Patents

Literature

156results about How to "Does not affect delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

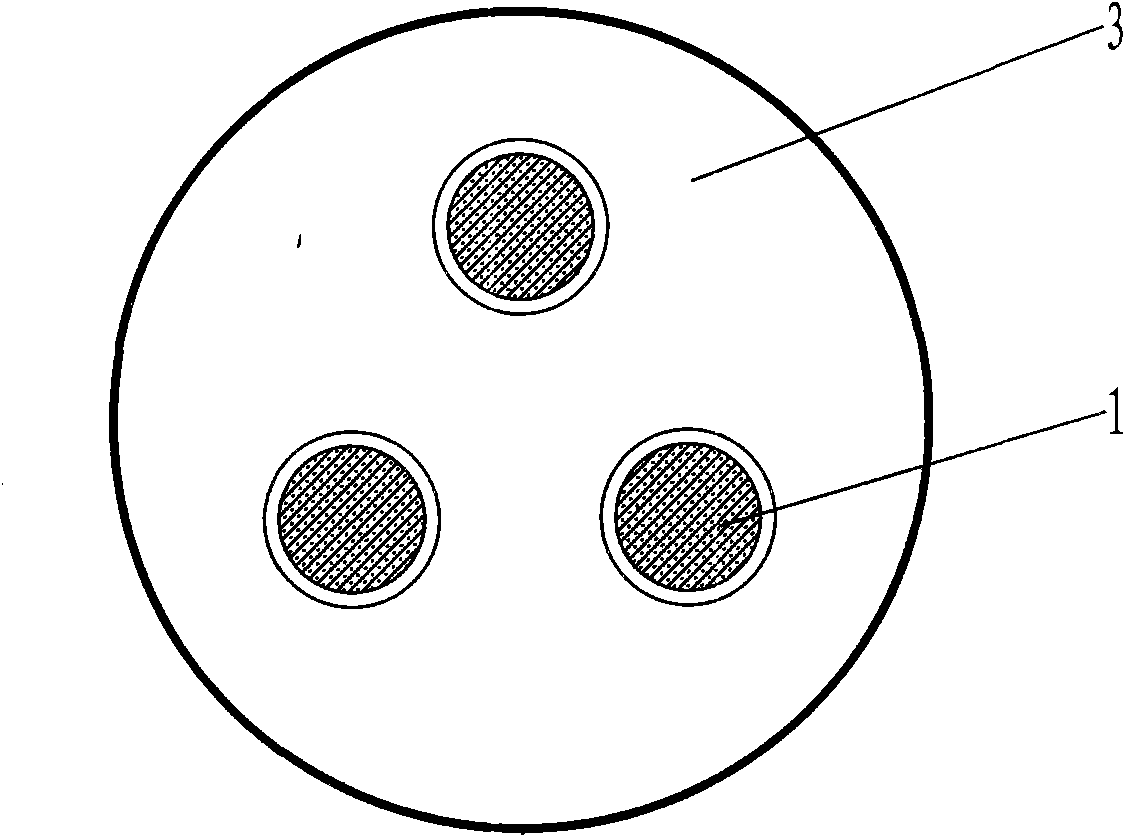

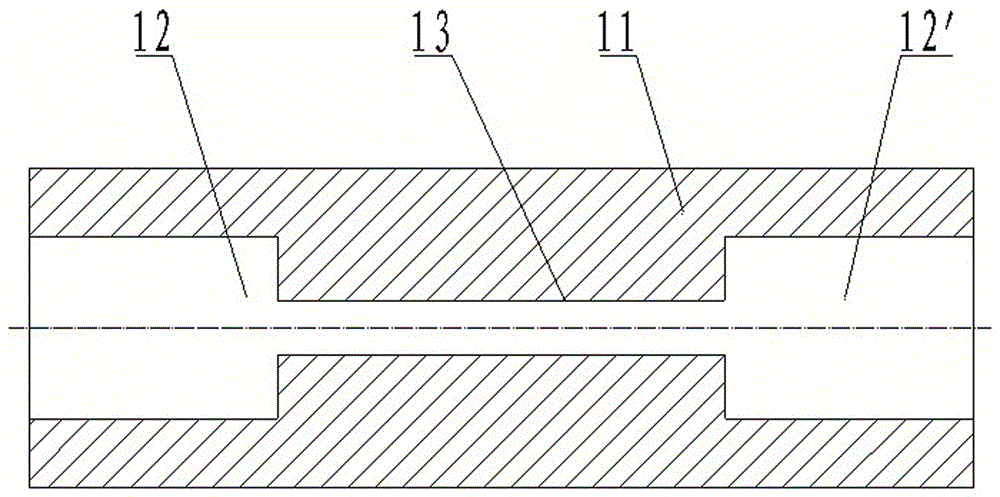

Insertion piece for measuring transient heat flow density distribution in fuel cell

ActiveCN102116679ADoes not affect deliveryEasy to disassembleMaterial heat developmentThermometers using electric/magnetic elementsHeat flowMeasurement device

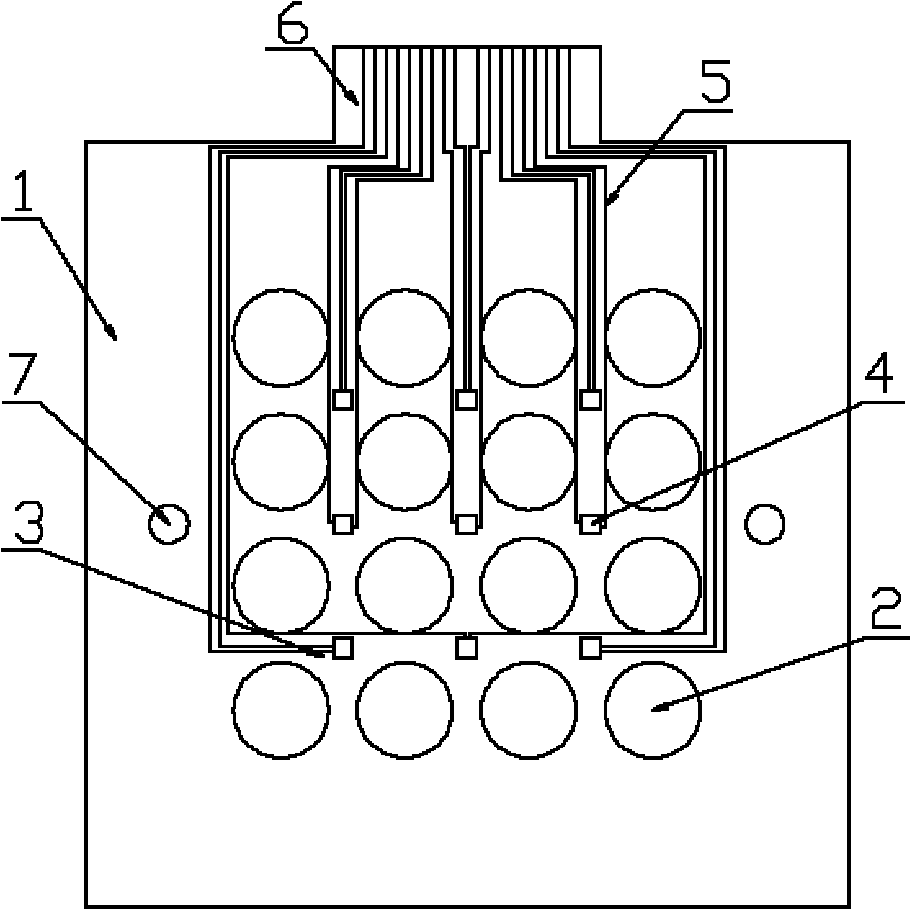

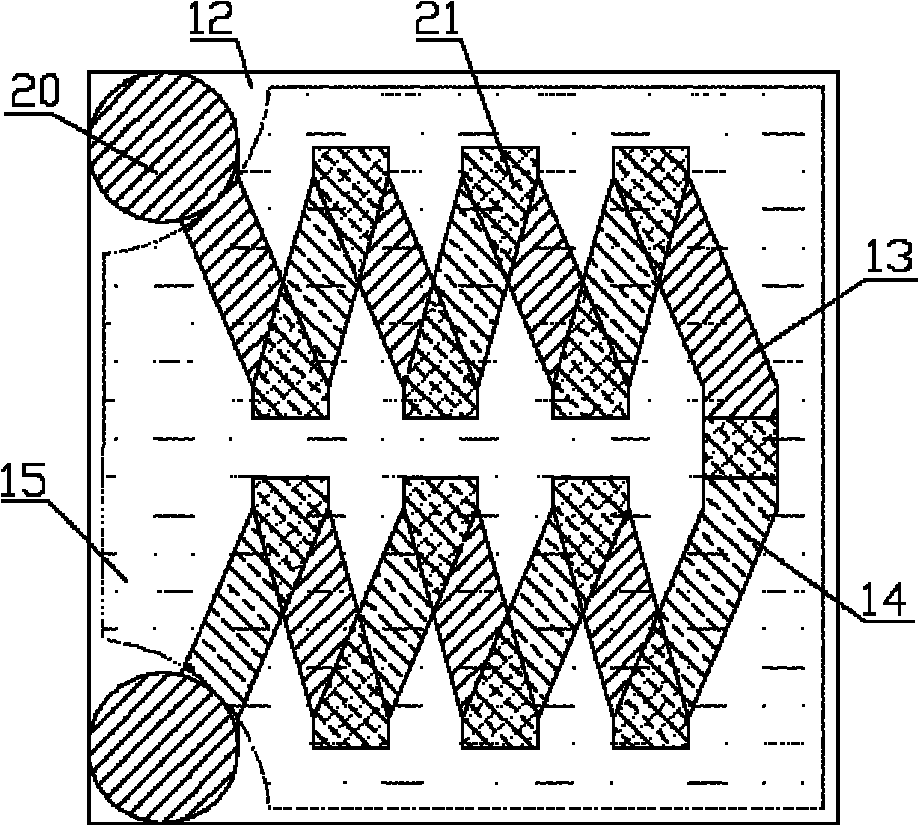

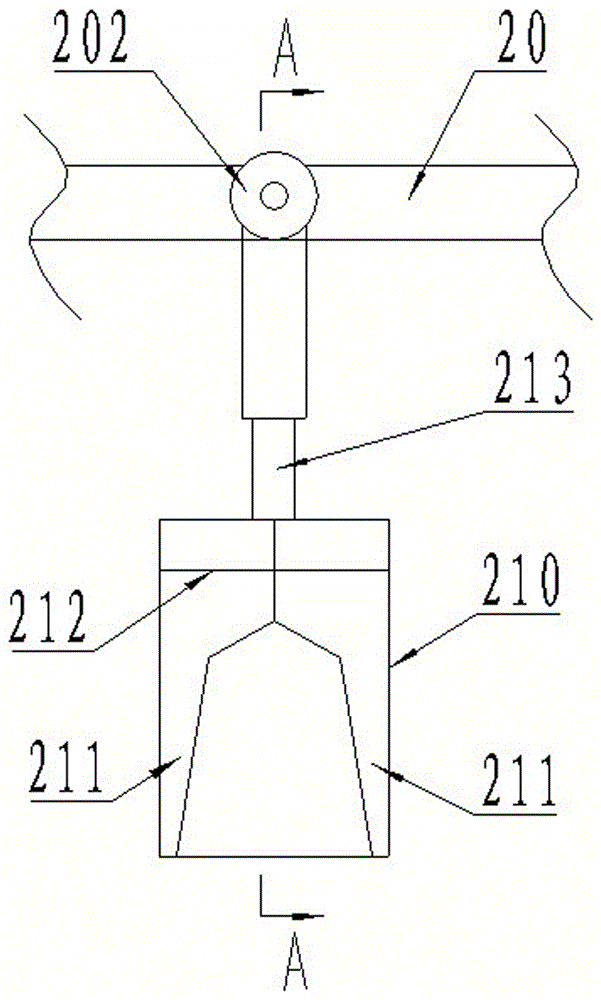

The invention discloses an insertion piece for measuring heat flow density distribution in a fuel cell, which is a device for measuring the heat flow density distribution in the fuel cell. The insertion piece comprises a gold-plated stainless steel substrate, and leaks and ribs, which are in the same sizes, the same shapes and the corresponding positions with grooves and ridges on a flow field plate of the fuel cell to be measured, are arranged on the substrate. A thin film heat flow meter is arranged on the rib between the adjacent leaks or holes on the measuring insertion piece respectively, the vacuum film coating technology is adopted for vapor deposition of seven layers of thin films, leading-out wires of the thin film heat flow meters extend to the edge of the substrate by adopting the method of printing a circuit, and a standard wiring port connected with an external circuit is further formed. The measuring insertion piece is placed between the flow field plate of the fuel cell and a membrane electrode. The insertion piece for measuring the heat flow density distribution in the fuel cell is completely independent of a measured object, and the fuel cell does not need to be transformed; furthermore, as the placement position of the insertion piece is very near to the membrane electrode, the insertion piece can measure the real-time heat flow density distribution situation in the fuel cell.

Owner:BEIJING UNIV OF TECH

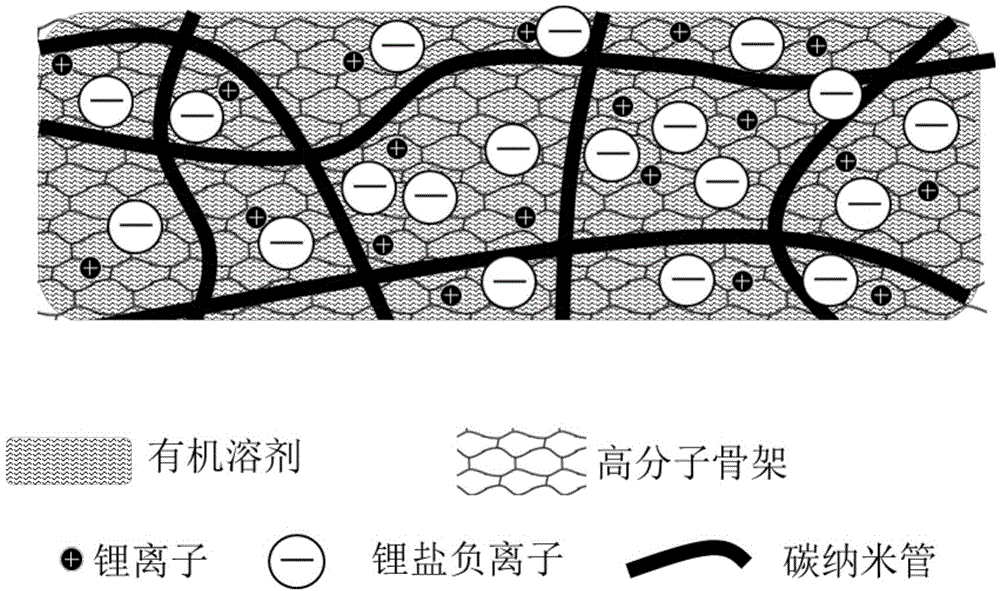

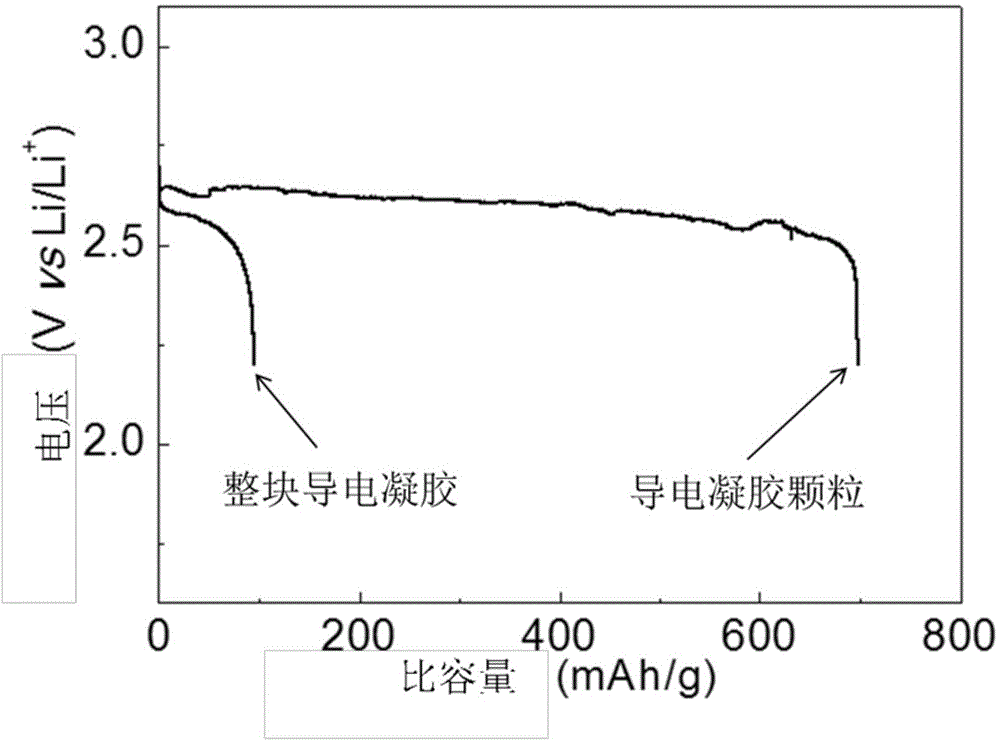

Air positive electrode constructed by conductive gel particles and lithium air battery

ActiveCN104659375AEasy and quick passFast deliveryFuel and primary cellsCell electrodesSolid structureLithium–air battery

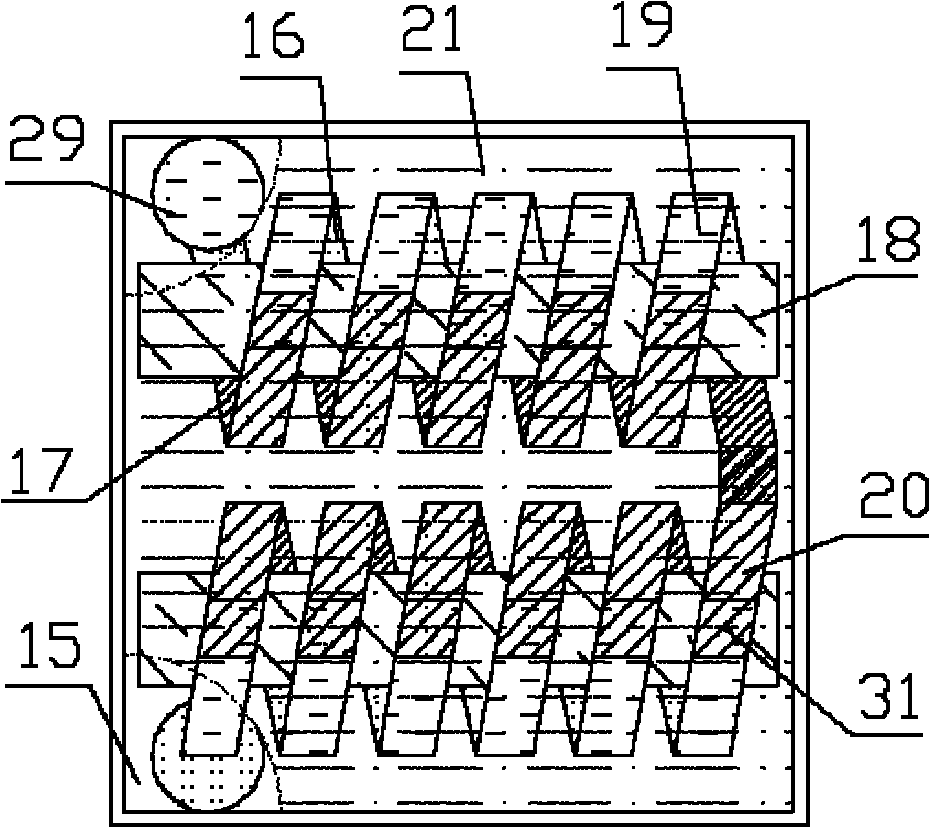

The invention discloses an air positive electrode constructed by conductive gel particles and a lithium air battery. The air positive electrode is characterized by being of a full-solid structure and comprising particles with arbitrary shapes, wherein the particles are prepared from conductive gel, gaps are formed among the particles, electrons and ions can be simultaneously conducted by conductive gel, and the size range of the particle sizes of the particles is 10-500 microns; the particles are stacked to form a laminated structure, and the thickness of the laminated structure is 50 microns to 5 millimeters. A battery cell of the lithium air battery is of a multi-layer winding type structure or a multi-layer laminating type structure and is formed by winding and laminating a plurality of repetitive units, and each repetitive unit comprises the air positive electrode. A rapid gas dispersion channel is formed in the air positive electrode and can be prepared to be relatively thick, so that the problem that oxygen is difficult to diffuse is effectively solved, and the air positive electrode can be truly input into actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

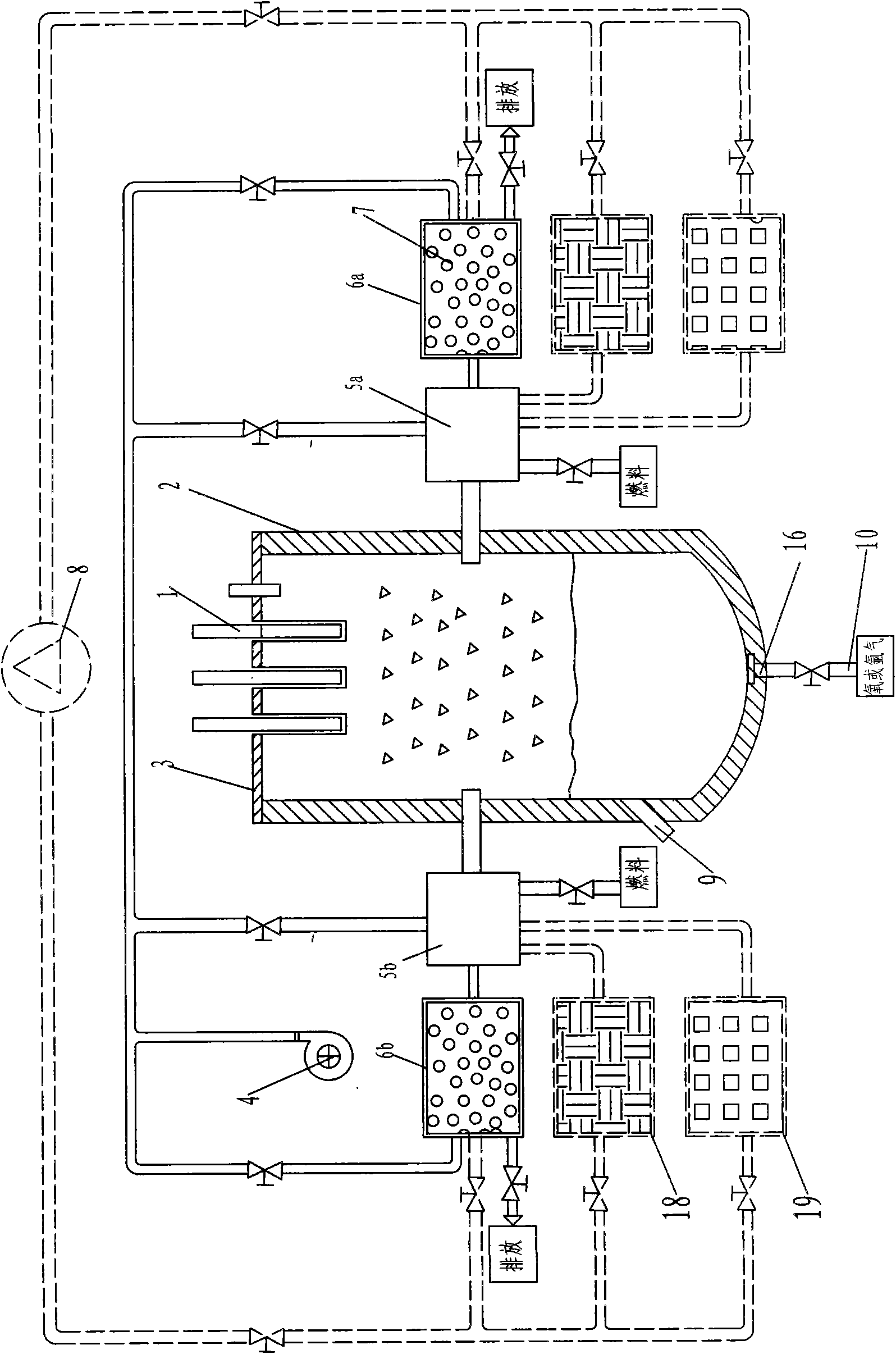

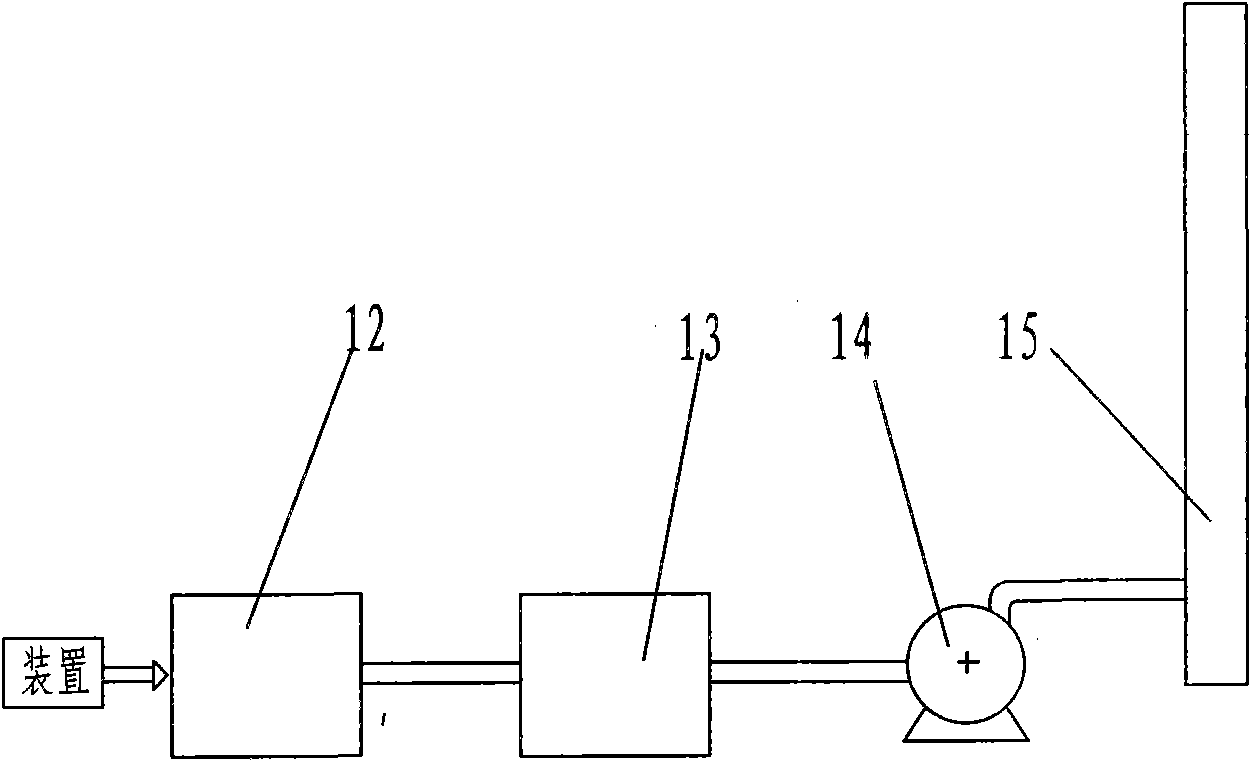

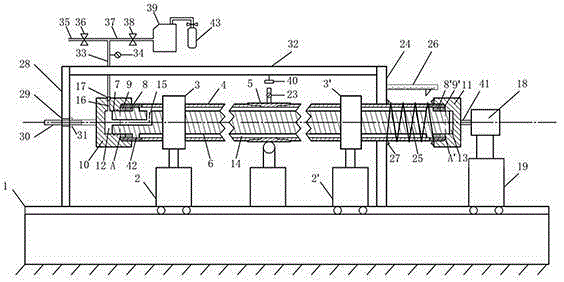

Method and device for making iron by smelting reduction

ActiveCN101649366ALess investmentReduce pre-restore timeCalcium carbideManufacturing convertersElectric arc furnaceSlag

The invention relates to a method and a device for making iron by smelting reduction. The method for making iron by smelting reduction comprises the following steps: putting raw material forming matters into a smelting ironmaking device; heating and reducing the raw material forming matters into metallic iron; after the reduced metalation rate of various oxides of iron reaches 40-95 percent in rawmaterials, heating and melting products of a reducing furnace; and producing direct reduction molten steel or molten iron produced by the similar blast furnace. The raw materials comprise a breath shell or a half-breath shell or an opening shell or the combination of the raw materials, a coating shells of the breath shell, the half-breath shell and the opening shell is prepared by adding an adhesive in calcium oxide or calcium carbonate or calcium carbide or the combination of the materials. The device for making iron by smelting reduction comprises an arc furnace, a buried arc furnace, a converter, an induction furnace, and the like. After reduction products are heated and melted, and oxygen or inert gas is blown into the arc furnace in order to remove slag. Due to the adoption of a shell coating technology, the method and the device effectively prevent from oxidizing reduced matters in the process, avoid bonding formed matters for contact and are combined with blowing gas and are good for making slag. Slag iron has good separation effect, and the produced iron and steel products have good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

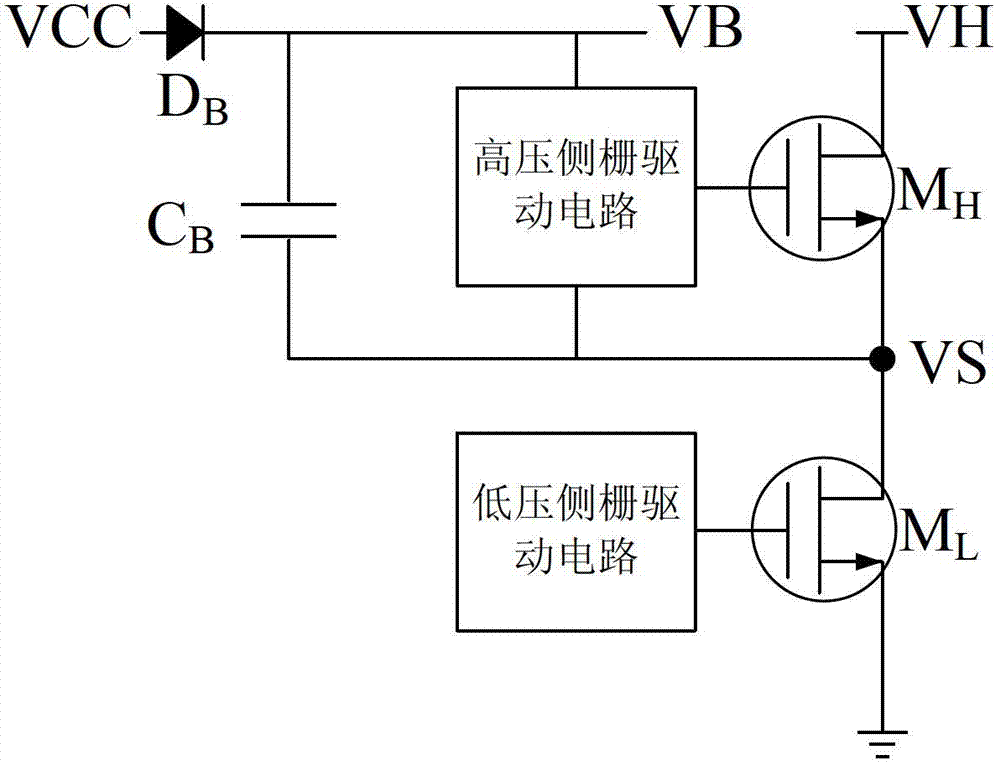

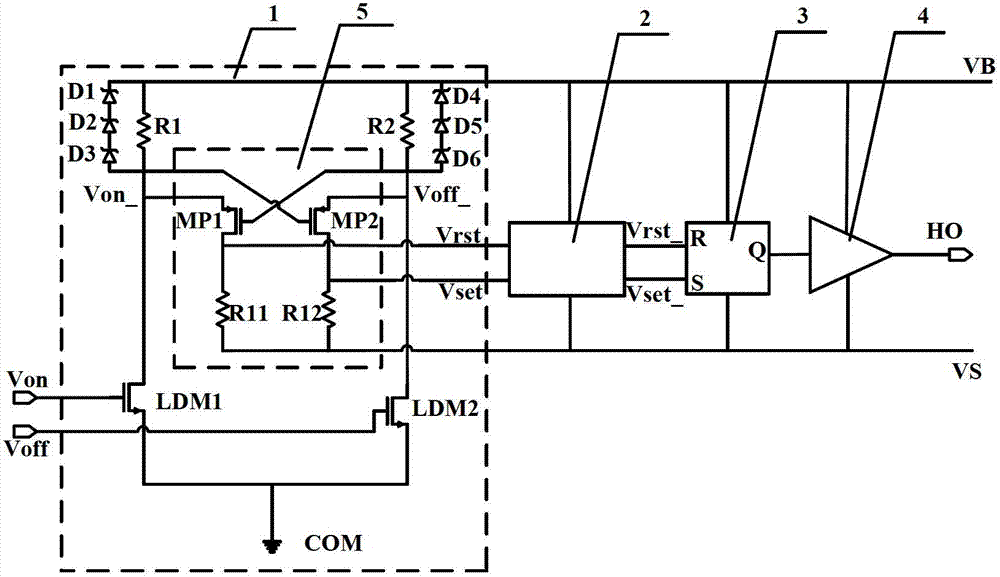

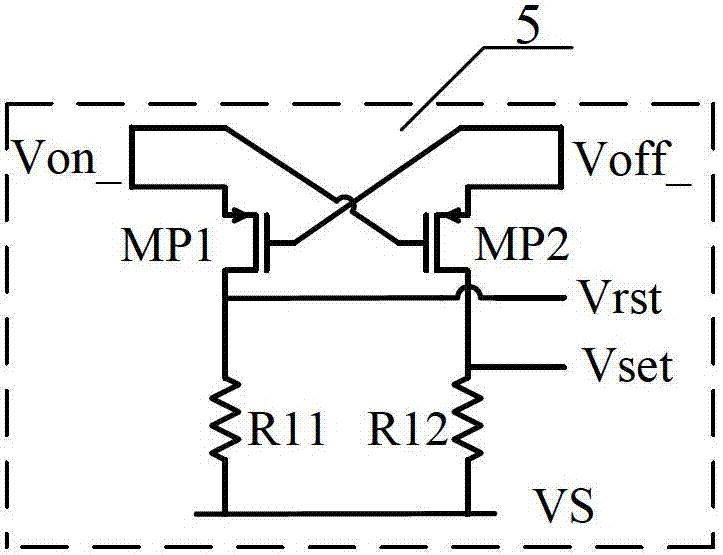

High-voltage side gate drive circuit capable of resisting noise interference

ActiveCN102769453AEliminate the effects of working statusDoes not affect deliveryReliability increasing modificationsProcess deviationsHigh voltage pulse

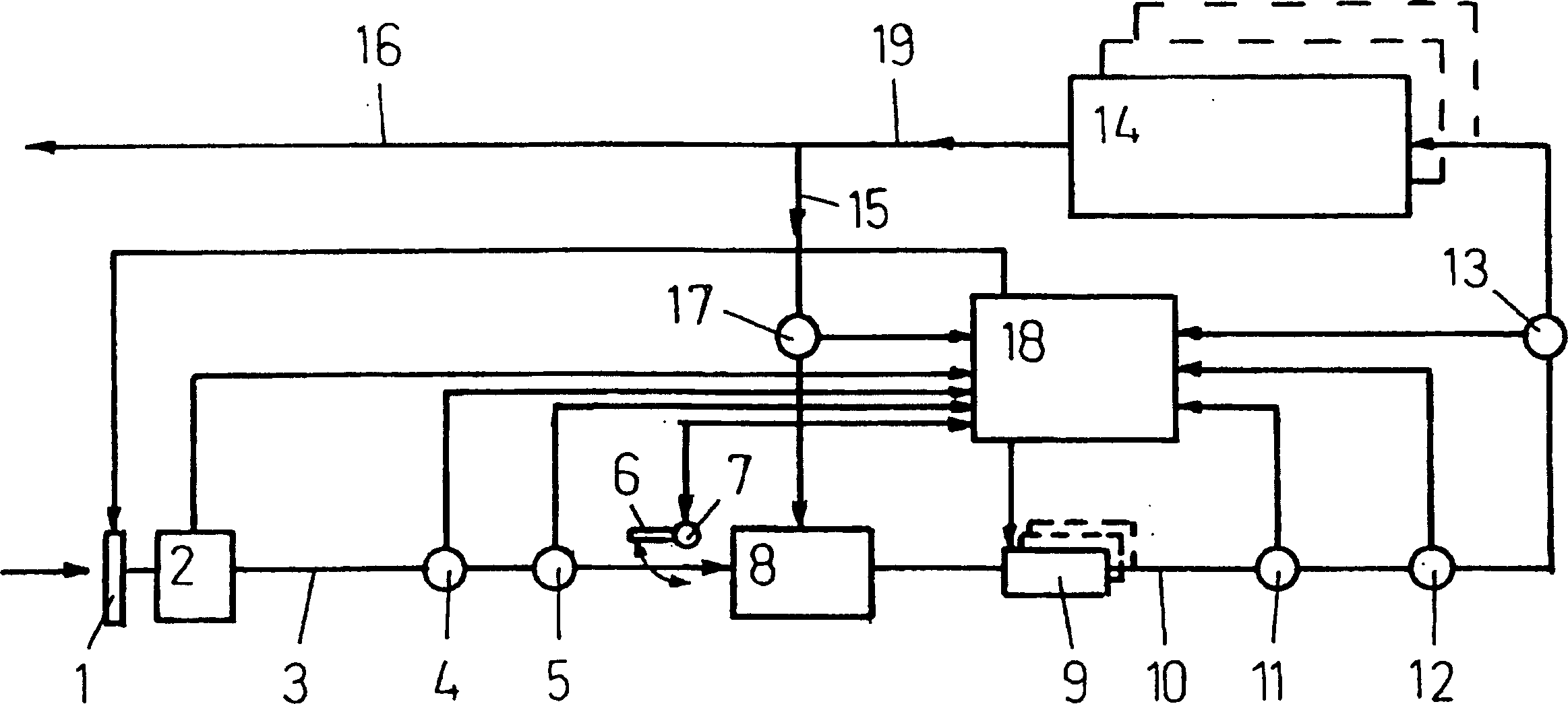

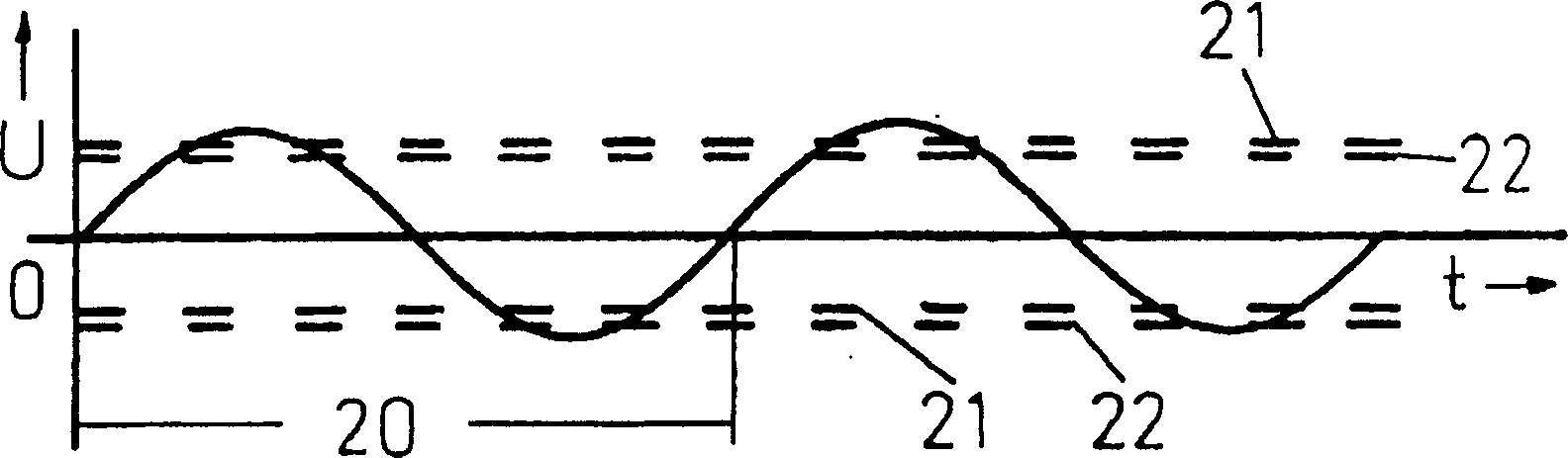

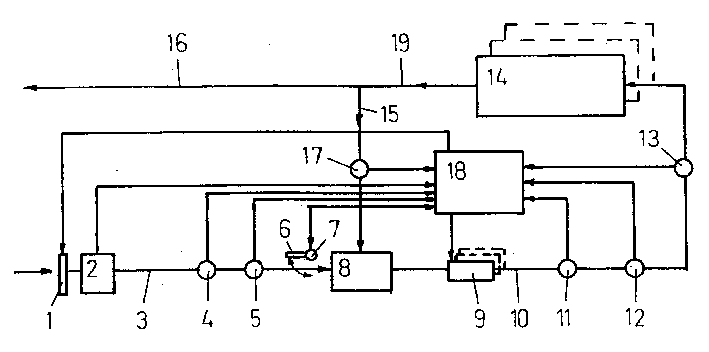

The invention provides a high-voltage side gate drive circuit capable of resisting noise interference. The high-voltage side gate drive circuit comprises a high-voltage level shift circuit, a differential-mode noise elimination circuit, an RS trigger and an output drive level circuit, wherein a low-side pulse signal is converted into a high-voltage pulse signal for output through the high-voltage level shift circuit; a common mode noise elimination circuit is connected between the output of the high-voltage level shift circuit and the input of the differential-mode noise elimination circuit; the common mode noise elimination circuit is used for eliminating a common mode noise signal generated in application; and the differential-mode noise elimination circuit eliminates the differential-mode noise introduced by process variations, outputs a normal pulse signal, reduces the normal pulse signal into a normal square signal through the RS trigger, outputs the square signal from the output drive level circuit and drives an external high-side power tube.

Owner:SOUTHEAST UNIV

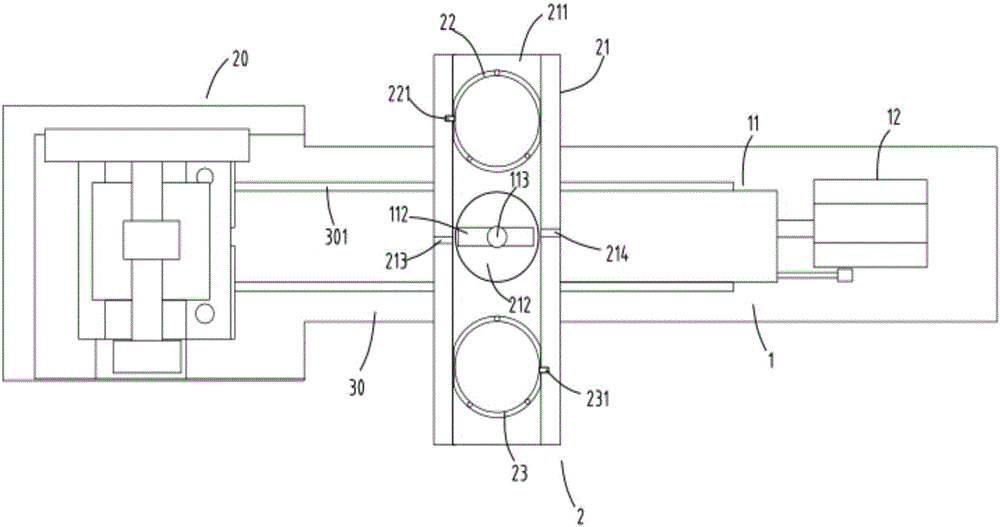

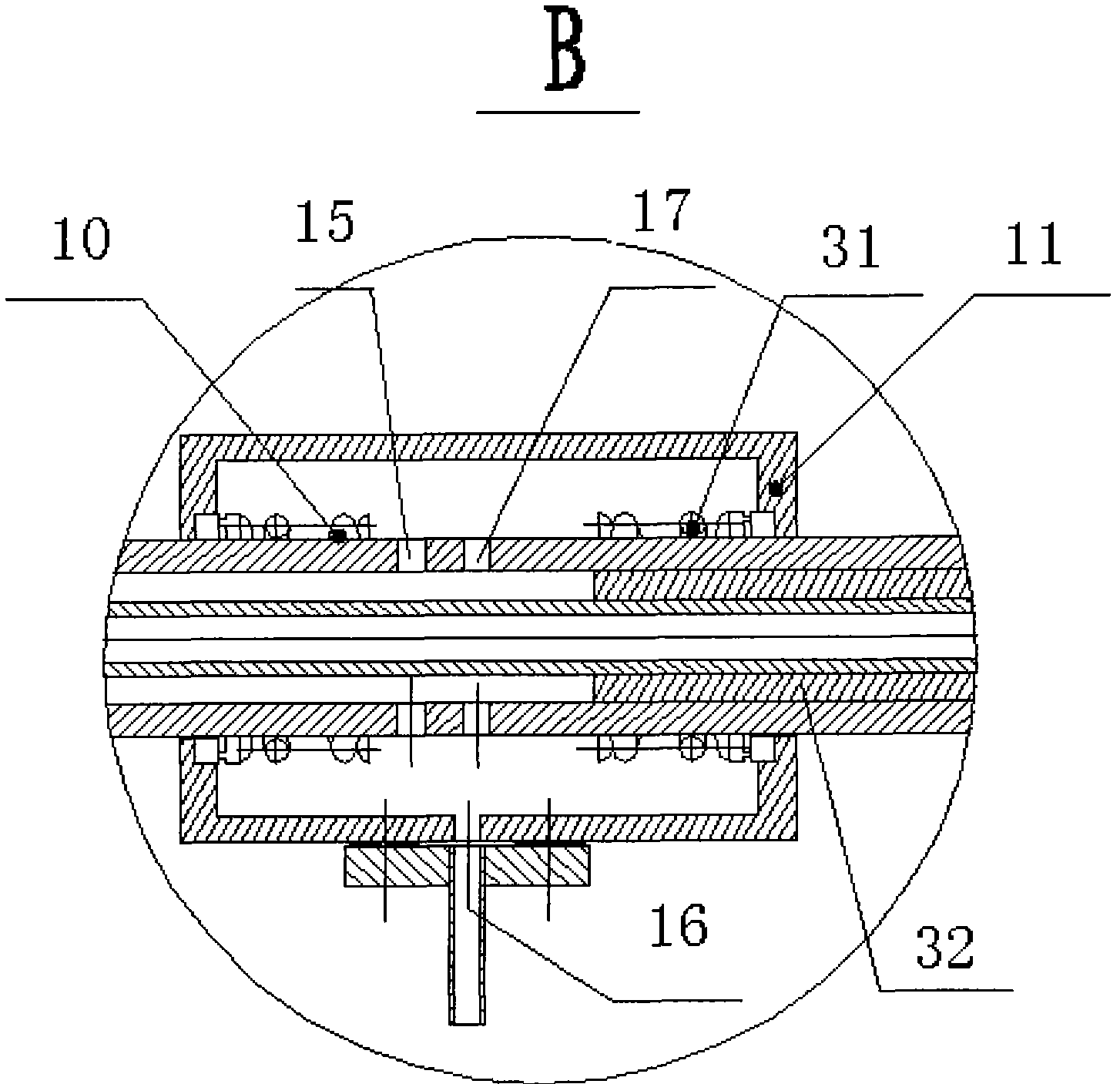

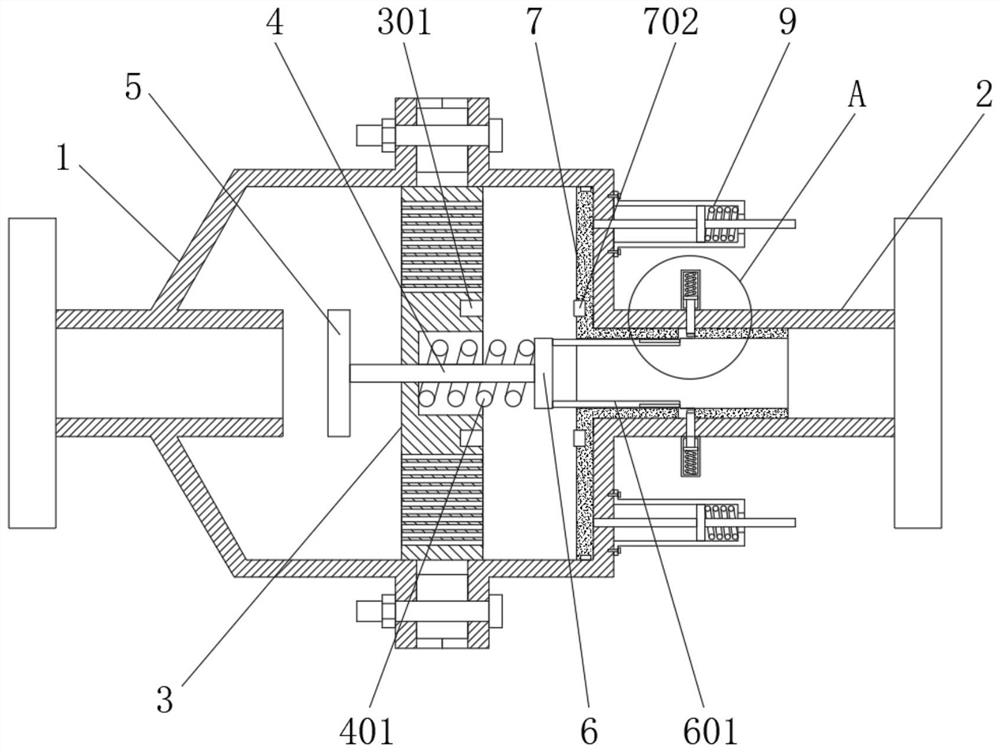

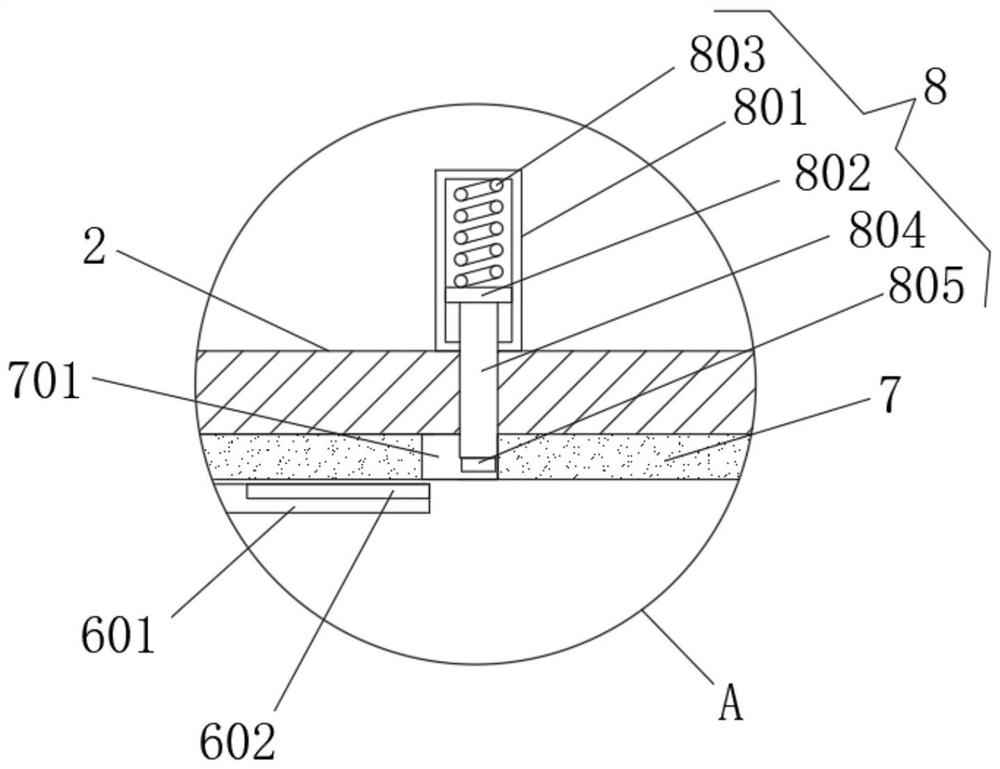

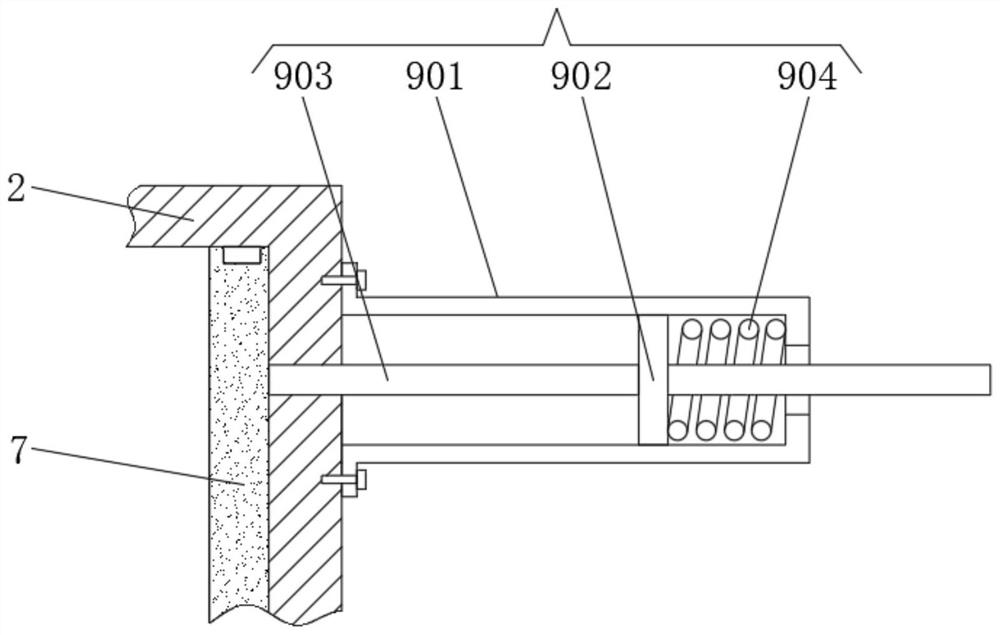

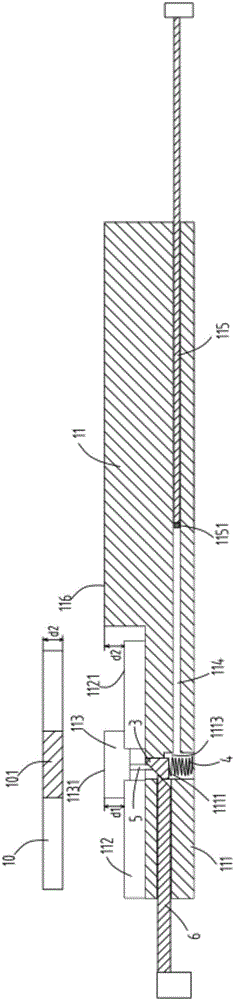

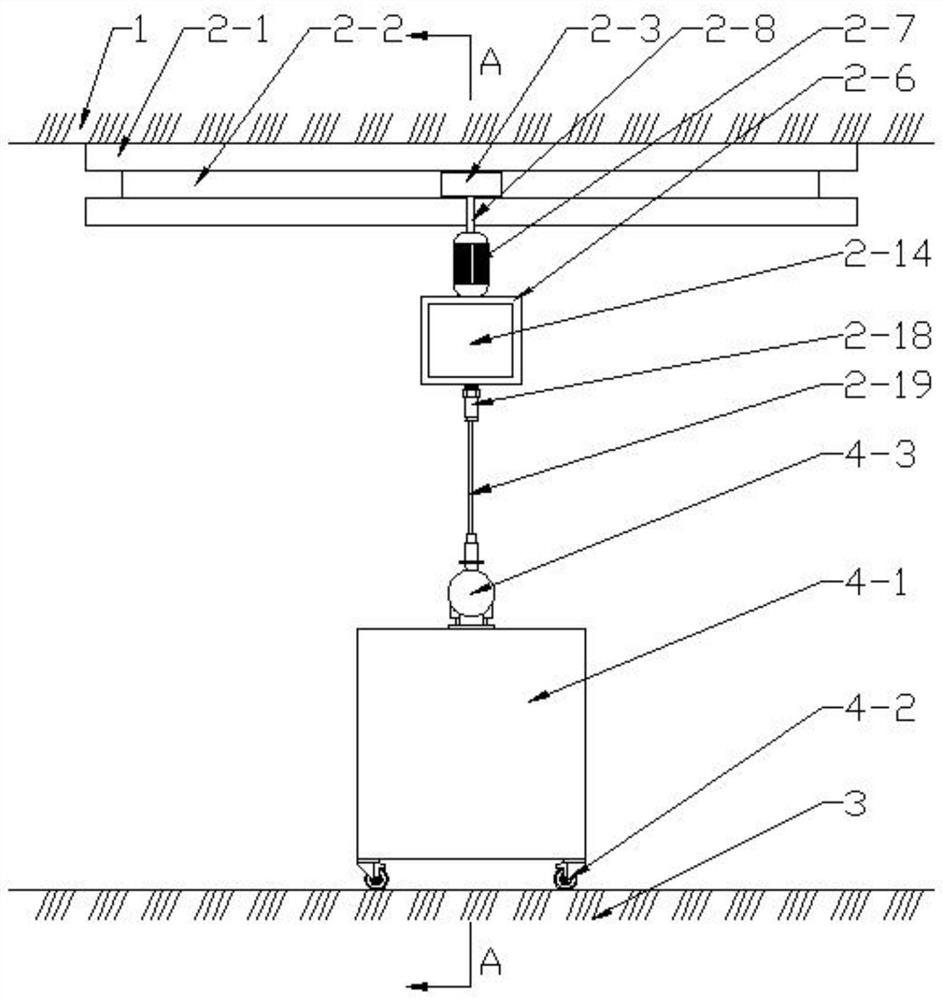

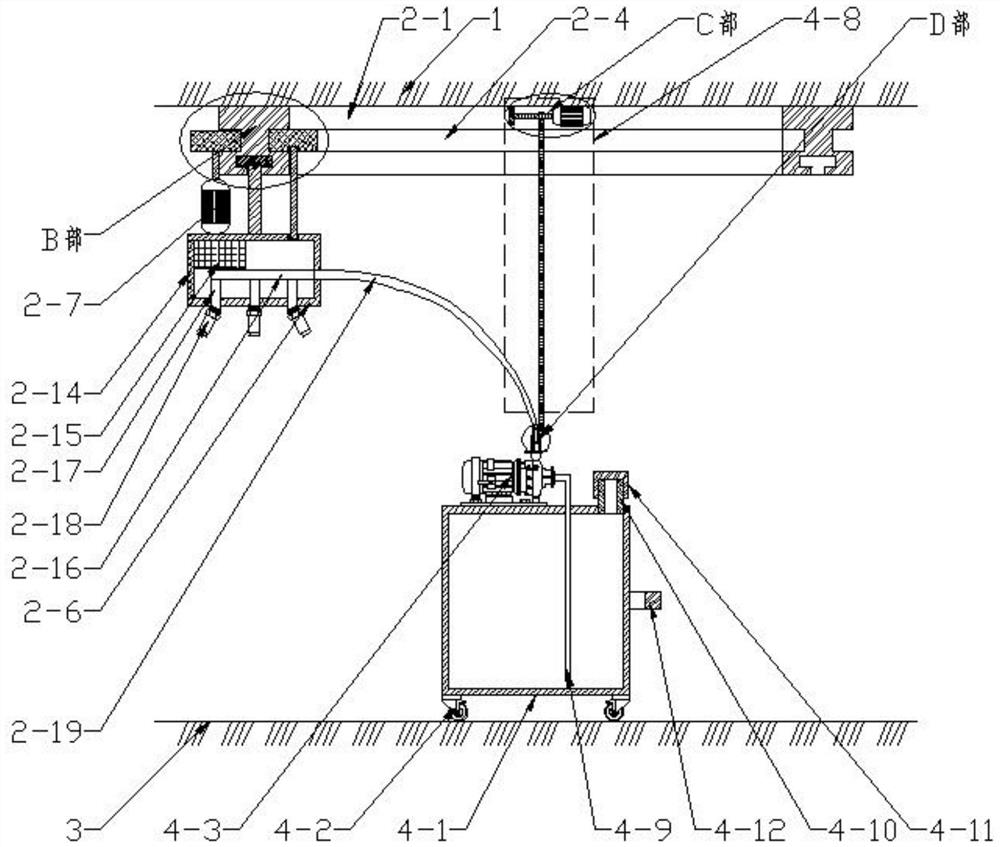

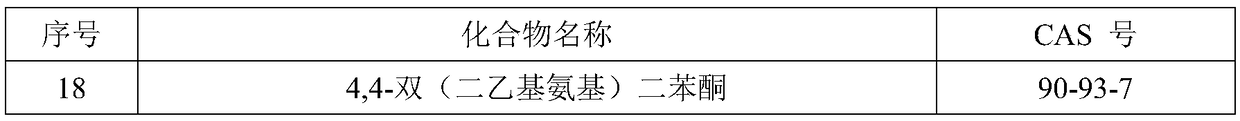

Dynamic test device and method for thread sealing performance of oil pipe adapter

InactiveCN105241612ADoes not affect deliverySimple structureDetection of fluid at leakage pointInternal pressureCoupling

The invention relates to a dynamic test device and method for the thread sealing performance of an oil pipe adapter in the technical field of petroleum oil pipelines. The test device comprises a sliding rail, a support base, an oil pipe clamp, an oil pipe test piece, a coupling, a core rod, seal assemblies at two ends of the oil pipe test piece, a vibration exciter, a bending moment loading module, a static load stretching module, a pressurization module, a top plate and a leakage tester. The test device is characterized in that the core rod is placed inside the oil pipe test piece to constitute an annular cavity, and then the two ends are sealed; a pressurization machine pressurizes the annular cavity; the vibration exciter, the bending moment loading module and the static load stretching module respectively apply a vibration load, a bending moment load and an axial stretching load to the oil pipe test piece. The dynamic test device and method can test the seal performance of an oil pipe under composite loads of inner pressure, stretching, bending moment and vibration loads; the technical scheme of the invention especially takes the dynamic factors into account and livingly simulates actual service conditions of the oil pipe; the test result is of great significance for guidance. The test device has a simple structure and good operationality.

Owner:SOUTHWEST PETROLEUM UNIV

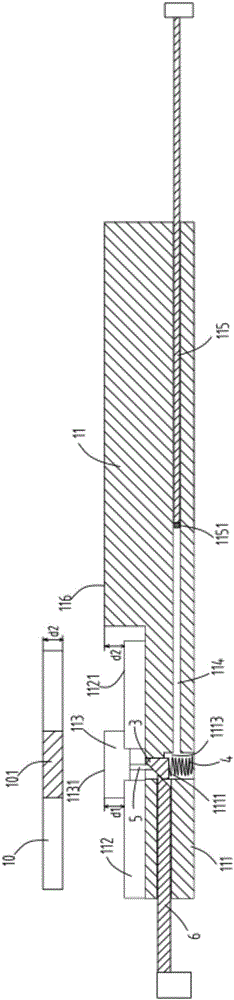

Transient temperature distribution sensor in fuel cell

ActiveCN102157743AAvoid problems such as leakageReduce volumeFuel cell heat exchangeThermometers using electric/magnetic elementsThin film thermocouplesCopper plating

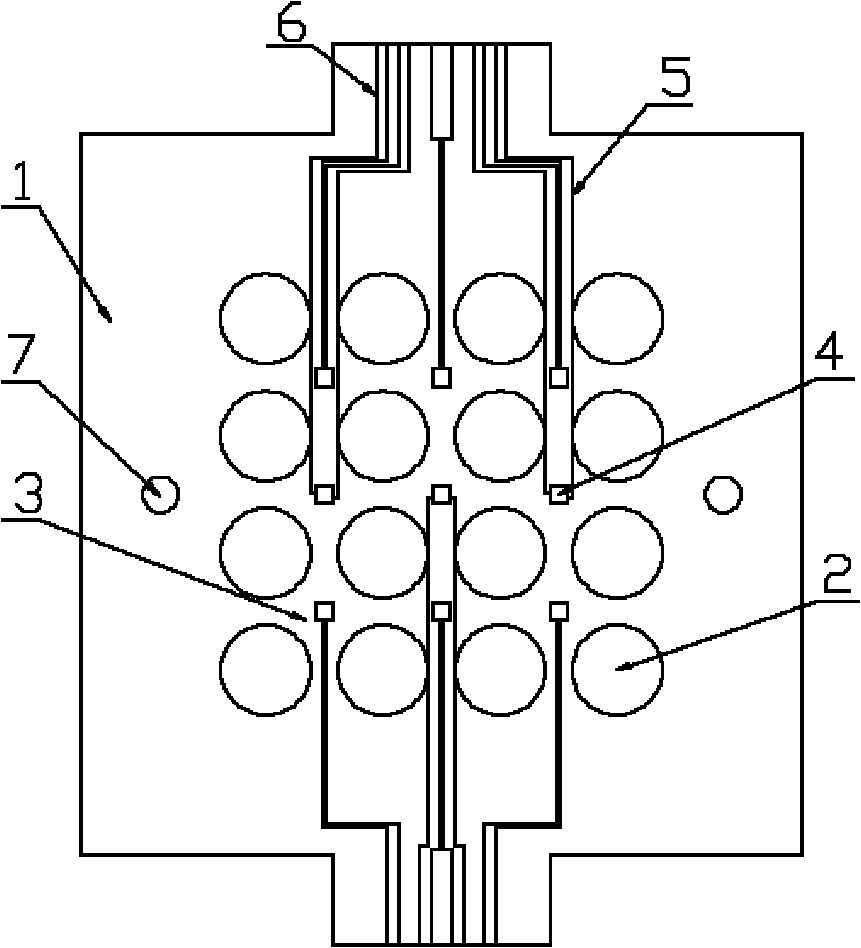

The invention discloses a transient temperature distribution sensor in a fuel cell, and thin film thermocouples are arranged on ribs between adjacent flow passages on a graphite flow field plate of the fuel cell for measuring transient temperature distribution in the fuel cell. The single thin film thermocouple is formed by adopting a vacuum evaporation coating technology for evaporation of four layers of thin films, a silicon dioxide insulating layer with the thickness of 0.1-0.15 mu m is plated at the first layer, copper is plated at the second layer, nickel is plated at the third layer, the thicknesses of the copper plated layer and the nickel plated layer are 0.08-0.1 mu m respectively, and a silicon dioxide thin layer with the thickness of 0.01-0.02 mu m is finally plated. Leading-out wires of the thin film thermocouples extend to the edge of the graphite flow field plate by utilizing the process of a printed circuit, a standard wiring port for connecting with an external circuitis further arranged, and a data acquisition system is used for exporting signals. A measuring device is simple and easy to operate, the real-time temperature distribution in the fuel cell is measured, the cell is easy to disassemble and assemble, and the impacts on the overall performances of the fuel cell are small.

Owner:BEIJING UNIV OF TECH

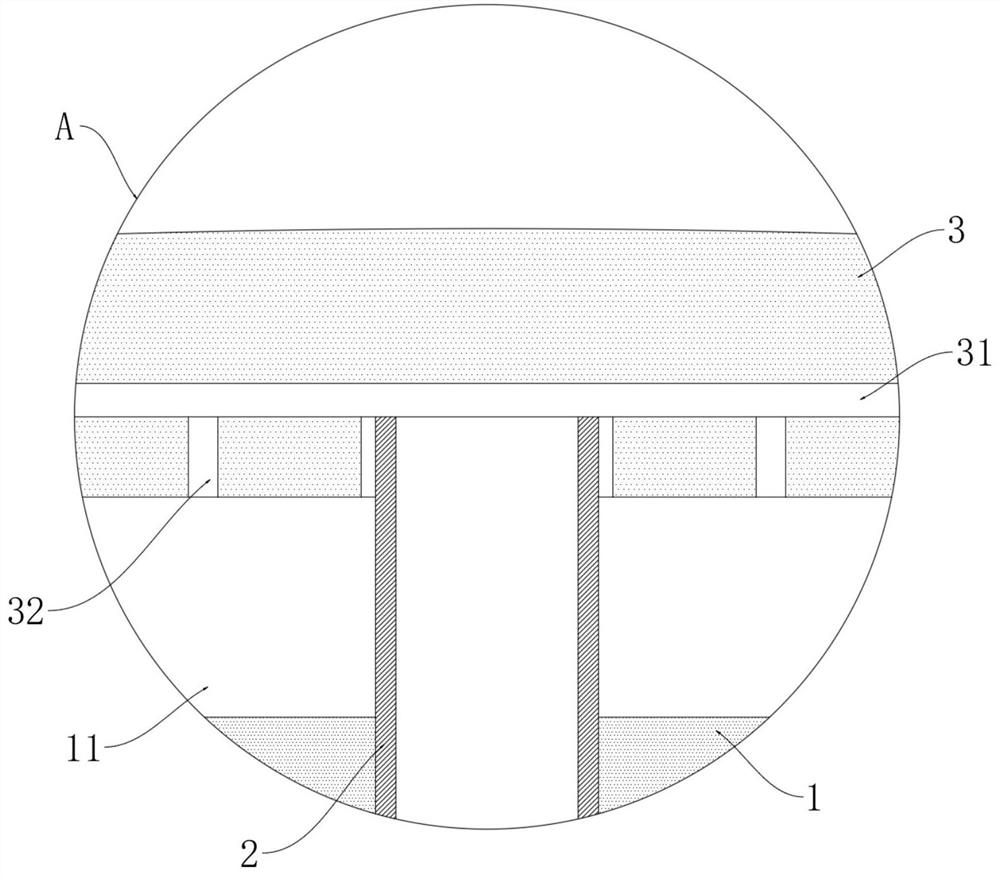

Heat insulation pipe body

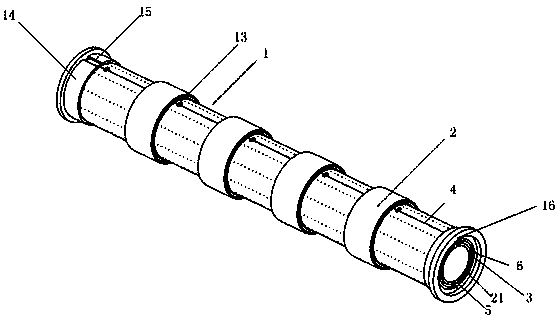

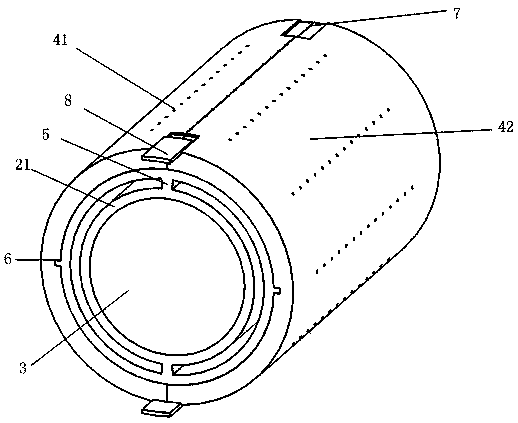

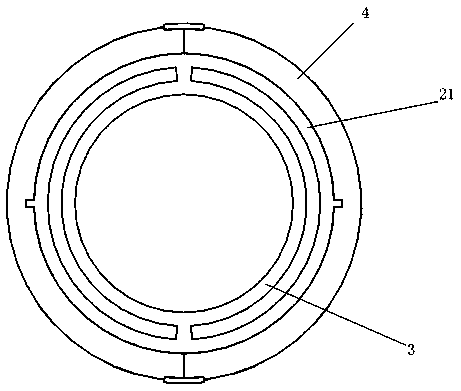

InactiveCN109611648AReduce use costEasy to disassembleThermal insulationPipeline expansion-compensationEngineering

The invention discloses a heat insulation pipe body. The heat insulation pipe body comprises a pipe body single body and a connecting mechanism, wherein the pipe body single body comprises an inner pipe, a middle pipe and a heat insulation single pipe; the inner pipe, the middle pipe and the heat insulation single pipe are sequentially arranged from inside to outside in a sleeved mode; the heat insulation single pipe is a detachable pipe body and comprises a left heat insulation single pipe and a right heat insulation single pipe, and splicing grooves are both formed in the head end of the left heat insulation single pipe and the tail end of the right heat insulation single pipe; and a sliding splicing pressing block is arranged on the head end splicing groove, and a heat insulating cavitywith a circular-ring-shaped section is arranged in the heat insulation single pipe. According to the heat insulation pipe body, a multi-medium simultaneous conveying multi-layer heat insulation pipeis adopted, so that multiple purposes of one pipe can be realized; the detachable heat insulation single pipe is adopted, so that the disassembly is convenient, only the damaged needs to be disassembled and replaced, and the disassembly cost is saved; a heat insulation cavity separation reaction heat-reduction device is adopted, can be used for carrying out a preferential reaction on the differentheat environments when conveying is performed by the pipe body so that an object to be conveyed can be more conveniently prevented from being affected by the temperature; and moreover, the pipe bodycan be replaced more conveniently.

Owner:乌兰察布中石油昆仑燃气有限公司

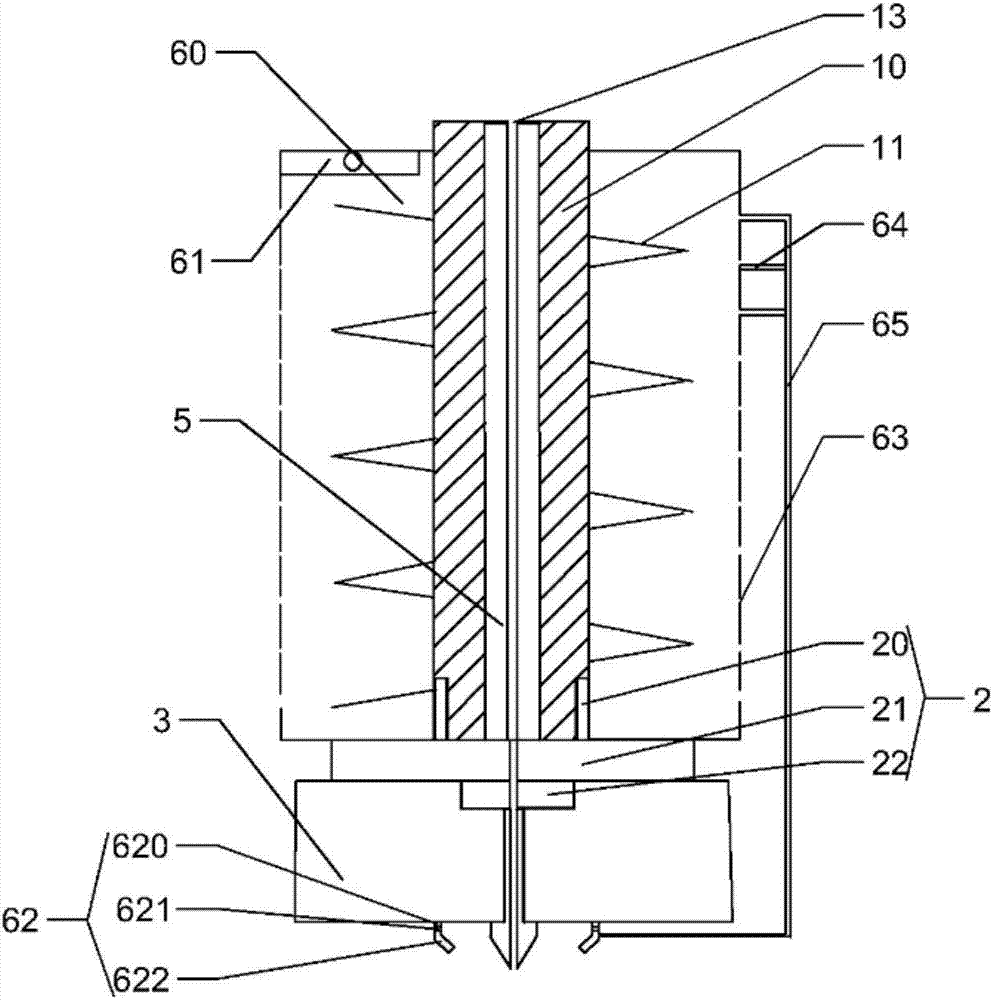

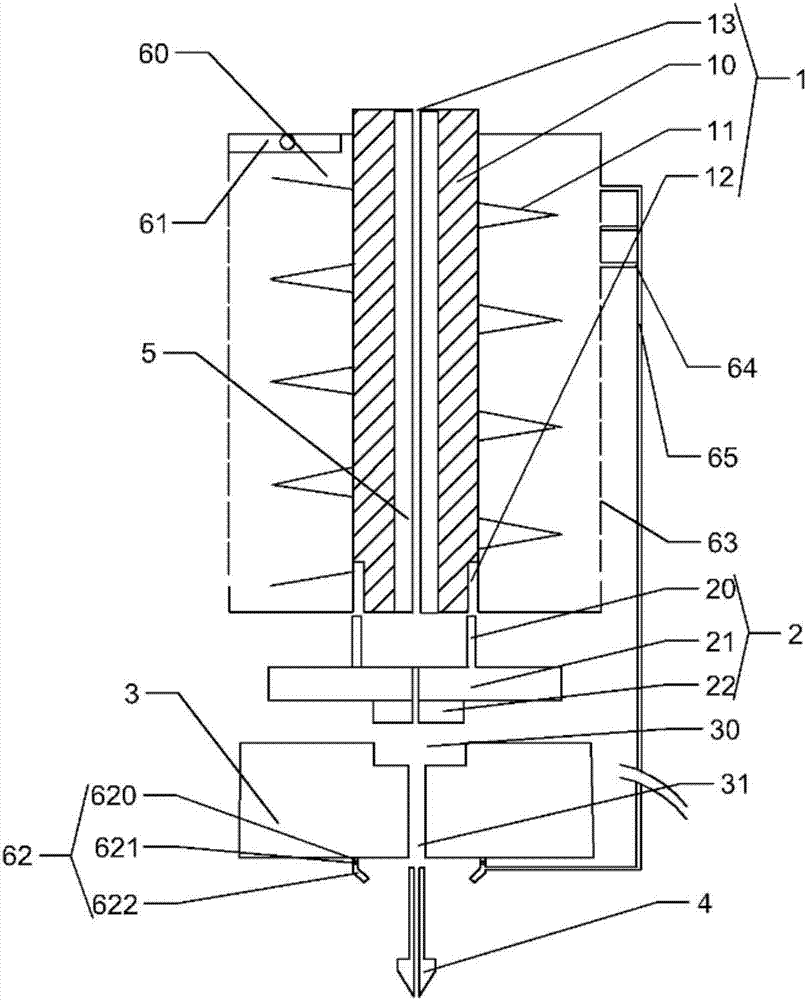

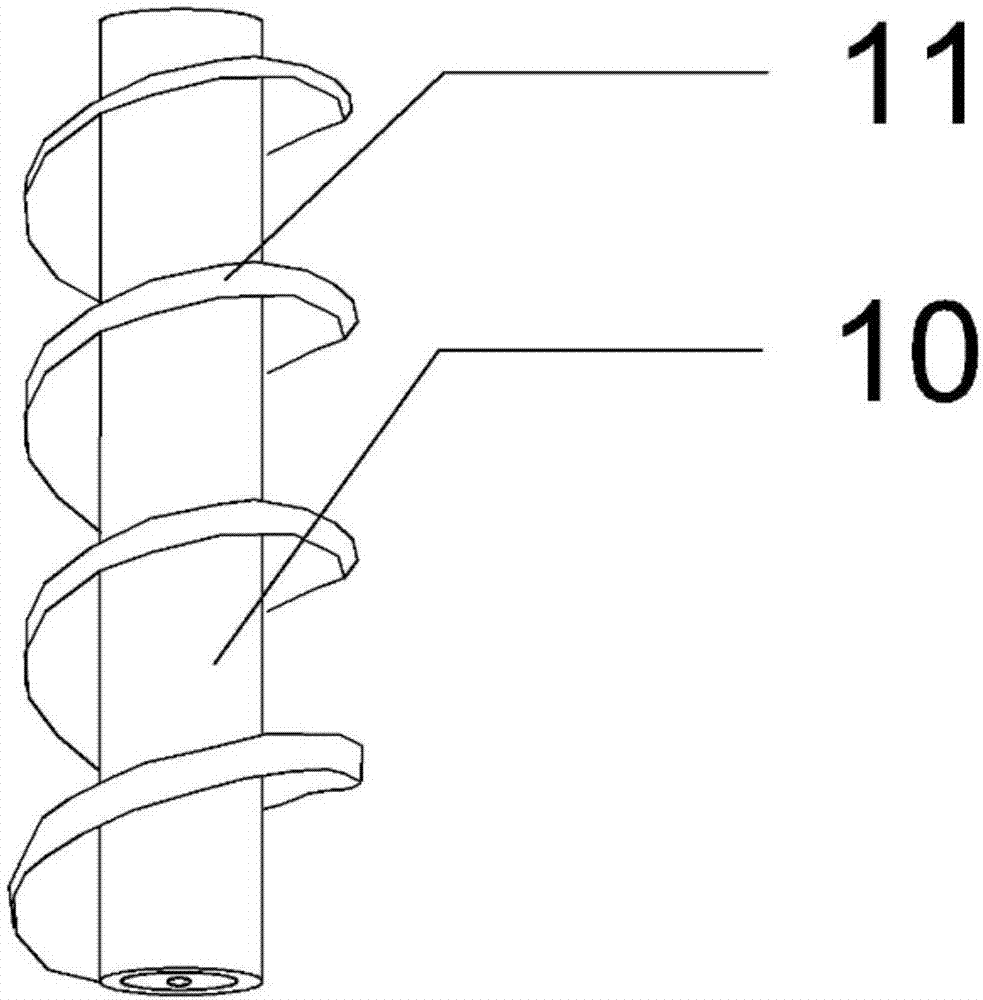

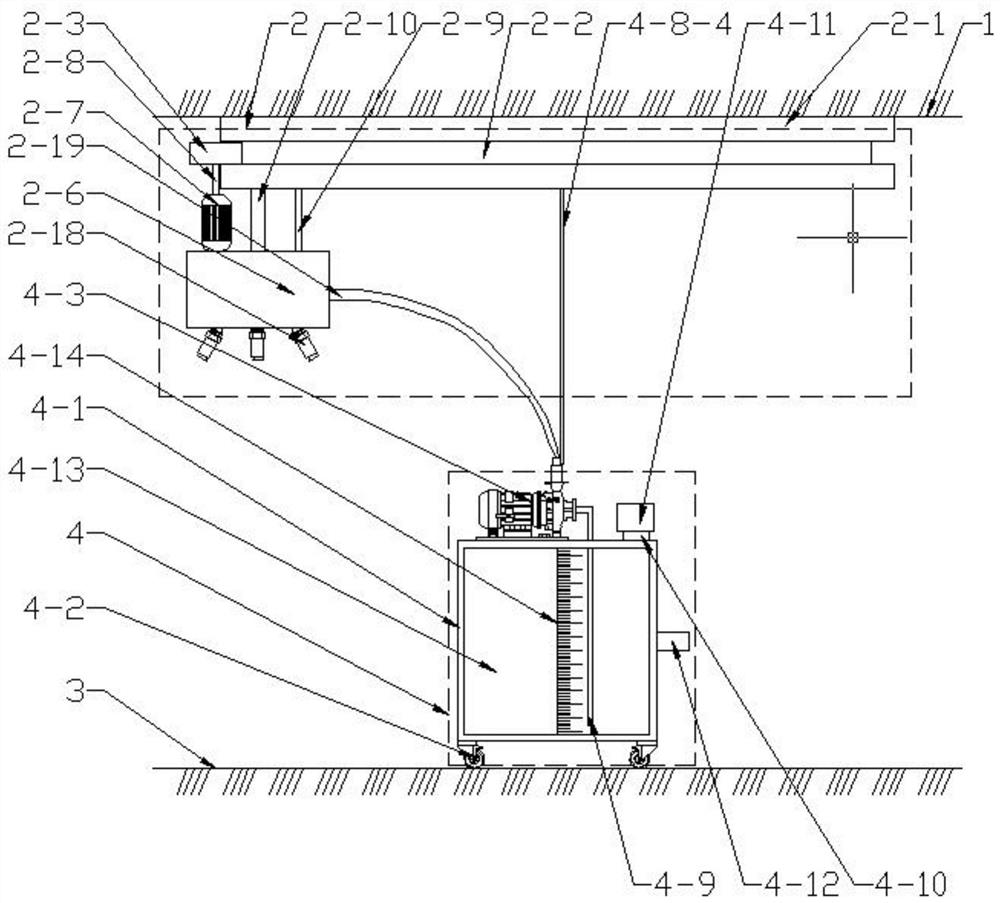

Spray head heat-dissipating device for 3D printer

ActiveCN106853685AEffective diffusionAffect temperatureManufacturing heating elements3D object support structuresPulp and paper industry3d printer

The invention discloses a spray head heat-dissipating device for a 3D printer. The spray head heat-dissipating device for the 3D printer comprises a heat-dissipating mechanism, a material guide pipe, a heat-insulating mechanism, a heating block and a spray head which are detachably connected with one another sequentially from top to bottom and are arranged coaxially; the heat-insulating mechanism comprises an upper pipe, a middle pipe and a lower pipe; the heat-dissipating mechanism comprises a heat-dissipating pipe, a rotating sheet and a groove; the upper pipe is inserted into the groove to be spirally connected with the heat-dissipating pipe; a shrink mouth is formed at one end, far away from the heat-insulating mechanism, of the heat-dissipating pipe; the upper end of the material guide pipe adheres to the shrink mouth; the lower end of the material guide pipe abuts against the upper surface of the middle pipe; an accommodating groove is formed in the upper surface of the heating block; a through hole is formed in the lower surface of the heating block; the lower pipe is inserted into the accommodating pipe to be spirally connected with the heating block; one end of the spray head is inserted into the through hole to be spirally connected with the heating block; an air supply mechanism comprises an air supply cover, a fan, a nozzle, a plurality of exhaust holes, an exhaust branched pipe and an exhaust main pipe; and the exhaust main pipe communicates with the nozzle. The spray head heat-dissipating device for the 3D printer has the beneficial effects of reducing and diffusing heat transmitted to the heat-dissipating pipe and effectively promoting rapid formation of materials extruded from the nozzle through the air supply mechanism.

Owner:江西祥泰彩印包装有限公司

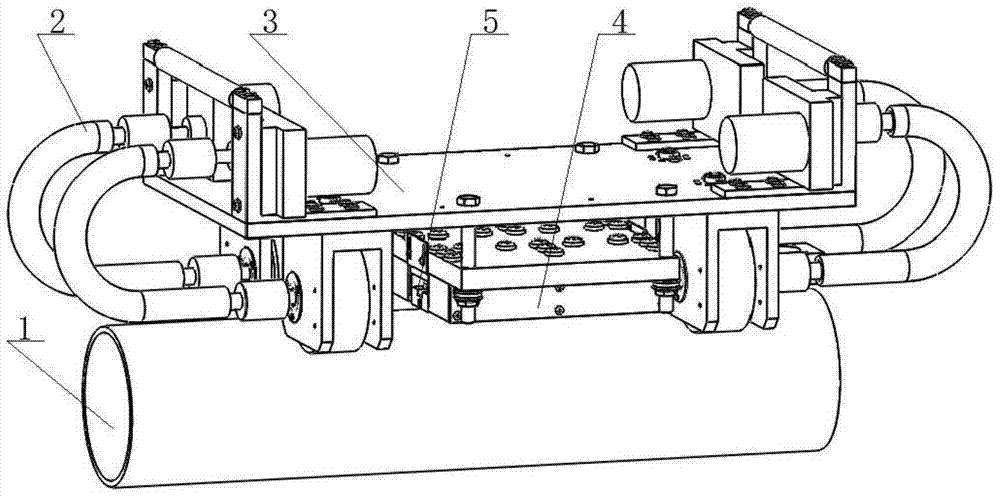

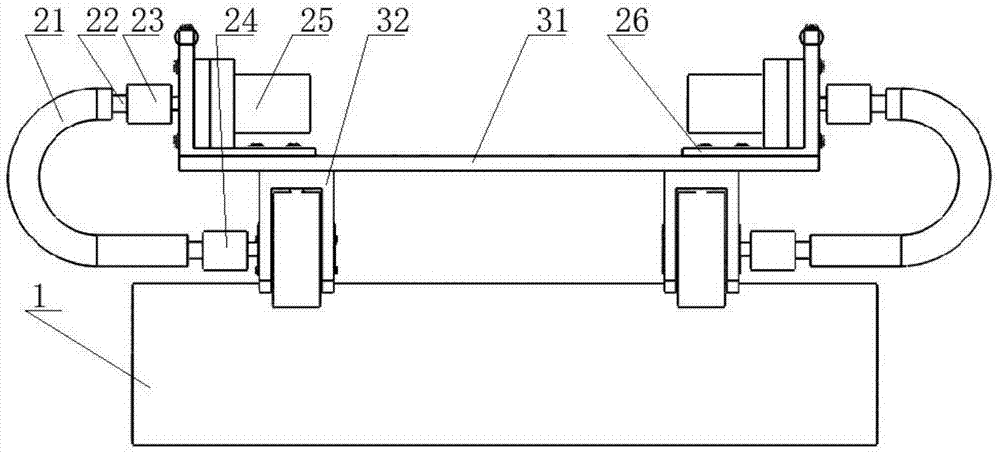

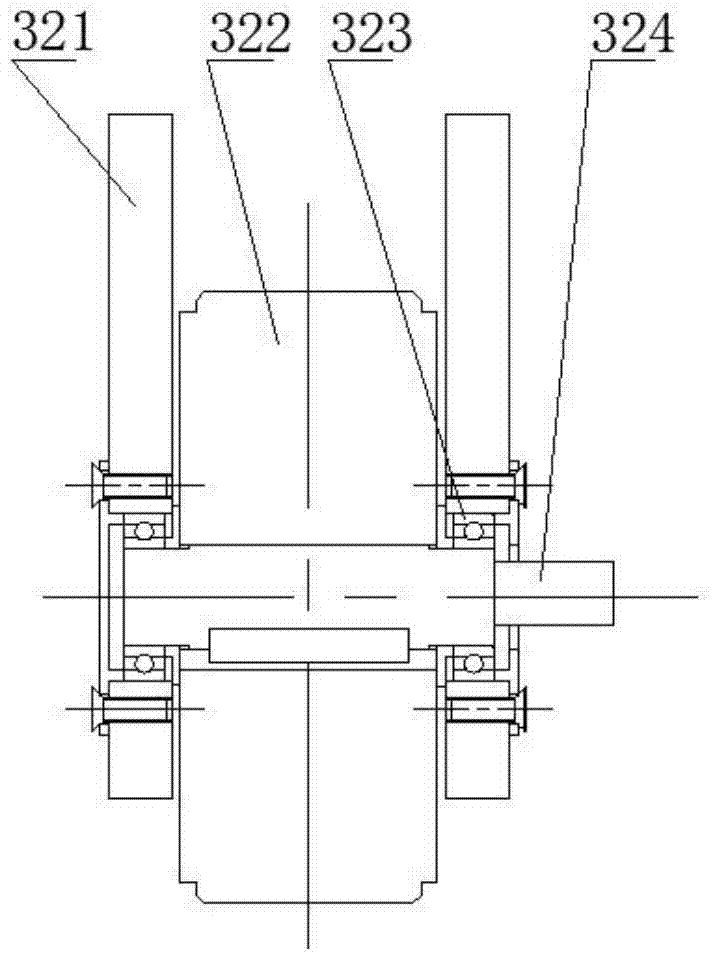

Pipeline defect scanning device

InactiveCN104502444AEasy to operateEasy to change the scan trackMaterial magnetic variablesCouplingMagnetization

The invention discloses a pipeline defect scanning device. The scanning device comprises four flexible shaft driving units, a scanning track adjusting mechanism, a permanent magnetic adsorption mechanism and an adjustable probe mechanism, wherein each flexible driving unit consists of a motor, a flexible shaft, a flexible shaft sleeve, a vehicle wheel group and a coupler; the scanning track adjusting mechanism consists of four vehicle wheel groups and a connecting plate; the permanent magnetic adsorption mechanism consists of two permanent magnet groups with opposite polarities and an armature; the magnetization directions of the magnets are perpendicular to the axis direction of a pipeline; the adjustable probe mechanism is a secondary adjusting mechanism, and a flat probe is used. A peripheral magnetization method is adopted for the device, and the longitudinal defects of the pipelines can be detected; the adjustable flat probe can be adaptive to the scanning of pipelines with multiple specifications; the device is adjustable in scanning track, novel in drive mode, compact in structure, small in size, light in weight, and can be widely applied to the defect scanning of pipelines.

Owner:HUAZHONG UNIV OF SCI & TECH

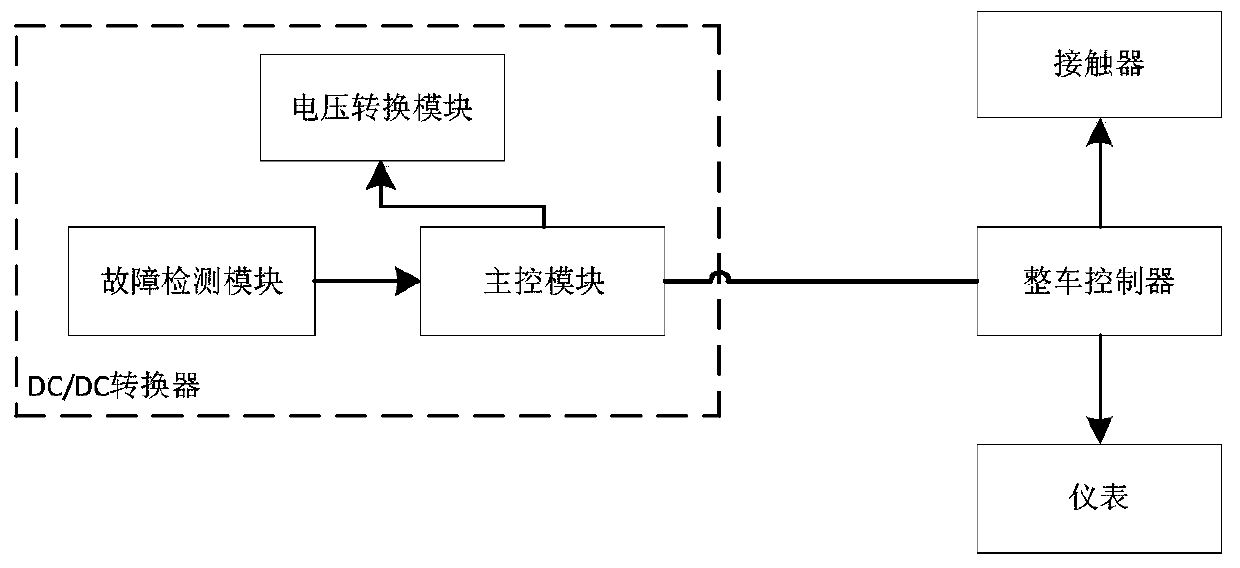

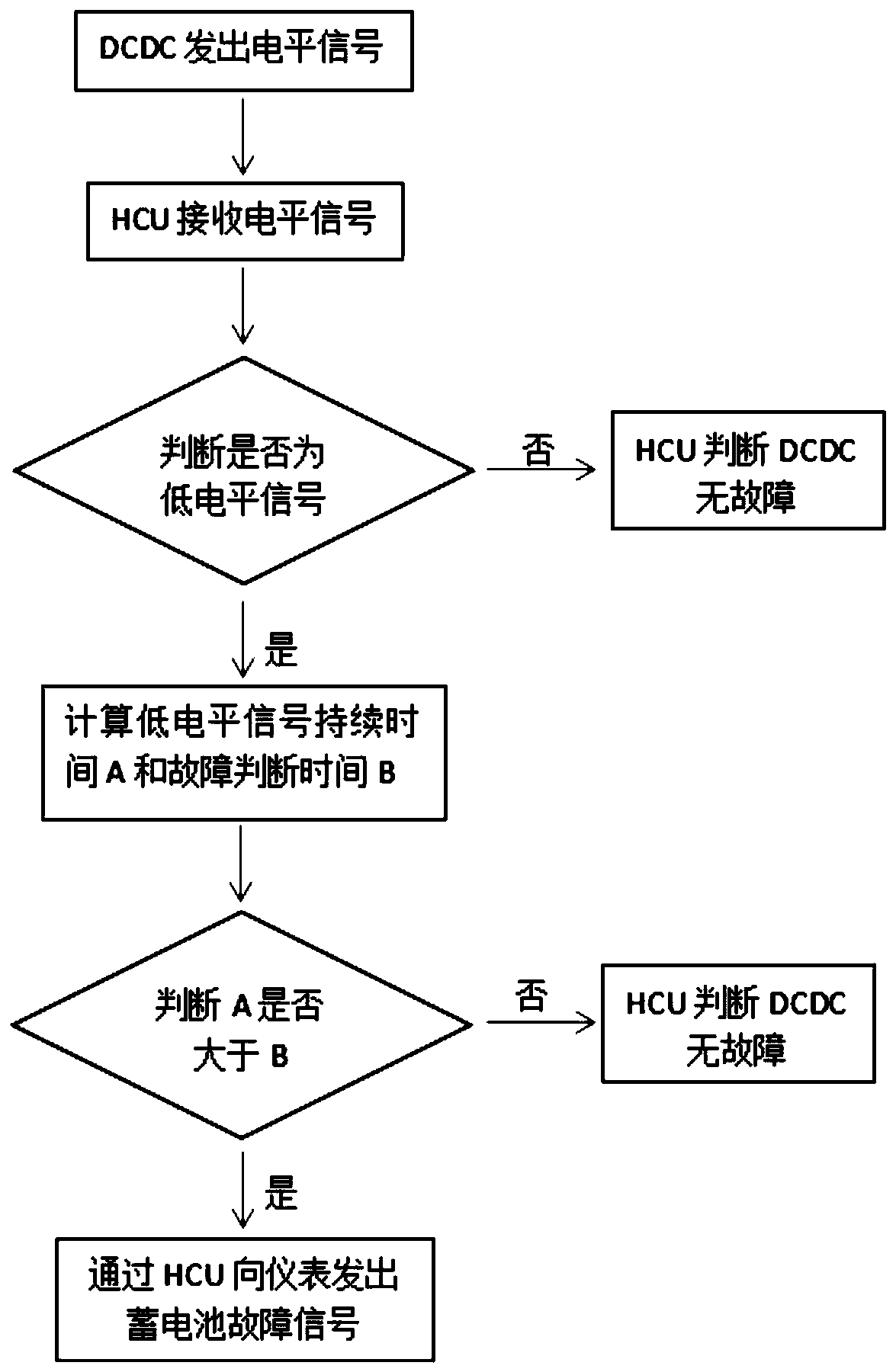

Fault detection system and method of DC/DC converter

InactiveCN109720204ALow costDoes not affect deliveryElectric devicesElectric vehicle charging technologyEngineeringDc fault

The invention discloses a fault detection system and method of a DC / DC converter. The DC / DC converter comprises a master control module, a voltage conversion module and a fault detection module. The master control module is connected with the voltage conversion module and the fault detection module. The output end of the master control module is connected with a fault diagnosis line. The master control module sends a level signal through the fault diagnosis line. A VCU detects the level signal sent through the fault diagnosis line and judges whether a fault exists in the DC / DC converter or notaccording to the high and low state of the level signal and the duration time. The system and method have the advantages that a CAN communication chip does not need to be adopted, the fault diagnosisline is directly adopted for outputting the high level, the VCU obtains the high level and conducts judgment, so that fault information is obtained, the cost of the DC / DC converter can be saved, transmission of a fault signal of the DC / DC converter is not affected, meanwhile, a storage battery is forbidden to be charged, and the situation that the storage battery is damaged due to unstable voltage in the DC / DC fault process is avoided.

Owner:HANTENG AUTOMOBILE CO LTD

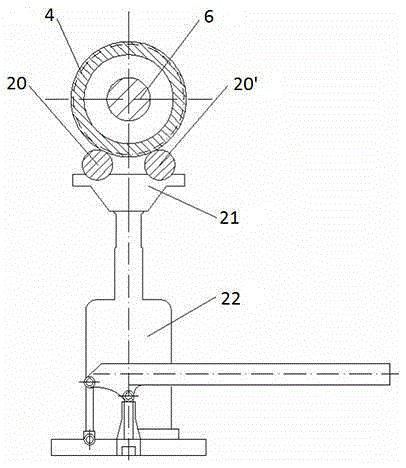

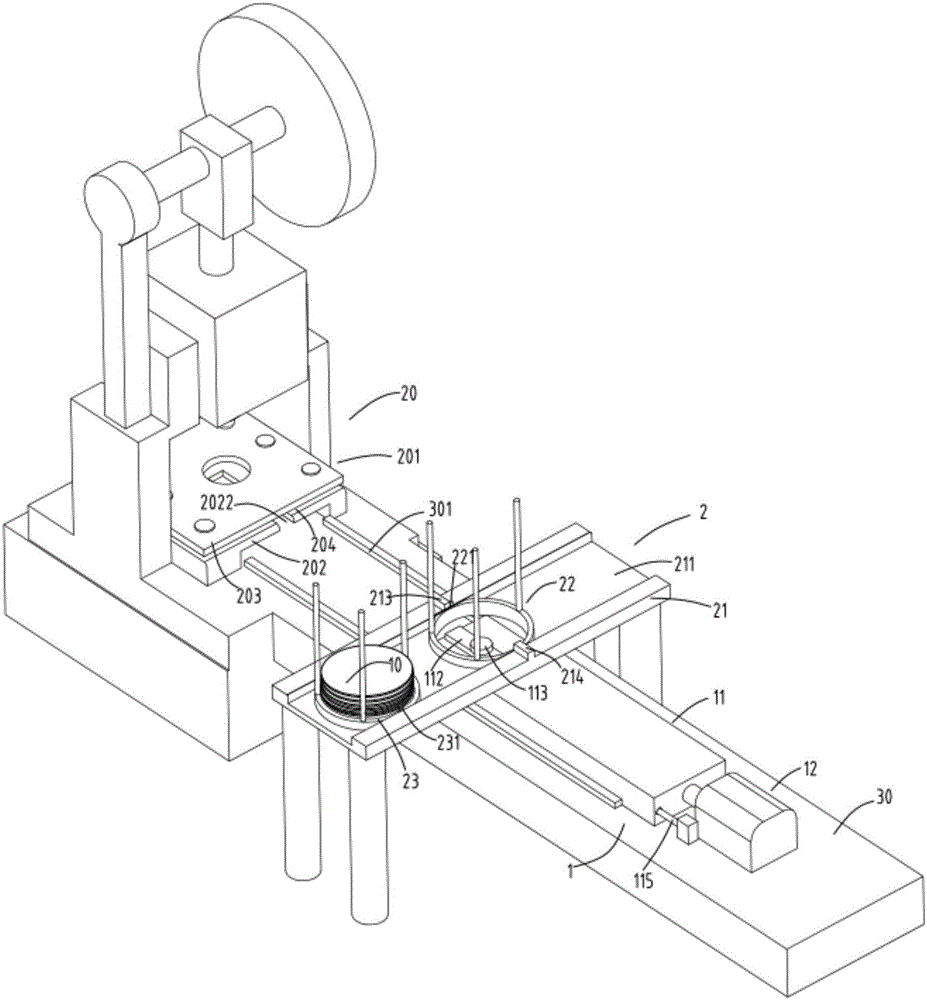

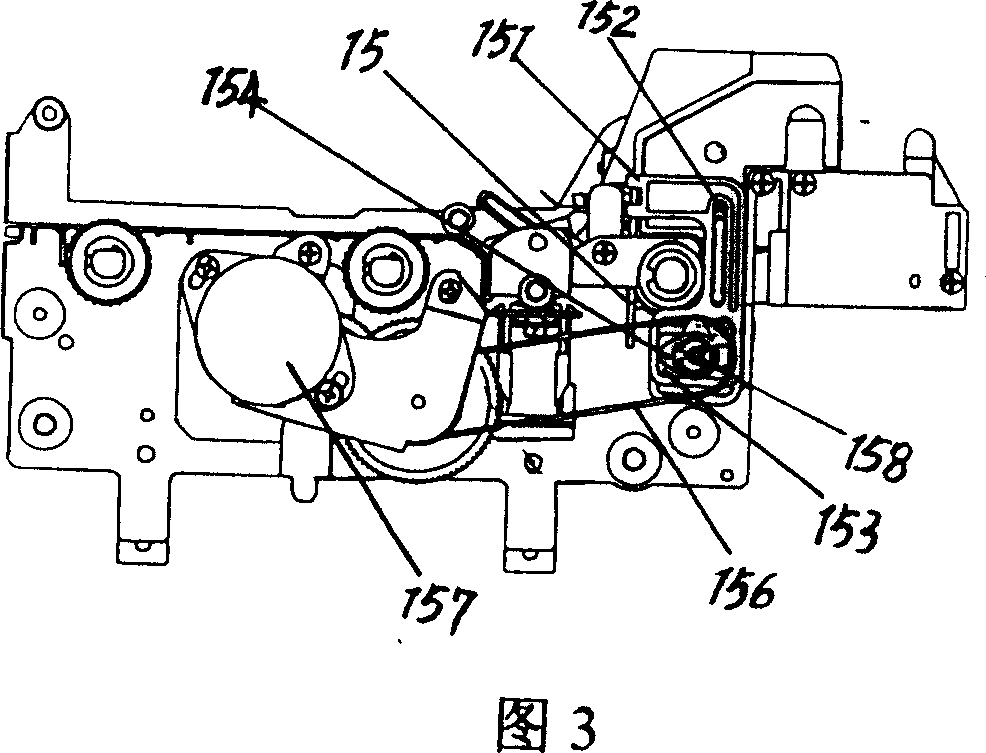

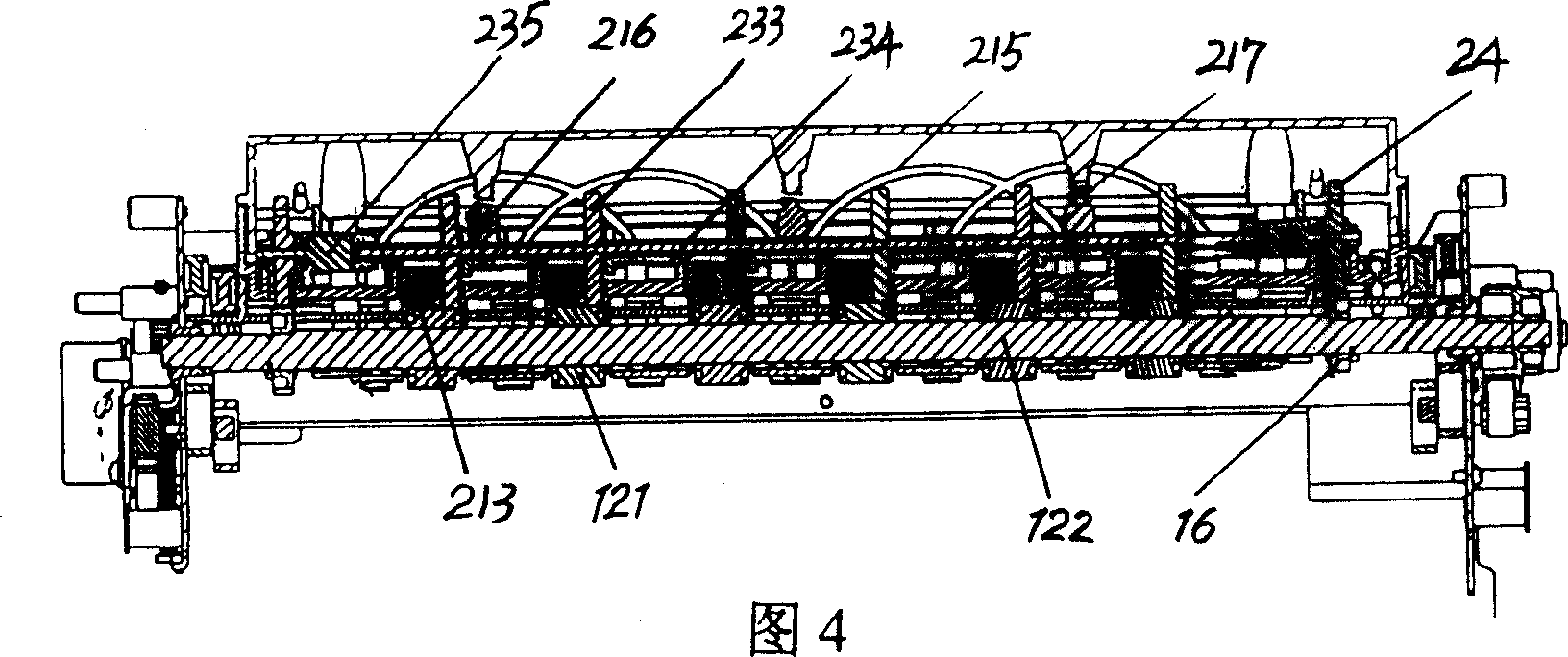

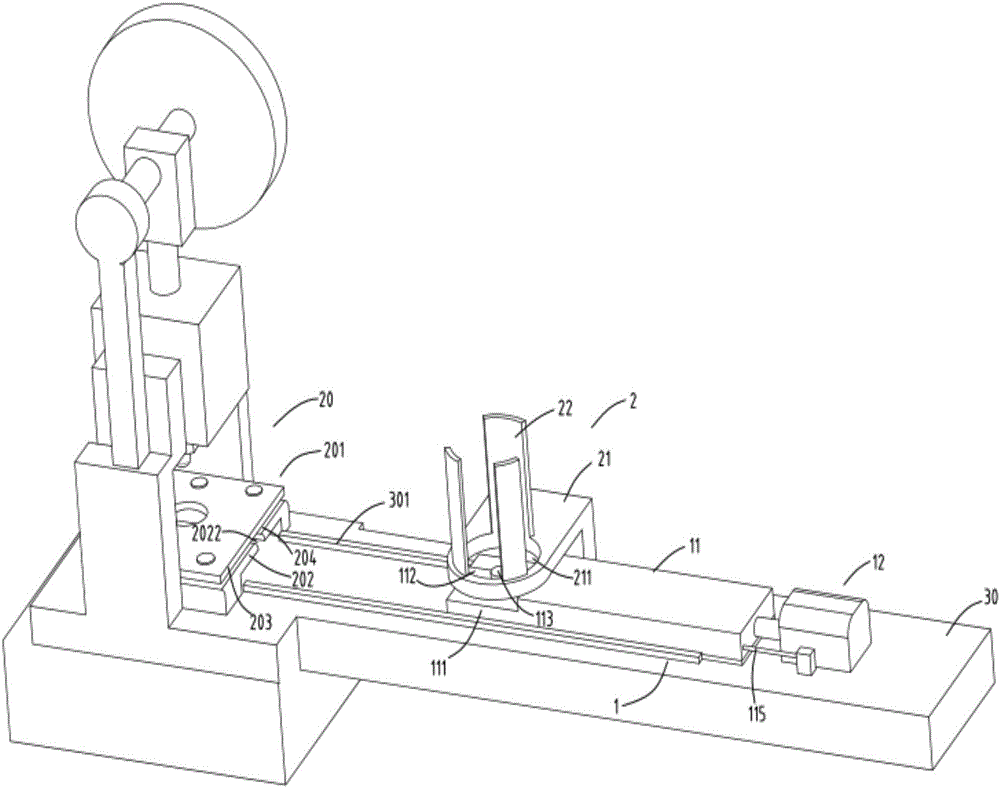

Accurate and continuous feeding device for punching of clutch coil housing

ActiveCN106424408AFully automatedIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to an accurate and continuous feeding device for punching of a clutch coil housing. The device comprises a conveying device for conveying a raw steel plate to a stamping station of a punching machine, and a supplying device for supplying materials to the conveying device, wherein the conveying device comprises a bearing body which is arranged on a working platform, and a pushing-pulling device for pushing the bearing body to reciprocate along a guide rail on the working platform; steps are arranged at one end, close to the punching machine, of the bearing body, and a supporting plate is arranged on the steps; a clamping head of which the diameter is in match with the diameter of a central hole of the raw steel plate is arranged on the supporting plate; the supplying device, comprising a supporting plate, a material rack a and a material rack b, is arranged above the clamping head; a chute b in match with the material rack a and the material rack b is formed in the supporting plate; a blanking hole is formed in the supporting plate. With the adoption of the accurate and continuous feeding device for the punching of the clutch coil housing, the problems in the prior art, such as low efficiency of manual charging during punching, waste of manpower, potential risk, and failure of continuous supplying of some automatic conveying devices, can be solved.

Owner:浙江瑞虹机电股份有限公司

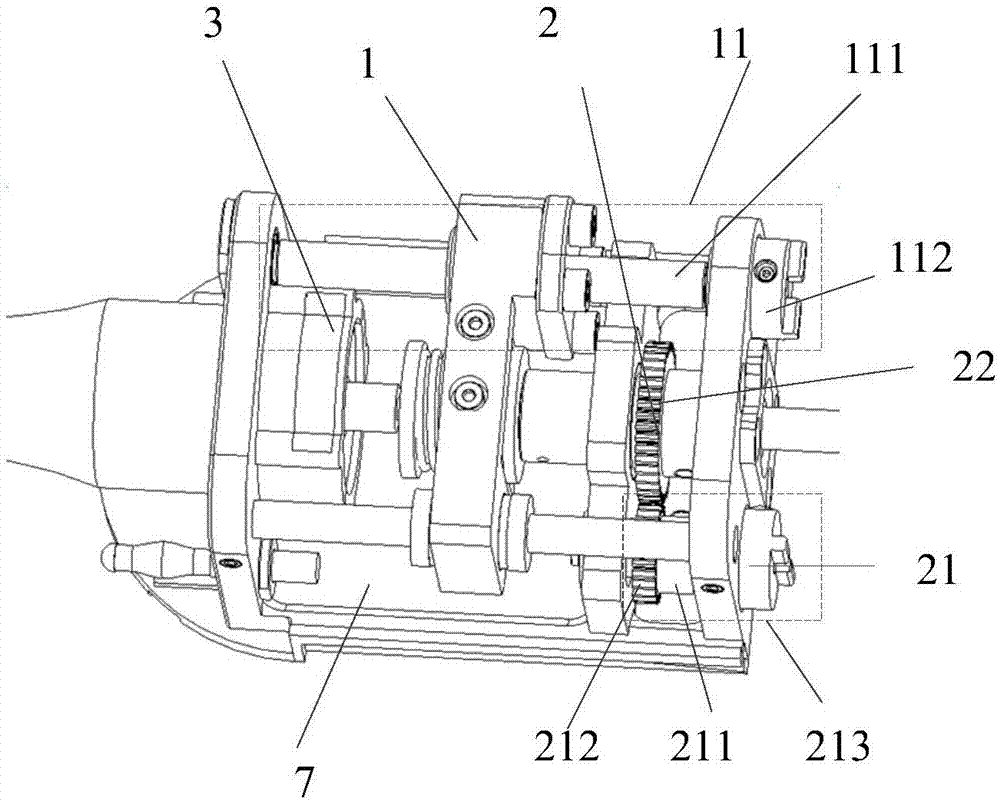

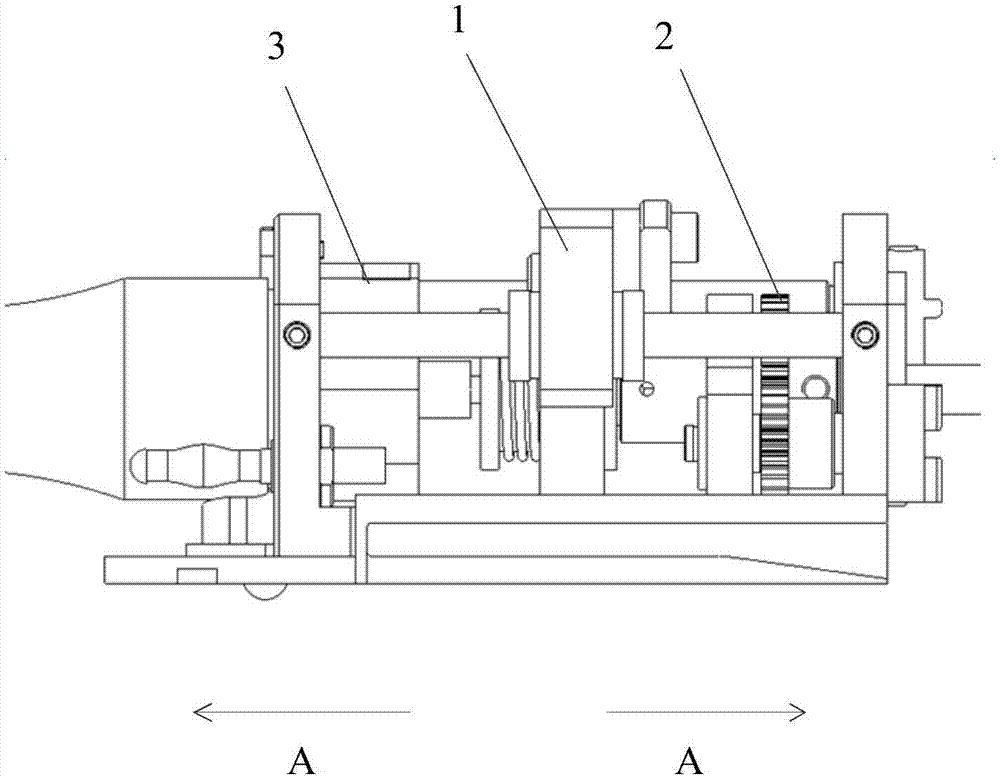

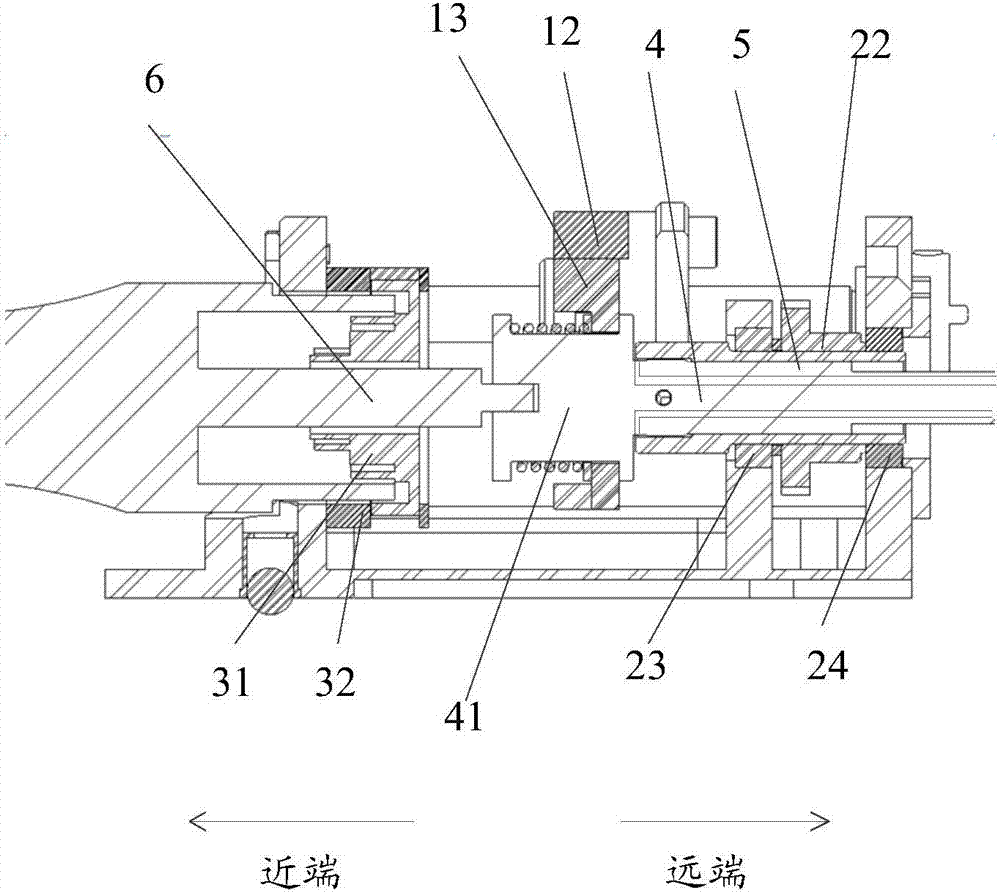

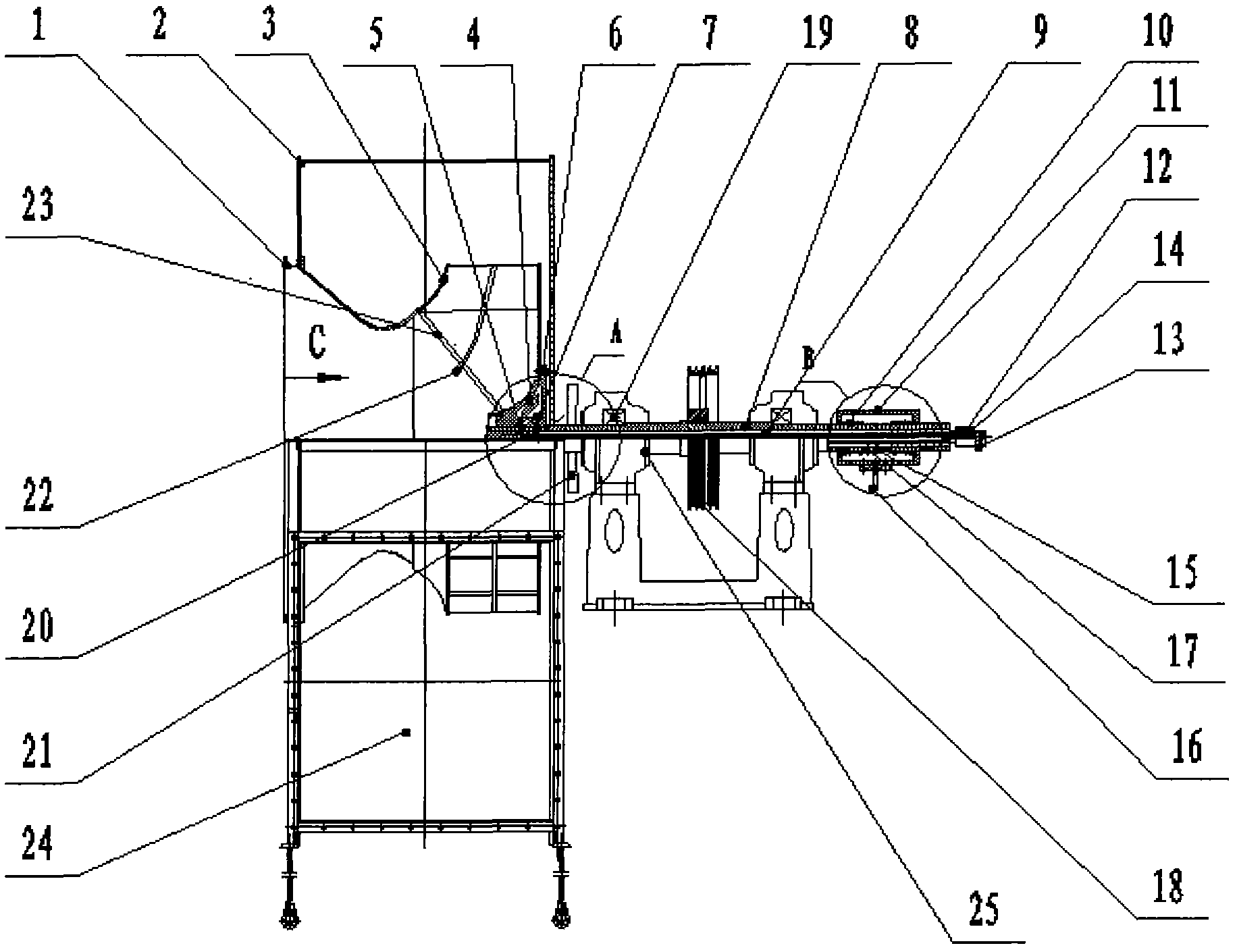

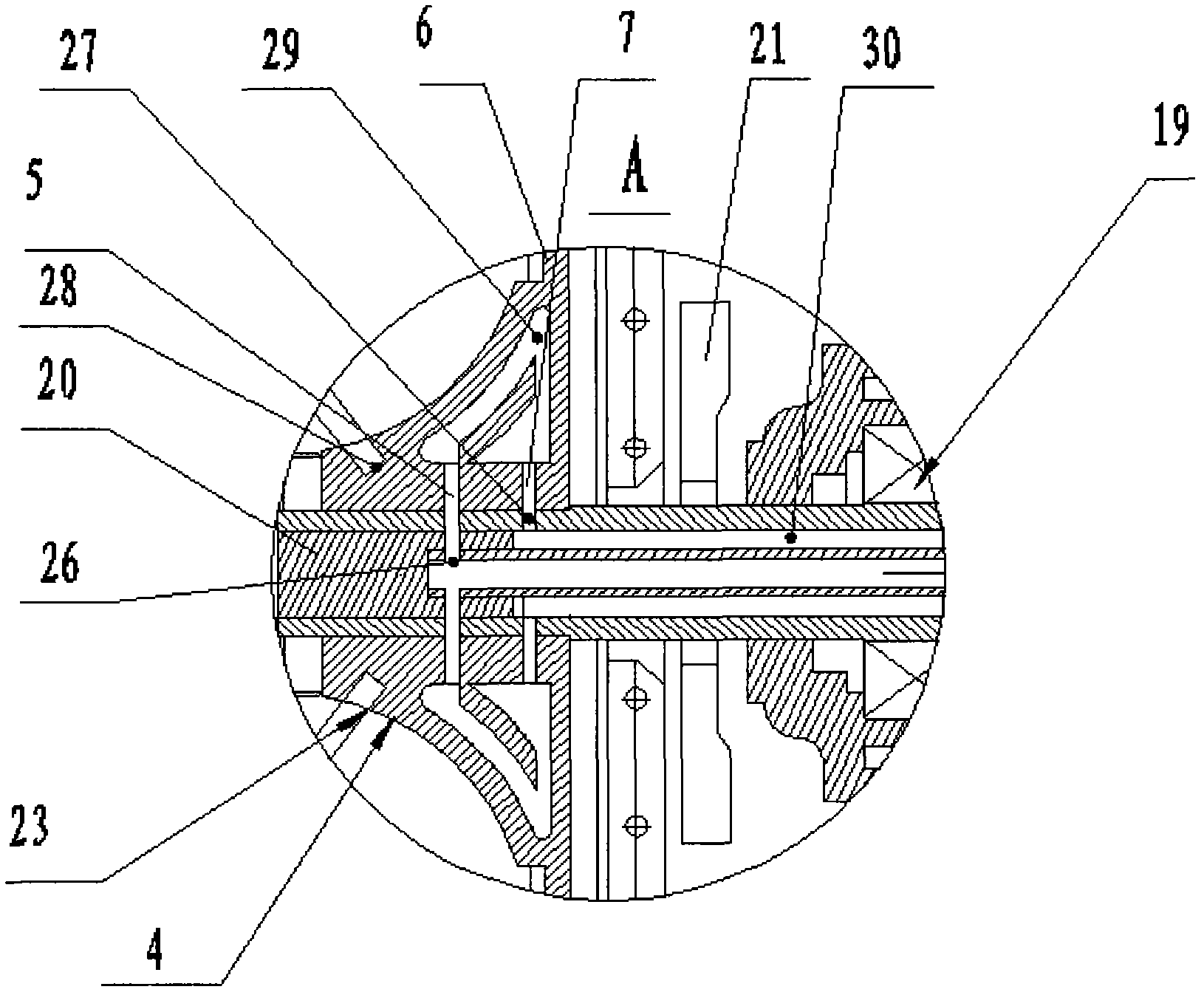

Ultrasound knife control device and minimally invasive surgery robot

ActiveCN107320156ADoes not affect deliveryIncrease flexibilityEndoscopic cutting instrumentsSurgical robotsLess invasive surgeryTransducer

The invention discloses an ultrasound knife control device and a minimally invasive surgery robot. The minimally invasive surgery robot comprises an opening and closing drive portion, a rotating drive portion, an energy conversion portion, a lead screw, a bushing and a guide rod, wherein the busing sleeves the lead screw; the opening and closing drive portion controls the opening and closing angle of a knife head of an ultrasound knife; the rotating drive portion drives the knife head of the ultrasound knife to rotate around the axial extension line of the bushing; an energy converter in the energy conversion portion transfers energy to the knife head of the ultrasound knife through the guide rod and the lead screw. The technical problem that the control device for the ultrasound knife of the minimally invasive surgery robot in the prior art is poor in flexibility in controlling the ultrasound knife is solved.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

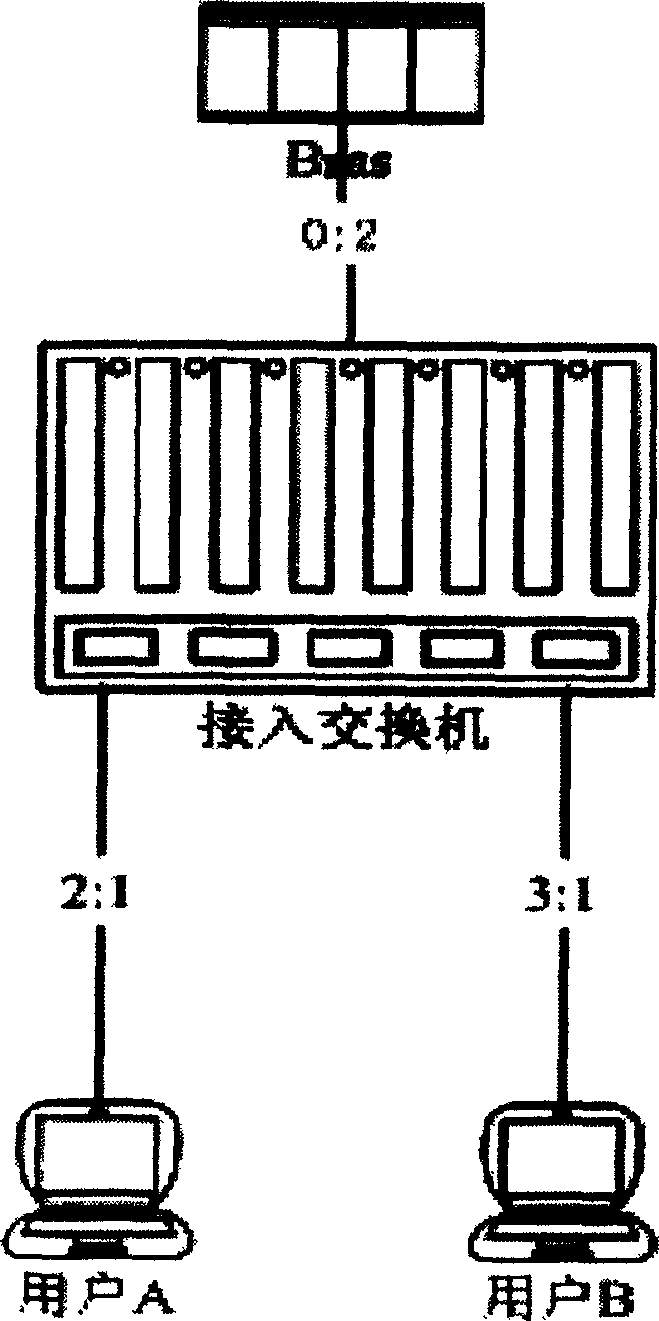

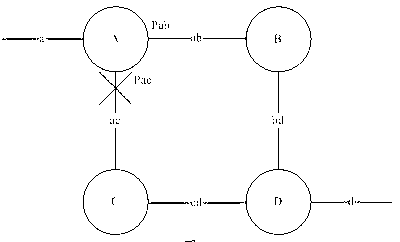

Method of isolation of bilayer VLAN port

InactiveCN1538685AImprove securityLimit communication rateData switching by path configurationSecuring communicationBroadcast packetBroadcast domain

The method for separating two ports includes such steps as user port restriction module of restricting down going broadcasting is added to FPGA on VLAN service board; with down going packets from main control board being received by service board, user port restriction module determines whether the packet is broadcasting packet (discarded) or other packets (passing). The invention is capable of turning broadcasting field off to realize isolation between users, and raise safety. Down going broadcasting is prohibited. Thus, communication speed in network is raised.

Owner:BEIJING HUAWEI DIGITAL TECH

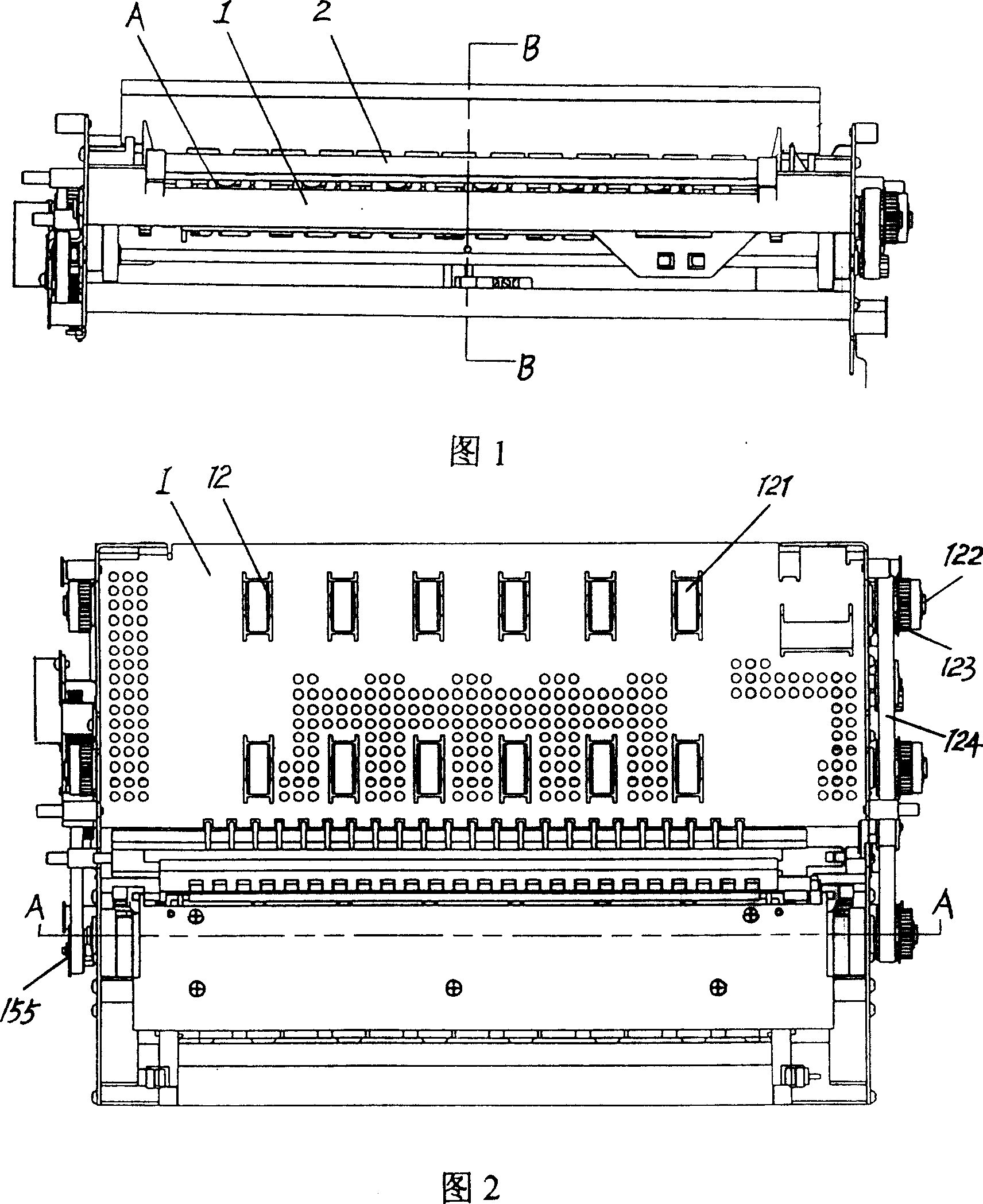

Automatic aligning device of printer

ActiveCN1931593AImprove print quality and accuracyReduce labor intensityOther printing apparatusElectric machineryElectricity

The automatic aligning device of printer includes one printing medium entering passage, one signal receiver set below the passage and with lower paper twisting wheel set and aligning light sensitive tube, one lower platform for the transmitting fiber, one upper paper twisting wheel set, one driving gear in the end of the lower paper twisting wheel set, one power transmitting belt driving the driving gear and one motor. It features the upper paper twisting wheel set on the movable carriage separated from the bottom frame, the balls in the slot on the bottom frame and the movable carriage connected to the elevating paper stopper. The present invention may be used to align and feed various printing mediums of different materials, different sizes and different thickness to ensure high printing quality and precision.

Owner:YUNNAN NANTIAN ELECTRONICS INFORMATION CORP +1

High-temperature resistant centrifugal fan

ActiveCN102230478AGuaranteed operational reliabilityReliable coolingPump componentsPumpsImpellerCentrifugal fan

The invention discloses a high-temperature resistant centrifugal fan, comprising a fan body, a driving group, a rotary joint and a cooling medium collector, wherein the fan body comprises an enclosure, a wind inlet, an impeller, a hub, a wheel disc and a wind outlet; the driving group comprises a main shaft and a belt wheel; the rotary joint is provided with a cooling medium inlet and a rotary joint seal; the main shaft is in a hollow structure, one end of the main shaft is connected with the hub of the impeller, and the other end of the main shaft is connected with the rotary joint; a core pipe is arranged inside the main shaft; an annular cavity is formed between the main shaft and the core pipe; the hub is in a hollow structure, and a hollow cavity is formed in the hub; the joint between the main shaft and the hub is provided with a cooling medium path; and the cooling medium enters the core pipe from a cooling medium inlet positioned on the rotary joint and is introduced into the hub via the cooling medium path to be cooled. According to the high-temperature resistant centrifugal fan disclosed by the invention, the fan can bear 1000-DEG C high-temperature gas delivery due to the hollow structures of the main shaft and the hub and the cooling of the cooling medium.

Owner:SHANDONG LINFENG TECH

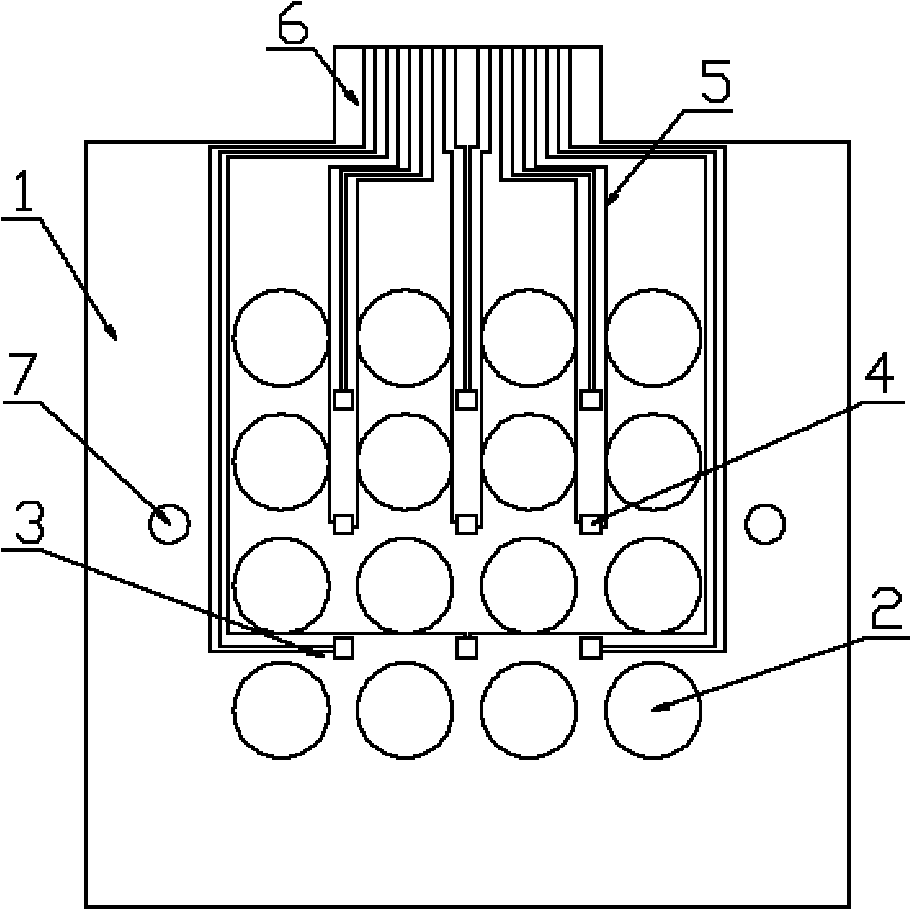

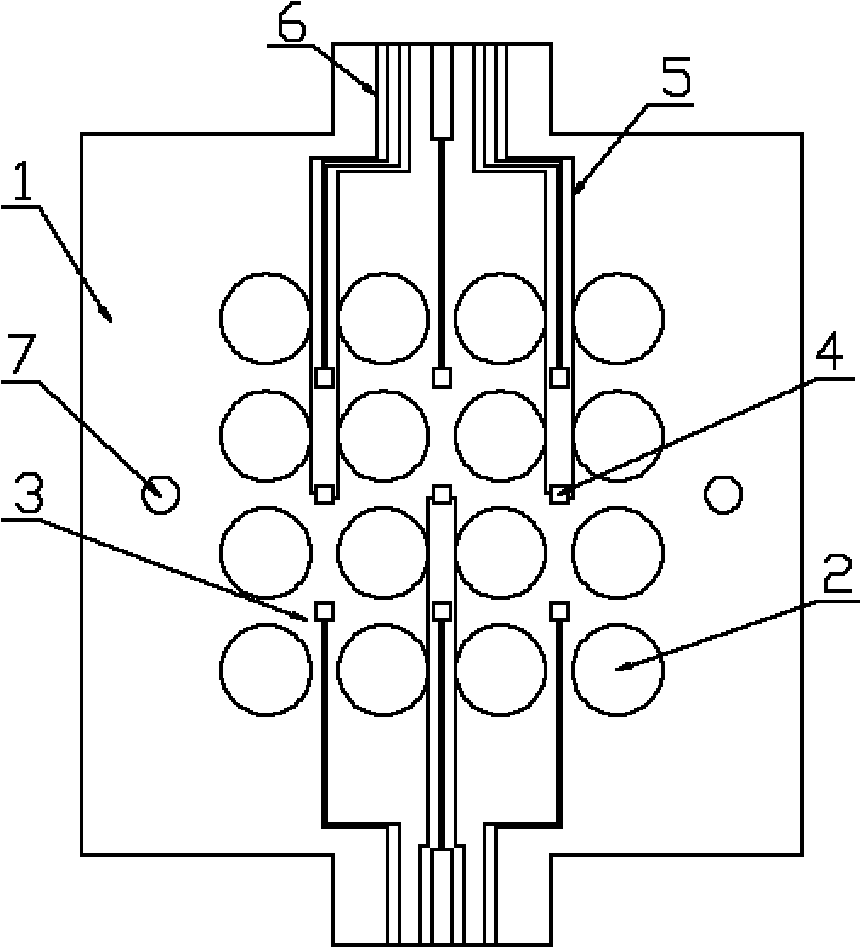

High-safety pipeline flame damper

ActiveCN111888693AImprove securityDoes not affect deliveryFire rescueFlame arresterAtmospheric sciences

The invention relates to the field of gas pipeline fire retardance and discloses a high-safety pipeline flame damper. The high-safety pipeline flame damper comprises a first fire retardance shell anda second fire retardance shell which are in flange connection. A fire retardance core disk is fixedly sleeved inside the joint between the first fire retardance shell and the second fire retardance shell. The outer edge of the fire retardance core disk is provided with a plurality of small channels. The middle portion of the fire retardance core disk is movably sleeved with a linkage shaft. One end of the linkage shaft is fixedly connected with a first baffle located on one side of a gas delivery pipeline in the first fire retardance shell. According to the high-safety pipeline flame damper, through the structural design the fire retardance core disk and a limiting gas delivery sleeve movably sleeved in the second fire retardance shell, the whole limiting gas delivery sleeve has tendency to move towards the fire retardance core disk under a normal state; when backfire occurs, flames go into the fire damper from the first fire retardance shell and are divided into a lot of fine flame flow by the small channels of the fire retardance core disk and then are extinguished without affecting continuous delivery of the flames.

Owner:蒯念生

Method of plating non-conductive film in vacuum

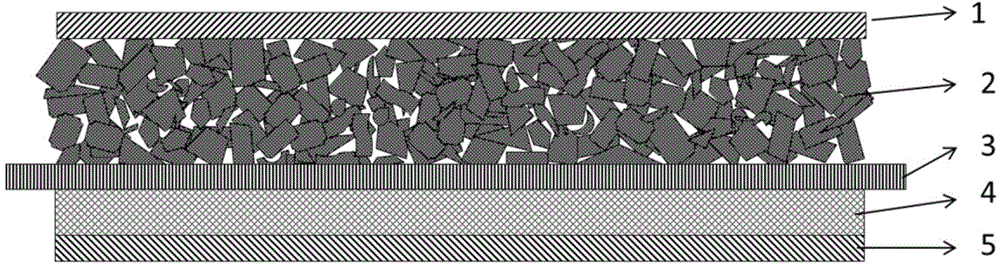

InactiveCN102505110AImprove the decorative effectDoes not affect deliveryVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceFilm-out

The invention provides a method of plating a non-conductive film in vacuum. The method comprises the following steps: providing a glass substrate; pre-treating the glass substrate so as to realize that the surface of the glass substrate is clean; loading the pre-treated glass substrate on a substrate rack, delivering the substrate rack to a vacuum chamber by virtue of a transmission system; setting a film material or a target material in the vacuum chamber, heating the film material or bombarding the target material so as to deposit the film material or the target material on the surface of the glass substrate to form a film, wherein the thickness of the film is between 10nm and 2,000nm, and the resistance of the film is more than 1M omega; and delivering the glass substrate with the plated film out of the vacuum chamber by virtue of the transmission system. The method provided by the invention has the following beneficial effects: 1, strong decoration, wherein different optical interference can be formed by controlling the thickness of the film and the proportion of materials in the film, so that decorative films of various colors can be produced; and 2, excellent insulation, wherein the resistance of the film is more than 1M omega by controlling the thickness of the film and the proportion of materials in the film, so that excellent insulation is formed, and contact and remote signal transfer are not influenced.

Owner:深圳市杰瑞表面技术有限公司

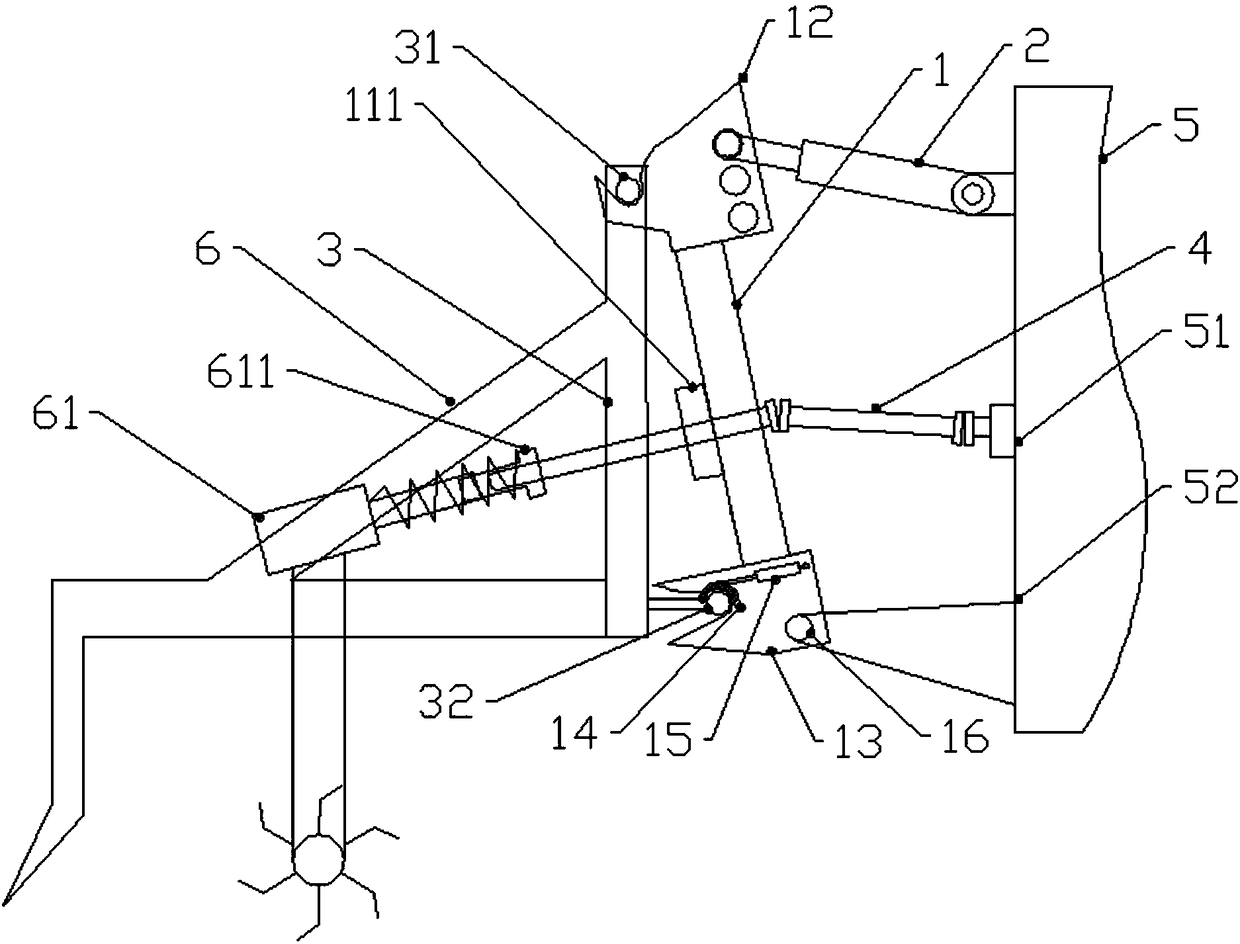

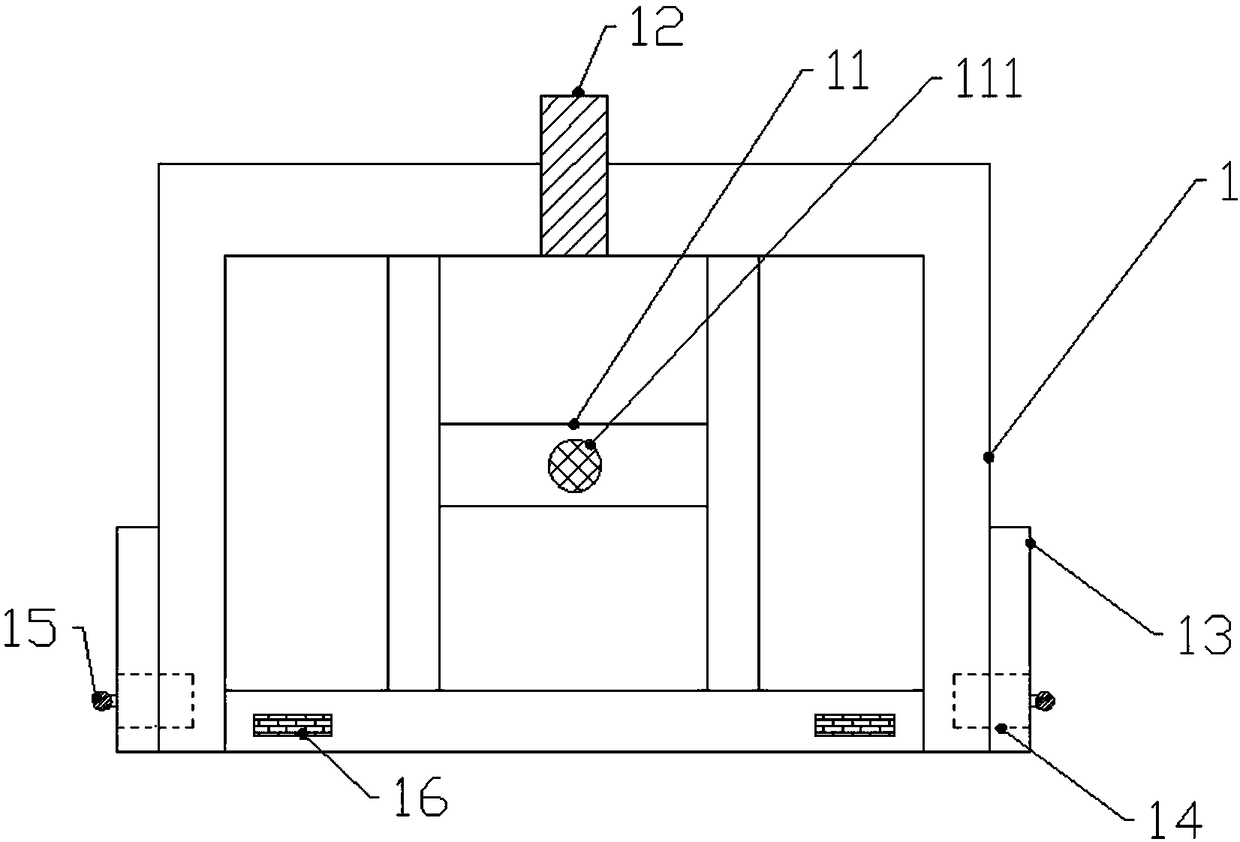

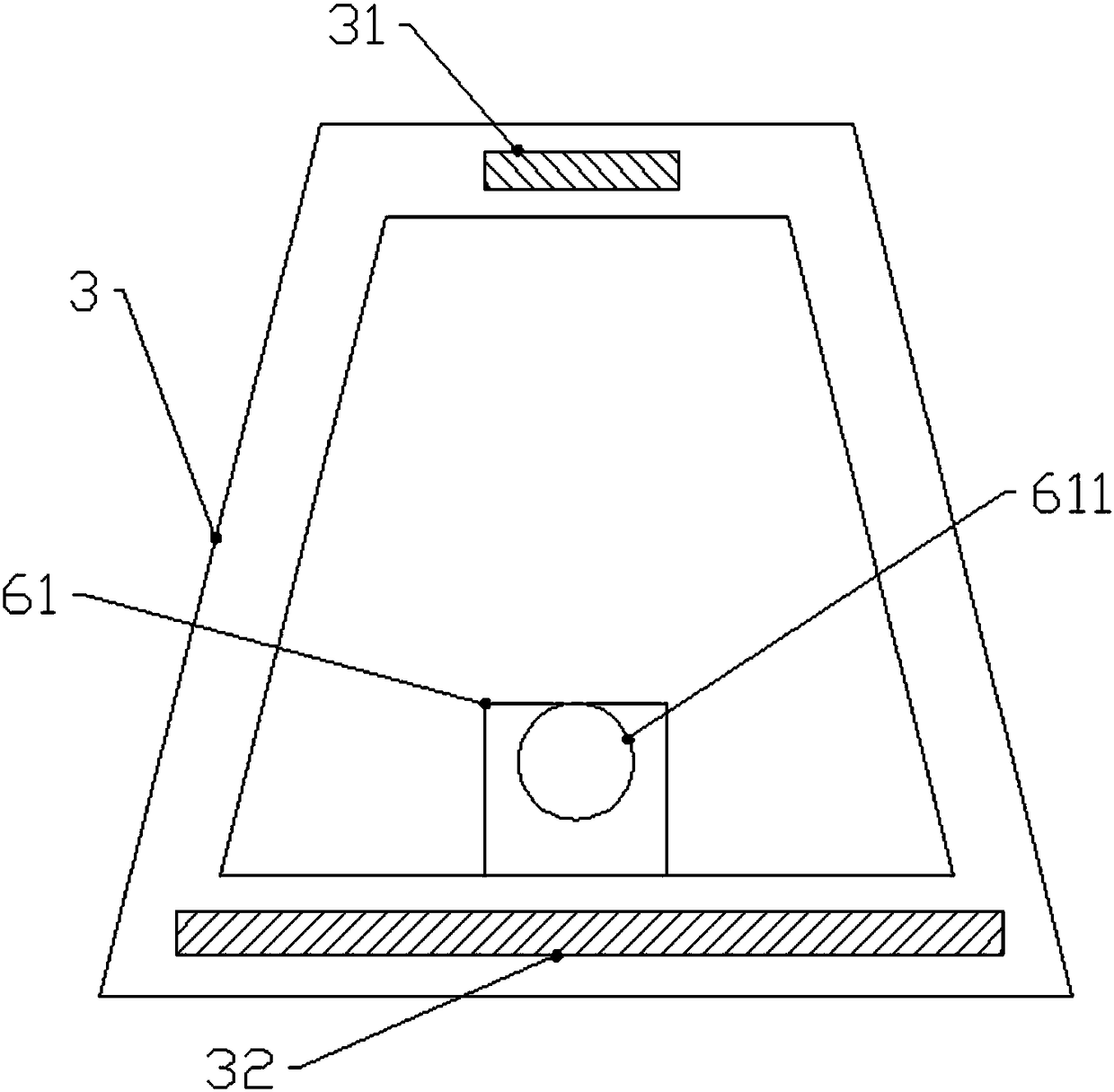

Rapid tractor hanging and connecting device with power output function

PendingCN108207152APrevent disengagementAdjust working heightAgricultural machinesHydraulic cylinderEngineering

The invention discloses a rapid tractor hanging and connecting device with a power output function. The rapid tractor hanging and connecting device is characterized in that the hanging and connectingdevice comprises a hanging and connecting device primary machine and a hanging and connecting device secondary machine, the hanging and connecting device primary machine is provided with a primary machine upper hook and a primary machine lower hook, the primary machine upper hook is connected with a tractor through a main hydraulic cylinder, the primary machine lower hook is connected with a lowersupport of the tractor, the hanging and connecting device secondary machine is connected with a farm tool, the farm tool is provided with a farm tool gearbox, the farm tool gearbox is provided with agearbox input shaft, a secondary machine upper hook is connected with the primary machine upper hook, the primary machine lower hook is connected with a lower supporting rod through a looking device,and the gearbox input shaft is connected with a tractor power output shaft. When the device works, separation of the lower supporting rod can be prevented by the locking device, and separation of thesecondary machine upper hook and the primary machine upper hook can also be prevented by the locking device. When the main hydraulic cylinder extends and retracts, the working height of the farm toolon the hanging and connecting device secondary machine can be adjusted, the primary machine upper hook are provided with a plurality of through holes for connecting with the main hydraulic cylinder,and the adjusting range of the working height of the farm tool can be widened.

Owner:NANJING AGRICULTURAL UNIVERSITY

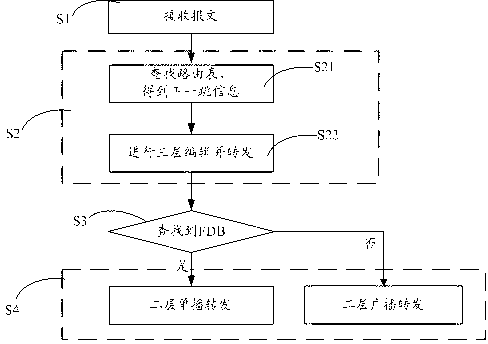

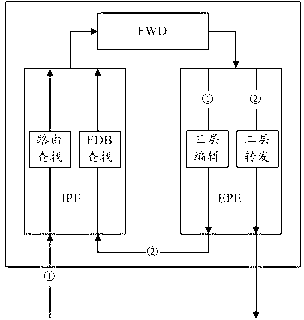

Method and chip for message processing of layer 3 next-hop independent of layer 2 forwarding table

InactiveCN102984067ADoes not affect deliveryImprove forwarding qualityData switching networksMessage processingLoopback

The present invention provides a method and a chip for message processing of a layer 3 next-hop independent of a layer 2 forwarding table, wherein the method comprises: S1, receiving a message; S2, performing a layer 3 editing for forwarding; S3, determining whether an FDB can be found via a destination MAC and VLAN; S4, if the FDB is found, performing layer 2 forwarding of the message; and if the FDB is not found, performing layer 2 broadcast of the message in the VLAN. Layer 3 forwarding information is enabled to be independent of the layer 2 forwarding information via the chip loopback function, and changes of layer 2 forwarding information are not allowed to affect the issue of the layer 3 forwarding information, to improve the forwarding quality of layer 3 services.

Owner:SUZHOU CENTEC COMM CO LTD

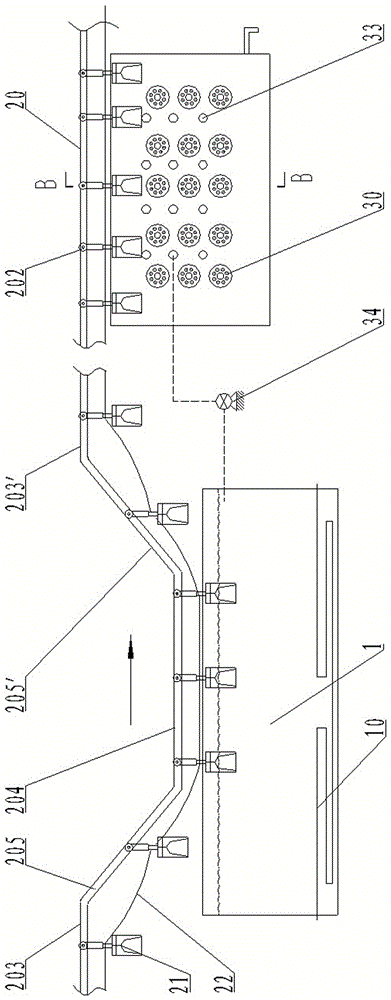

Special dip blanching and feather picking production line for slaughtering poultry

InactiveCN106417554ANot easy to fall offDoes not affect deliveryPoultry plucking mechanismsProduction lineDrive wheel

The invention provides a special dip blanching and feather picking production line for slaughtering poultry. The production line can be used for carrying out feather blanching and feather picking operations on the slaughtered poultry bodies, has the advantages of high efficiency, high reliability and low use cost, and is clean and hygienic. The boiling water feather blanching device comprises a boiling water tank, a plurality of poultry hanging racks which are moveably arranged on a track, and a transmission belt for driving the poultry hanging racks to travel along the track. The feather picking device comprises a box body with two open ends and a driven wheel arranged outside the box body, wherein two side walls of the box body are provided with a plurality of feather removers through bearings; each feather remover comprises a brush tray arranged inside the box body; a brush rod is arranged on the brush tray; the brush tray is connected with the driven wheel through a rotating shaft; and the driven wheel is connected with a power unit in a drive mode. The track above the boiling water tank is bent downwards to form a lower track matched with the boiling water tank; the lower track has the height capable of enabling the poultry hanging racks to be integrally immersed in the boiling water tank; and the track on the upper end of the box body has the height capable of enabling the integral poultry hanging racks to pass through the box body.

Owner:安徽兴牧畜禽有限公司

Safety device for air in at least one room of a building

InactiveCN1575399AConstant loadReduce the ratioMechanical apparatusAir-treating devicesHazardous substanceAir treatment

The invention relates to a safety device for the air in at least one room of a building, wherein the room is provided with at least one inlet pipe for sucking external air and at least one air treatment apparatus. The safety device is characterized in that the device can protect the people in the room from air pollution, more particularly the invasion of harmful substances or organisms. The inlet pipe is provided with at least one air pollution detector which is connected with a safety door via a control device; the safety door can hermetically close the inlet pipe when air pollution appears. The safety device has the advantage that air is treated with the technical proposal that the detector is arranged at the head of the inlet pipe and the safety door and the air treatment apparatus are arranged at the terminal of the inlet pipe so that one part of the waste air in the room can be reused as the feed air of the room.

Owner:LK LUFTQUALITAT

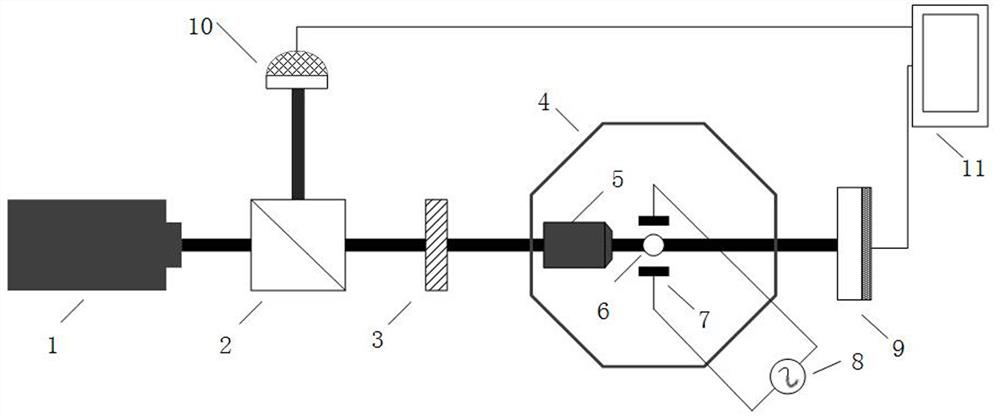

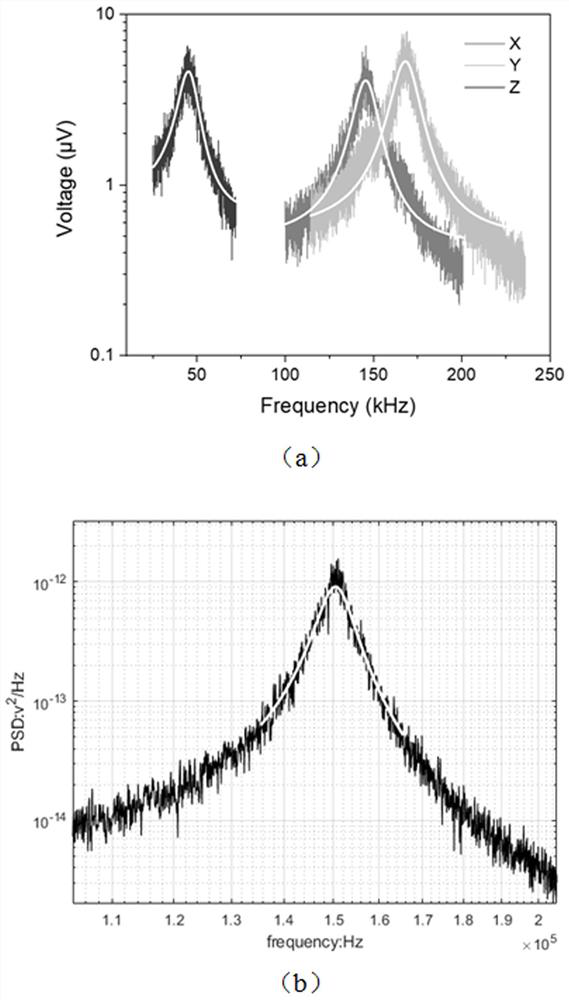

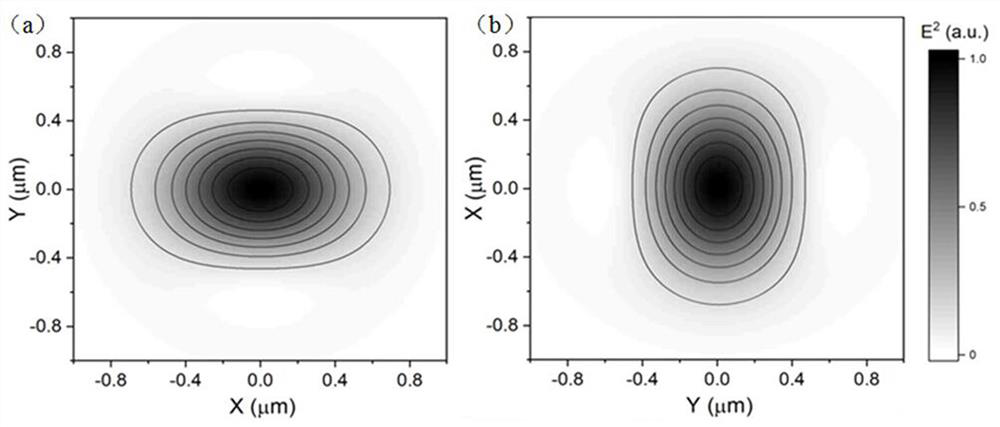

Multi-dimensional optical tweezers calibration device and method based on electric field quantity calibration

ActiveCN112863728ADoes not affect deliveryBrightness monitoringNanoparticle analysisUsing electrical meansParticle physicsOptical polarization

The invention discloses a multi-dimensional optical tweezers calibration device and method based on electric field quantity calibration, and provides a one-dimensional electric field calibration device to realize three-axis electric field force calibration of particles by utilizing the polarization dependence characteristic of a tight focusing light trap. According to the method, a particle electric field force calibration system is compatible with a particle delivery and particle detection system; the complexity of the device is simplified, and the calibration complexity is weakened.

Owner:ZHEJIANG LAB +1

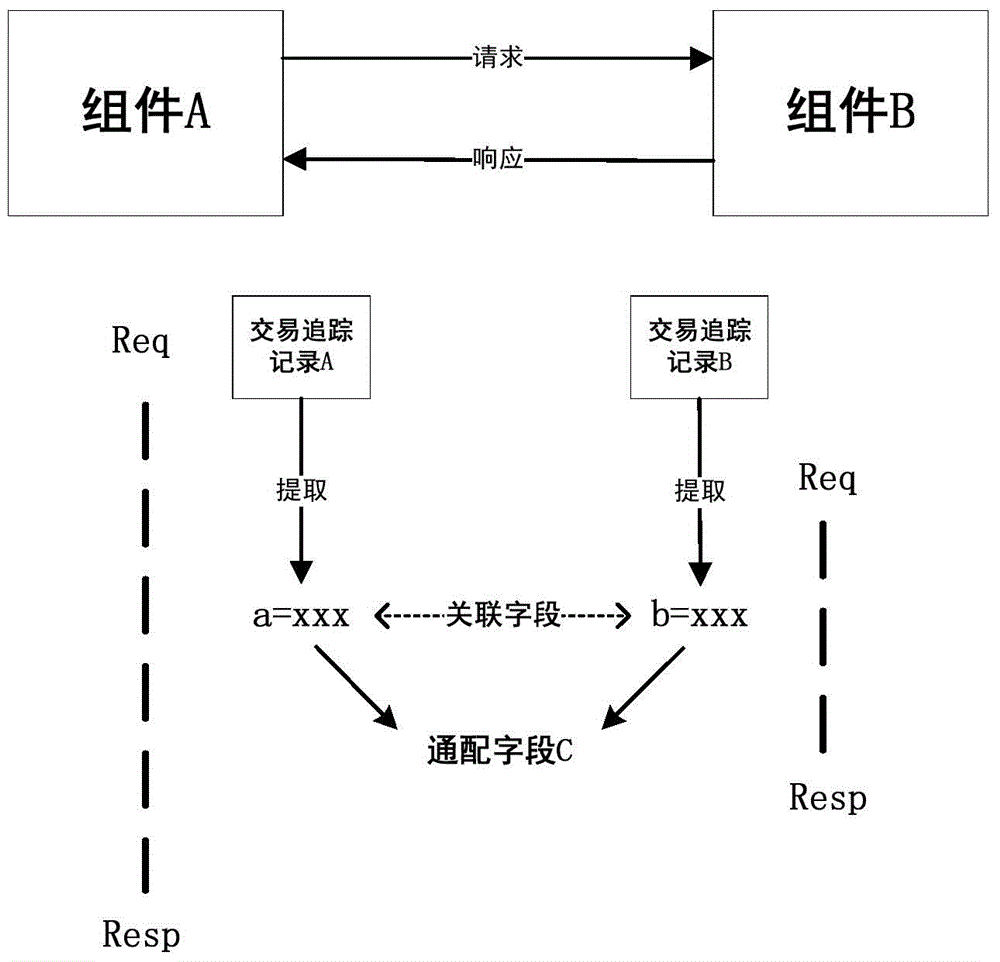

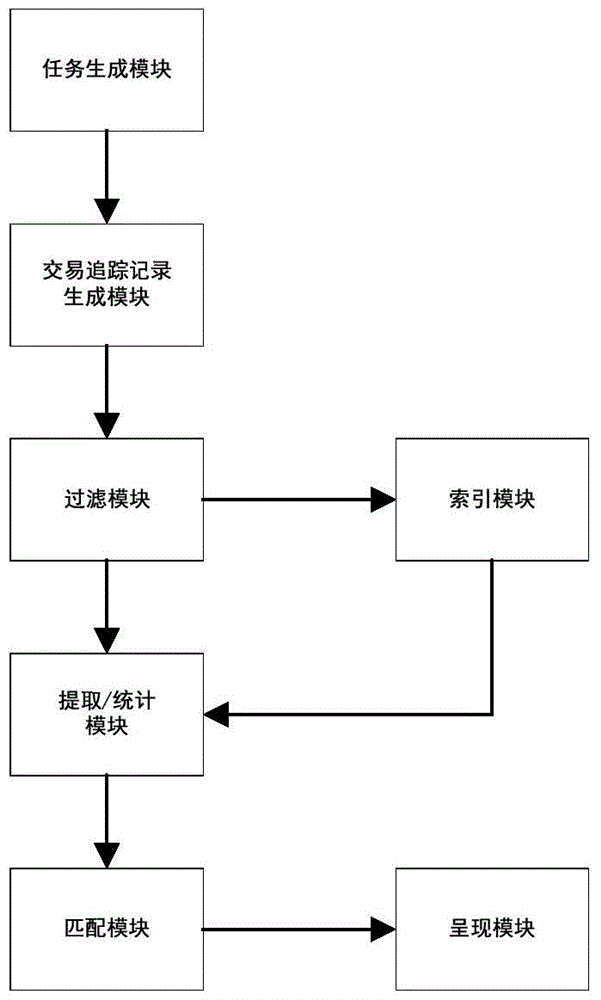

System and method for associating multistage assembly transactions

ActiveCN105719072AIntegrity guaranteedEnsure safetyResourcesComplex mathematical operationsData miningDependency relation

The invention provides a system and method for associating multistage assembly transactions. The method comprises steps of generating transaction tracking records of all assemblies; setting accusation screening parameters of to-be-associated transactions; screening transaction tracking records satisfying the association screening parameters from a transaction tracking record of a start point assembly; and screening transaction tracking records matching the screened-out start point assembly from a transaction tracking record of a non-start point assembly. According to the invention, association problems in processing of the same transaction of front and back multiple assemblies in a business link are solved; on the premise that integrity and safety of association data are ensured, time required for searching is accelerated; real-time and precise calculation, determination of associated transactions and full collecting can be achieved; association transactions amongassemblies are collected based on the premise of determination of dependency relations between front and back assemblies; searching time is greatly reduced; and by use of multiple determination principles, accuracy of determination is improved.

Owner:SHANGHAI NETIS TECH

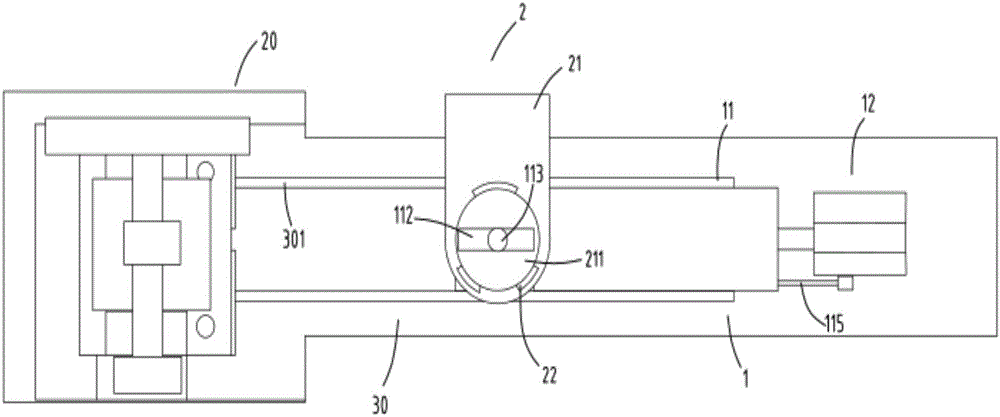

Automatic feeding device improving punching precision of clutch coil shell

ActiveCN106424417AFully automatedIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressPush pull

The invention relates to an automatic feeding device improving the punching precision of a clutch coil shell. The automatic feeding device comprises a conveying device and a supply part. The conveying device comprises a bearing body arranged on a workbench and a push-pull device pushing the bearing body to move back and forth on a guide rail on the workbench. A step is arranged at the end, close to a punch, of the bearing body and provided with a material supporting plate. The material supporting plate is provided with a material clamping head with the diameter matched with the hole diameter of a center hole of a raw material steel plate. The material clamping head can stretch and contract vertically, the height of the part, stretching out of the upper surface a of the material supporting plate, of the material clamping head is d1, and d1 is smaller than or equal to the thickness d2 of the single raw material steel plate. The vertical distance between the upper surface a of the material supporting plate and the upper surface b of the bearing body is d2. A conveying gap for the raw material steel plate to get in and out is reserved between the bearing plate and a buffering plate at the punching station. The upper surface c of the bearing plate and the upper surface a of the material supporting plate are located on the same horizontal plane. The problems that in the prior art, the manual feeding efficiency of punching is low, labor power is consumed, and potential safety hazards exist are solved.

Owner:浙江瑞虹机电股份有限公司

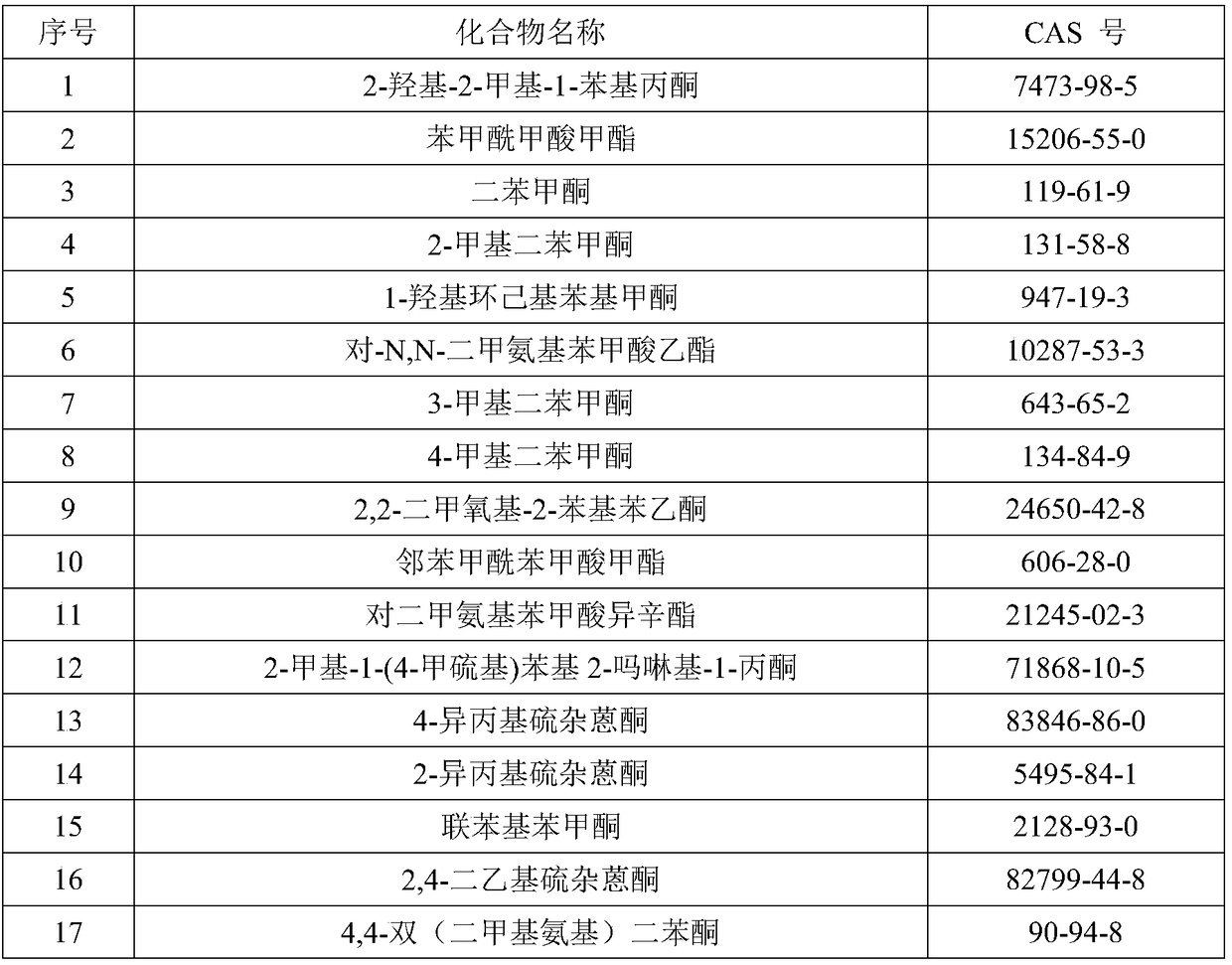

Benzophenone purity reference material and preparation method thereof

ActiveCN108663246AWith uncertaintyReduce uncertaintyComponent separationPreparing sample for investigationBenzophenoneFood packaging

The invention discloses a benzophenone purity reference material and a preparation method thereof, and relates to analysis and test of a photoinitiator used in various packaging materials, wherein thebenzophenone purity reference material can be used as a reference material in food packaging, cigarette packaging, workshop air detection and other tests. The preparation method of the benzophenone purity reference material comprises the following steps: (1) purification of a crude product of benzophenone; and (2) evaluation of a certified value and uncertainty of the benzophenone purity reference material. The benzophenone purity reference material provided by the invention has good stability under a storage condition of 0 DEG C, accurate certificating method, reliable traceability and relatively small synthesis uncertainty (0.1%-0.3%), can solve a problem that a current test method cannot trace a quantity value, can improve comparison consistency of test results of various units, and fills a blank of development of the benzophenone purity reference material at home and abroad.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

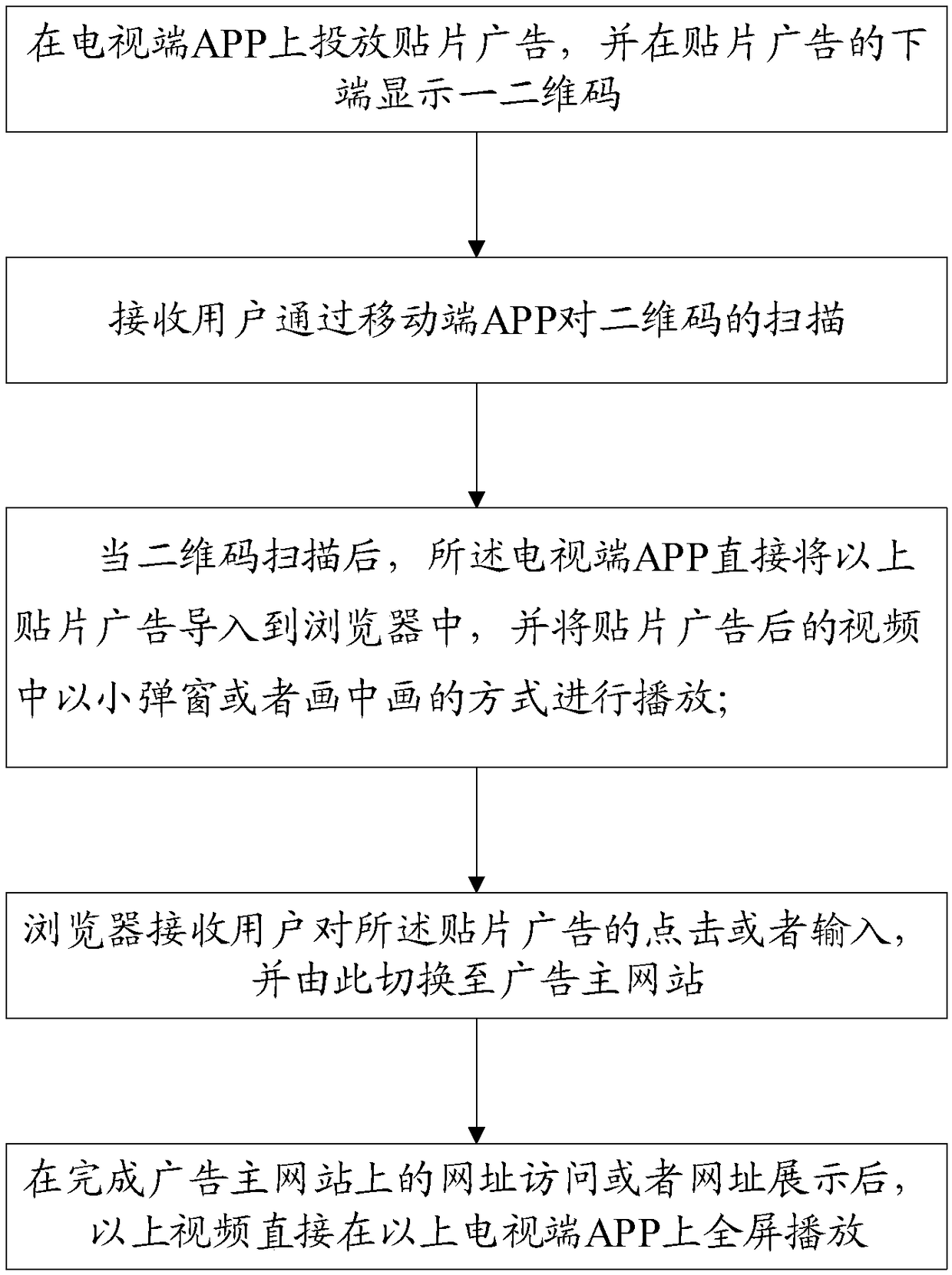

Method and device for putting cross-screen advertisement

InactiveCN108289235ARealize displayDoes not affect deliverySelective content distributionMarketingWorld Wide WebCable television

Owner:BEIJING ZHANGKUO MOBILE MEDIA TECH

Humidifier for laboratory equipment

ActiveCN112815438AFully humidifiedUniform humidificationLighting and heating apparatusSpace heating and ventilation detailsElectric machineryControl theory

Owner:HEBEI CHEM & PHARMA COLLEGE

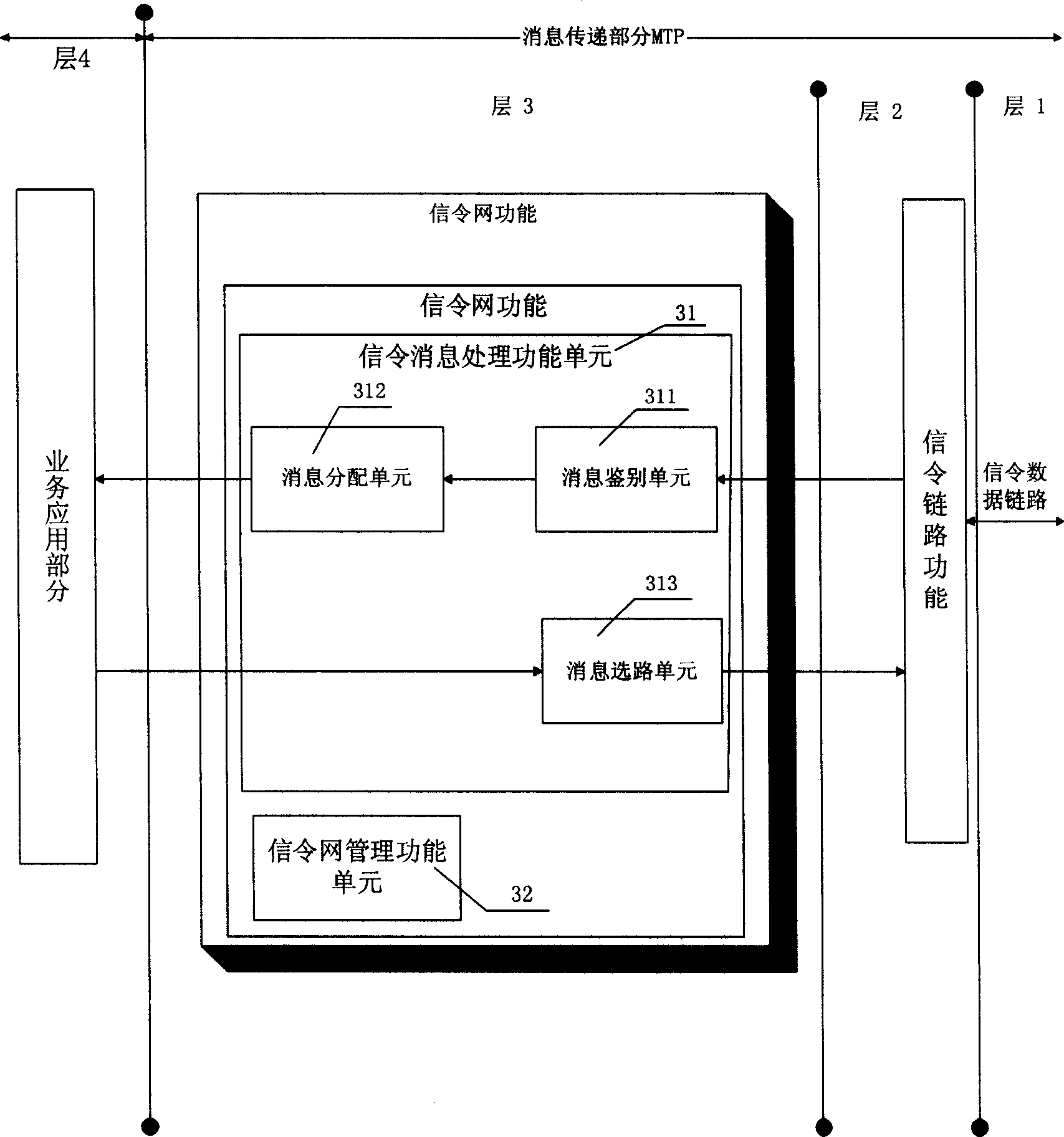

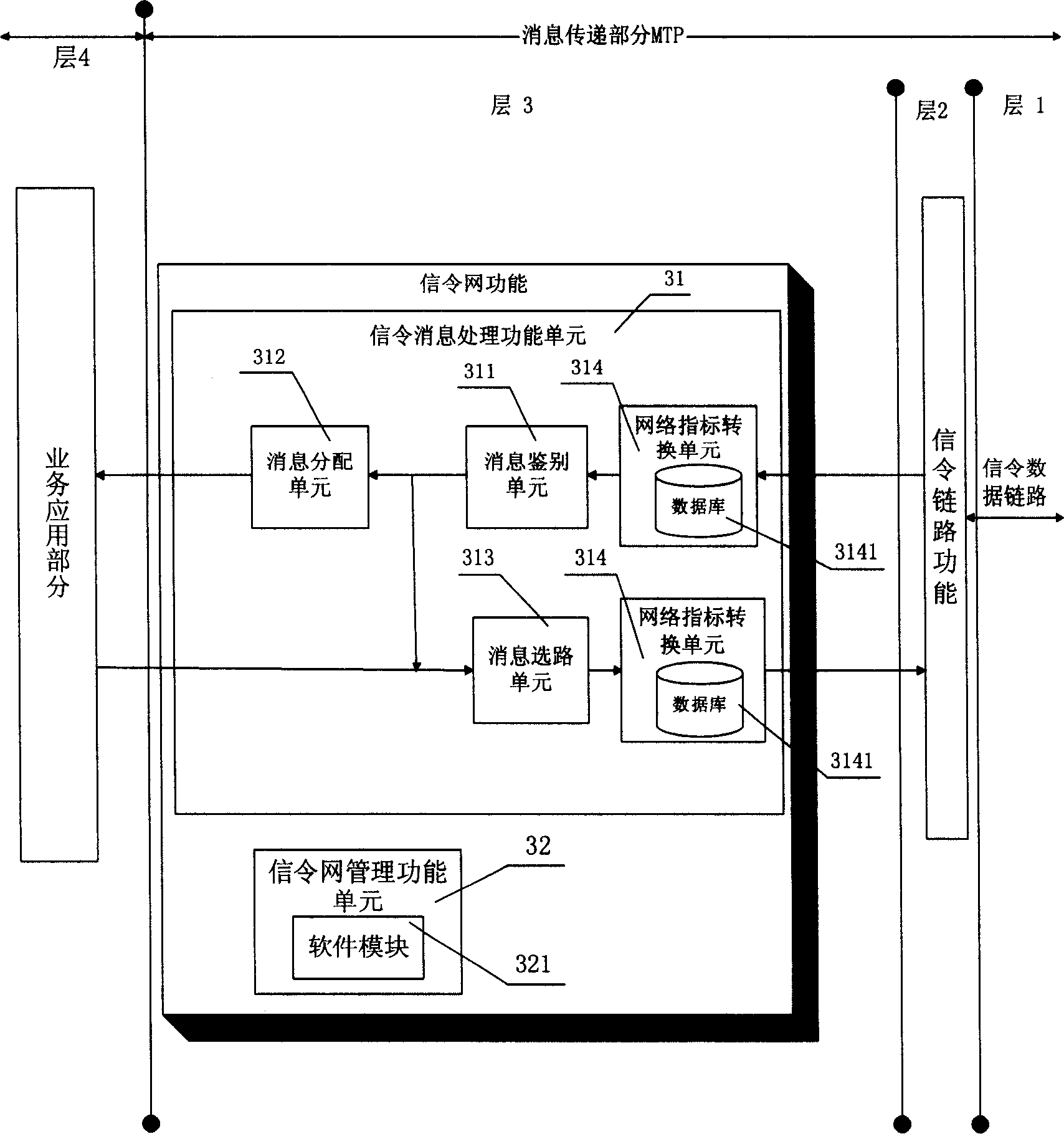

A signaling message transfer apparatus, and method of receiving/transmitting signaling message thereof

ActiveCN1630378AIncrease capacityIncrease load energyNetwork connectionsSelection arrangementsSignaling networkSignaling system

This invention refers to a signaling message transfer device and method for transmitting / receiving message for transferring signaling message between signaling points of No 7 signaling system. Said invention leads the logic network concept in original No 7 signaling message process device, developing the definition of logic network indication language and process software, making one signaling point in No 7 signaling network support plurality of networks through combination of logic network indication language and signaling point coding, breaking the limit of there are only sixteen signaling links of adjacency signaling point and limited signaling point coding resource in current communication network to increase communication network capacity and loading ability.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

A photoinitiator mixed solution standard material and a preparing method thereof

ActiveCN108931591AReduce uncertaintyDoes not affect deliveryComponent separationMetrological traceabilityStandard uncertainty

A photoinitiator mixed solution standard material and a preparing method thereof are disclosed. The standard material is a standard solution containing 18 photoinitiators, with the definite concentration value and corresponding combined standard uncertainty of each photoinitiator meeting related standard requirements. The method includes (1) purifying 18 photoinitiator crude products; (2) evaluating definite values and uncertainty of the purified products; (3) preparing a mixed solution standard of the 18 photoinitiators; and (4) evaluating definite values and uncertainty of the mixed solutionstandard material of the 18 photoinitiators. The photoinitiator mixed solution standard has good stability during storage at 0 DEG C, a definite value evaluating method is accurate, source tracing isreliable, and relative combined uncertainty is low (0.5-2.0%). The photoinitiator mixed solution standard material can overcome a problem that testing methods at present cannot achieve metrological traceability, increases comparison consistency of each unit testing result, and fills the gap of development of photoinitiator mixed solution standard materials at home and abroad.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

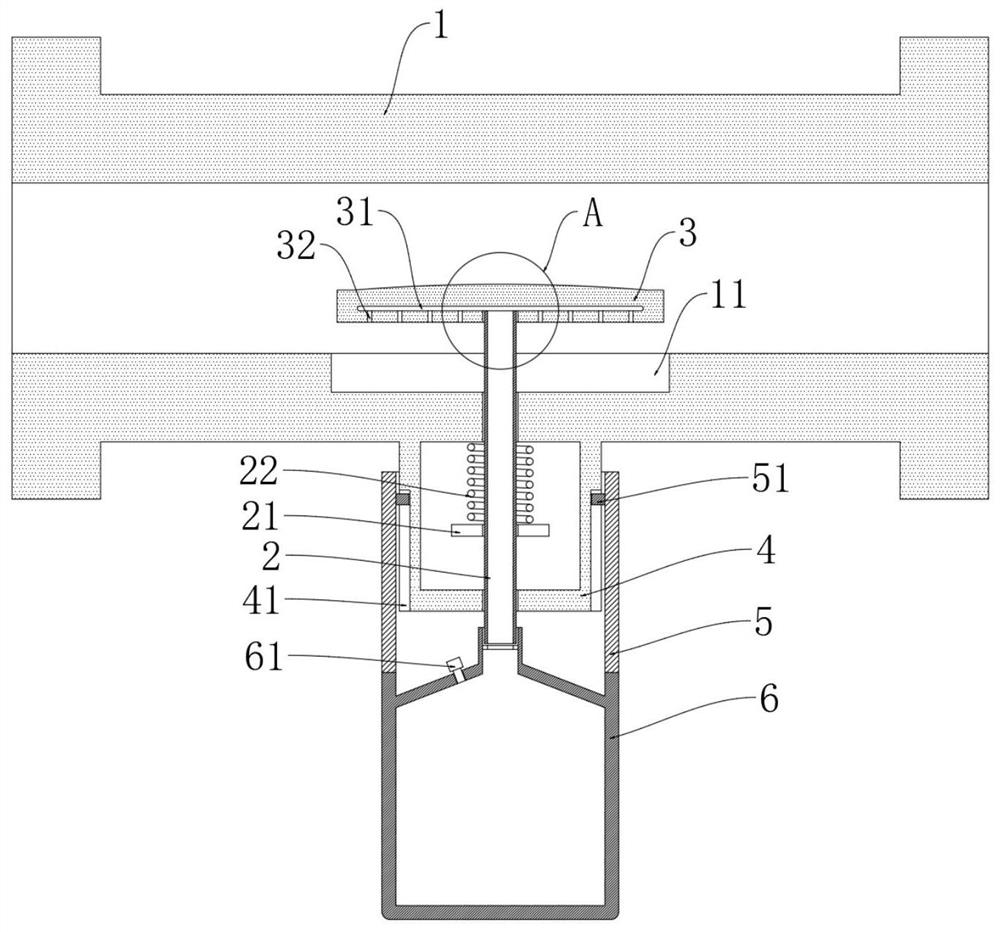

Automatic quantitative sampling connector for pipeline fluid

InactiveCN112414787ADoes not affect deliveryRealize the function of automatic quantitative samplingWithdrawing sample devicesStructural engineeringPipe

The invention discloses an automatic quantitative sampling connector for a pipeline fluid. The automatic quantitative sampling connector comprises a connecting pipe, wherein a sealing groove is formedin the inner wall of the connecting pipe, a sampling pipe is inserted into the groove bottom part of the sealing groove in a sealed and sliding mode, a sealing plate is installed at the end, locatedin the sealing groove, of the sampling pipe, a liquid discharging cavity is formed in the sealing plate, and a plurality of liquid discharging holes communicating with the liquid discharging cavity are formed in the side wall, close to the sealing groove, of the sealing plate. A sealing pipe and a sealing plug are used for slotting and sampling in the connecting pipe, non-stop sampling is achieved, fluid conveying is not affected, single-time rotating automatic quantitative sampling is achieved through pressure of fluid on the sealing plate, the sealing pipe and a sampling bottle and guiding of a sliding column and a quantitative sampling groove, and the automatic quantitative sampling connector is more convenient and more reliable.

Owner:SANLONG CATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com