uniformly stirring the materials, addingan oxidizing agent and reacting the materials, washing the material, and drying the product to obtain the fiber for in-situ growth of nano manganese dioxide. The particle size scope distribution of the nano manganese dioxide particles is narrow, the distribution of the nano manganese dioxide particles on the surface of the fiber is uniform, shedding is difficulty happened, and the obtained producthas the excellent performance of fiber and nano manganese dioxide, can be processed as a wood functional material having decorative performance and functional performance, can perform catalytic purification of formaldehyde in a room without illumination, and enriches an application field of nano manganese dioxide.

Owner:SOUTH CHINA UNIV OF TECH

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolute pressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for preparation of compound containing 6A group element using reductant

ActiveCN101848858AUniform sizeGood dispersionMaterial nanotechnologyGallium/indium/thallium compoundsGroup elementSolvent

Provided is a process for preparation of a compound containing a group 6A element which includes reaction of at least one compound selected from a group consisting of group IB element containing compounds and group 3 A element containing compounds with a group 6A element containing compound carried out using a reductant in a desirable solvent to produce a compound containing group 1B-6A elements,a compound containing group 3 A-6A elements and / or a compound containing group 1B-3A-6A elements.

Owner:LG CHEM LTD

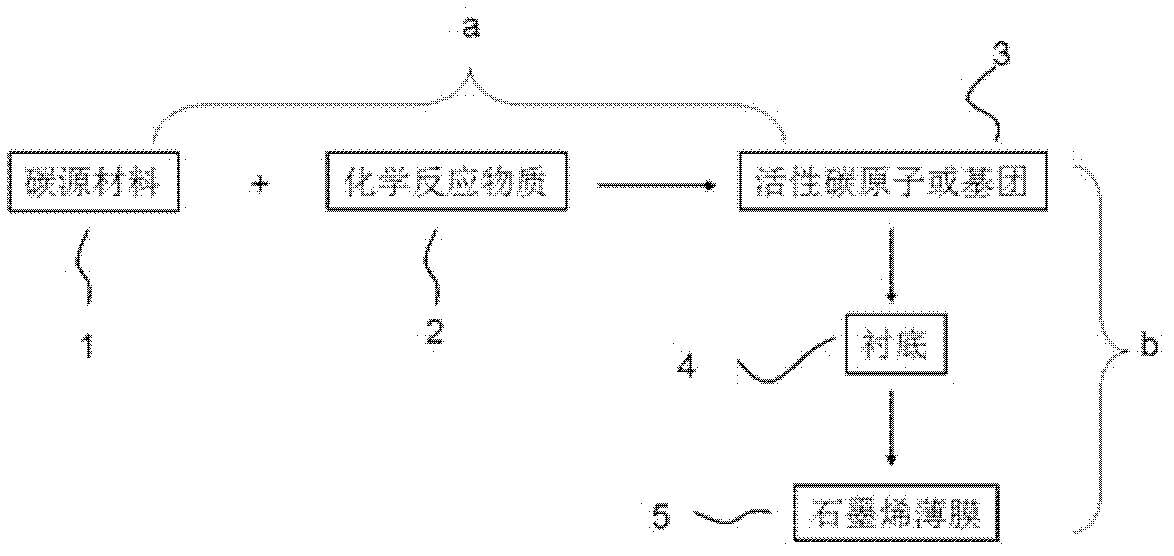

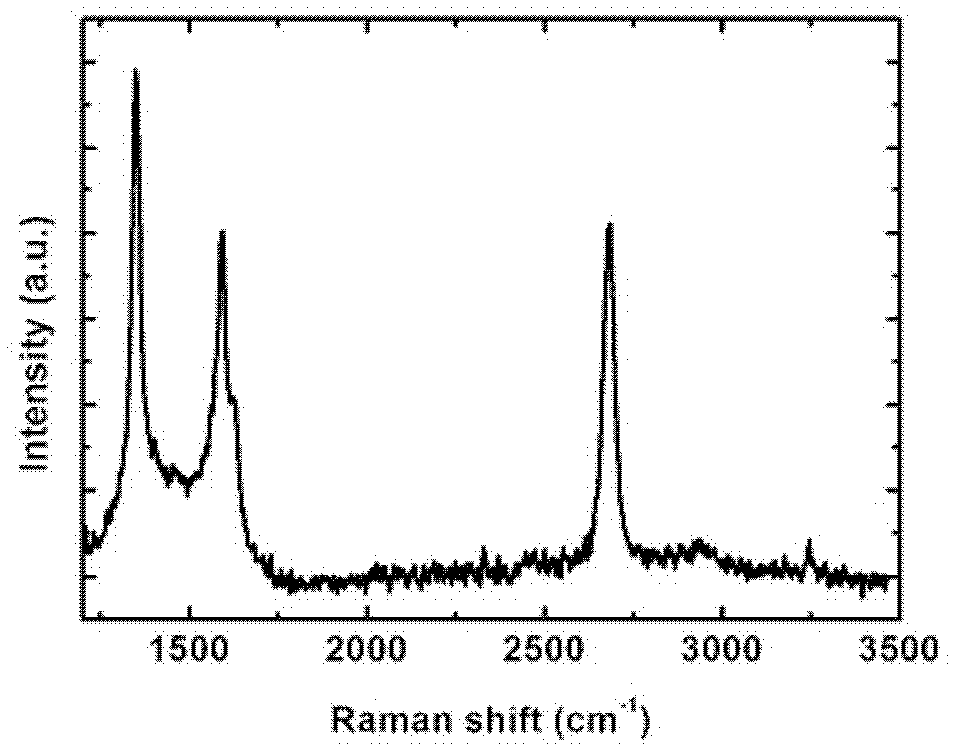

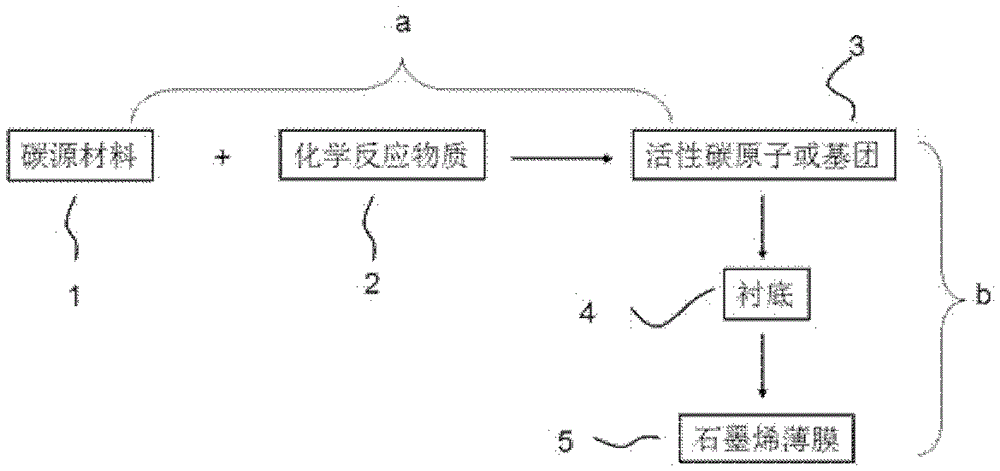

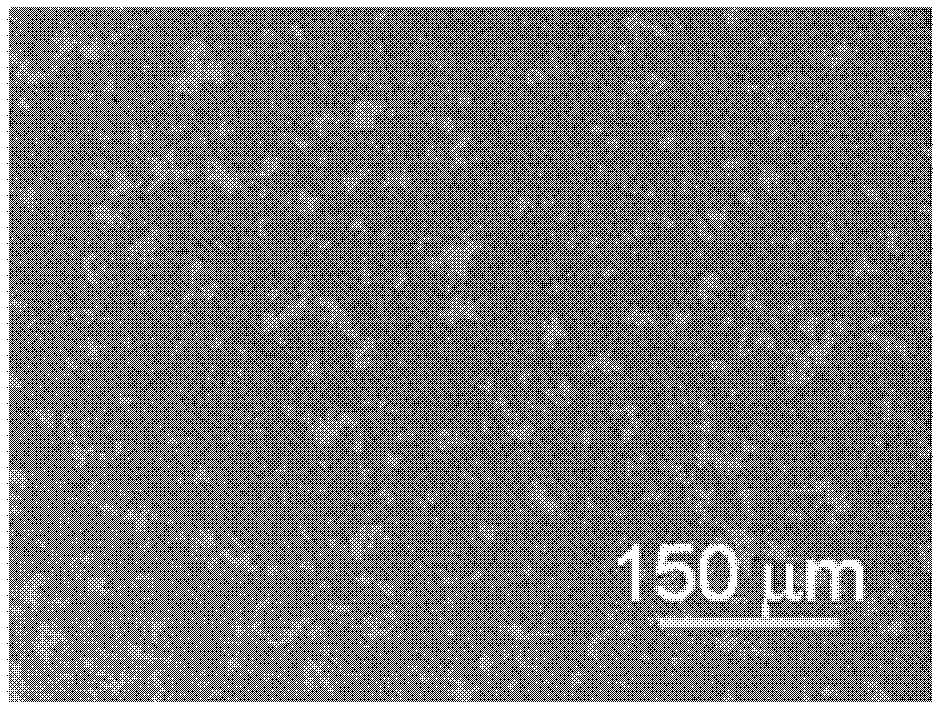

Method for synthesizing graphene film through chemical reaction

ActiveCN103011137ASimple methodWide range of reaction conditionsGrapheneSolid carbonChemical reaction

The invention discloses a method for synthesizing a graphene film through chemical reaction. Through a chemical reaction between a gaseous carbon source, a solid carbon source and a liquid carbon source containing carbon elements or the mixed carbon source material of any two or more of the carbon sources and a chemical reacting substance, carbon atoms in the carbon source material are activated and then deposit on a substrate to grow a graphene film. The method disclosed by the invention is characterized in that the method for producing carbon atoms for synthesizing a graphene film is different from conventional methods such as chemical vapor deposition, the carbon source material for synthesizing a graphene film is widely available, and the synthesis of the graphene film is not restricted by the substrate; the structure and size of the grown graphene film are easy to control; and the method is suitable for preparing graphene films in large scale.

Owner:NINGBO RONGHE WIRE CO LTD

A kind of graphene material based on solid-phase mechanochemical reactor and preparation method thereof

Owner:SICHUAN UNIV

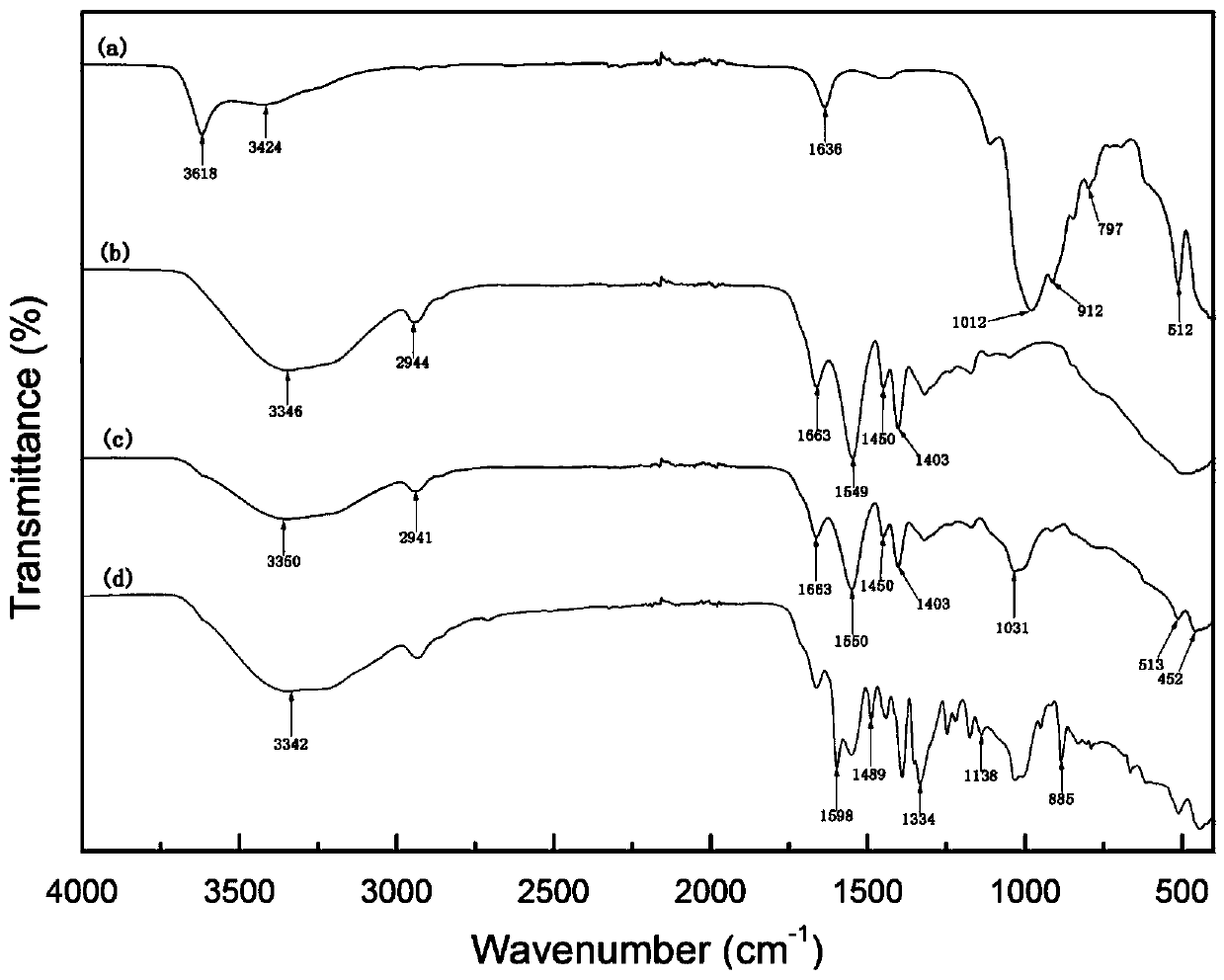

Preparation method and application of a cationic dye composite adsorption material

InactiveCN108341906BEasy to prepareLess conditions are required for the reactionOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceFunctional monomer

The invention discloses a preparation method of a cationic-dye composite adsorbing material and application. The preparation method comprises the following steps of: adopting partially-neutralized acrylic acid and acrylamide as functional monomers, adopting montmorillonite as a filling agent, adopting N,N' methylene bisacrylamide as a crosslinking agent, adopting ammonium persulfate as an initiator, adopting sodium hydrogen sulfite as a coagulant aid, and adopting water as a medium, synthesizing into poly(acrylic acrylamide) / montmorillonite composite hydrogel by free-radical polymerization, i.e., the cationic-dye composite adsorbing material. The composite adsorbing material has the beneficial effect that the cationic dyes such as methylene blue can be effectively adsorbed to achieve thepurpose of reasonably treating sewage; the preparation method is simple in synthesis process, controllable in material cost, convenient in solid-liquid separation and wide in application range, is a method with a wide application prospect and can meet the need of sewage treatment with rapid development.

Owner:FUZHOU UNIV

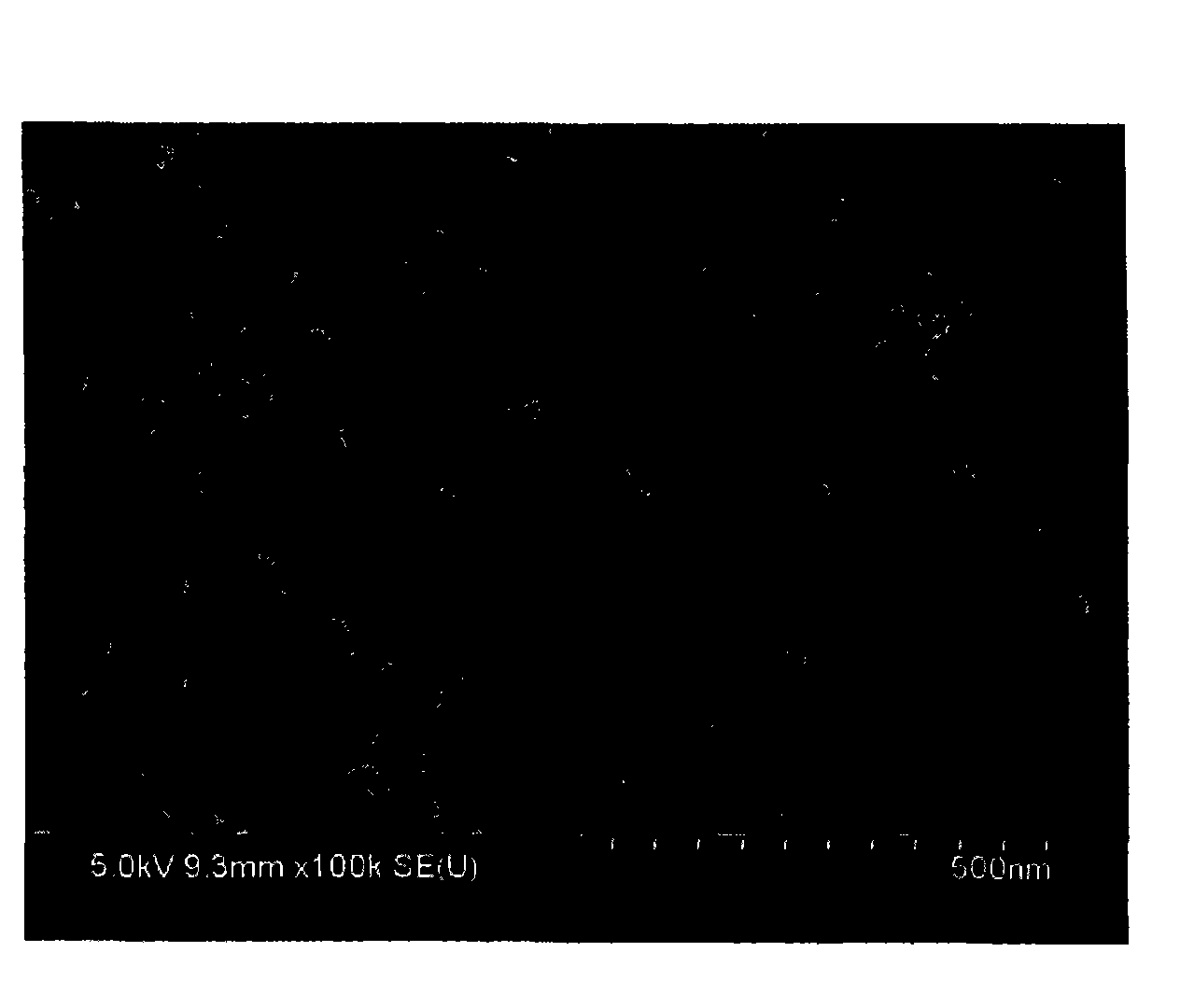

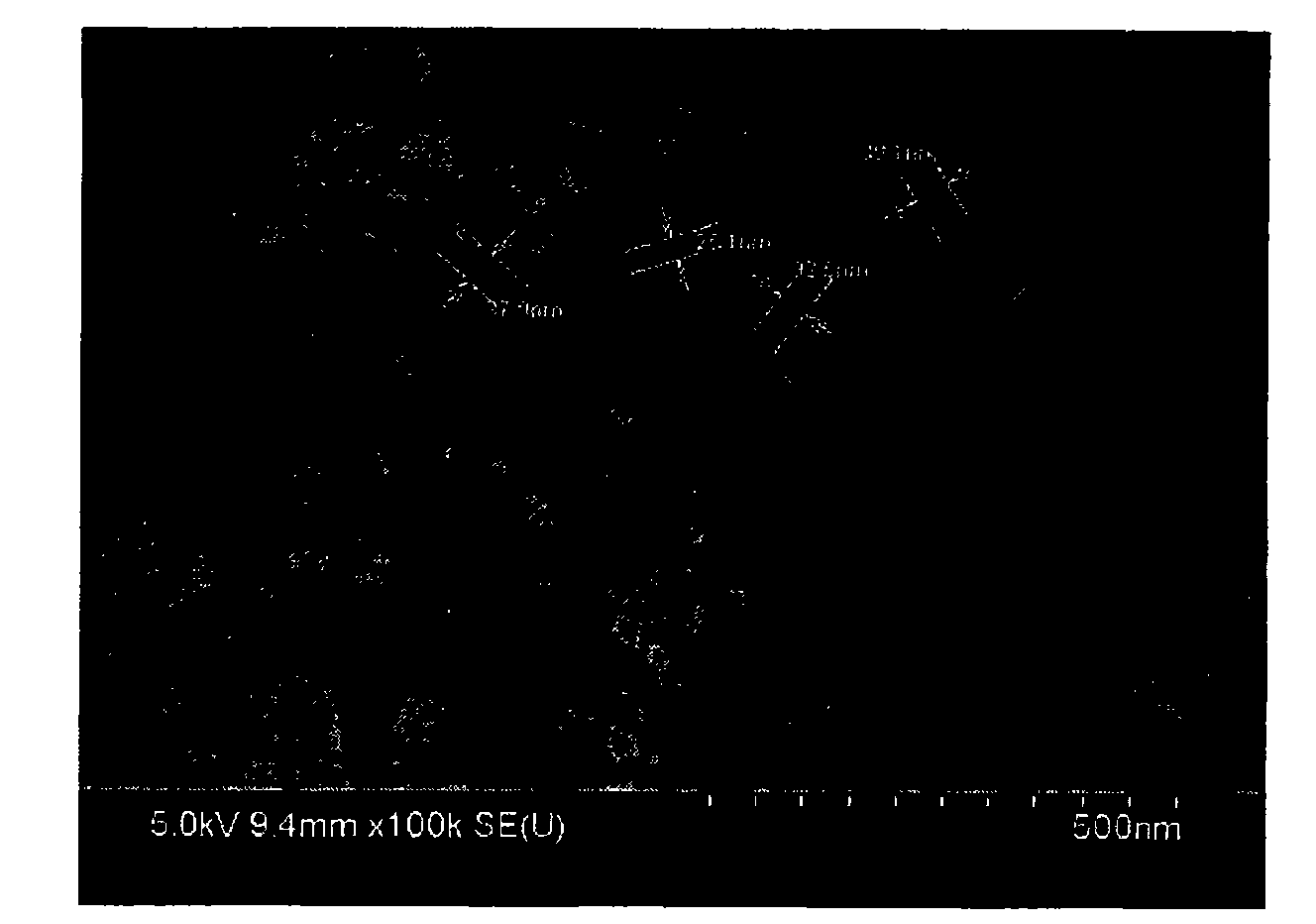

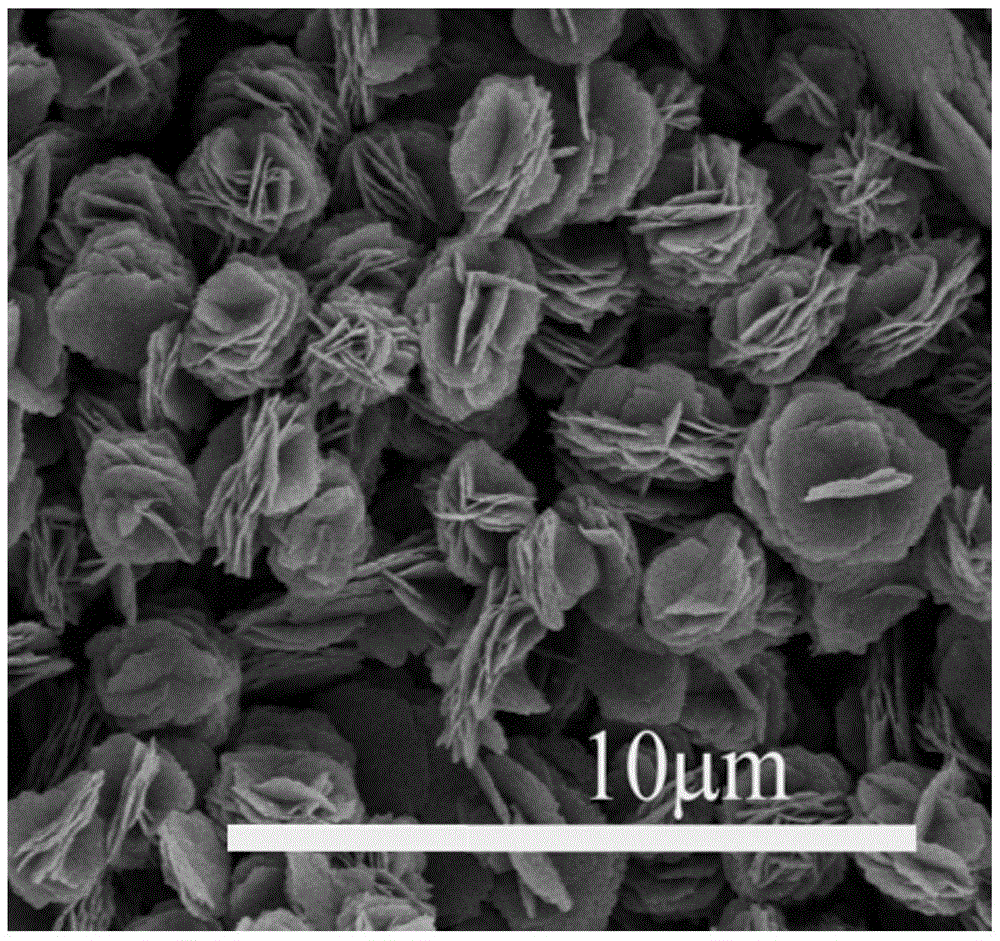

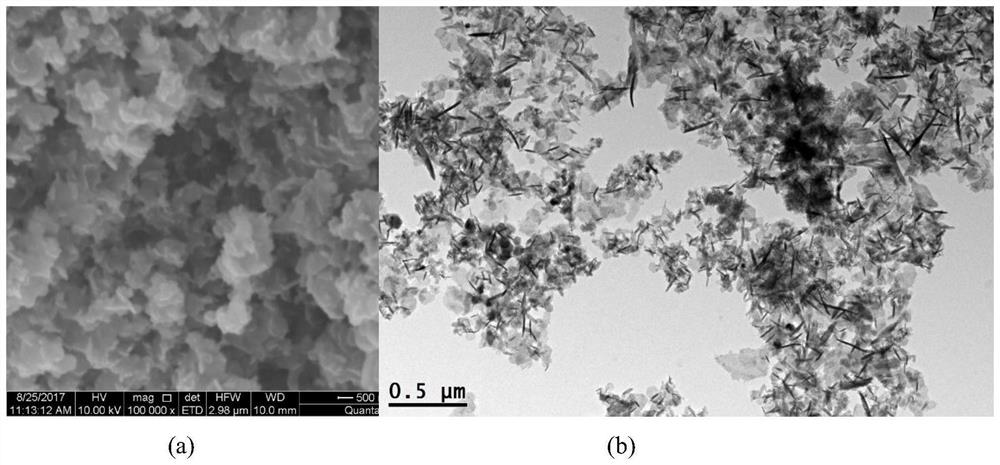

Fullerene derivative microflower and preparation method thereof

The invention belongs to the technical field of compound preparation, particularly relates to a fullerene derivative microflower and further discloses a preparation method of the fullerene derivative microflower. The preparation method is based on the known surfactant assisted self-assembly method in the prior art and is further developed. The stirring condition of a N-methyl-2-(4-dimethyl amidogen) phenyl-3,4-fullerene pyrrolidine carbon tetrachloride solution and a hexadecyl trimethyl ammonium bromide isopropanol solution is optimized, and the obtained N-methyl-2-(4-dimethyl amidogen) phenyl-3,4-fullerene pyrrolidine microflower is of a spherical flower-shaped structure, the spherical flower is composed of curved surface microsheets standing in a mutually-crossed mode, and the microsheets are of a single crystalline structure and are 1-2 micrometers long, 1-2 micrometers high and 10-20 manometers thick.

Owner:HUANGSHAN UNIV

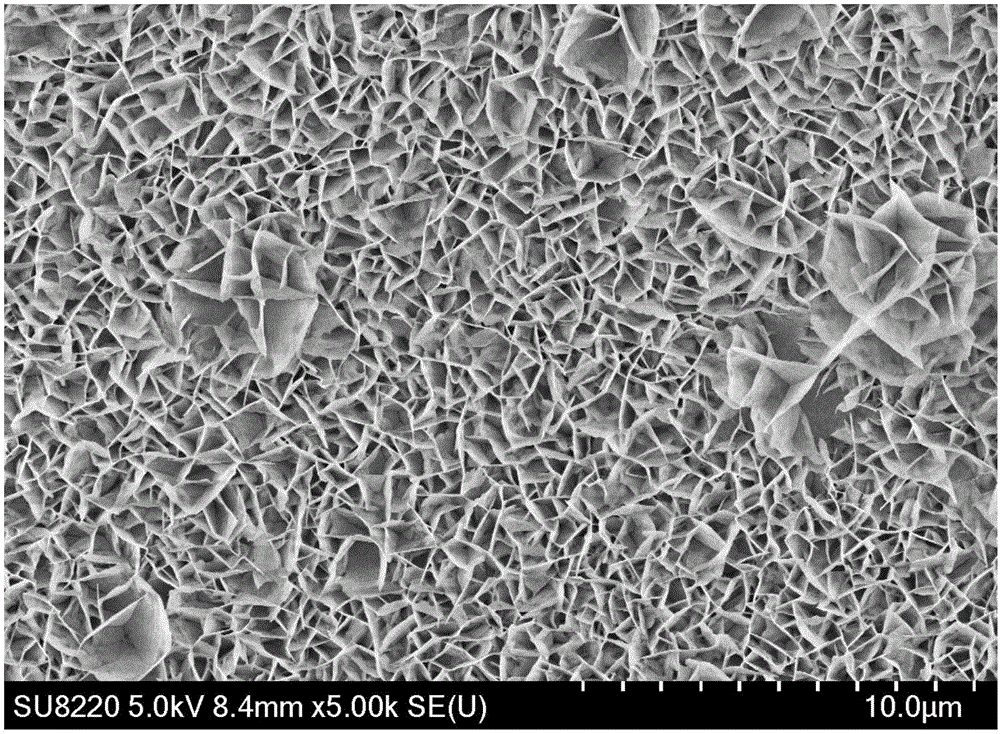

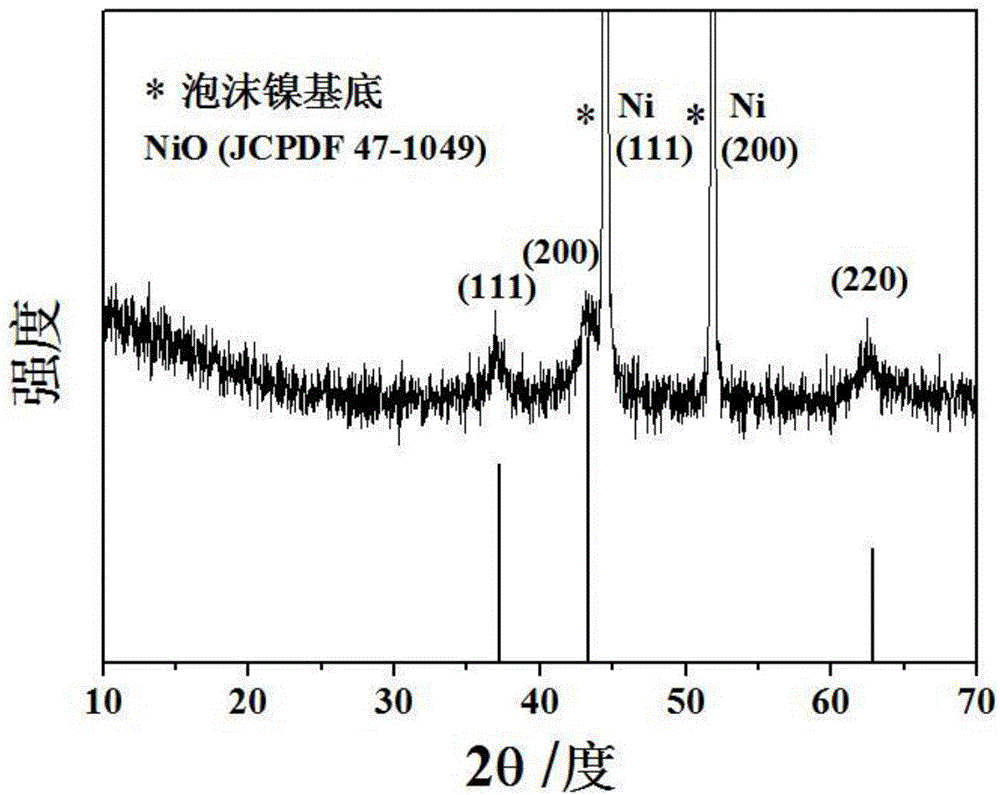

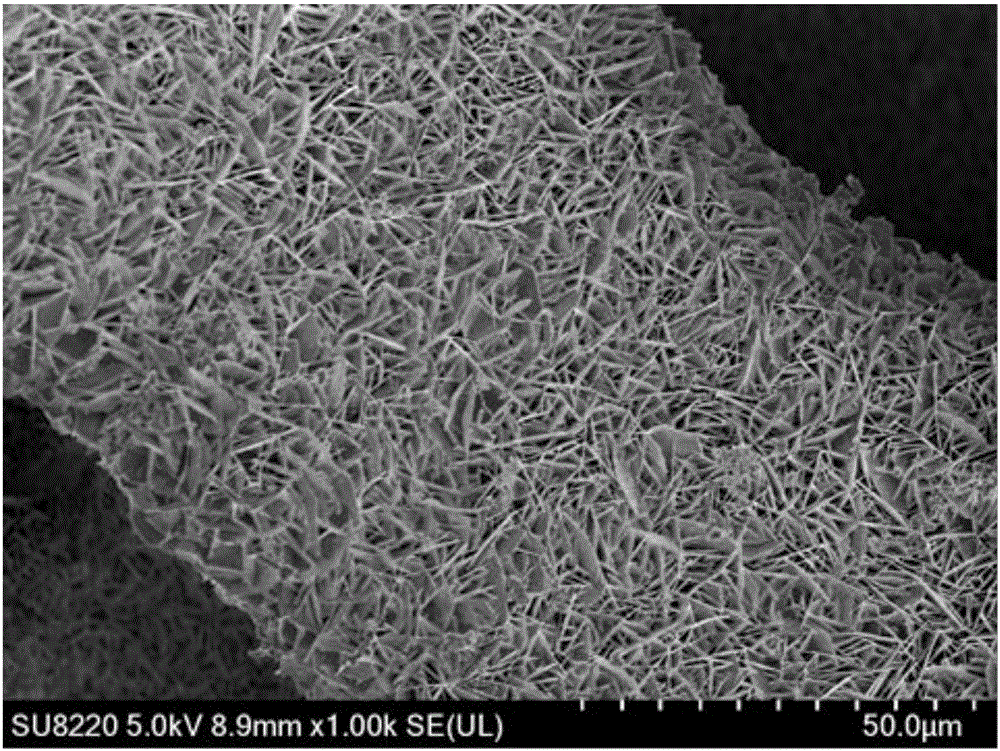

Preparation method of metal compound nano-structure thin-film material

InactiveCN106848278AImprove utilization efficiencyIncrease the scope of applicationMaterial nanotechnologyHybrid capacitor electrodesIonDirected self assembly

The invention discloses a preparation method of a metal compound nano-structure thin-film material. The method comprises the following steps: preparing a solution from a strong acidic-weak basic metal salt with hydrolysis ability; putting the solution into a metal substrate which is cleaned in advance; and inducing continuous hydrolysis reaction of metal ions through the metal substrate at a hydrolysis reaction temperature of the metal ions to prepare a multi-metal compound nano-structure thin-film material. The thin-film material can be taken as an electrode material directly or through thermal treatment. According to the preparation method of the metal compound nano-structure thin-film material, a nano-structure thin film can efficiently grow on the surface of the metal substrate through continuous directional self-assembly; the synthesis technology is simple; any strong acid, strong alkali or strong oxidant does not need to be used in the reaction process; the method is environment-friendly; the reaction condition range is wide and the applicable object range is wide; isometric amplification is easy to implement; and a large scale is easy to implement.

Owner:GUANGXI UNIV

Preparation method of heat conduction film

ActiveCN112028060AHigh single layer (less layer) rateSmall sizeGrapheneHeat-exchange elementsSlurryHeat conservation

The invention provides a preparation method of a heat conduction film. The preparation method comprises the following steps: pre-polymerizing an organic polymer monomer and a radical initiator in an aqueous solution to obtain a first product; adding graphite oxide into the first product, and carrying out dispersion treatment on the graphite oxide to obtain a second product; adding an inorganic acid into the second product to adjust the pH value of the mixed solution to be less than or equal to 3 to flocculate the second product, and separating the obtained flocculate to obtain organic polymermodified graphite oxide precursor slurry; and coating the surface of a base material with the slurry, and drying; after drying, stripping the dried substance on the surface of the base material to obtain a slurry dry film; carrying out heat treatment and reduction treatment on the slurry dry film to obtain a thermal reduction film; heating the thermal reduction film to 1000-1200 DEG C at a first heating rate in an inert atmosphere, heating the thermal reduction film to 2600-3000 DEG C at a second heating rate after heat preservation is completed, and obtaining a high-temperature carbonized film after heat preservation is completed; and carrying out physical shaping treatment on the high-temperature carbonized film to obtain the heat conduction film.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

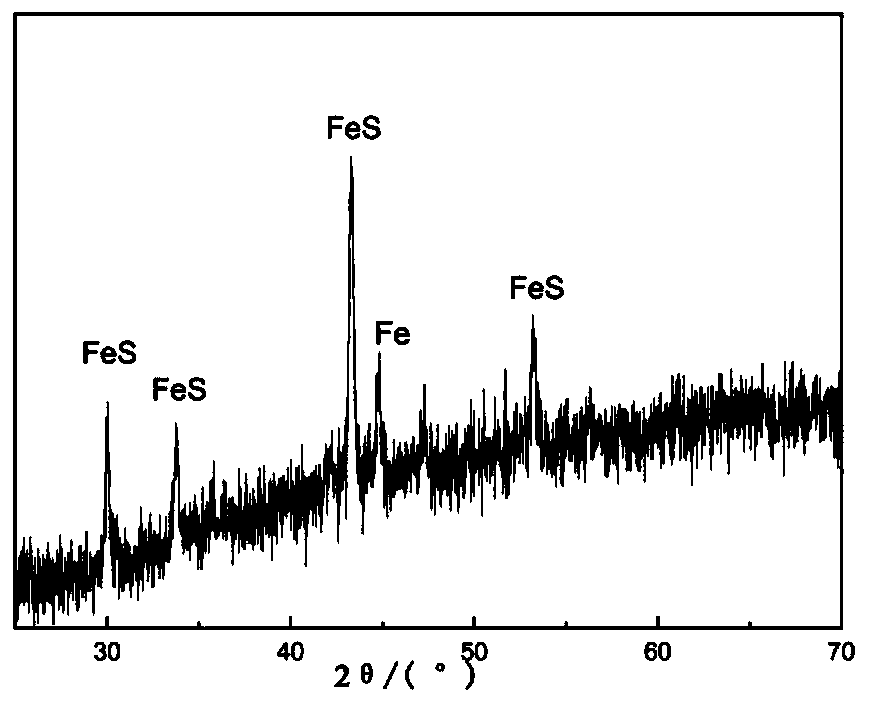

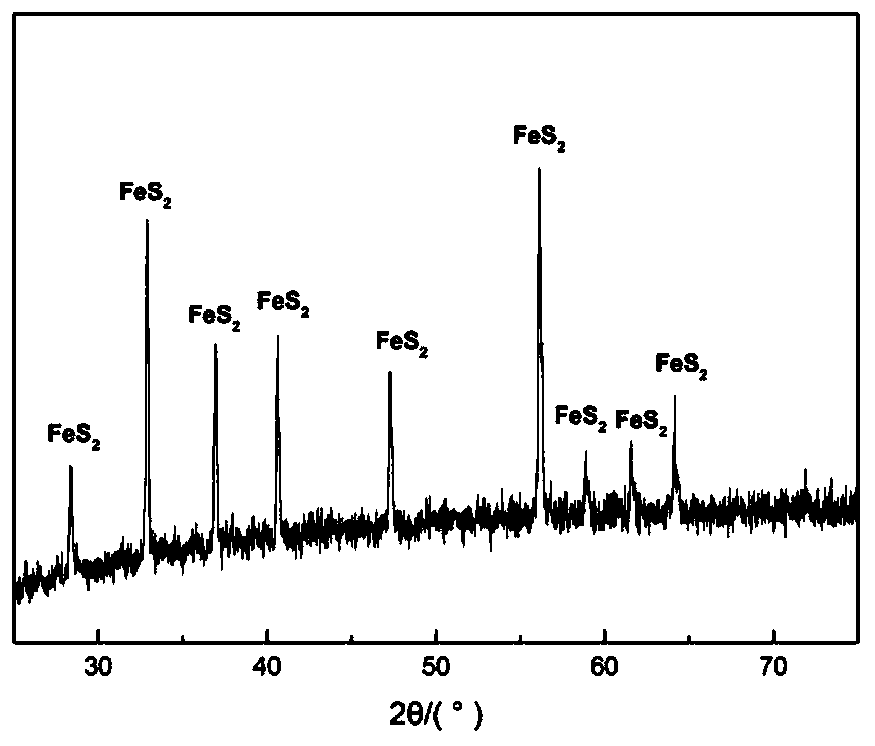

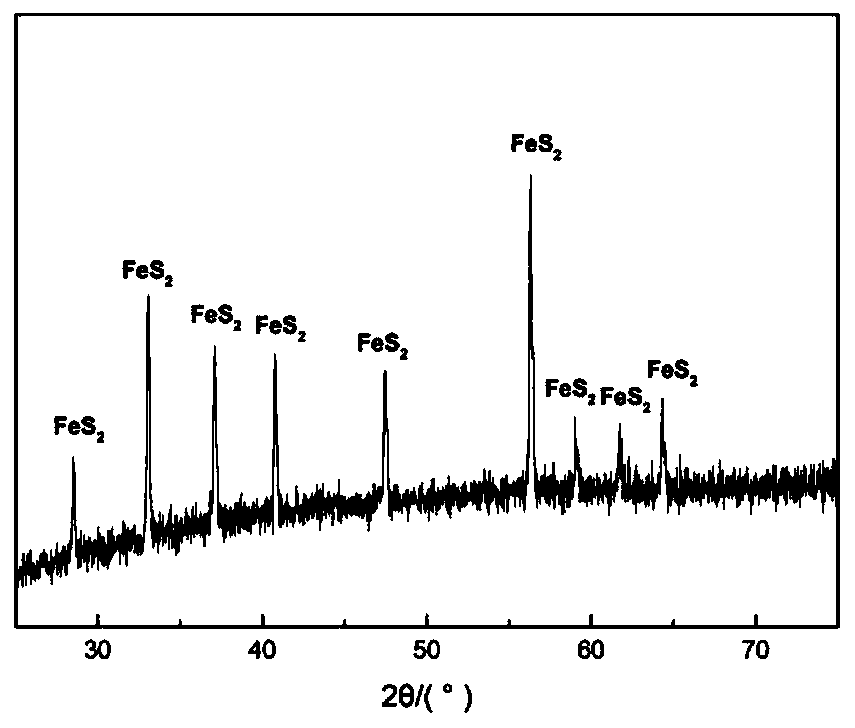

Method for preparing pyrite type iron disulfide by high-temperature high-pressure one-step chemical method

PendingCN110980815ASolving Difficult Diffusion ProblemsSpeed up preparationUltra-high pressure processesTransportation and packagingPyritePhysical chemistry

The invention discloses a method for preparing pyrite type iron disulfide by a high-temperature high-pressure one-step chemical method, and belongs to the technical field of functional material preparation. The method mainly comprises the steps: uniformly mixing ferrous sulfide and sulfur powder to obtain a mixture; pressing and molding the mixture to prepare a block; and placing the block formedby powder pressing molding under a high pressure higher than one atmospheric pressure, and carrying out a reaction at a high temperature of higher than 300 DEG C to obtain the pyrite type iron disulfide. The reaction raw materials are easy to obtain and low in price, ferrous sulfide is directly selected as the raw material, the reaction process is simplified, the reaction raw materials and products are solid, intermediate products cannot be discharged into the environment, the anti-interference capacity of a reaction system is high, and reaction conditions are wide and easy to control.

Owner:JILIN UNIV

Method for synthesizing graphene film by chemical reaction

ActiveCN103011137BSimple methodWide range of reaction conditionsGrapheneSolid carbonChemical reaction

Owner:NINGBO RONGHE WIRE CO LTD

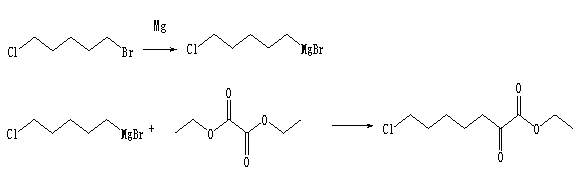

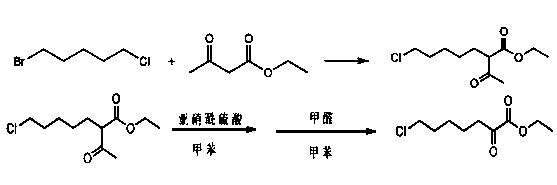

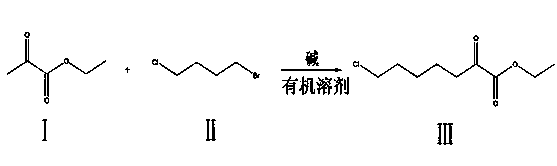

Method for synthesizing 7-chloro-2-oxoheptanoate

InactiveCN102285884BLow costHigh yieldOrganic compound preparationCarboxylic acid esters preparationOrganic solventSynthesis methods

The invention discloses a method for synthesizing 7-chloro-2-oxoheptanoate, which comprises: dissolving ethyl pyruvate in an organic solvent, adding alkali and 1-bromo-4-chlorobutane in turn, and performing a condensation reaction; filtering the product of the reaction, removing solvent from filtrate by reduced-pressure distillation; purifying by distillation; and thus, obtaining 7-chloro-2-oxoheptanoate. In the invention, nontoxic and cheap ethyl pyruvate is used as a main raw material and subjected to one-step condensation reaction with 1-bromo-4-chlorobutane under the action of alkali to form the 7-chloro-2-oxoheptanoate, and the yield of the product reaches 88 to 98 percent. The synthesis method disclosed by the invention has the advantages of high product yield, simple steps, wide reaction conditions, low cost, environment friendliness and the like and is suitable for large-scale industrial production.

Owner:左国幼

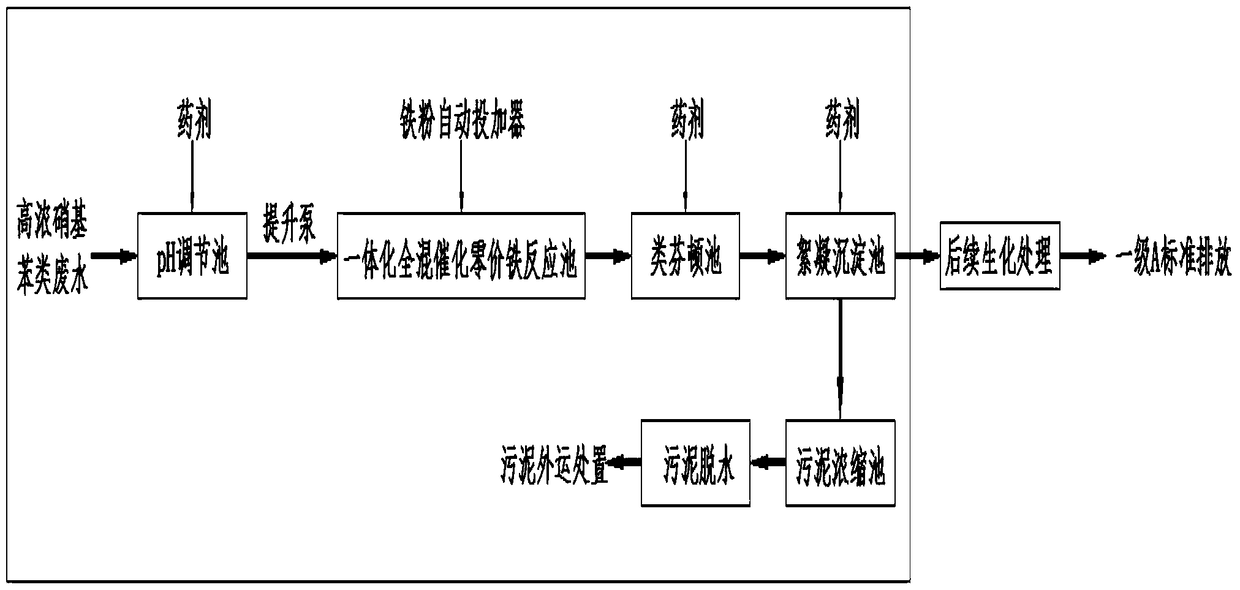

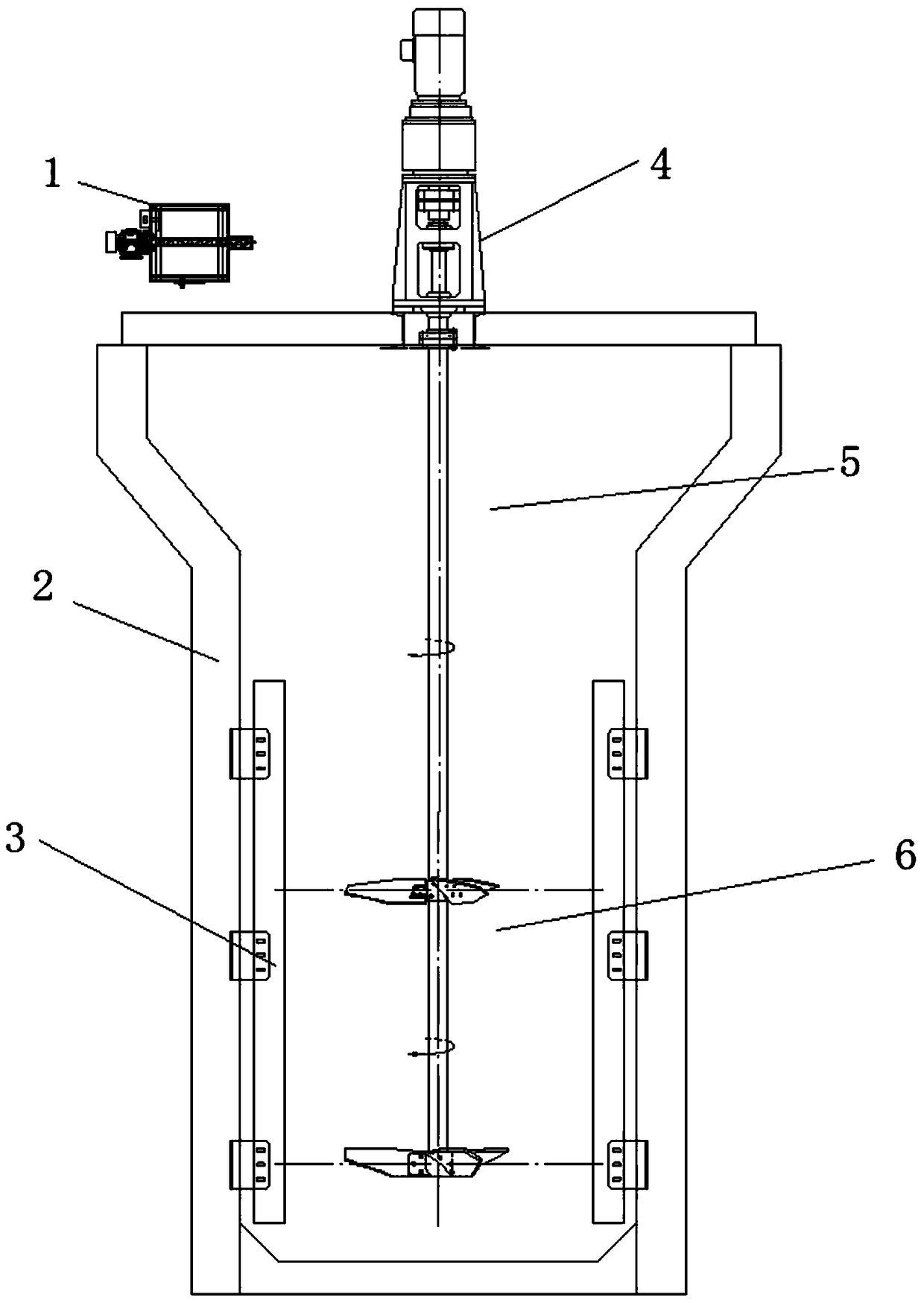

A kind of high-concentration nitrobenzene wastewater pretreatment device and treatment method

ActiveCN105645633BReduce consumptionDegradation is efficient and economicalWater treatment compoundsWater contaminantsHigh concentrationReduction treatment

The invention discloses a high-concentration nitrobenzene wastewater pretreatment device and treatment method, belonging to the field of organic chemical industry wastewater treatment. The device and method solve the problems of high pretreatment difficulty, low treatment efficiency, high treatment cost, complex operation and the like in the existing high-concentration nitrobenzene wastewater treatment method. The pretreatment device is sequentially composed of a pH regulating tank, an integrated complete-mixing zero-valent iron reaction tank, a Fenton-like reaction tank and a flocculating settling tank. The integrated complete-mixing zero-valent iron reaction tank has high reduction treatment capacity for nondegradable organic matters, can not harden after long-term operation, and has the advantages of wide pH value range, low iron powder consumption, lower operating cost and simple operation. The Fenton-like reaction tank performs Fenton oxidation by utilizing Fe<2+> and H2O2 which are dissolved out by the integrated complete-mixing catalytic zero-valent iron reduction reaction, thereby lowering the pollutant concentration under economical conditions. Thus, the high-concentration nitrobenzene wastewater pretreatment method has the advantages of favorable treatment effect and lower operating cost, is simple to operate, and can stably satisfy the subsequent biochemical treatment requirements.

Owner:NANJING UNIV +1

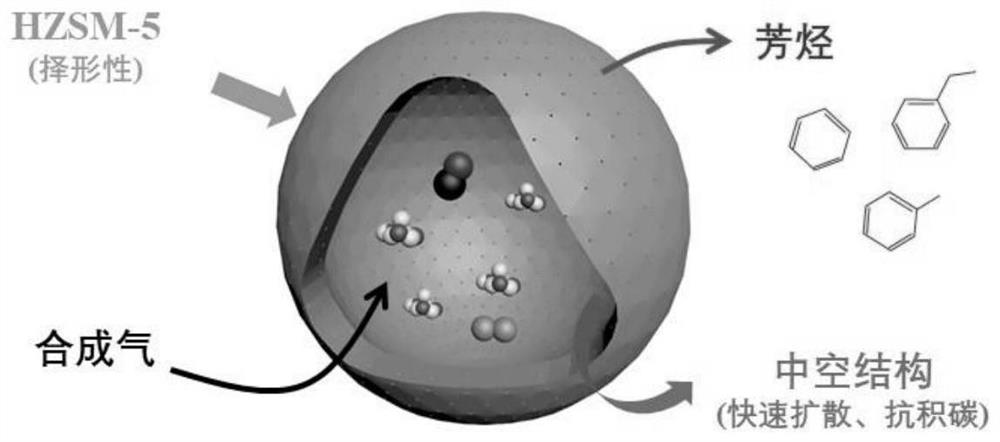

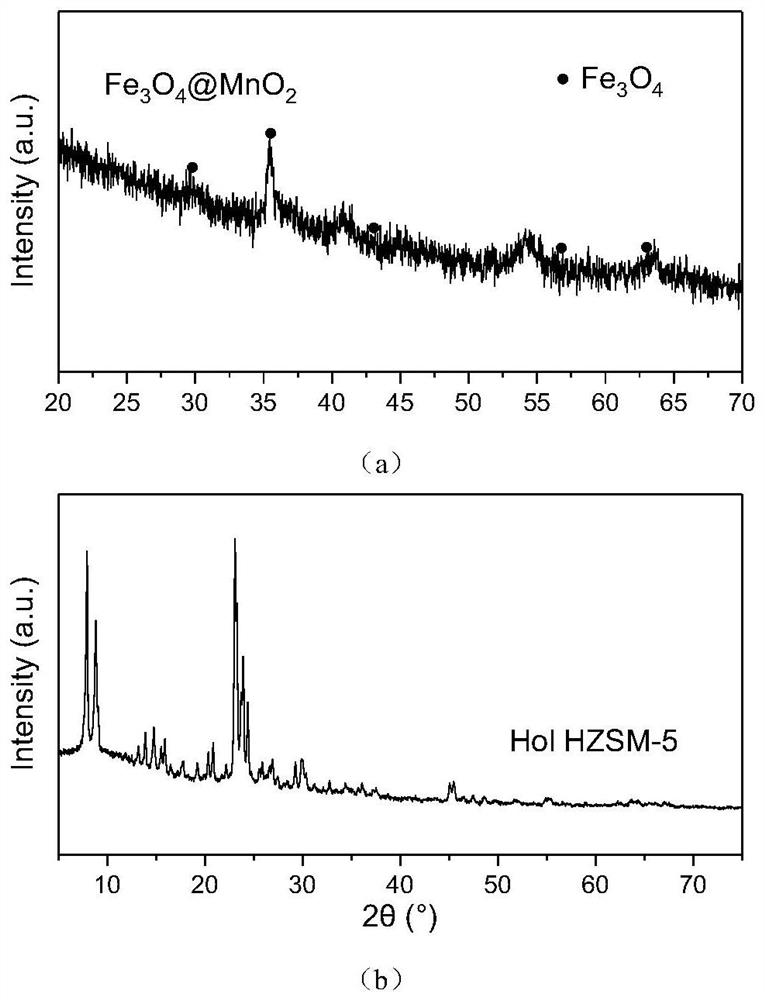

A composite catalyst for directly producing aromatics from synthesis gas and its preparation method

ActiveCN110385141BSimple preparation processSuitable for large-scale industrial productionMolecular sieve catalystsLiquid hydrocarbon mixture productionPtru catalystAromatic hydrocarbon

Owner:WUHAN UNIV

Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

InactiveCN101530772BIncreased durabilityDense wallHeat-exchange elementsMicroballoon preparationStored energyPolymer science

A preparing method for phase transited stored energy microcapsule covered with an organic polymer material adopts the following steps: (1) mixing the 10 weight organic phase transited material and 0.5-2.5 weight nonionic surfactant under the condition of heating and blending; (2) picking the organic polymer material monomer A, B 2-3 weight to add to 40-60 weight water, blending and mixing as the water phase; (3) adding the oil phase to the water phase, blending the material as the creaming liquid at 30-50 centigrade, adding the free radical to the initiator for the poly-reaction 1-8h at 35-90centigrade; then adjusting the low temperature as blending the material and adding the cross linker, filtering, washing and drying to obtain the finished products. The organic polymer material achieves the phase transited capsule envelopment via the creaming polymer reaction of the wall material; the microcapsule is the spherical; the granule is distributed evenly; the polymer wall material has astable intensity, great tightness and great mechanical performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A kind of enzymatic hydrolysis product of epimedium total flavonoids and its preparation method and application

ActiveCN106420880BImprove binding efficiencyImprove the conversion rate of enzymatic hydrolysisAntineoplastic agentsPlant ingredientsHelicaseCervical cancer

The invention relates to an enzymatic hydrolysis product of total flavonoids of Epimedium, which is produced by enzymatic hydrolysis of total flavonoids of Epimedium through immobilized snail enzymes, and the enzymatic hydrolysis product has higher Better anti-tumor activity and better oral absorption. The invention also discloses a preparation method of the enzymatic hydrolysis product. The method uses immobilized enzymes to enzymolyze the total flavonoids of Epimedium herba, and the selected helicase has high binding efficiency, good stability, and high enzymatic hydrolysis conversion rate with the immobilized carrier. Moreover, the immobilized enzyme can also be recycled, which can save resources and realize green production. The present invention also relates to the application of the enzymatic hydrolyzate in anti-tumor. The total flavonoid enzymatic hydrolyzate of Epimedium herba obtained according to the technical scheme provided by the present invention is effective against human lung cancer A549 cells, liver cancer HepG2 cells, breast cancer MCF‑7 cells, cervical cancer Hela cells have significant proliferation inhibitory effect and can be used for the treatment of lung cancer, liver cancer, breast cancer and cervical cancer.

Owner:JIANGSU PROVINCE INST OF TRADITIONAL CHINESE MEDICINE

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolutepressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

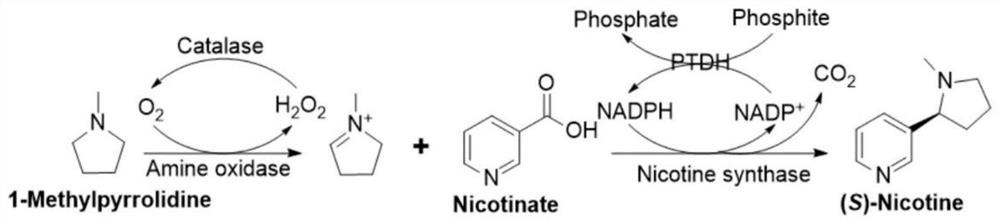

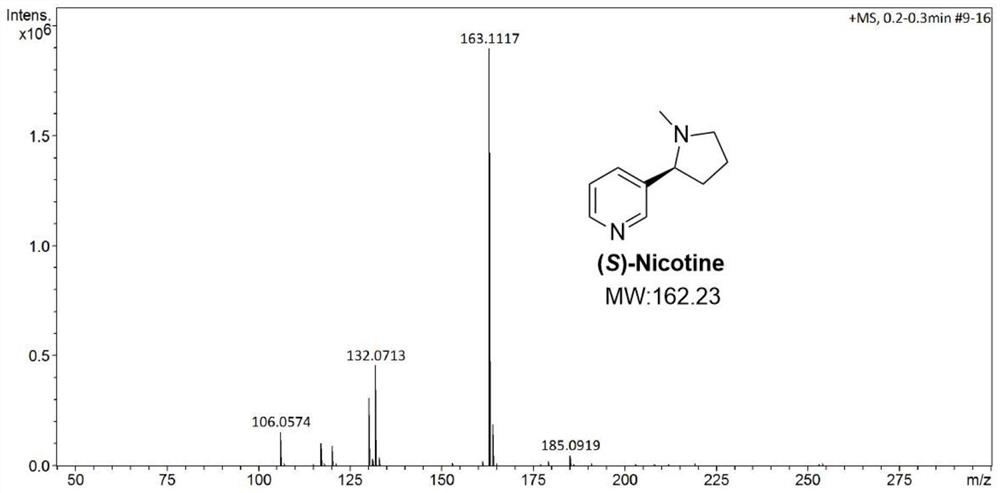

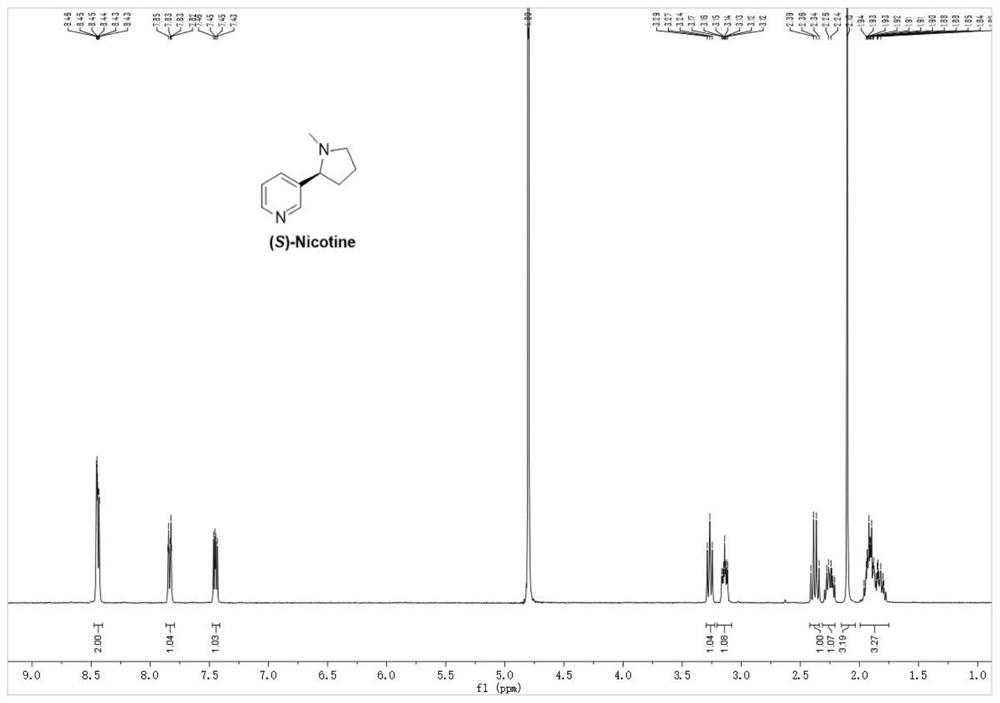

Preparation method of S-nicotine

ActiveCN113621590AReduce manufacturing costWide variety of sourcesOxidoreductasesGenetic engineeringNicotine synthesisOxidative enzyme

The invention relates to the technical field of biosynthesis, in particular to a preparation method of S-nicotine. According to the invention, amine oxidase is creatively utilized to oxidize 1-methylpyrrolidine into corresponding imine, and then the imine and nicotinic acid are condensed and decarboxylated under the catalysis of nicotine synthetase to obtain the final product S-nicotine. According to the method, the S-nicotine with specific chirality can be obtained through two-step reaction in a reaction system, the synthetic route is short, the yield is high, the reaction conditions are mild, and large-scale production is easy to realize; and meanwhile, the raw materials are wide in source, low in price, low in production cost and environmentally friendly, the production cost of nicotine is remarkably reduced, and the nicotine better meets the requirements of current green industrial production at the same time.

Owner:SHENZHEN READLINE BIOTECH CO LTD

A method for removing impurities from desulfurized gypsum in a power plant

Owner:ROAD ENVIRONMENT TECH

A kind of fullerene derivative micron flower and preparation method thereof

The invention belongs to the technical field of compound preparation, particularly relates to a fullerene derivative microflower and further discloses a preparation method of the fullerene derivative microflower. The preparation method is based on the known surfactant assisted self-assembly method in the prior art and is further developed. The stirring condition of a N-methyl-2-(4-dimethyl amidogen) phenyl-3,4-fullerene pyrrolidine carbon tetrachloride solution and a hexadecyl trimethyl ammonium bromide isopropanol solution is optimized, and the obtained N-methyl-2-(4-dimethyl amidogen) phenyl-3,4-fullerene pyrrolidine microflower is of a spherical flower-shaped structure, the spherical flower is composed of curved surface microsheets standing in a mutually-crossed mode, and the microsheets are of a single crystalline structure and are 1-2 micrometers long, 1-2 micrometers high and 10-20 manometers thick.

Owner:HUANGSHAN UNIV

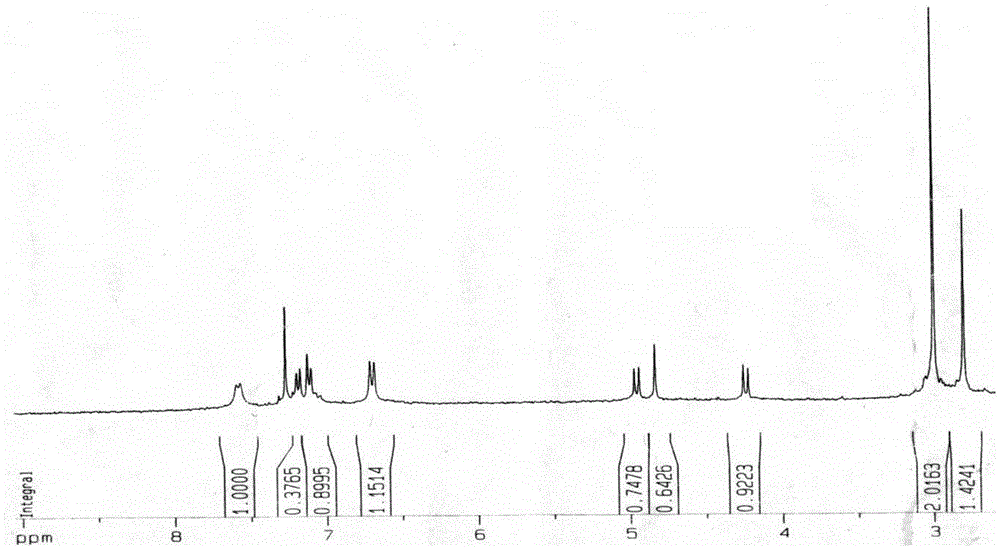

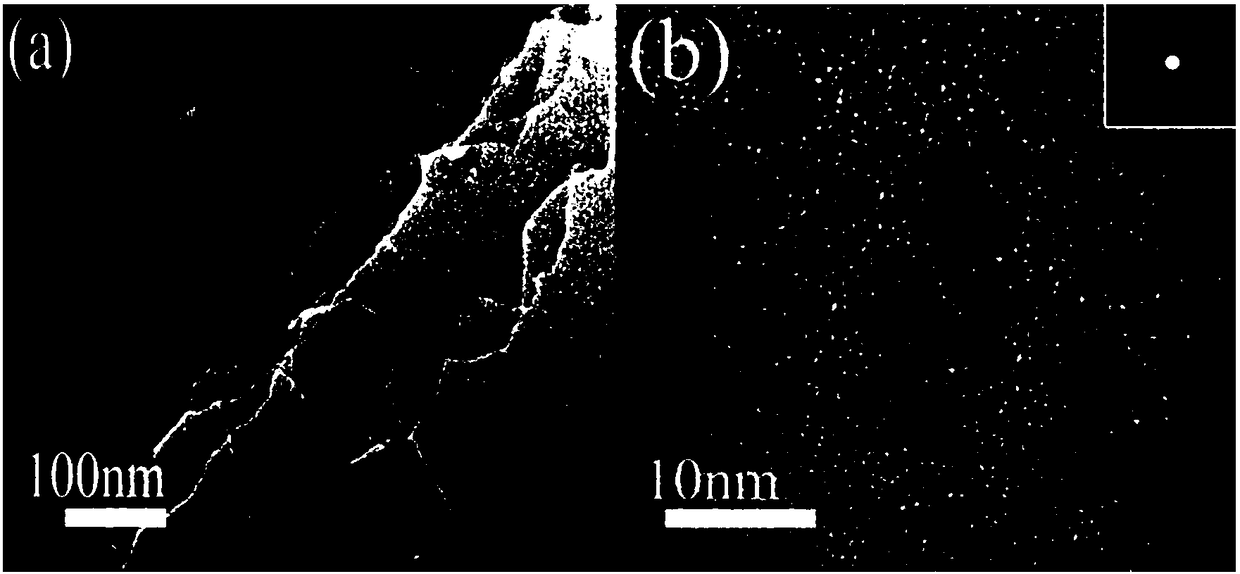

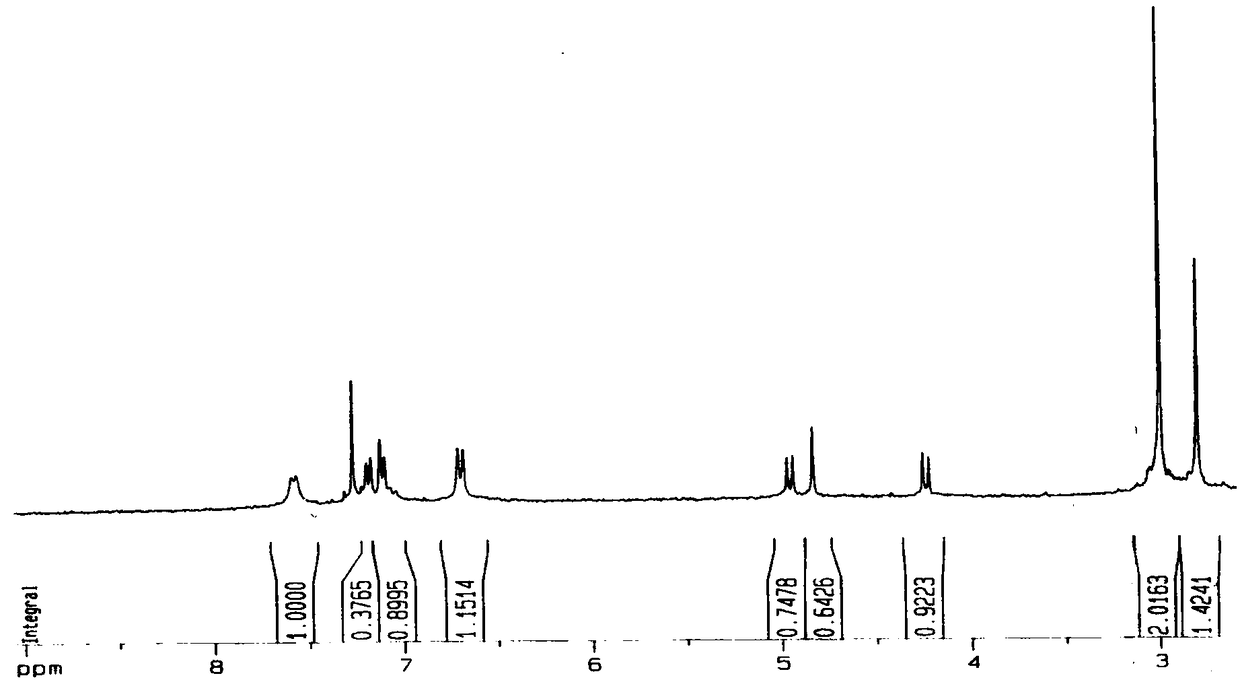

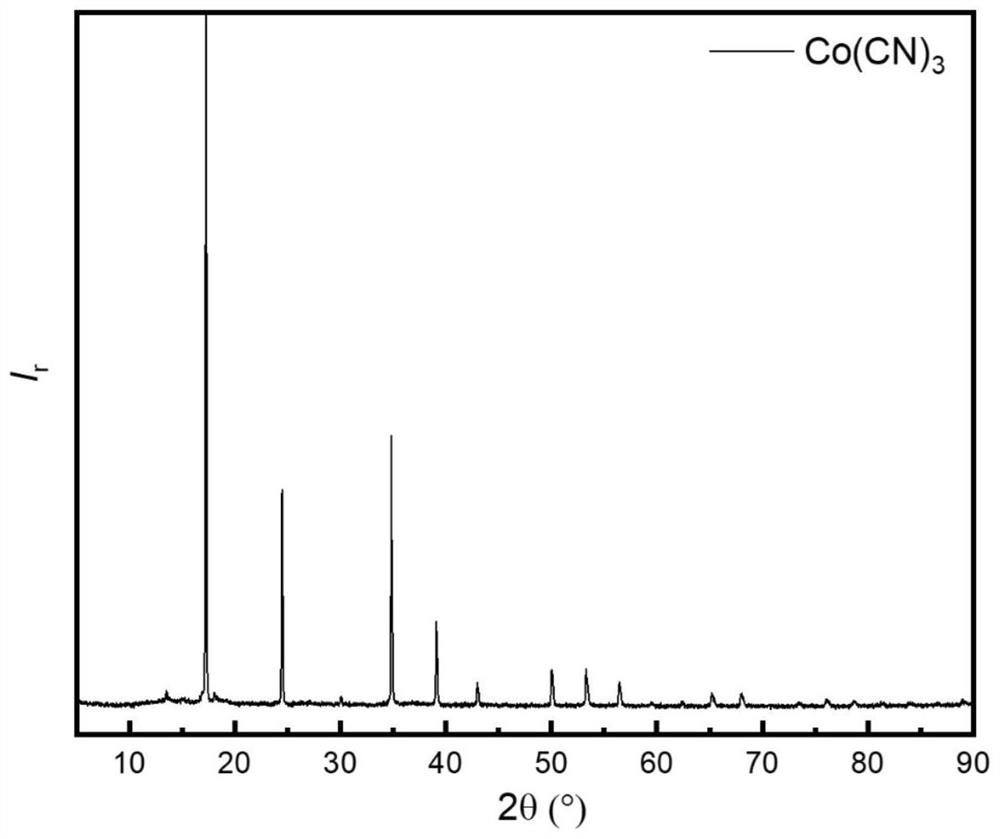

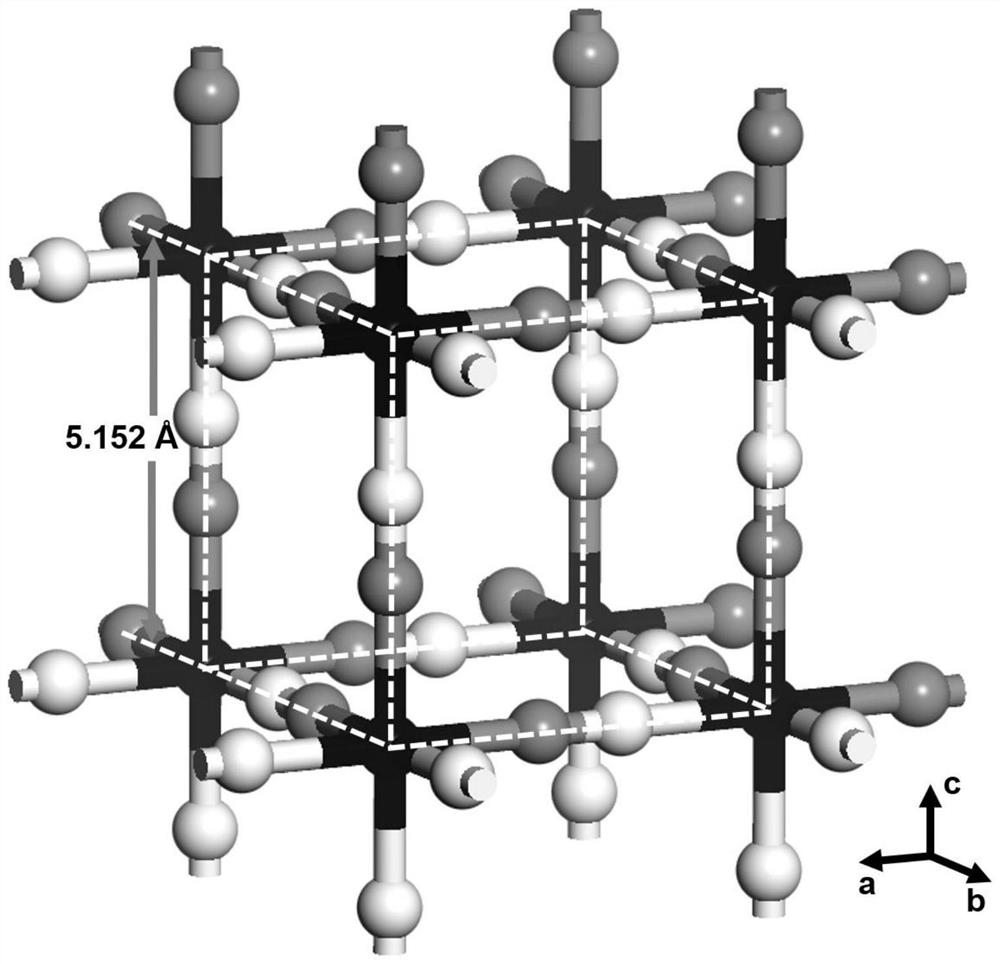

Regularly coordinated cobalt or iron-doped cobalt-based electrocatalyst and its preparation and use

ActiveCN113540480BQuick responseHigh crystallinityFuel and secondary cellsCell electrodesCrystal systemPtru catalyst

The invention belongs to the field of preparation of catalyst materials, and in particular relates to a regularly coordinated cobalt or iron-doped cobalt-based electrocatalyst and its preparation method and application. The electrocatalyst is a crystalline material, which belongs to a simple cubic crystal system. The eight vertices of the unit cell are cobalt or isomorphously substituted iron, and the metal atoms are in a 6-coordination structure, which is connected by its ligand cyanide (-CN) , that is, each side of the unit cell is connected to the cyano group formed by C and N, the unit cell parameter is α=β=γ=90°, and the crystal can present a monodisperse regular cube, Truncated cubic or octahedral morphology. The catalyst has excellent crystallinity, regular and single coordination, has a single-site active center, and the reaction site is clear and definite, which can be used for the study of crystal face-dependent catalytic activity. The catalyst has excellent catalytic activity and stability as a working electrode for oxygen reduction, oxygen evolution, hydrazine hydrate oxidation, metal-air battery and hydrazine hydrate fuel cell.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com