A kind of high-concentration nitrobenzene wastewater pretreatment device and treatment method

A pretreatment device, nitrobenzene technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of difficult pretreatment, low treatment efficiency, high treatment cost, etc., and achieve low operating cost , good treatment effect and low consumption of iron powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

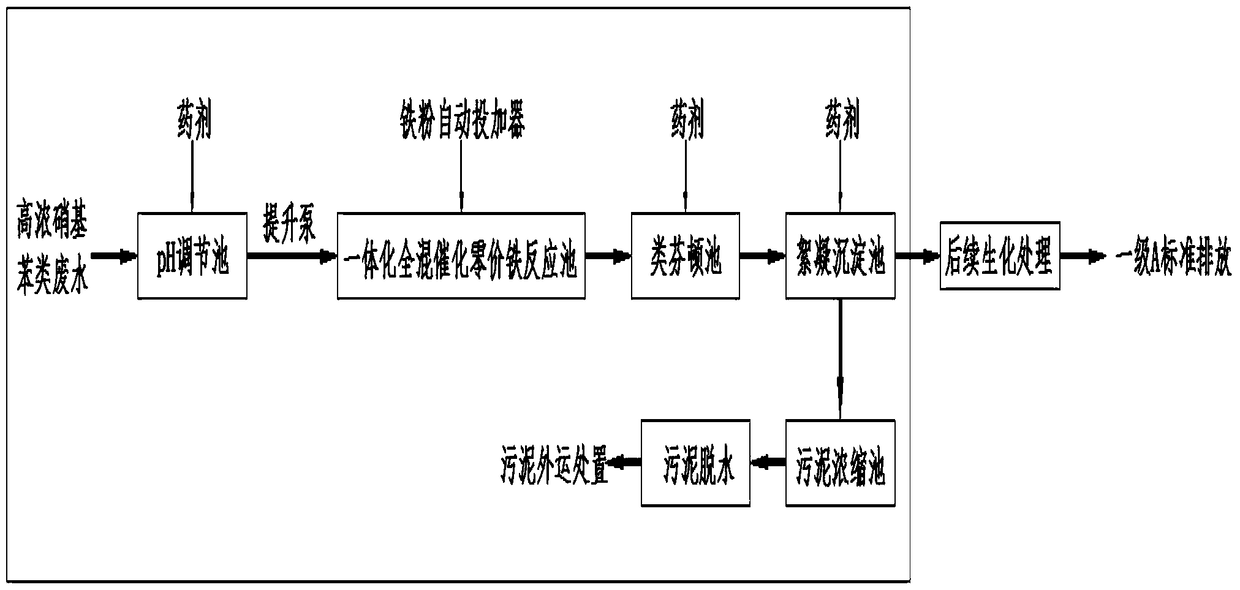

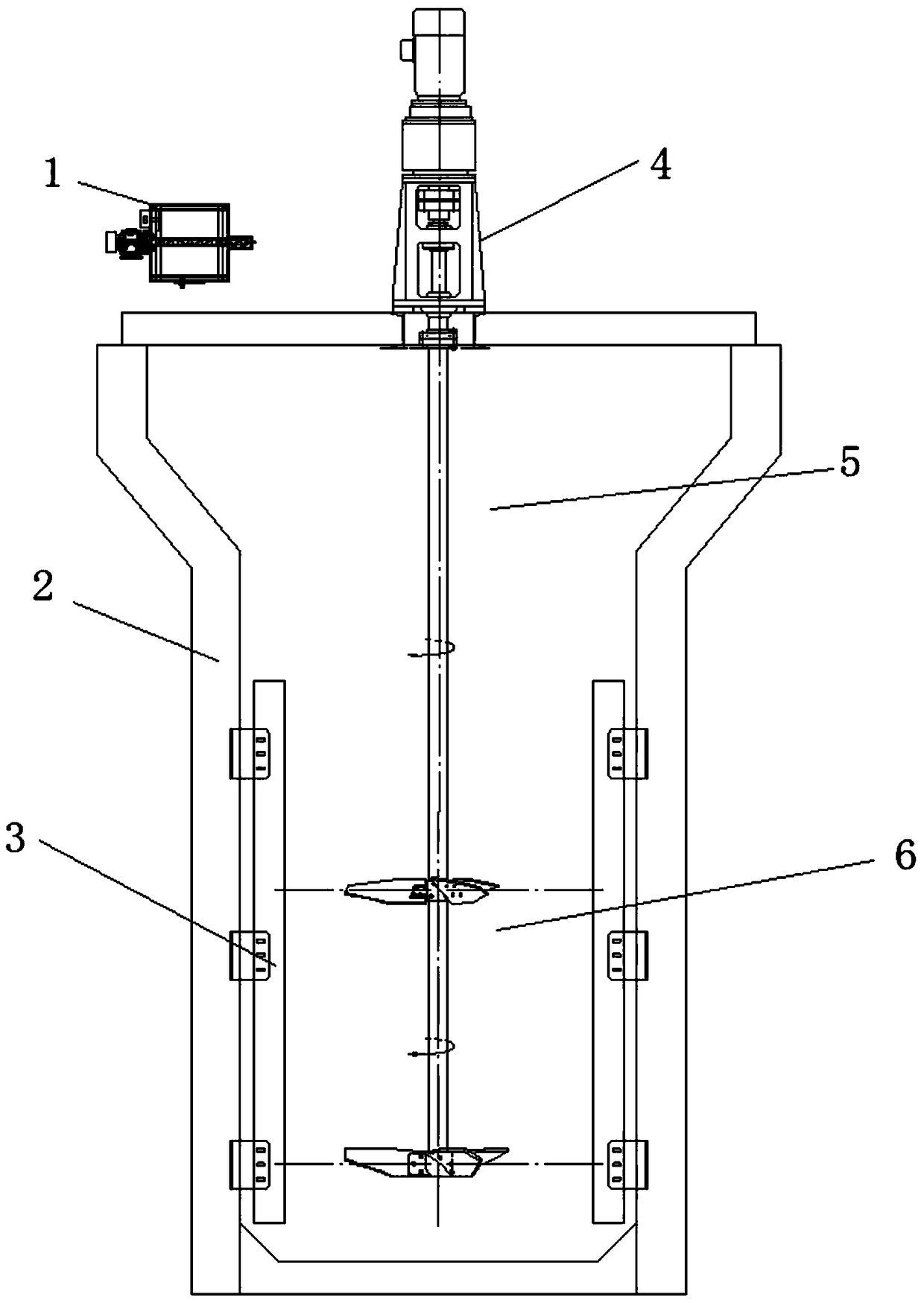

[0038] Such as figure 1 and figure 2 As shown, a high-concentration nitrobenzene wastewater pretreatment device includes a pH adjustment tank, an integrated fully mixed zero-valent iron reaction tank, a Fenton-like reaction tank and a flocculation sedimentation tank, and an integrated fully mixed zero-valent iron reaction tank Including iron powder automatic doser 1, reaction pool 2, baffle structure 3 and full mixing mixer 4, reaction pool 2 includes settling area 5 and reaction area 6, integrated full mixing zero-valent iron reaction pool adopts mechanical stirring; settling area 5 is a diameter-expanding structure, that is, the upper diameter of the settlement zone 5 is larger than the lower diameter, and the middle is transitionally connected. The Fenton-like reaction pool is composed of 6 reaction pools, the front 2 reaction pools are mechanically stirred, and the rear 4 reaction pools are air stirred.

[0039] The above-mentioned high-concentration nitrobenzene wastew...

Embodiment 2

[0045] The structure of the high-concentration nitrobenzene waste water pretreatment device in this embodiment is the same as that of Embodiment 1. The waste water treated in this embodiment is DNAN washing waste water (DNAN process produced by nitration and nitration of chlorobenzene), and the water quality is: the COD concentration is about 10000mg / L, the concentration of nitrobenzene is 1000mg / L, and the pH value is about 7.0.

[0046] 1) There is no need for pH adjustment, and the pH adjustment tank is directly pumped into the integrated fully mixed zero-valent iron reaction pool (the integrated fully mixed zero-valent iron reaction pool independently designed by Jiangsu Nanda Environmental Protection Technology Co., Ltd., the number is IFMP-ZVI- ND), the lifting flow rate is 20m 3 / h, the reaction residence time is 45min, the consumption of cast iron powder per ton of wastewater is about 0.50kg, and the initial dosage of manganese / copper composite material in the reaction...

Embodiment 3

[0051] The structure of the high-concentration nitrobenzene wastewater pretreatment device in this example is the same as in Example 1. The wastewater treated in this example is nitrotoluene production wastewater (the process is toluene mixed acid nitration), and the water quality is: COD concentration is 5000~ 7000mg / L, the concentration of nitrobenzene is 500mg / L, and the pH is 1.5-2.5.

[0052] 1) In the pH adjustment tank, use NaOH to adjust the pH of the high-concentration nitrobenzene wastewater to be treated to 3-7, and then the pump lifts it into the integrated fully mixed zero-valent iron reaction tank (using the integrated integrated zero-valent iron reaction tank independently designed by Jiangsu Nanda Environmental Protection Technology Co., Ltd. In the fully mixed zero-valent iron reaction pool, the serial number is IFMP-ZVI-ND), the pump lift flow rate is 15m 3 / h, the reaction residence time is 20min, the consumption of cast iron powder per ton of wastewater is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com