Special dip blanching and feather picking production line for slaughtering poultry

An assembly line and poultry technology, applied to poultry plucking machines, slaughtering, poultry processing, etc., can solve the problems of low cost of use, and achieve the effects of convenient laying, ensuring passability, and enlarging the closed area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

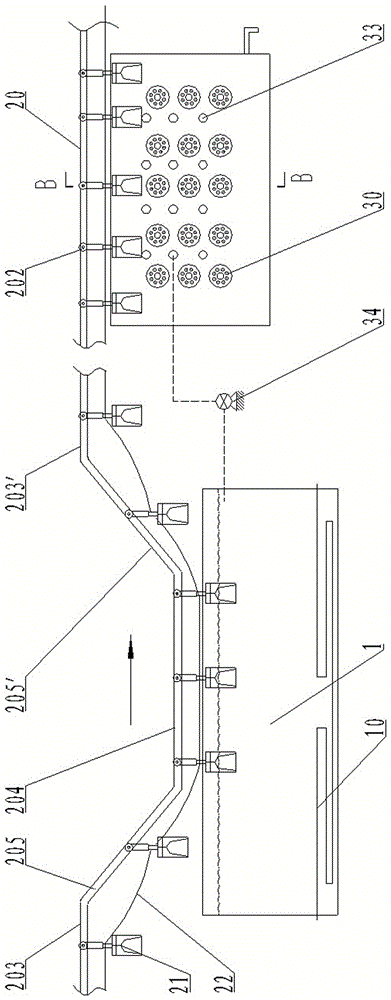

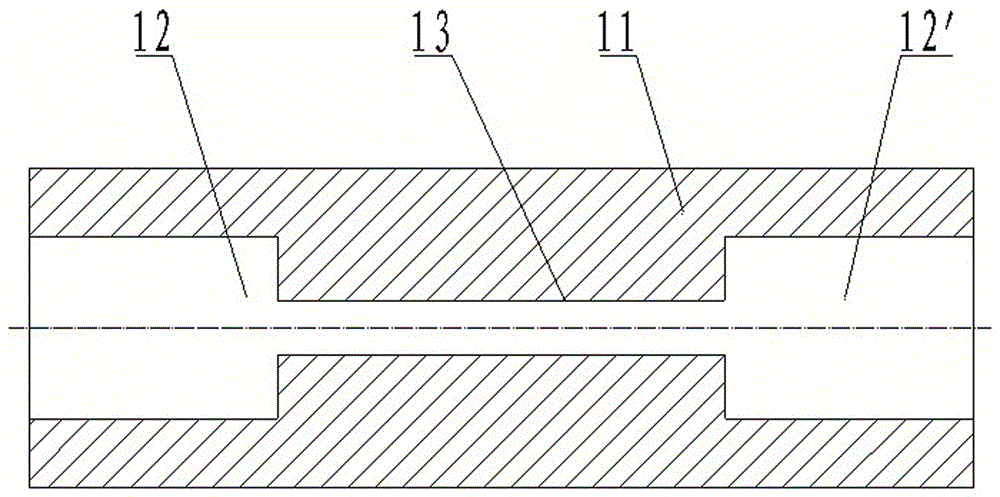

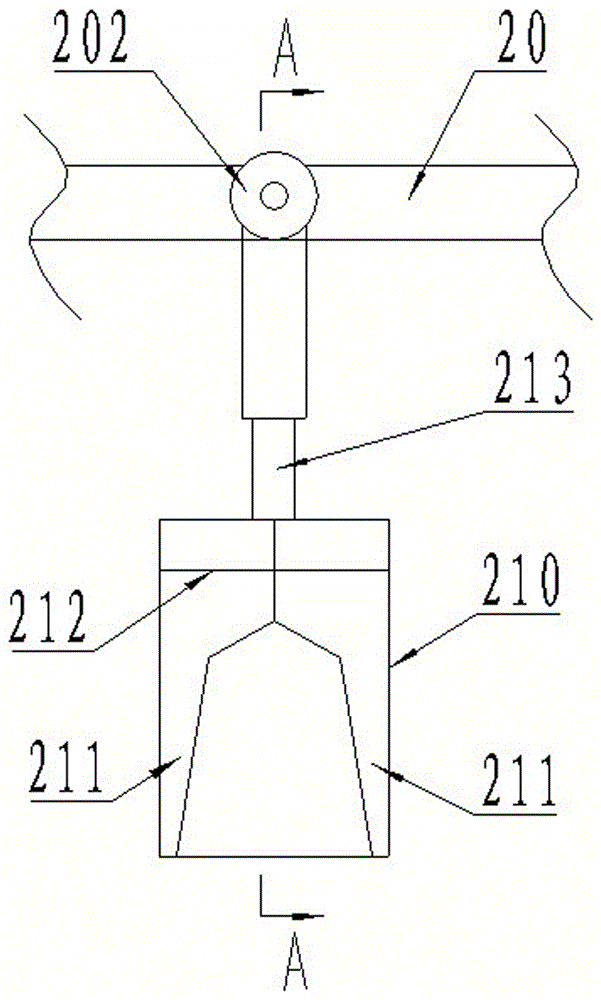

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that this embodiment provides a scalding and plucking line dedicated to slaughtering poultry, which includes a boiling water scalding device and a plucking device, and also includes a track 20 connecting the boiling water scalding device and the plucking device; The boiling water scalding device includes a boiling pool 1, a heating coil 10 is arranged in the boiling pool 1, a plurality of poultry racks 21 are movably arranged on the track 20, and a plurality of poultry racks 21 are driven along the The driving belt 22 on the track 20; the plucking device includes a box body 3, the two ends of the box body 3 are open; the two side walls of the box body 3 are provided with a plurality of hair removal devices through bearings, the The hair removal device includes a brush pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com