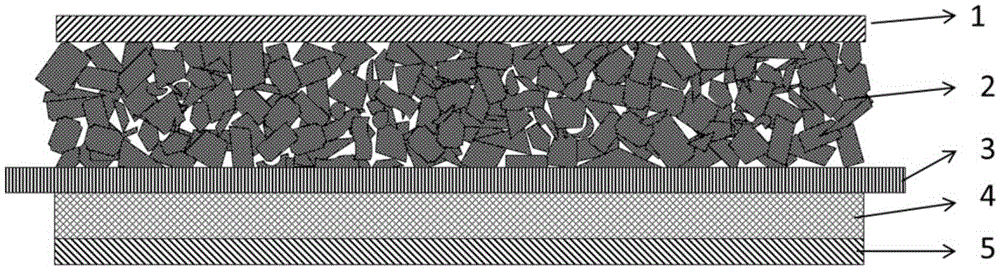

An air positive electrode composed of conductive gel particles and its lithium-air battery

A lithium-air battery, air cathode technology, applied in electrical components, battery electrodes, fuel cell type half cells and primary battery type half cells, etc., can solve the difficulty of oxygen diffusion and the small thickness of the air cathode can not meet the practical application requirements and other problems to achieve the effect of increasing the discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

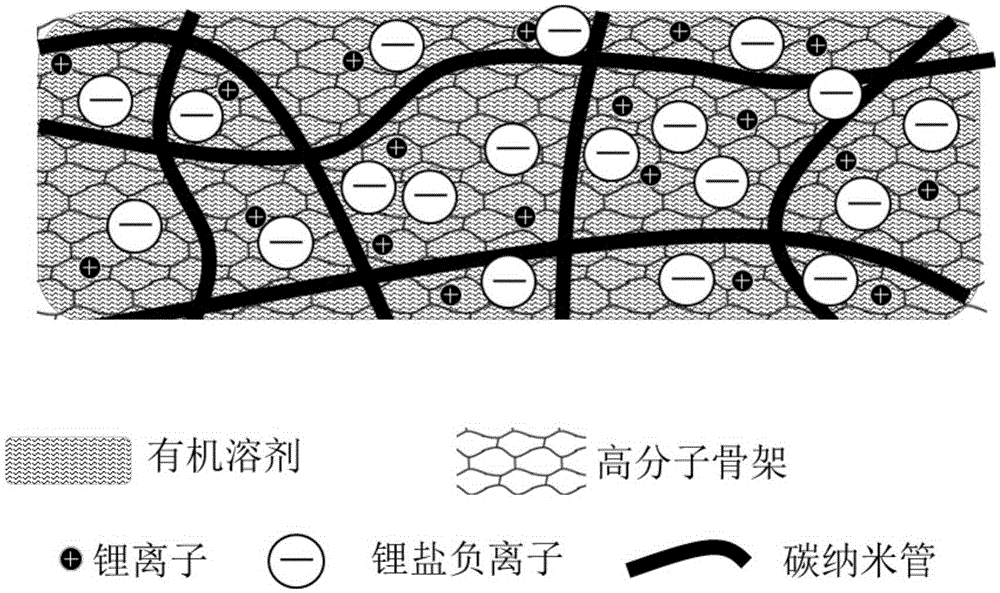

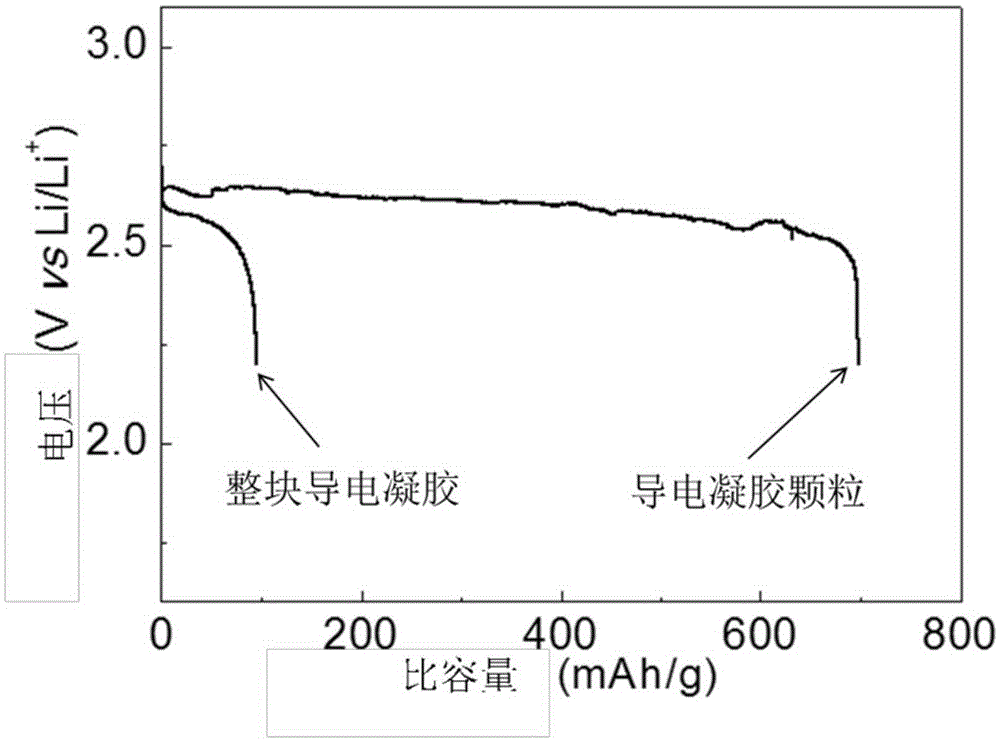

[0039] This example prepares carbon nanotube (CNT) / vinylidene fluoride hexafluoropropylene copolymer (PVDF-HFP) / tetraethylene glycol dimethyl ether (TEGDME) / lithium bistrifluorosulfonimide (LiTFSI) Conductive gel particles. The conductive gel particles in this example were prepared into an air positive electrode and assembled into a button-type lithium-air battery to test the performance of the air positive electrode.

[0040] In the conductive gel, CNT is used as a conductive filler, PVDF-HFP is used as a gel-forming skeleton polymer, TEGDME is used as an organic solvent, and LiTFSI is used as a lithium salt.

[0041] The preparation process of the conductive gel particles is as follows: (1) using CVD-grown sponge-like carbon nanotubes (CNT sponges) with a density of about 10 mg / mL as an electronically conductive framework. (2) Heat and dissolve the polymer PVDF-HFP in acetonitrile to form a concentration of 50mgmL -1 (3) immerse the CNT sponge in step (1) in the polymer so...

Embodiment 2

[0049] This embodiment prepares palladium (Pd) / carbon nanotube (CNT) / polyethylene oxide (PEO) / tetraethylene glycol dimethyl ether (TEGDME) / bistrifluoromethylsulfonylimide lithium (LiTFSI) composition Conductive gel particles. The conductive gel particles in this example were prepared into an air positive electrode and assembled into a button-type lithium-air battery, and the performance of the air positive electrode was tested.

[0050] In the conductive gel, Pd nanoparticles are used as a catalyst for oxygen reduction reaction and oxygen evolution reaction, CNT is used as a conductive filler, PEO is used as a gel-forming skeleton polymer, TEGDME is an organic solvent, and LiTFSI is used as a lithium salt.

[0051] Compared with Example 1, on the basis of Example 1, this example loaded some Pd nanoparticles on the surface of CNT, and replaced the skeleton polymer in the gel. The specific implementation method is as follows: (1) The sponge-like carbon nanotube (CNT sponge) gro...

Embodiment 3

[0054] This embodiment prepares manganese oxide (MnO 2 ) / Ketjen black (KB) / polyvinylidene fluoride (PVDF) / tetraethylene glycol dimethyl ether (TEGDME) / lithium tetrafluoroborate (LiBF 4 ) composed of conductive gel. The conductive gel particles in this example were prepared into an air positive electrode and assembled into a button-type lithium-air battery, and the performance of the air positive electrode was tested.

[0055] In this conductive gel, MnO 2 Nanoparticles as catalyst for oxygen reduction reaction, KB as conductive filler, PVDF as backbone polymer for gel formation, TEGDME as organic solvent, LiBF 4 as a lithium salt.

[0056] The preparation process of the conductive gel particle is as follows: (1) KB is used as the electronic conductive framework. (2) Heat and dissolve the polymer PVDF in 1mol / L LiBF 4 / TEGDME organic electrolyte, the formation concentration is 50mg·mL -1 (3) Add KB to the polymer solution obtained in step (2), heat to 120°C under the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com