Method for preparing pyrite type iron disulfide by high-temperature high-pressure one-step chemical method

A technology of pyrite type and iron disulfide, which is applied to the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, iron sulfide, etc., which can solve the problem of reduced quality of reaction products, insufficient sulfide degree, and extremely long maintenance Time and other issues, to achieve the effect of easy control of reaction conditions, broad reaction conditions, and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

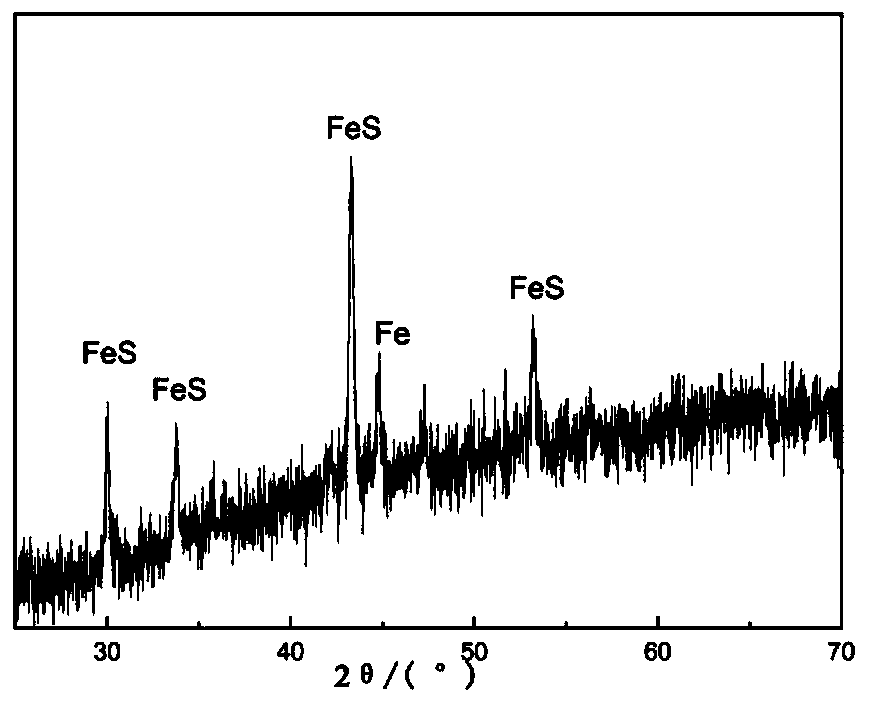

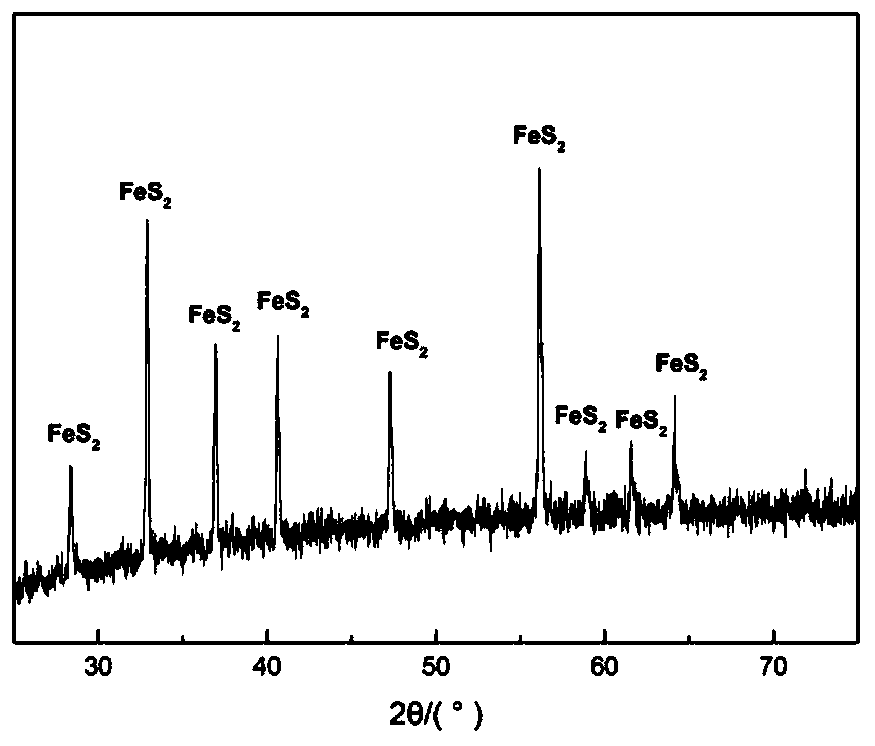

[0026] The raw materials are iron sulfide ferrous sulfide and sulfur powder, and the two are mixed in a molar ratio of 1:4. Among them, the iron sulfide ferrous sulfide has not been purified, and the XRD spectrum is as follows figure 1 shown. The mixed sample powder is pressed into a block. The block obtained by pressing the powder is assembled into a composite assembly with pyrophyllite as the external pressure transmission medium, metal oxide ceramics as the internal pressure transmission medium, and graphite tube as the heating element. A six-sided top press was used to provide pressure and temperature to the synthetic assembly. Ensure that the reactants in the synthesis assembly are kept at a high temperature of 550°C for 2 hours under a high pressure of 1GPa. The X-ray diffraction pattern of the product after the reaction is as follows figure 2 As shown, it can be seen from the figure that the synthesized product is pure phase pyrite type iron disulfide.

Embodiment 2

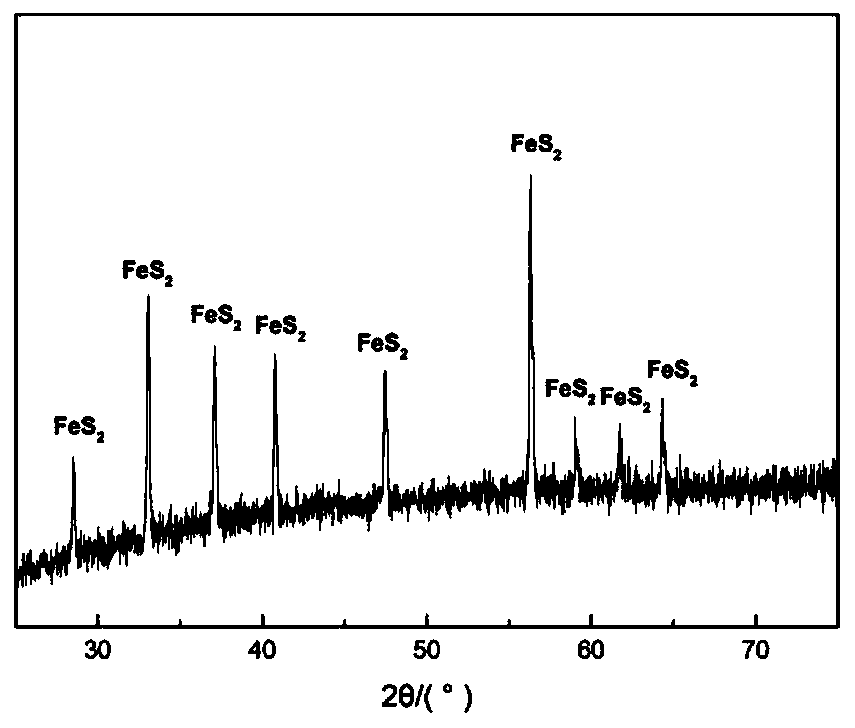

[0028] The raw materials are the same as in Example 1, and the molar ratio of the raw materials is adjusted to 1:3 for mixing, and the mixed sample powder is pressed into a block. The block obtained by pressing the powder is assembled into a composite assembly with pyrophyllite as the external pressure transmission medium, metal oxide ceramics as the internal pressure transmission medium, and graphite tube as the heating element. A six-sided top press was used to provide pressure and temperature to the synthetic assembly. Ensure that the reactants in the synthesis assembly are kept at a high temperature of 600°C for 1.5 hours under a high pressure of 2GPa. The product after the reaction can be known as pyrite type iron disulfide through XRD analysis, such as image 3 shown.

Embodiment 3

[0030] The raw materials are the same as in Example 1, and the molar ratio of the raw materials is adjusted to 1:2 for mixing, and the mixed sample powder is pressed into a block. The block obtained by pressing the powder is assembled into a composite assembly with pyrophyllite as the external pressure transmission medium, metal oxide ceramics as the internal pressure transmission medium, and graphite tube as the heating element. A six-sided top press was used to provide pressure and temperature to the synthetic assembly. Ensure that the reactants in the synthesis assembly are kept at a high temperature of 650°C for 2.5 hours under a high pressure of 5GPa. The product after the reaction can be known as pyrite type iron disulfide through XRD analysis, such as Figure 4 shown.

[0031] It can be seen from the above examples that the present invention has the characteristics of easy acquisition of raw materials, no need for purification, low cost, short reaction time, high prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com