Method and device for making iron by smelting reduction

A smelting furnace and cooling device technology, applied in the field of smelting reduction ironmaking, can solve the problems of easy oxidation of raw material moldings and difficult separation of slag and iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The device is an electric arc furnace for ironmaking, and the raw material is a breathing shell.

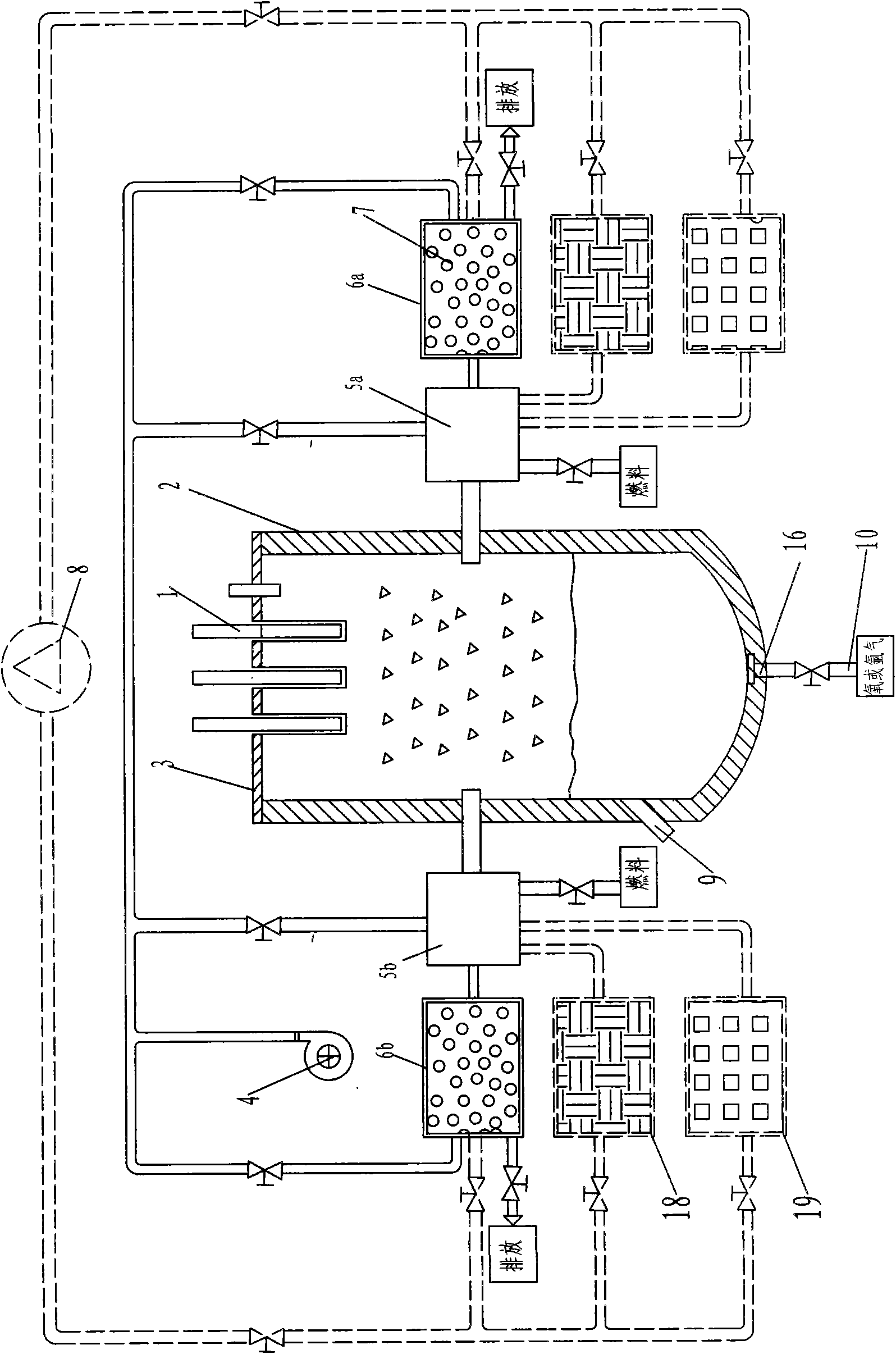

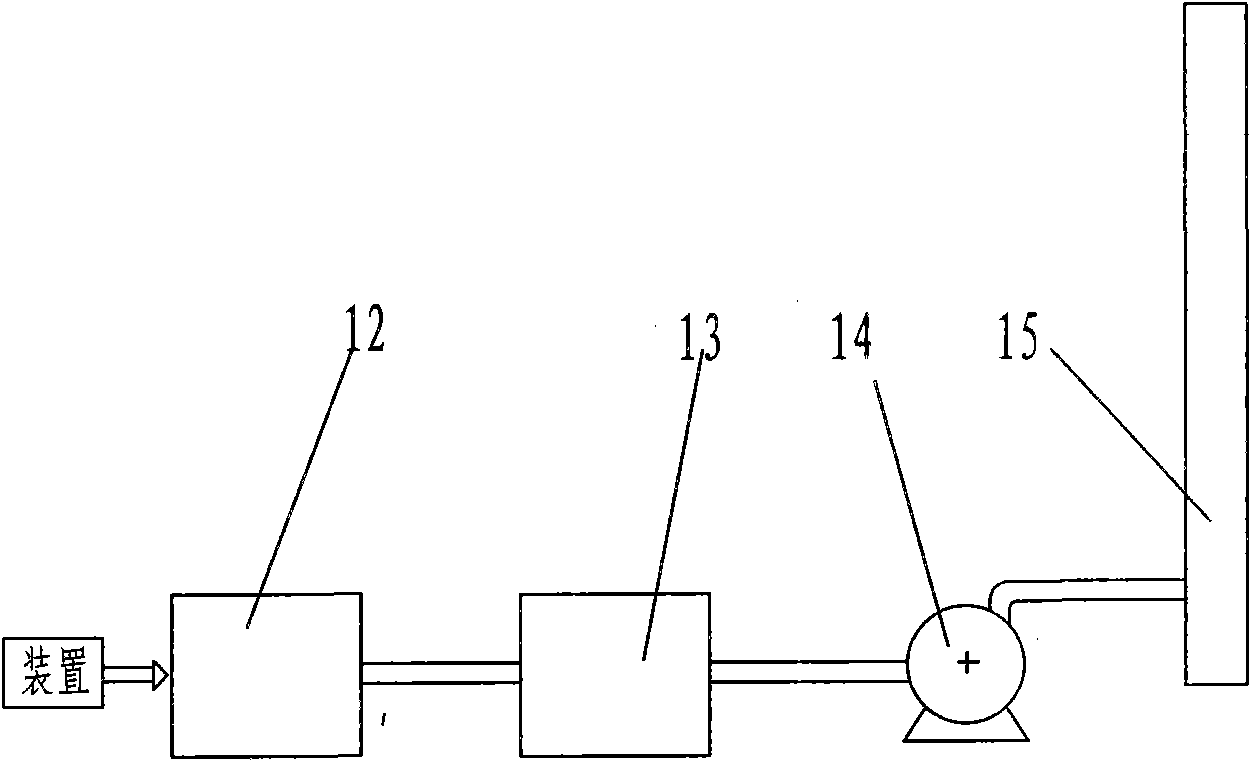

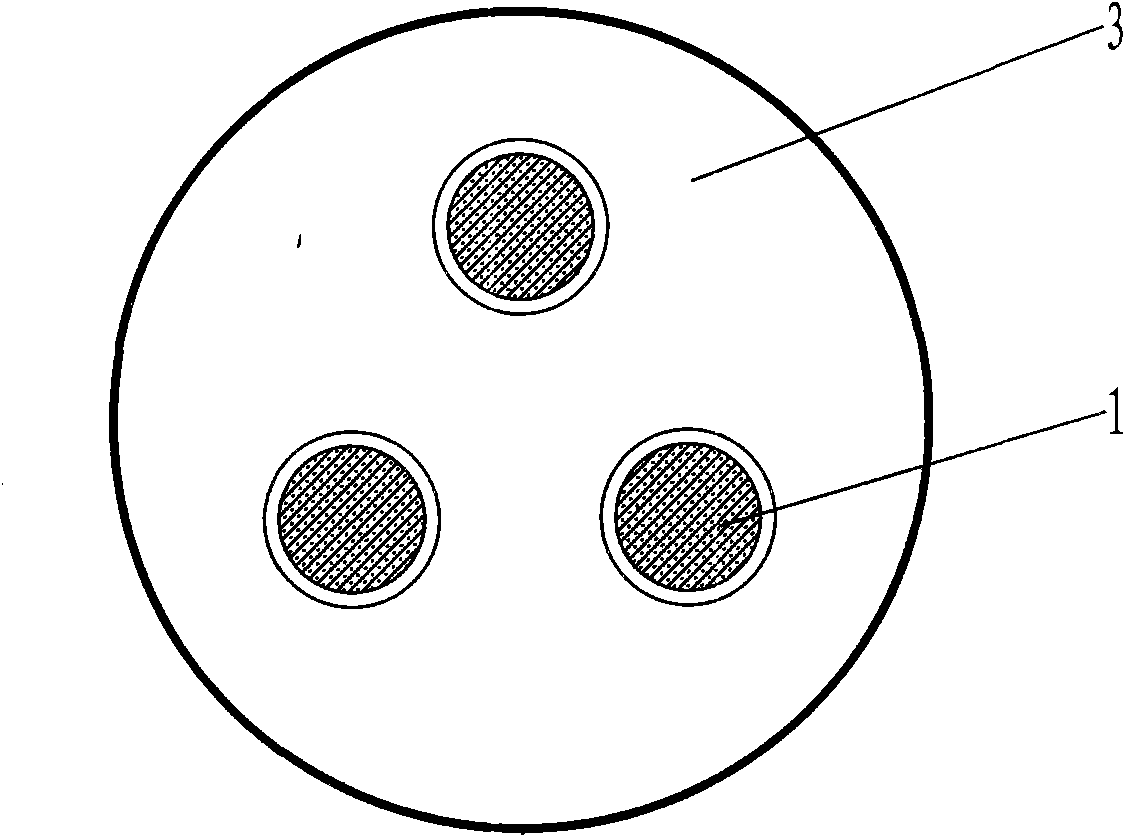

[0045] The device of electric arc furnace smelting reduction ironmaking described in the present invention is as figure 1 As shown, it includes a furnace body 2, a furnace cover 3, feeding equipment and discharging equipment, and the lower part of the furnace body 2 has a molten iron / steel outlet 9. A gas inlet 16 is provided at the bottom of the electric arc furnace, and the gas inlet is connected with a gas pipeline 10 . Such as image 3 As shown, there are three electrode jacks on the furnace cover 3, which are respectively inserted into the electrode 1, and the three electrode jacks are distributed in a triangle. A pair of heating furnaces 5a, 5b and a pair of regenerators 6a, 6b outside the furnace body 2, and the two heating furnaces are installed on both sides outside the furnace body 2. The heating furnace is connected with the furnace body 2 of the electric arc...

Embodiment 2

[0056] The device is submerged arc furnace ironmaking, and the raw material is semi-breathing shell.

[0057] Submerged arc furnace smelting reduction ironmaking equipment such as Figure 4 As shown, it includes a furnace body 2, a furnace cover 3, an electrode 1, and supporting heating furnaces 5a, 5b, regenerators 5a, 5b, and a gas treatment device 8. A gas inlet 16 is provided at the bottom of the electric arc furnace, and it is connected with a gas pipeline 10 connect. The gas processing device includes circulating gas booster, gas cooling and purification device, gas storage tank and other devices, and the gas processing device may or may not be used. In order to make full use of waste heat, the device is also equipped with two or more slag cooling devices 18 and two or more pig iron or continuous casting slab or rolling material cooling devices 19 . The heat of molten slag or continuous casting slab or rolling material is brought into the furnace body 2 through the hea...

Embodiment 3

[0068] The device is a converter, and the raw material is an open shell.

[0069] The converter smelting reduction ironmaking device such as Figure 5 As shown, it includes a furnace body 2, a furnace cover 3, electrodes and supporting furnaces 5a, 5b, regenerators 6a, 6b and a gas treatment device 8. The cover of the converter is provided with a gas inlet 16 and a desulfurizer feeding port 11 , and the gas inlet 16 is connected with the gas pipeline 10 . In order to make full use of waste heat, the device is also equipped with two or more slag cooling devices 18 and two or more pig iron or continuous casting slab or rolling material cooling devices 19 . The heat of molten slag or continuous casting slab or rolling material is brought into the furnace body 2 through the heating furnaces 5a and 5b by utilizing the circulation of the precipitated gas.

[0070] The process steps of converter smelting reduction ironmaking are as follows:

[0071] (1) Preparation of open shell: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com