Method of preparing solar cell on N-type silicon substrate

A technology for solar cells and silicon substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low market share of N-type cells, immature preparation processes, and difficulty in equipment fabrication, saving conventional processes, The effect of low equipment cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

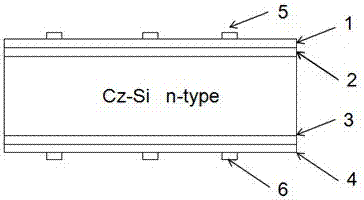

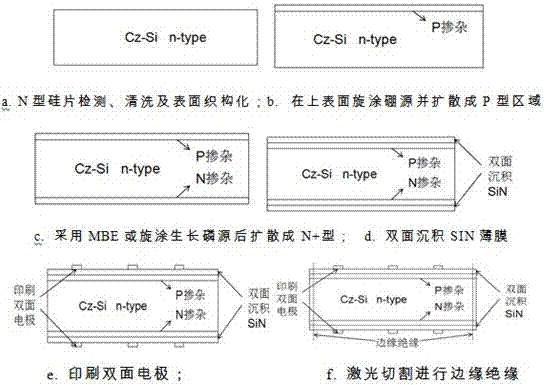

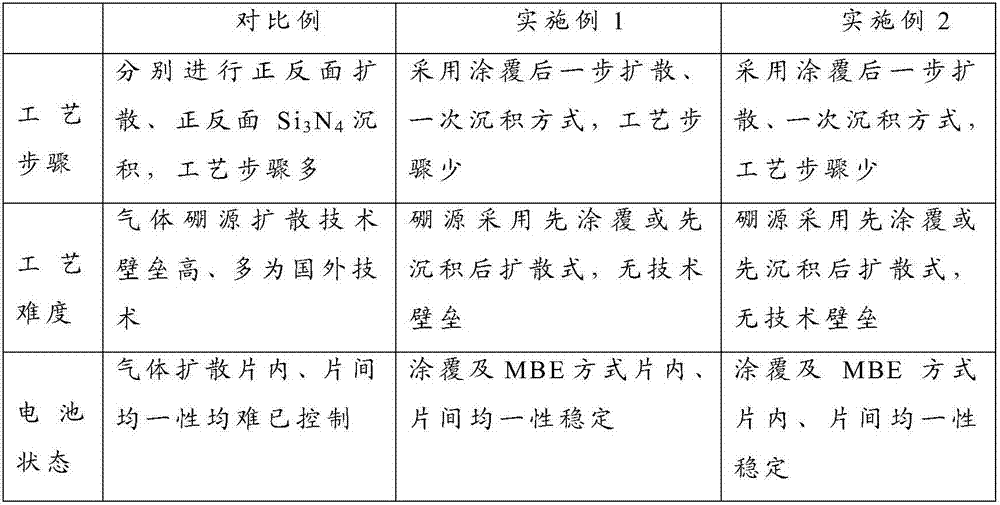

[0028] A method for preparing double-sided solar cells based on N-type silicon wafers

[0029] (1) First, the N-type silicon wafer is cleaned and textured, and a pyramid structure is formed on both sides of the silicon wafer;

[0030] (2) Spin-coating equipment is used on the front surface of the N-type silicon wafer after texturing to coat a layer of high-concentration organic boron source with a boron content greater than 50%, so as to form a P-type doped region 2 on the surface, and make the front PN Junction; the rotation speed of the spin coating process is 5000R / min, the thickness of the boron source after coating is 5um, and the depth of the boron source doping node after diffusion is 150nm;

[0031] (3) N-type phosphorus source coating is performed on the back of the Si wafer by MBE or spin coating to form an N-type doped region 3 on the surface; the front and back of the battery are spin-coated, and MBE is used on the back to form two layers of superimposed PN Juncti...

Embodiment 2

[0039] A method for preparing double-sided solar cells based on N-type silicon wafers

[0040] (1) First, the N-type silicon wafer is cleaned and textured, and a pyramid structure is formed on both sides of the silicon wafer;

[0041] (2) Spin-coating equipment is used on the front surface of the N-type silicon wafer after texturing to coat a layer of high-concentration organic boron source with a boron content greater than 50%, so as to form a P-type doped region 2 on the surface, and make the front PN Junction; spin coating process speed 10000R / min, boron source thickness after coating is 10um, boron source doping node depth is 500nm after diffusion advance;

[0042] (3) N-type phosphorus source coating is performed on the back of the Si wafer by MBE or spin coating to form an N-type doped region 3 on the surface; the front and back of the battery are spin-coated, and the back is spin-coated to form a two-layer superposition Shaped PN junction, the battery can generate elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com