Patents

Literature

49 results about "Metalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metalation (Alt. spelling: Metallation) is a chemical reaction which involves the bonding of a metal atom to what is typically an organic molecule to form a new compound. This reaction usually involves the replacement of a halogen atom in an organic molecule with a metal atom to form an organometallic compound. In the laboratory, metalation is commonly used to activate organic molecules during the formation of C—X bonds (where X is typically Carbon, Oxygen, or Nitrogen), which are necessary for the synthesis of many organic molecules.

Preparation of Aminoaryl and Aminoheteroaryl Boronic Acids and Derivatives Thereof

InactiveUS20080269523A1High yieldEconomically sensibleGroup 3/13 element organic compoundsBulk chemical productionArylBoronic acid

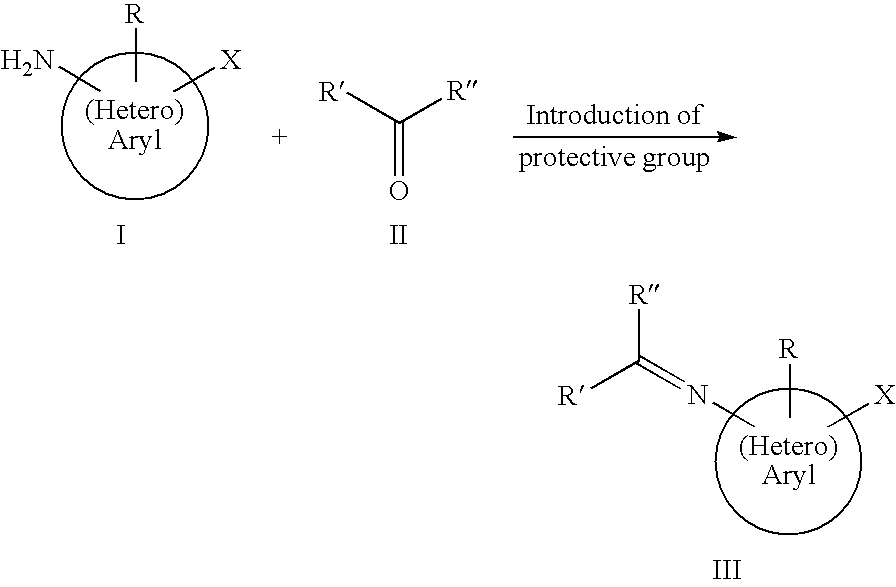

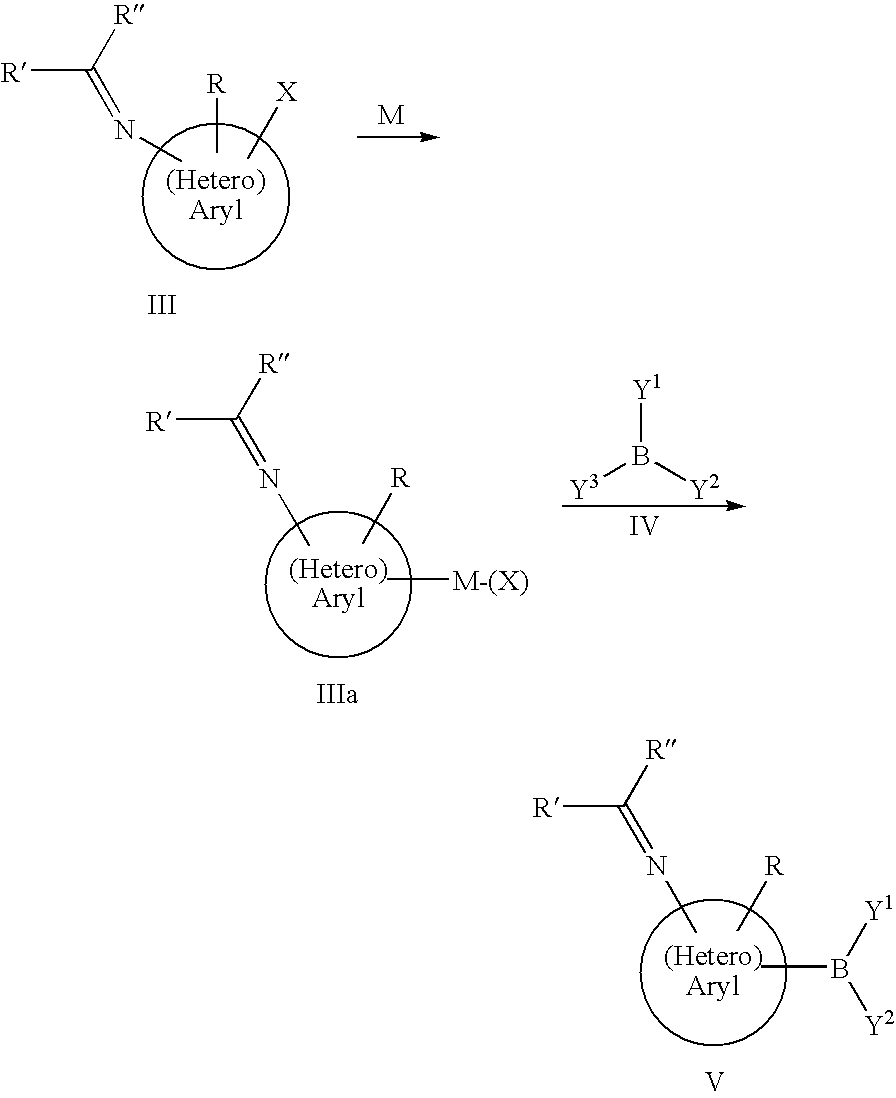

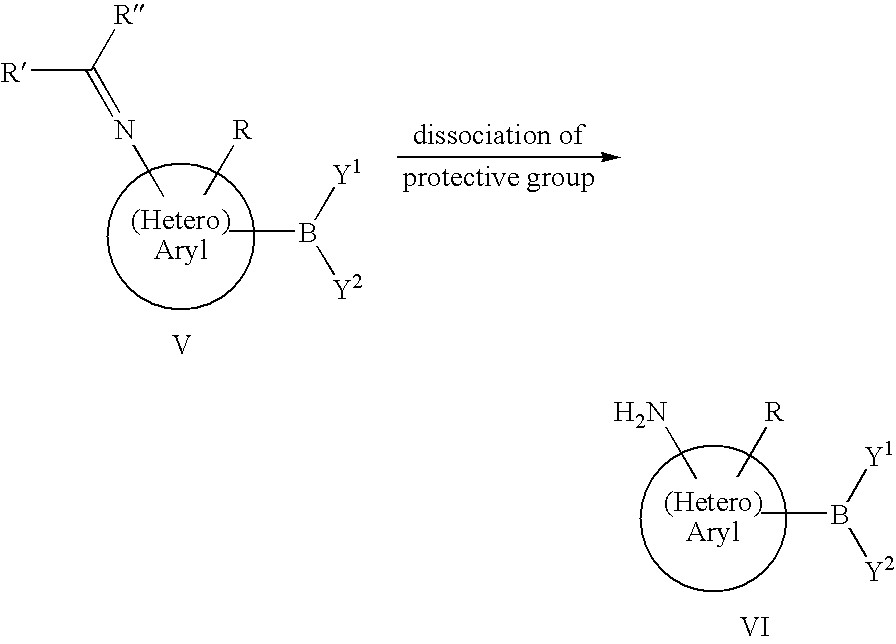

The invention relates to a method for preparation of aminoaryl- or aminoheteroarylboronic acids and esters and salts thereof in which an optionally substituted aminoaryl or aminoheteroaryl compound is protected at its nitrogen site via condensation with a carbonyl compound, subsequently metalated and converted with a suitable boron compound. Depending on the subsequent work-up and removal of the protective group, the corresponding boronic acid, the anhydride or the boronic acid ester thereof is obtained

Owner:ARCHIMICA GMBH

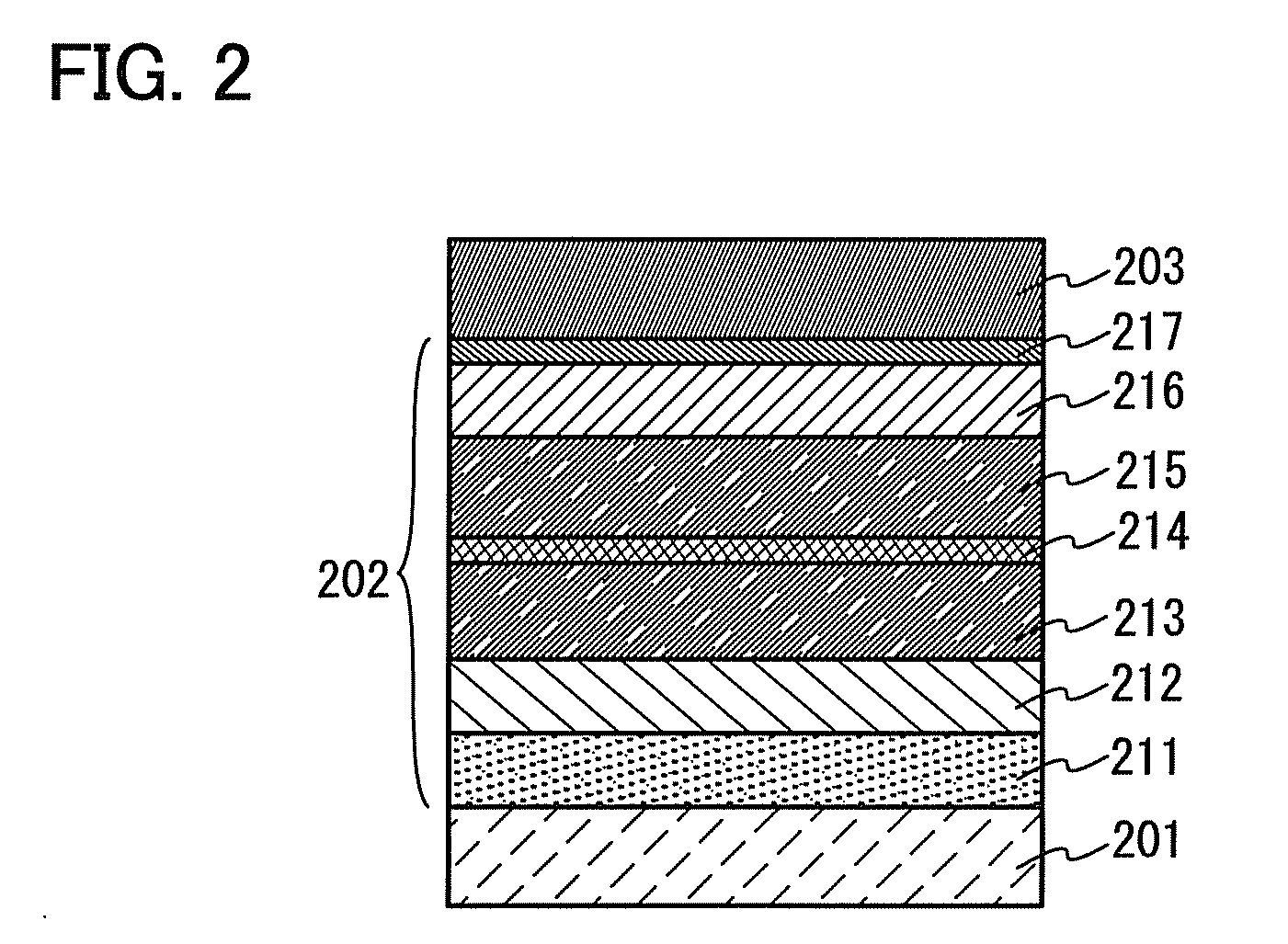

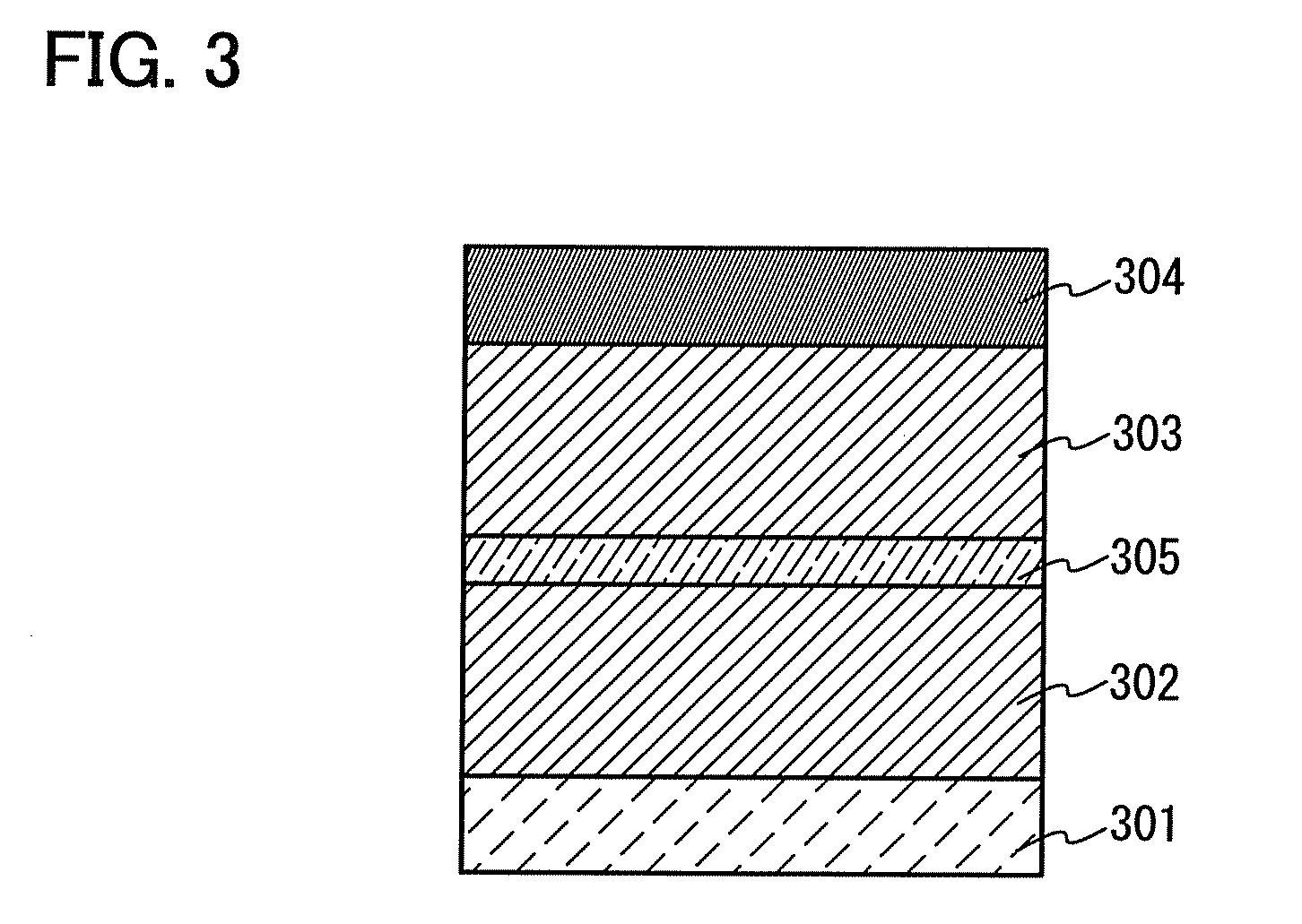

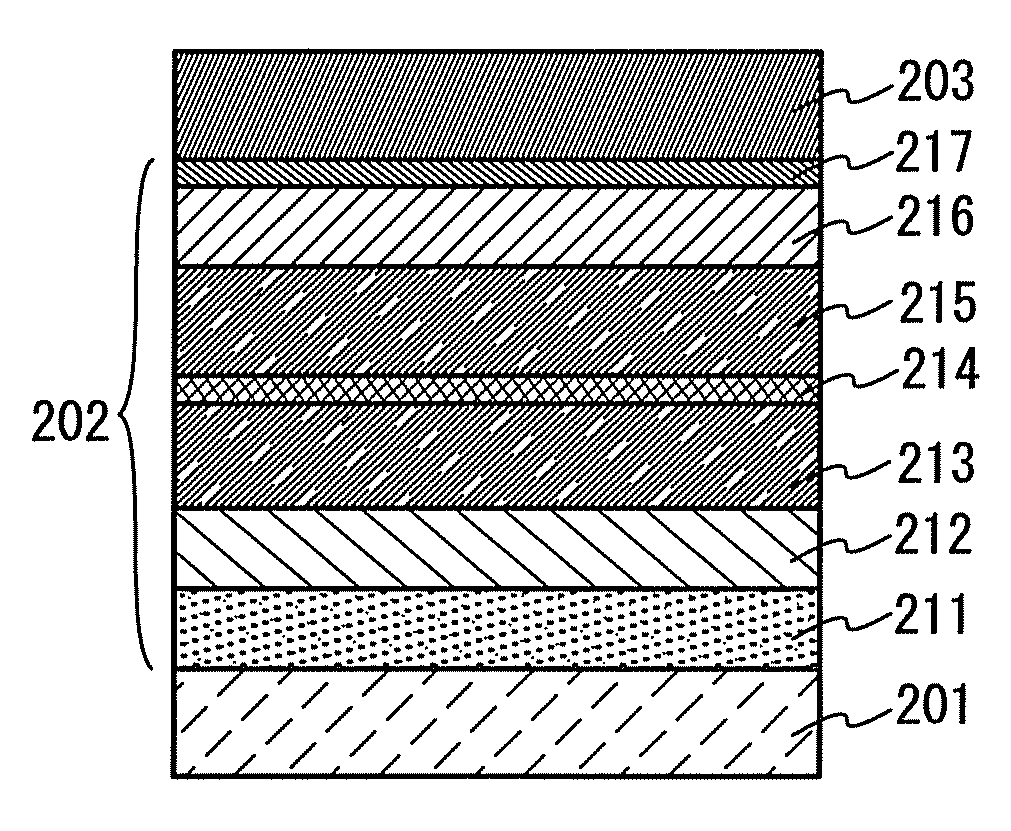

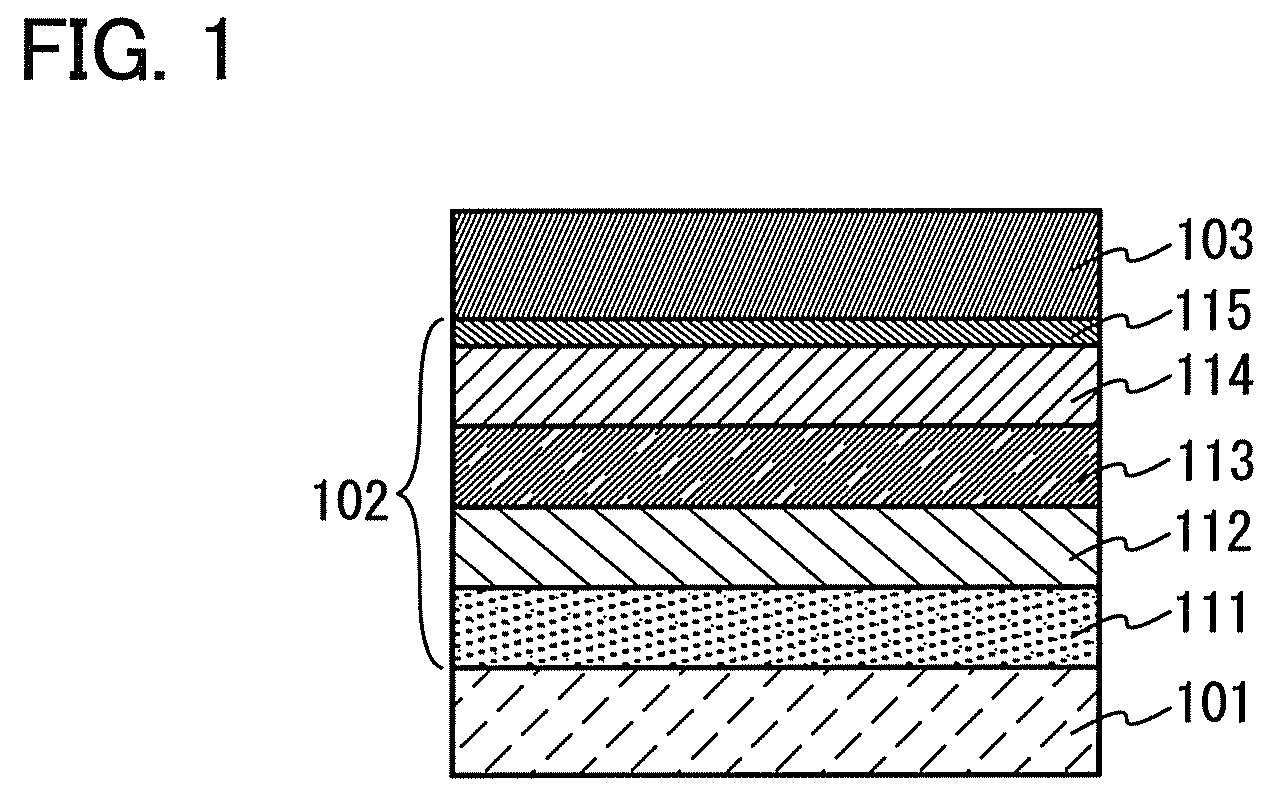

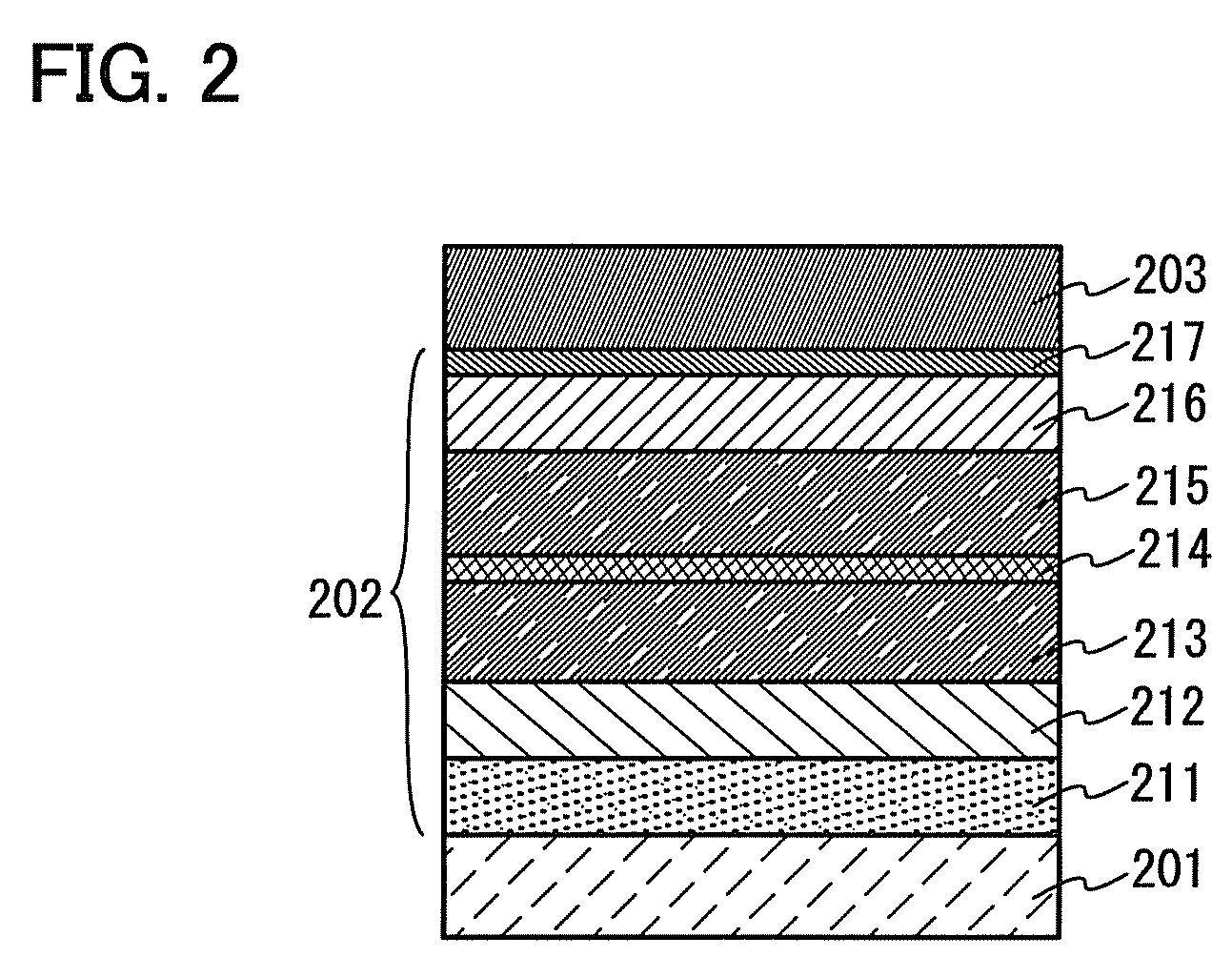

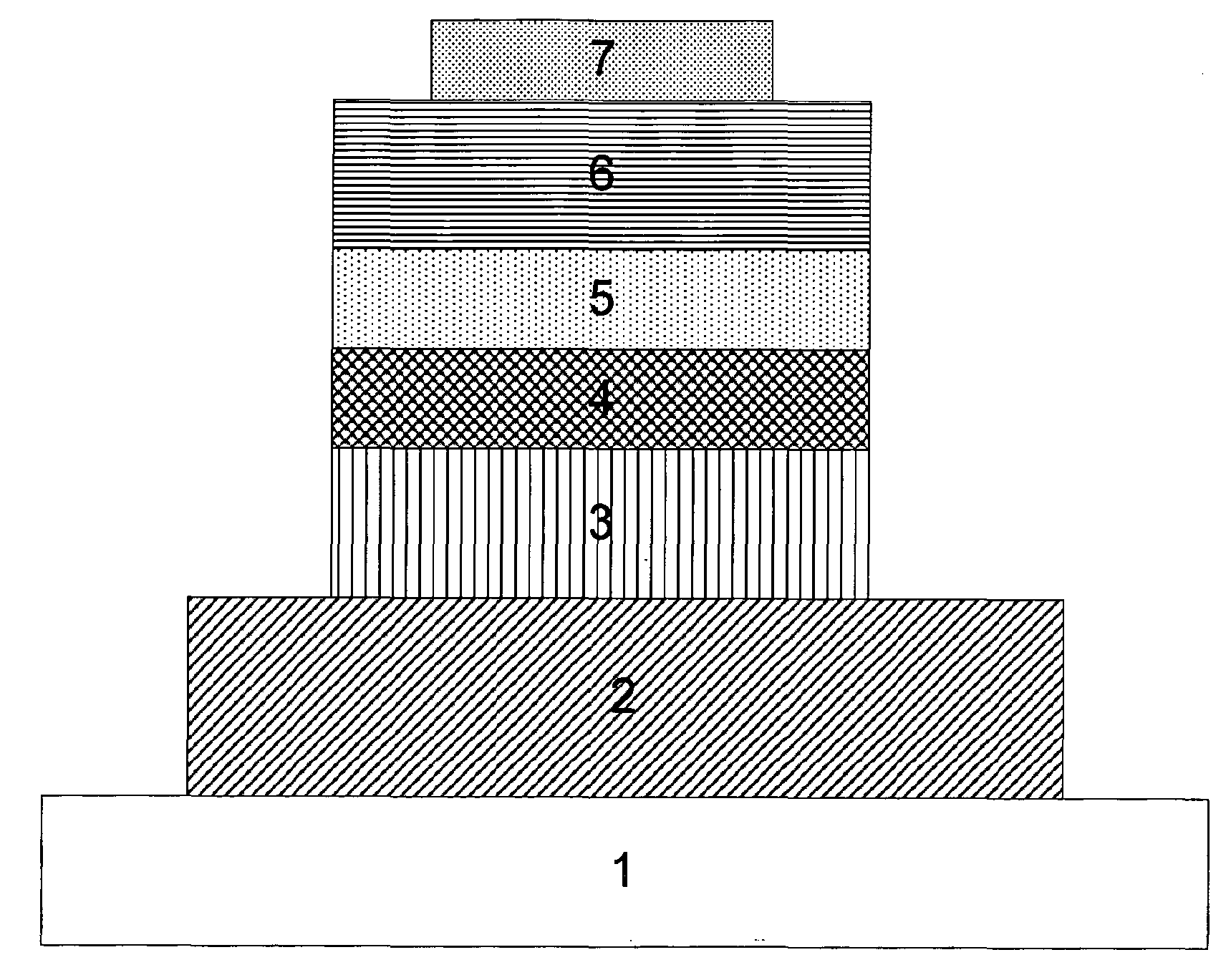

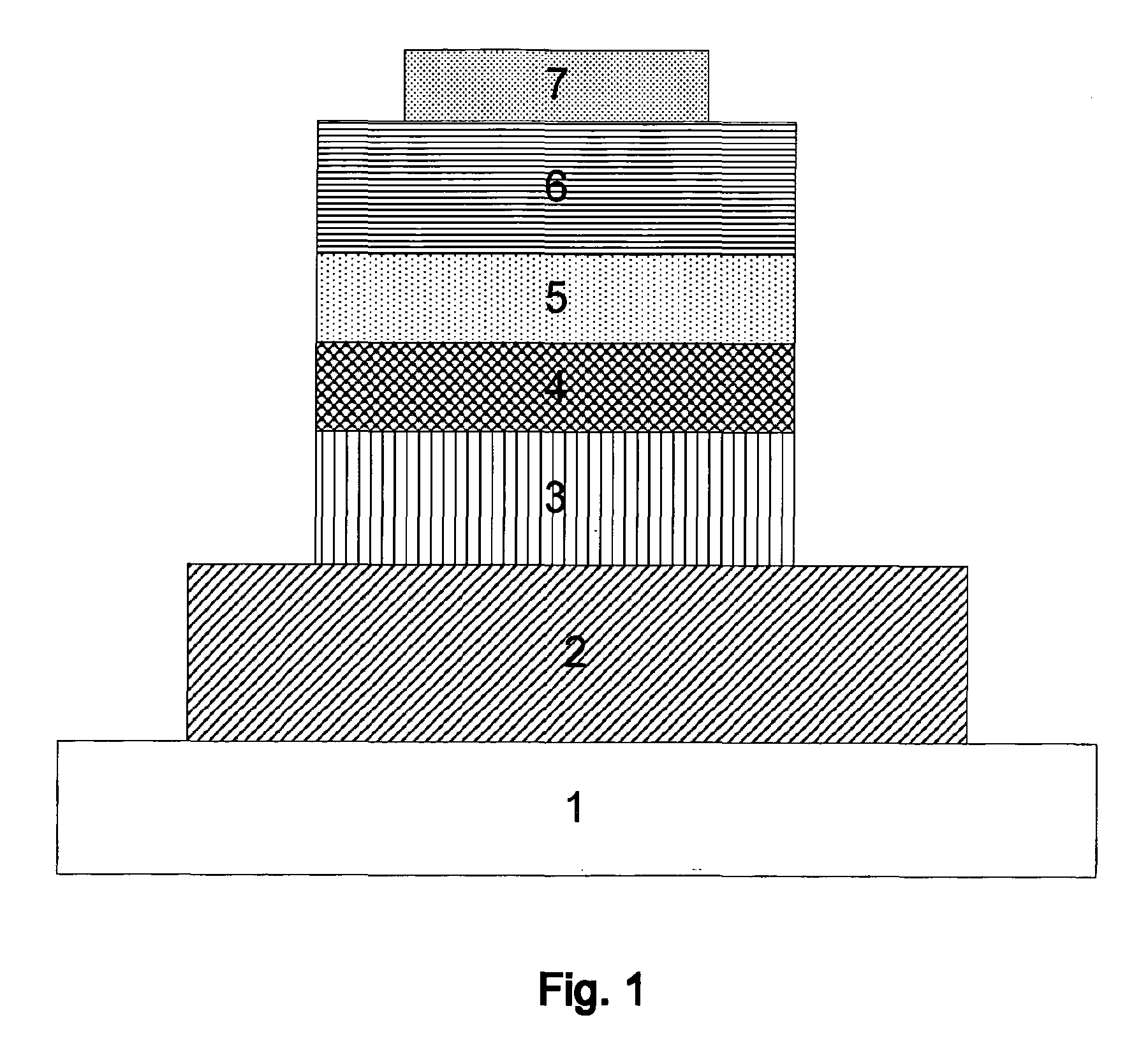

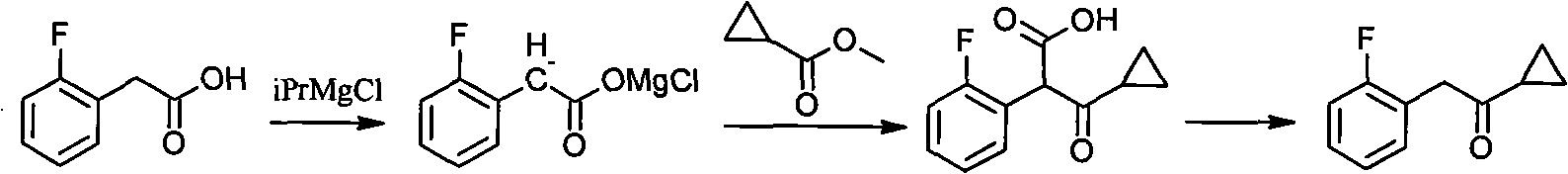

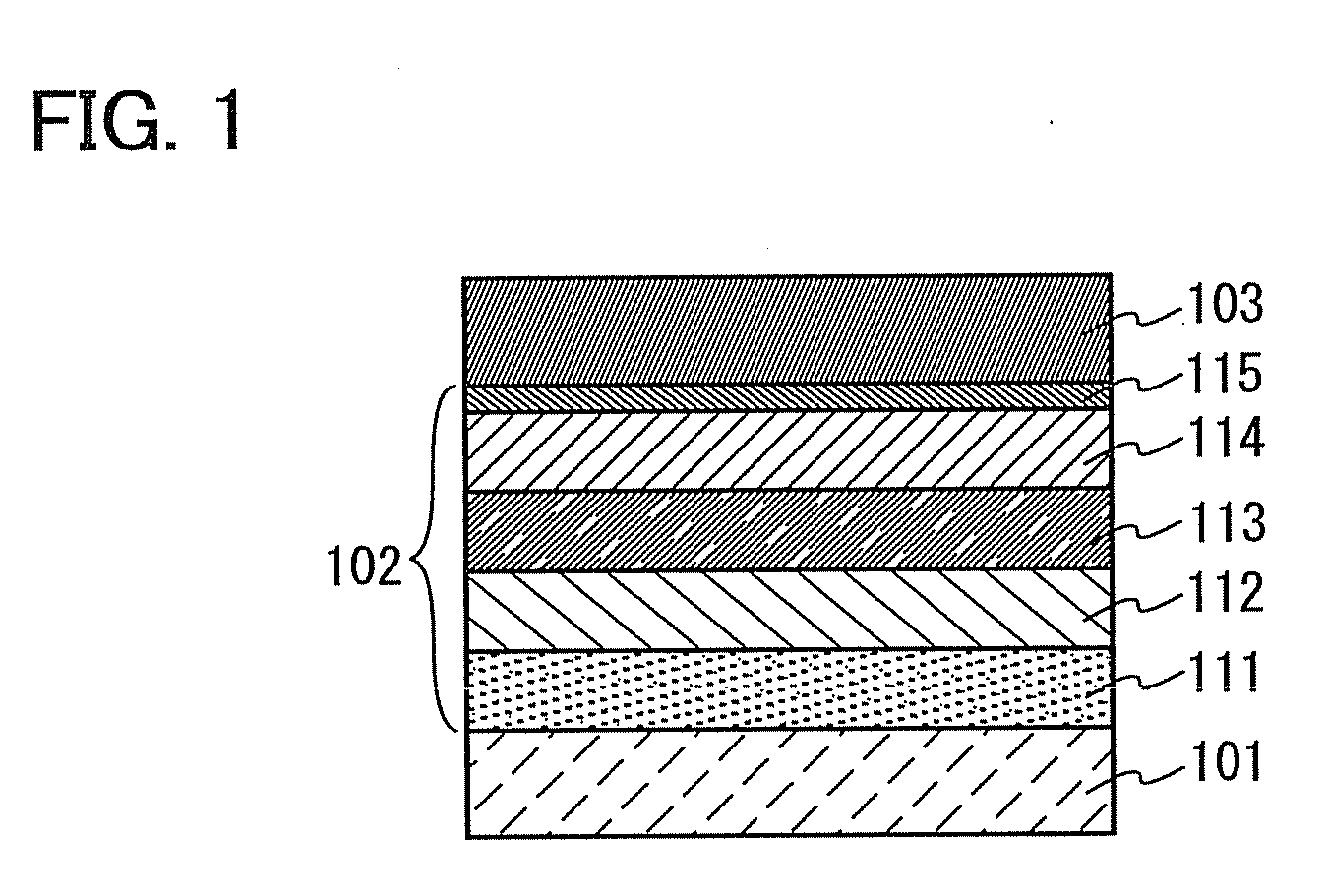

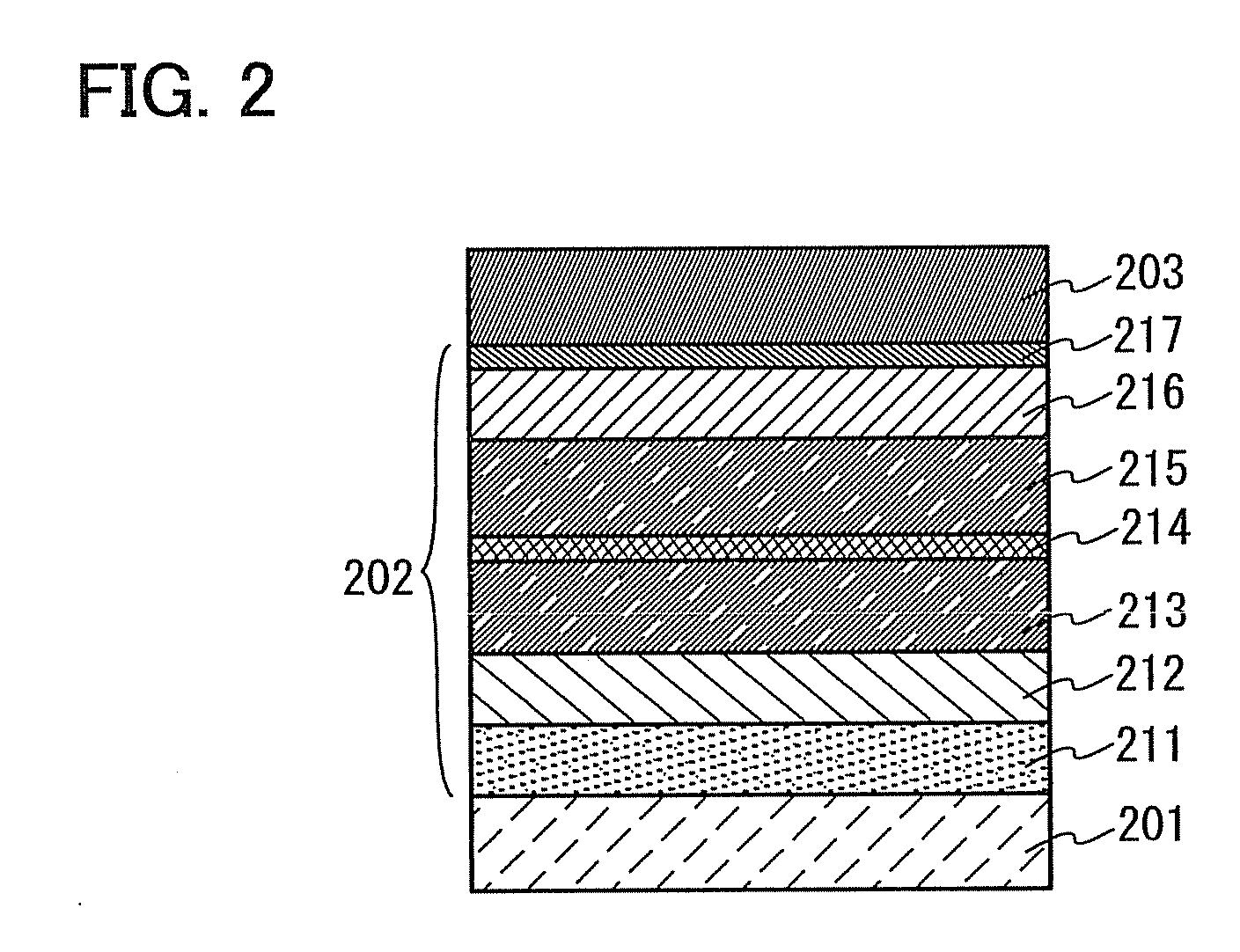

Organometallic Complex, and Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device Using the Organometallic Complex

InactiveUS20100181905A1Easy to synthesizeGroup 5/15 element organic compoundsGroup 3/13 element organic compoundsSimple Organic CompoundsMetalation

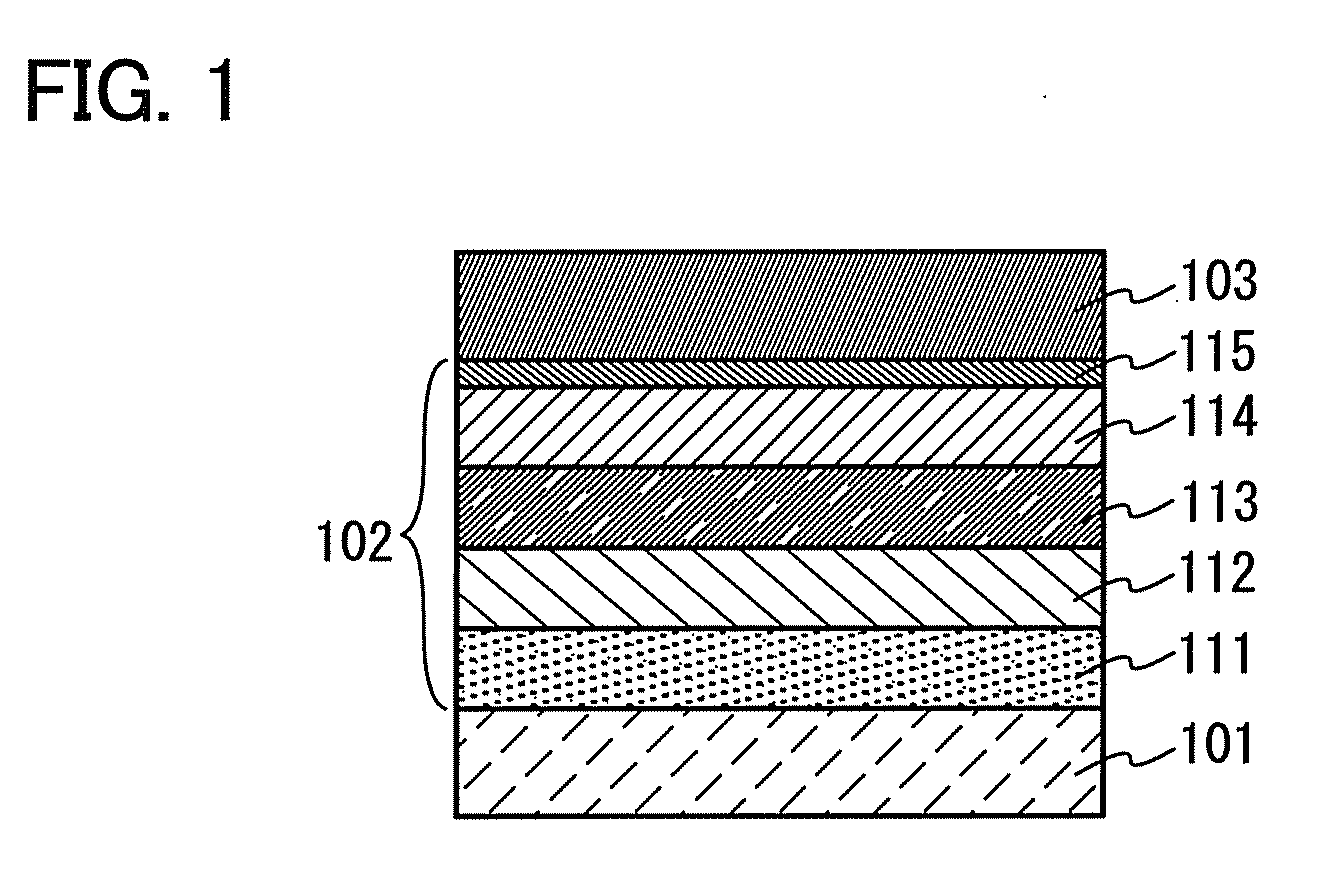

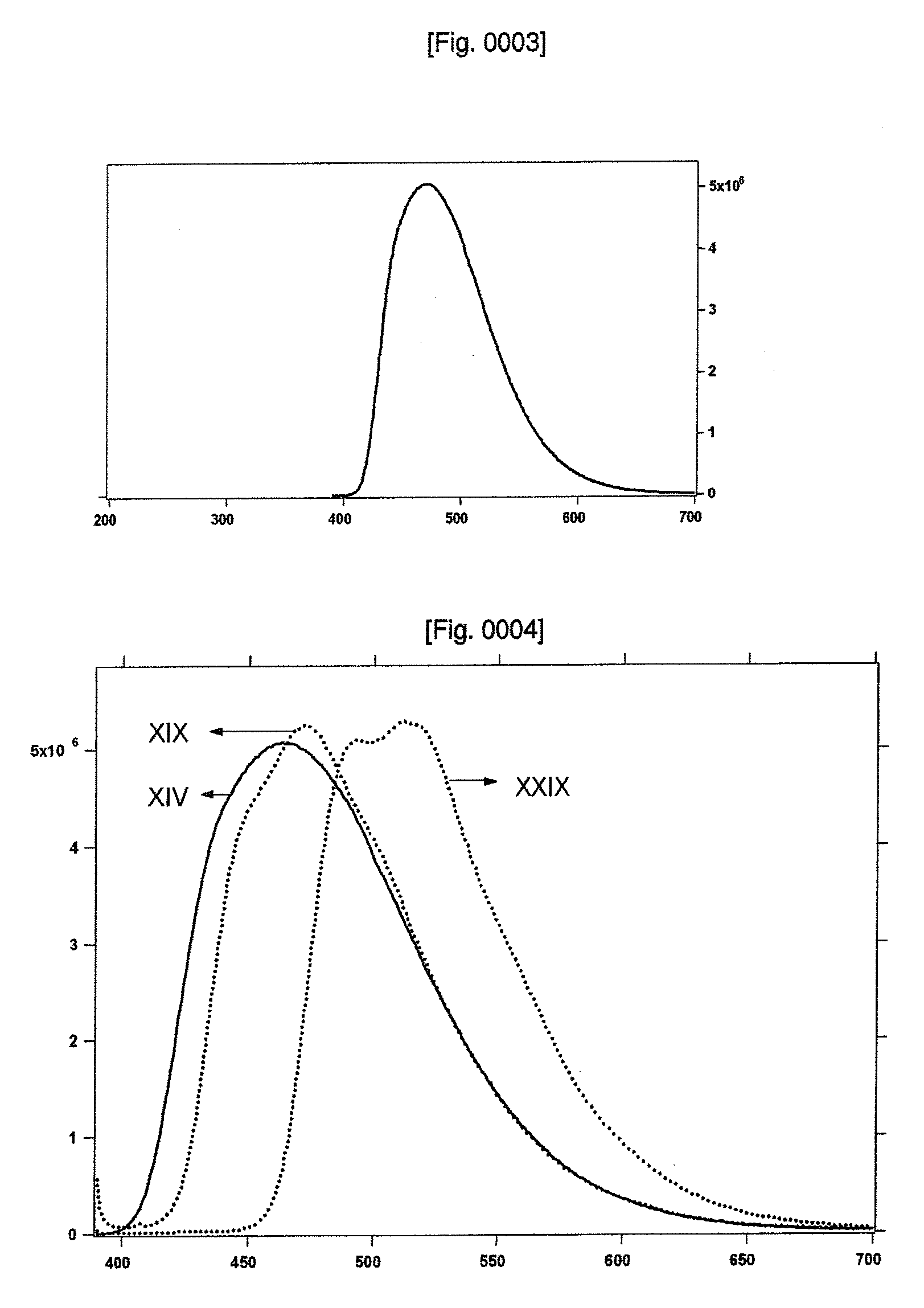

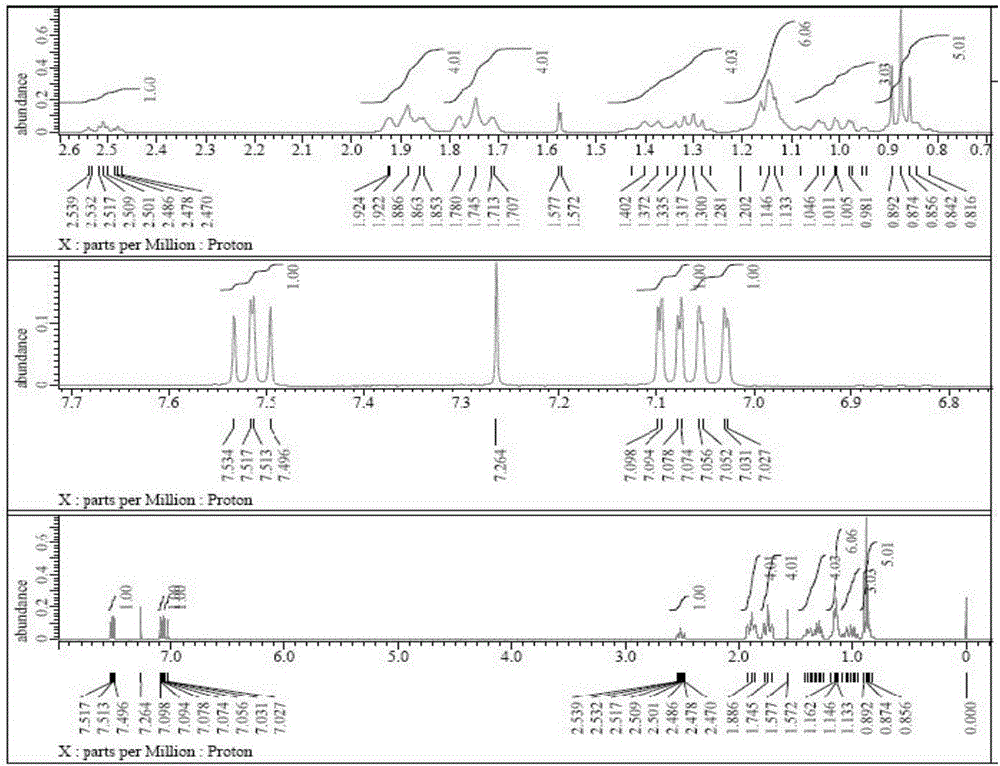

To provide a novel organometallic complex capable of emitting phosphorescence by using an organic compound with which a variety of derivatives can be easily synthesized as a ligand. In addition, to provide an organometallic complex which exhibits red emission. To provide an organometallic complex formed by ortho-metalation of an m-alkoxyphenyl pyrazine derivative represented by General Formula (G0) below with respect to an ion of a metal belonging to Group 9 or Group 10. In addition, to provide an organometallic complex which exhibits red emission formed by ortho-metalation of an m-alkoxyphenyl pyrazine derivative represented by General Formula (G0) below with respect to an ion of a metal belonging to Group 9 or Group 10.

Owner:SEMICON ENERGY LAB CO LTD

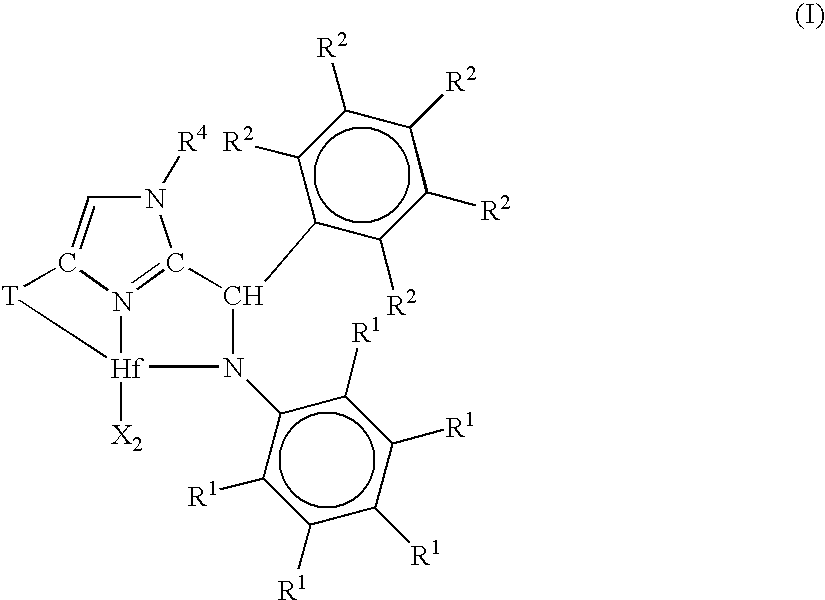

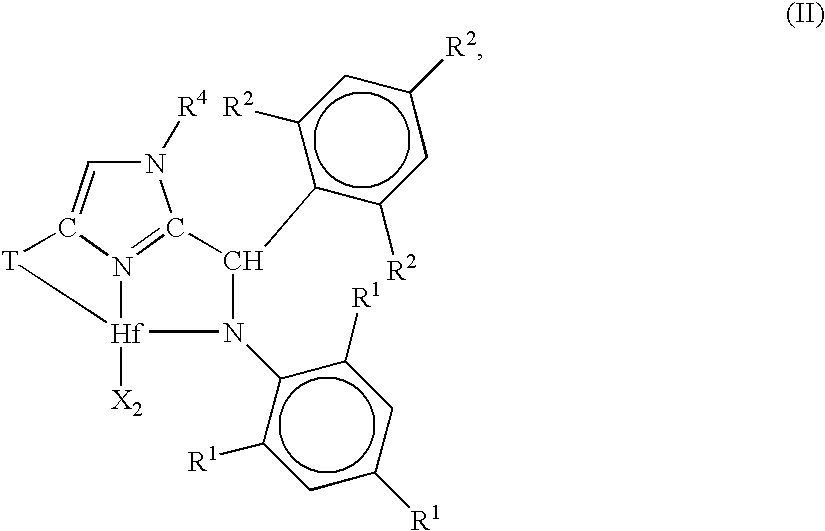

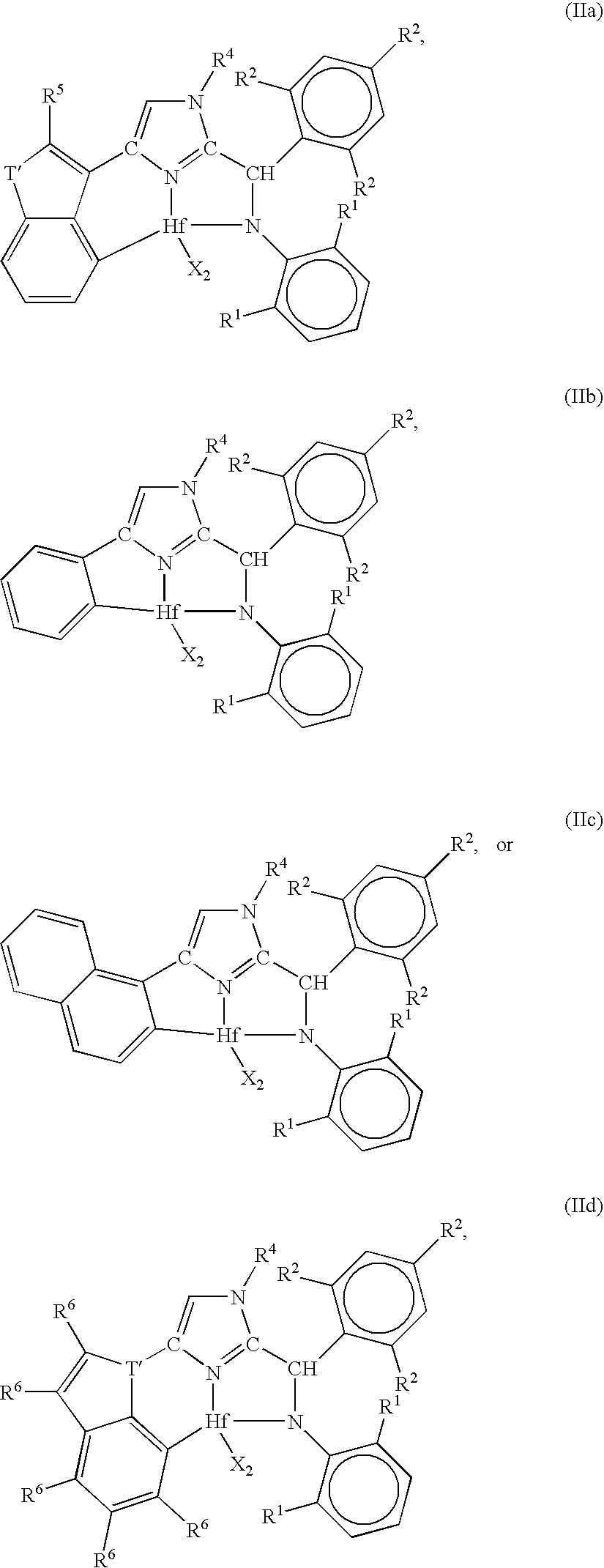

Ortho-metallated hafnium complexes of imidazole ligands

InactiveUS20090306318A1High molecular weightHigh catalytic efficiencyGroup 4/14 element organic compoundsGroup 8/9/10/18 element organic compoundsMetalationHafnium

Hafnium complexes of heterocyclic organic imidazol-2-yl ligands containing internal orthometallation and their use as components of olefin polymerization catalyst compositions, especially supported catalyst compositions, are disclosed.

Owner:DOW GLOBAL TECH LLC

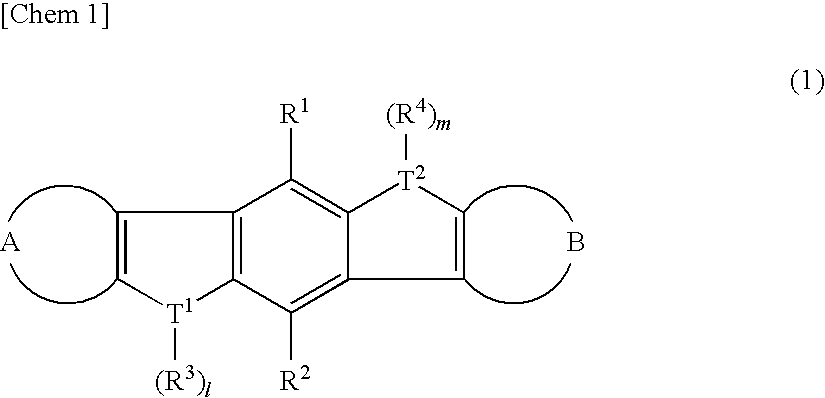

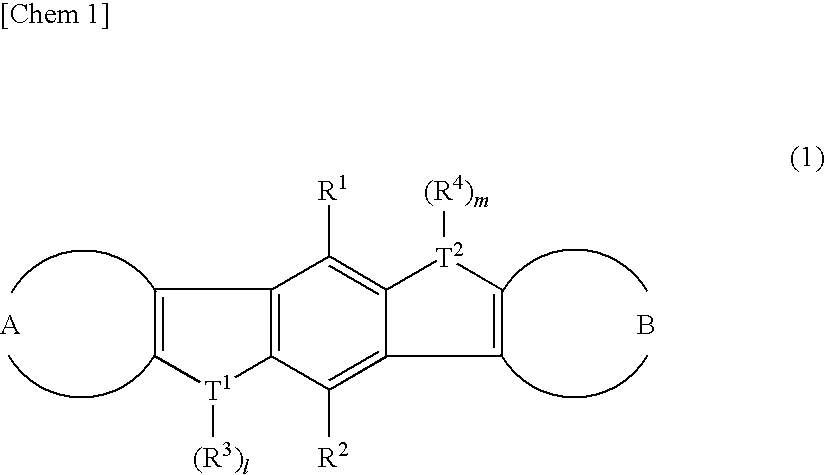

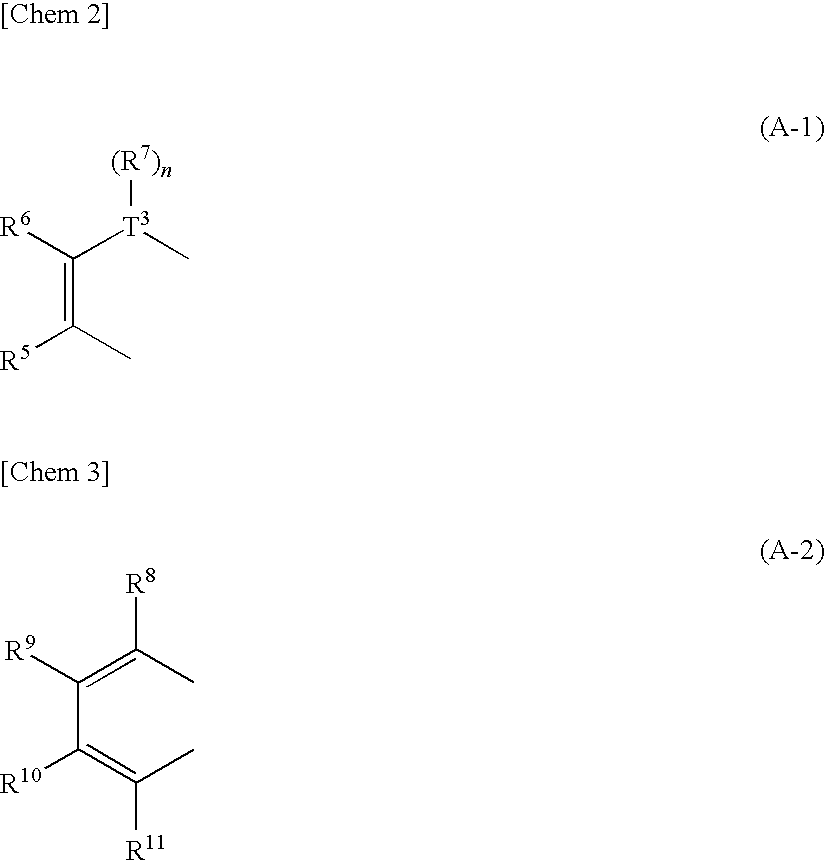

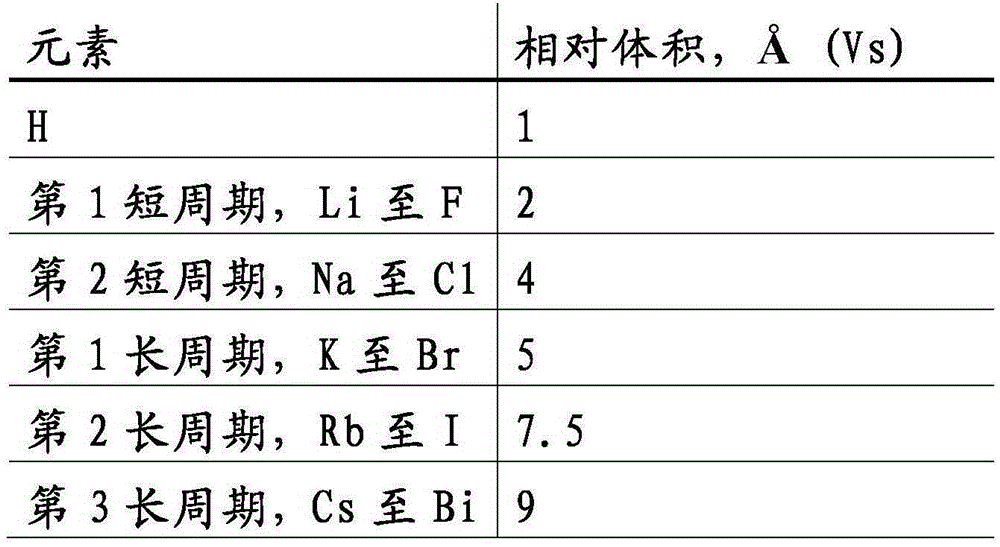

Heteroacene derivative, tetrahaloterphenyl derivative, and processes for producing the same

ActiveUS8138355B2Improve antioxidant capacityOrganic compound preparationGroup 5/15 element organic compoundsSemiconductor materialsOxidation resistant

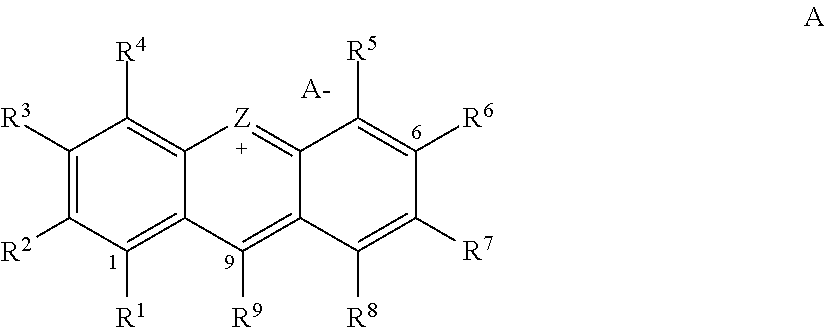

There are provided a heteroacene derivative having an excellent oxidation resistance and capable of forming a semiconductor active phase by a coating process, and an oxidation-resistant organic semiconductor material using the same, as well as an organic thin film.A heteroacene derivative represented by the formula (1) is obtained by tetrametalation of a tetrahaloterphenyl derivative with a metalation agent and subsequent treatment of the resulting compound with reaction agents:wherein the substituents R1 to R4 are the same or different and each represents a hydrogen atom, a fluorine atom, a chlorine atom, an aryl group having 4 to 30 carbon atoms, an alkyl group having 3 to 20 carbon atoms, or a halogenated alkyl group having 1 to 20 carbon atoms; T1 and T2 are the same or different and each represents sulfur, selenium, tellurium, oxygen, phosphorus, boron, or aluminum; l and m each is an integer of 0 or 1; and rings A and B are the same or different and each has a structure represented by the following formulae (A-1) or (A-2).

Owner:TOSOH CORP

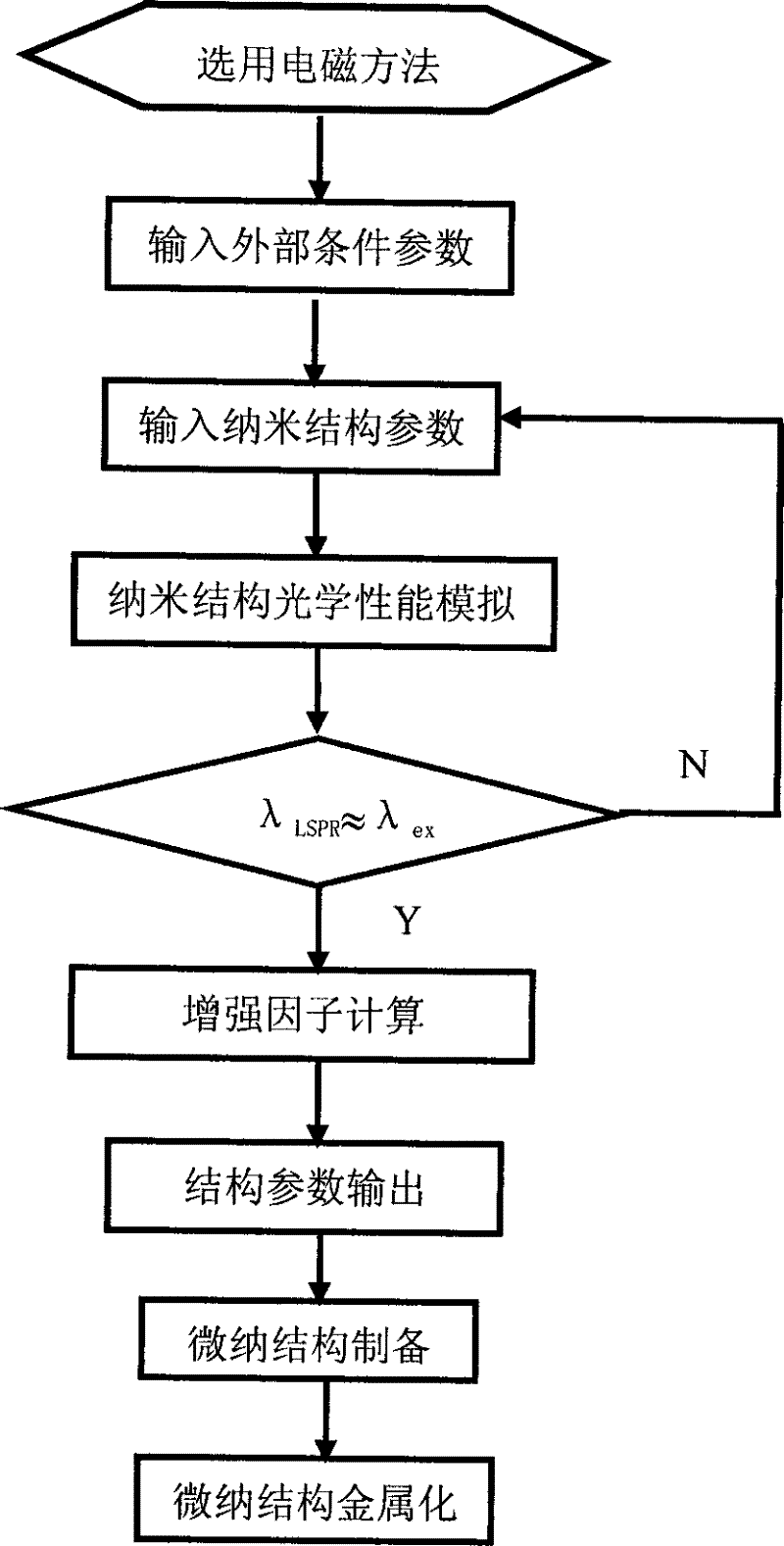

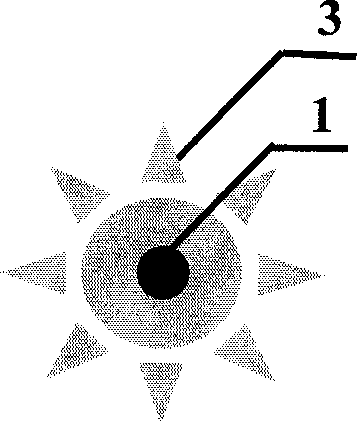

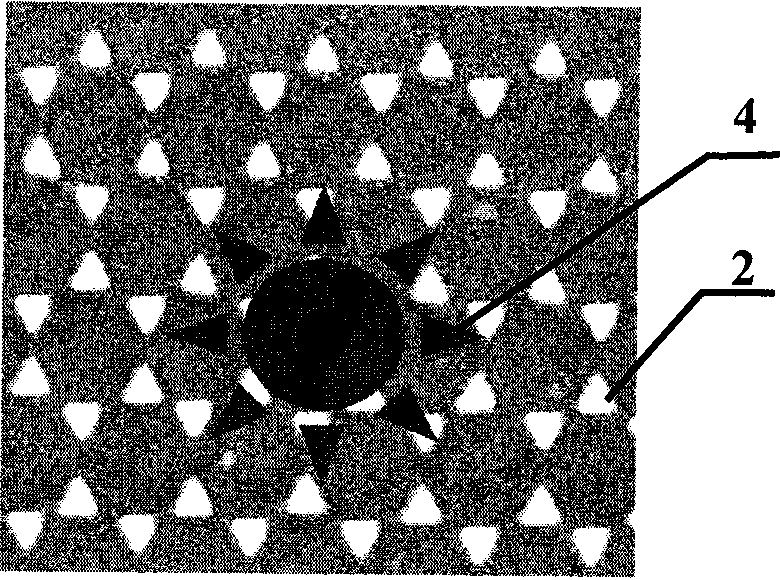

Metal micro-nano structure for improving Raman scattering of molecule

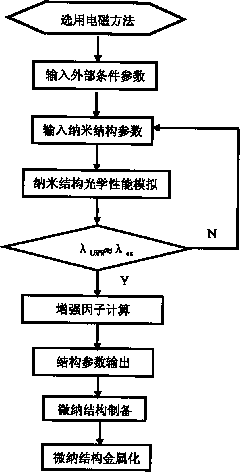

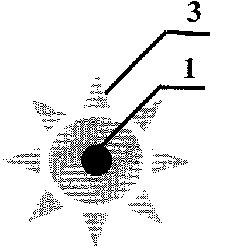

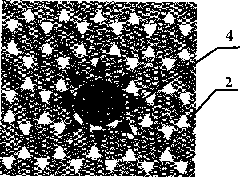

InactiveCN101799420AOvercome the disadvantages of low cost and expensive equipmentSolve the key technical problems of low concentration detectionRaman scatteringInternal memoryMicro nano

The invention relates to a metal micro-nano structure for improving Raman scattering of molecule, which comprises the following steps: (1) estimating limitation of internal memory capacity of a computer; (2) determining parameters such as mesh partition, peripheral medium environment conditions and exciting light condition, and primarily determining initial parameters of the metal micro-nano structure; (3) calculating scattering property Qsca of the metal micro-nano structure; (4) calculating plasma resonant frequency gamma LSPR for simulating the metal micro-nano structure and comparing the plasma resonant frequency gamma LSPR with the system exciting light frequency gamma ex, if the plasma resonant frequency is basically equal to the system exciting light frequency, the next step is entered, and if the plasma resonant frequency is not equal to the system exciting light frequency, the parameters of the peripheral medium environment condition of the metal micro-nano structure is changed; (5) calculating Raman reinforcing factor of the metal micro-nano structure; (6) preparing the micro-nano structure through the parameters of the metal micro-nano structure obtained in the step (4); (7) and realizing the metalation of the micro-nano structure. The metal micro-nano structure can maximally strengthen the Raman scattering of the molecule to be tested, can realize the low-concentration detection, and is simple and practical.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

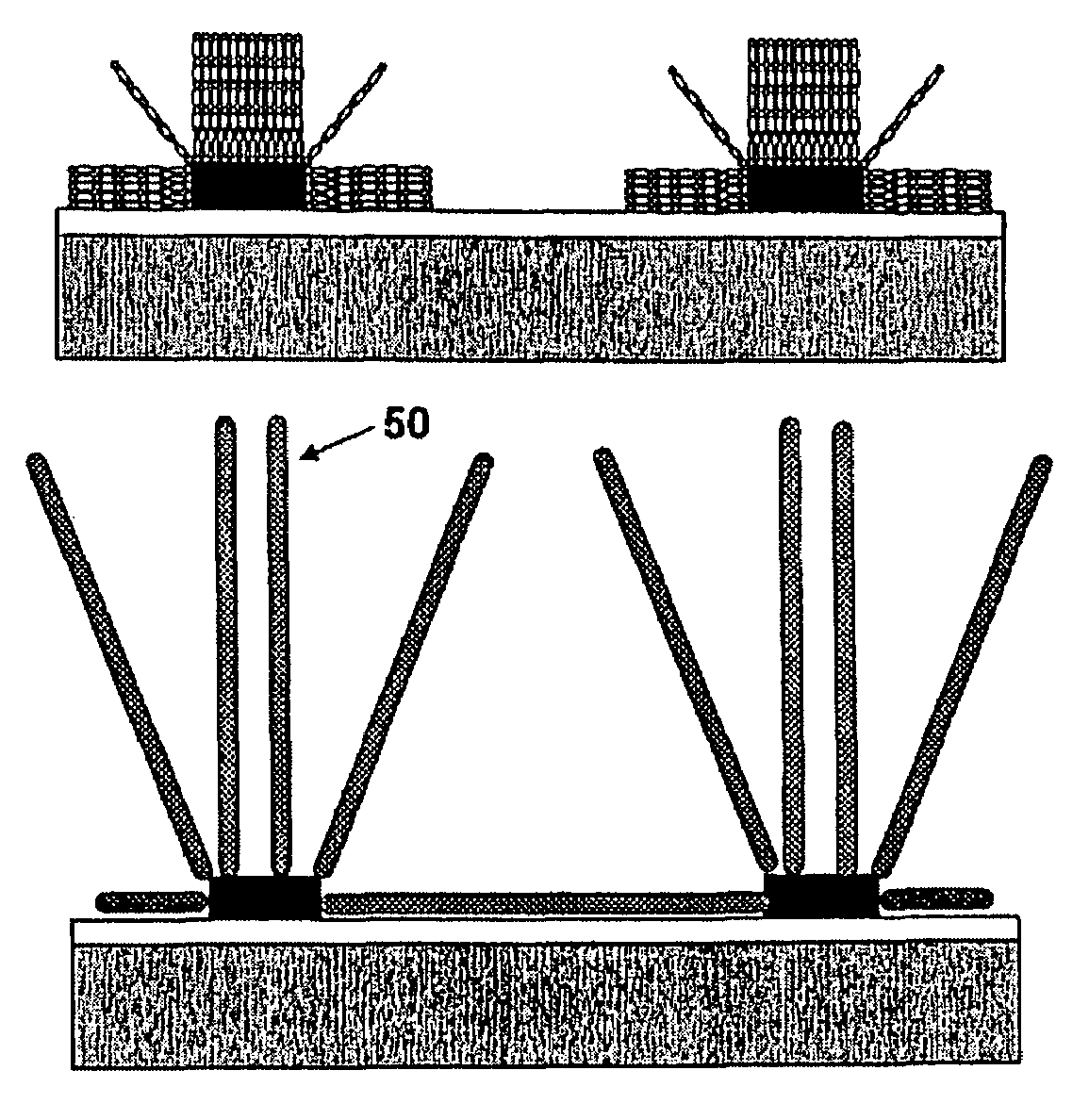

Formation of carbon and semiconductor nanomaterials using molecular assemblies

ActiveUS7544546B2Material nanotechnologyPolycrystalline material growthMetal oxide nanoparticlesGas phase

The invention is directed to a method of forming carbon nanomaterials or semiconductor nanomaterials. The method comprises providing a substrate and attaching a molecular precursor to the substrate. The molecular precursor includes a surface binding group for attachment to the substrate and a binding group for attachment of metal-containing species. The metal-containing species is selected from a metal cation, metal compound, or metal or metal-oxide nanoparticle to form a metallized molecular precursor. The metallized molecular precursor is then subjected to a heat treatment to provide a catalytic site from which the carbon nanomaterials or semiconductor nanomaterials form. The heating of the metallized molecular precursor is conducted under conditions suitable for chemical vapor deposition of the carbon nanomaterials or semiconductor nanomaterials.

Owner:GLOBALFOUNDRIES U S INC

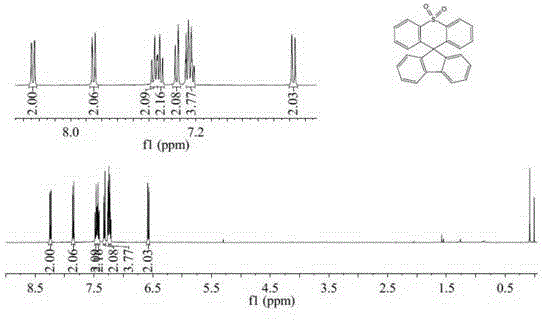

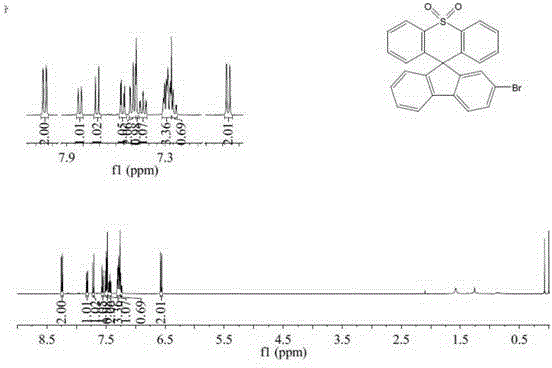

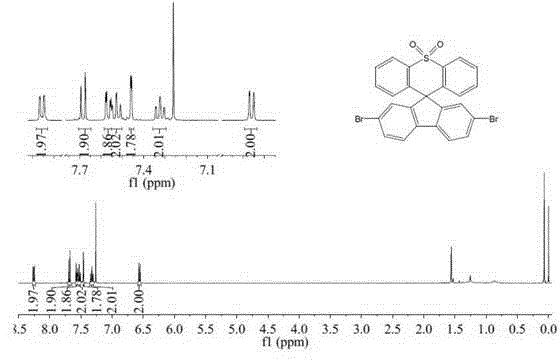

Preparation method for 9,9-diaryl thiophene xanthene-10,10-dioxide

InactiveCN104557856AFlexible designEasy to operateOrganic chemistryNonlinear opticsOrganic synthesis

The invention discloses a preparation method for 9,9-diaryl thiophene xanthene-10,10-dioxide, and belongs to the field of fine organic synthesis and organic semiconductor material preparation. The preparation method comprises the following steps: using diphenylsulphone as a starting material and tetrahydro furan as a solvent, conducting ortho metalation reaction on diphenylsulphone under the action of n-butyllithium within a temperature range of -78-0 DEG C to obtain a corresponding aryl lithium salt; allowing the aryl lithium salt to react with an added aryl formic ether ester derivative, and performing hydrolysis to obtain a corresponding tertiary alcohol; dissolving the tertiary alcohol and electron-rich aromatic with an acetate or methylene chloride solution, using Lewis acid as a catalyst, and carrying out friedel-crafts reaction to obtain the 9,9-diaryl thiophene xanthene-10,10-dioxide. The preparation method has the advantages that the reactions are easy to control, the operation is simple, the cost is low, the repeatability is good, the productivity is high, and the product quality is high; an organic modular unit and an organic functional semiconductor can be conveniently made; the 9,9-diaryl thiophene xanthene-10,10-dioxide is used in the fields of organic light emitting diodes, organic transistors, organic laser, and organic nonlinear optics, and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

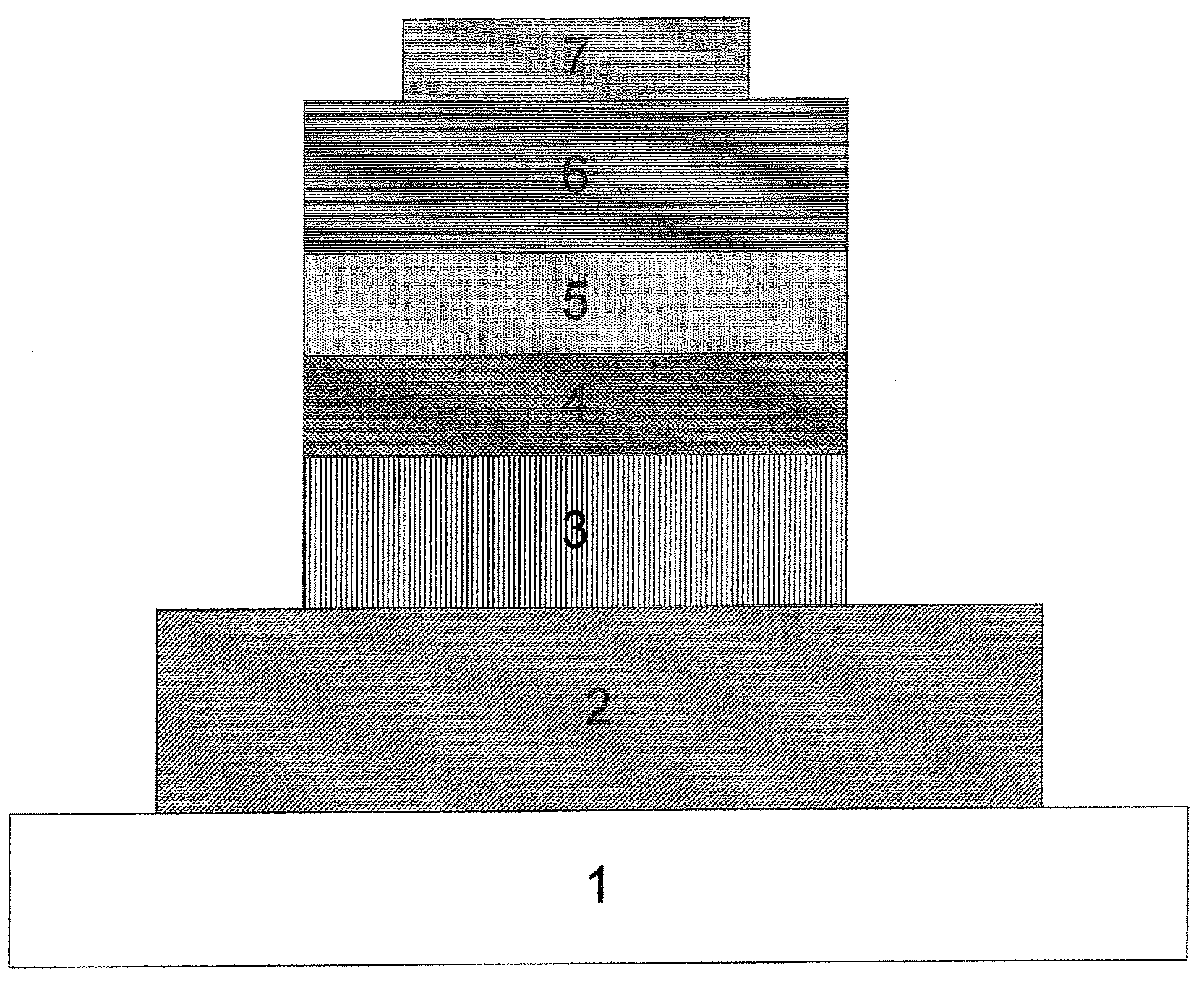

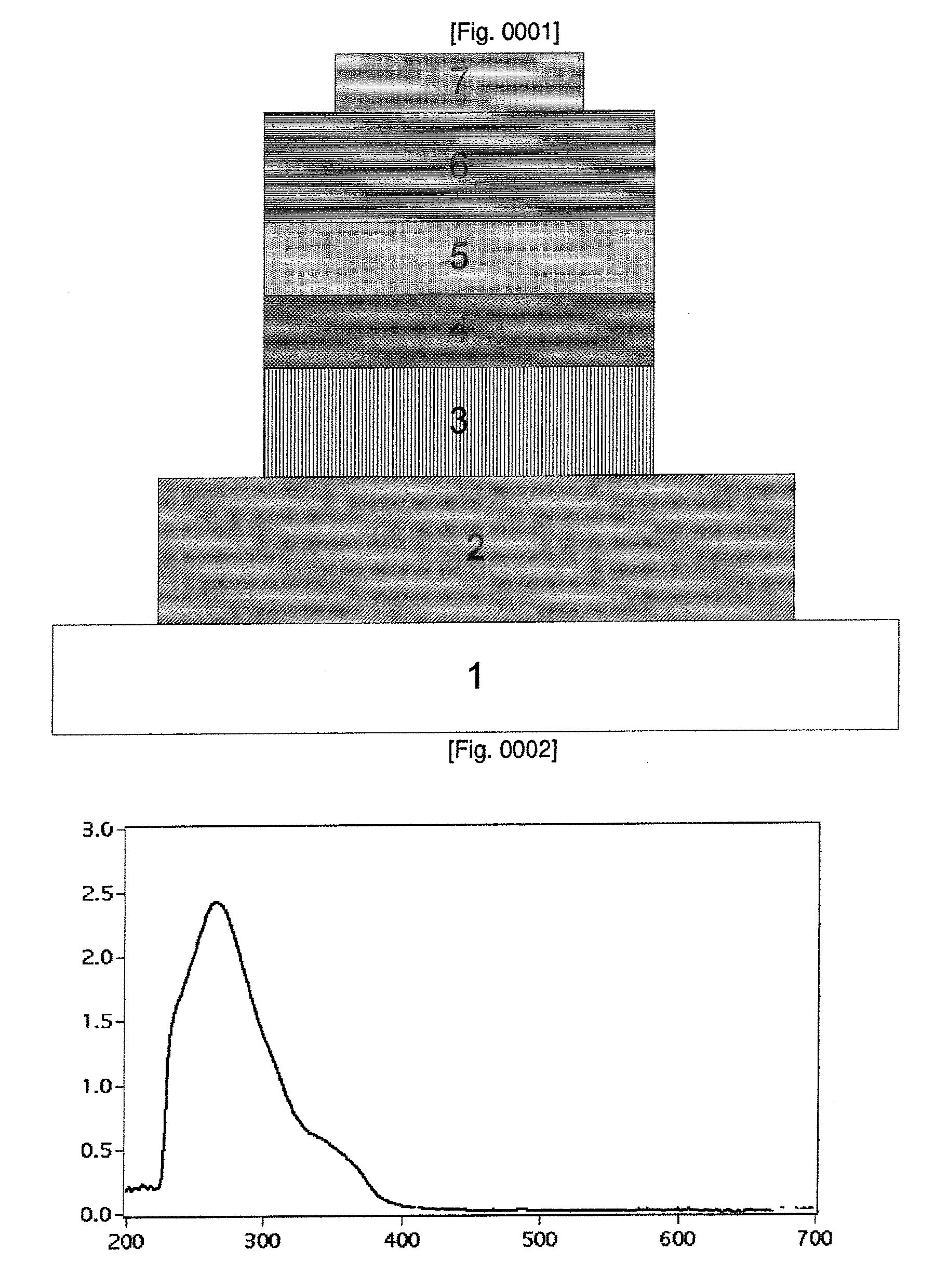

Organometallic complex, and light-emitting element, light-emitting device, electronic device, and lighting device using the organometallic complex

InactiveUS8227975B2Easy to synthesizeIndium organic compoundsDischarge tube luminescnet screensSimple Organic CompoundsMetalation

Owner:SEMICON ENERGY LAB CO LTD

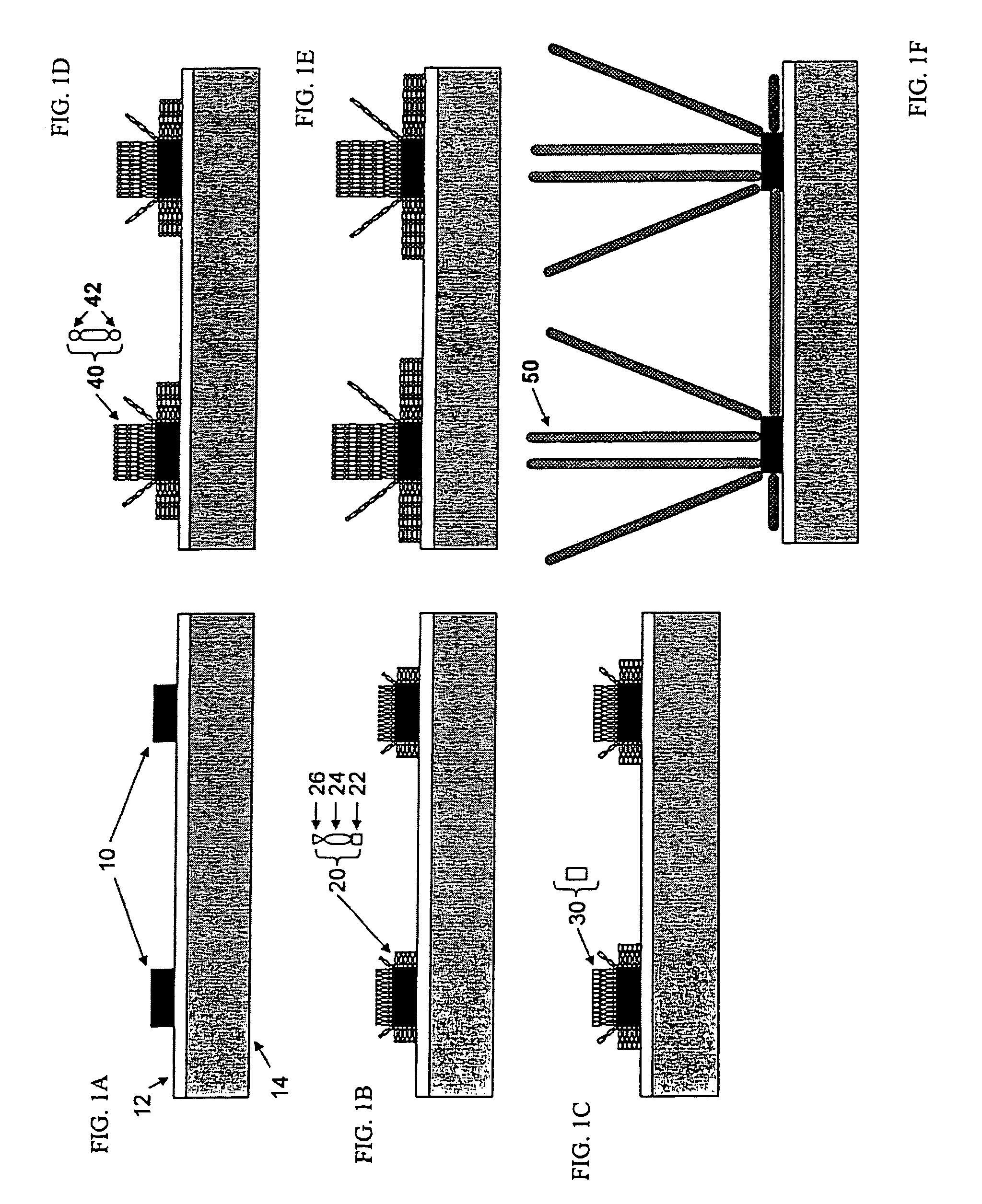

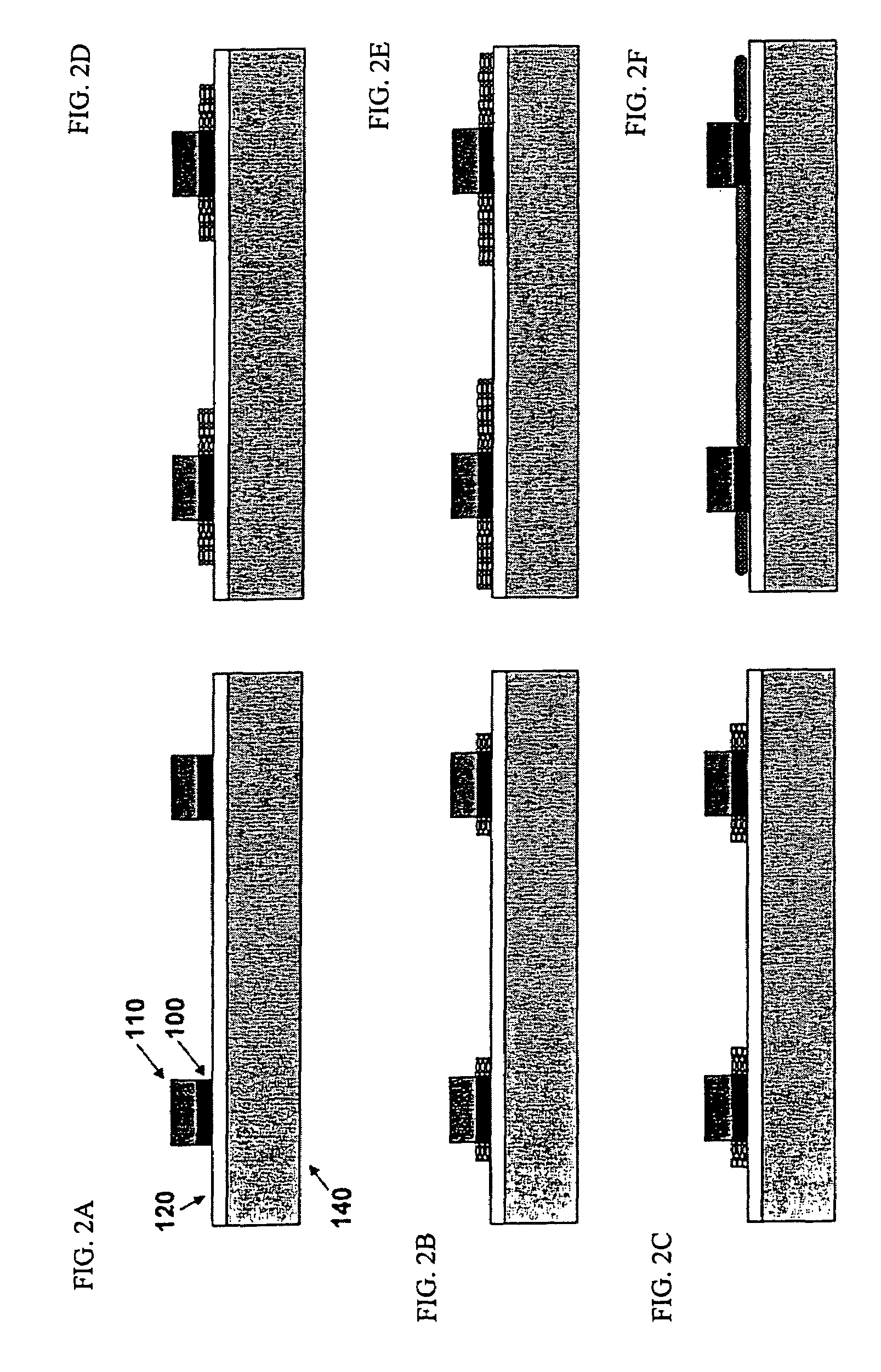

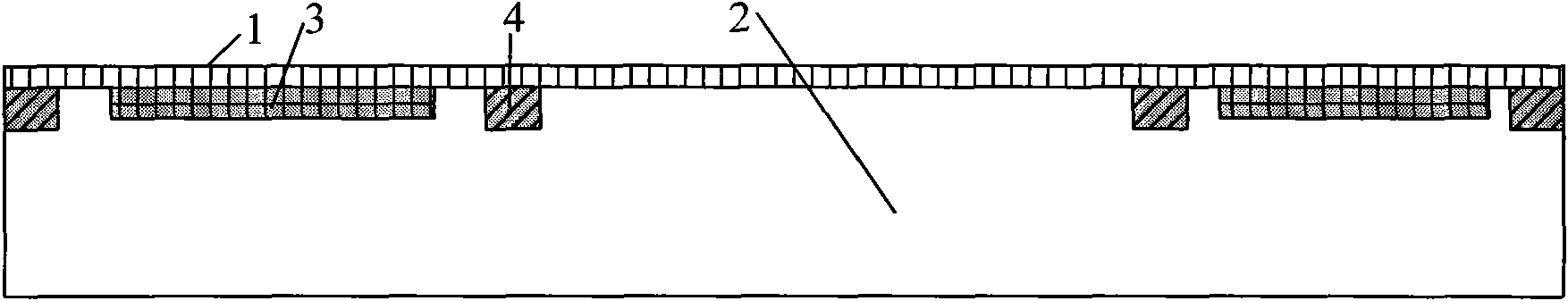

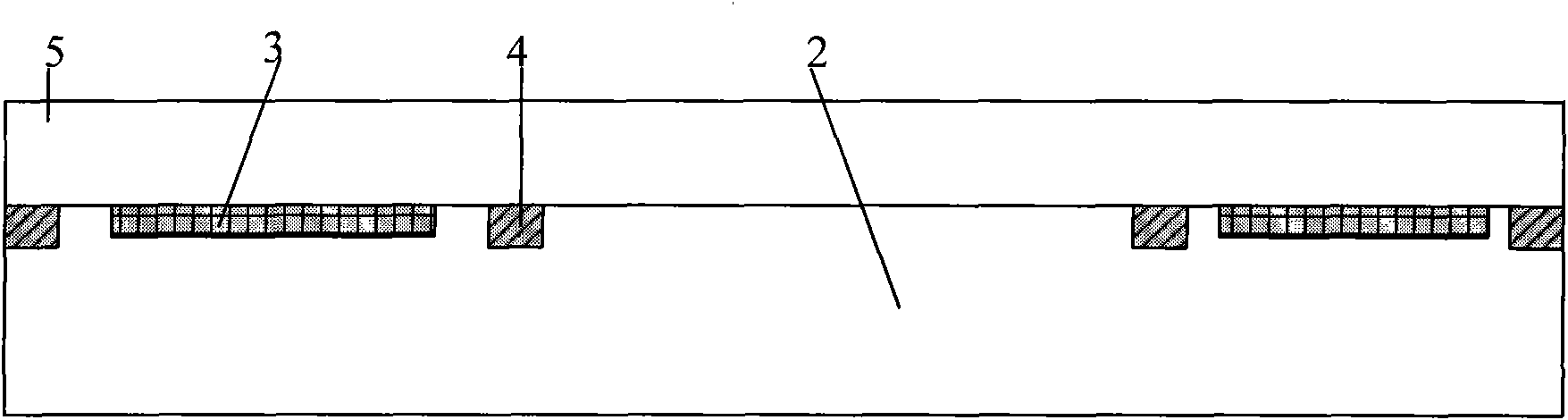

Method for manufacturing monolithic polysilicon cantilever structure

InactiveCN102086019ASolve stickingAchieve monolithic integrationDecorative surface effectsChemical vapor deposition coatingGyroscopeSignal processing circuits

The invention relates to a method for manufacturing a monolithic polysilicon cantilever structure. In the invention, a processing step of the polysilicon cantilever structure is inserted in a conventional BiCMOS (Bipolar Complementary Metal Oxide Semiconductor) technical process, the deposition and the annealing of polysilicon are finished and an MEMS (Micro-Electro-Mechanical Systems) high-temperature process is prevented from influencing on the metalation process before the metalation process. In the release process of the polysilicon cantilever structure, a special etching solution is adopted, and a negative photoresist is used as a post of the polysilicon cantilever structure so as to effectively avoid the problem of substrate adhesion in the cantilever structure release process by using a wet method. The method provided by the invention solves the technical problems of compatibility between a manufacture process of the polysilicon cantilever structure and a processing process of a BiCMOS circuit, realizes the monolithic integration of the polysilicon cantilever structure and a BiCMOS signal processing circuit, and can be widely applied to the monolithic integration manufacture field of MEMS sensors, such as capacitive accelerometers, gyroscopes, and the like.

Owner:NO 24 RES INST OF CETC

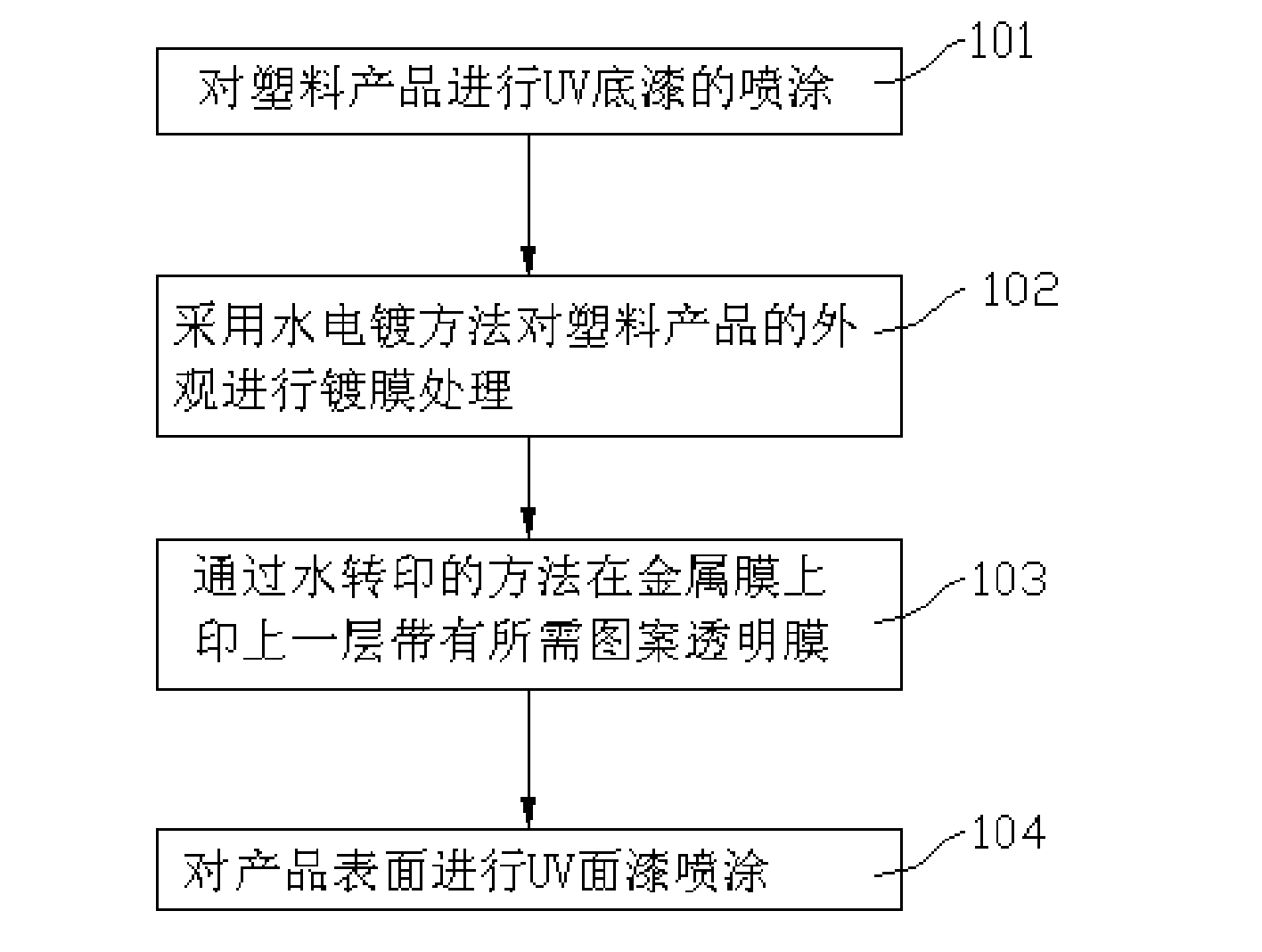

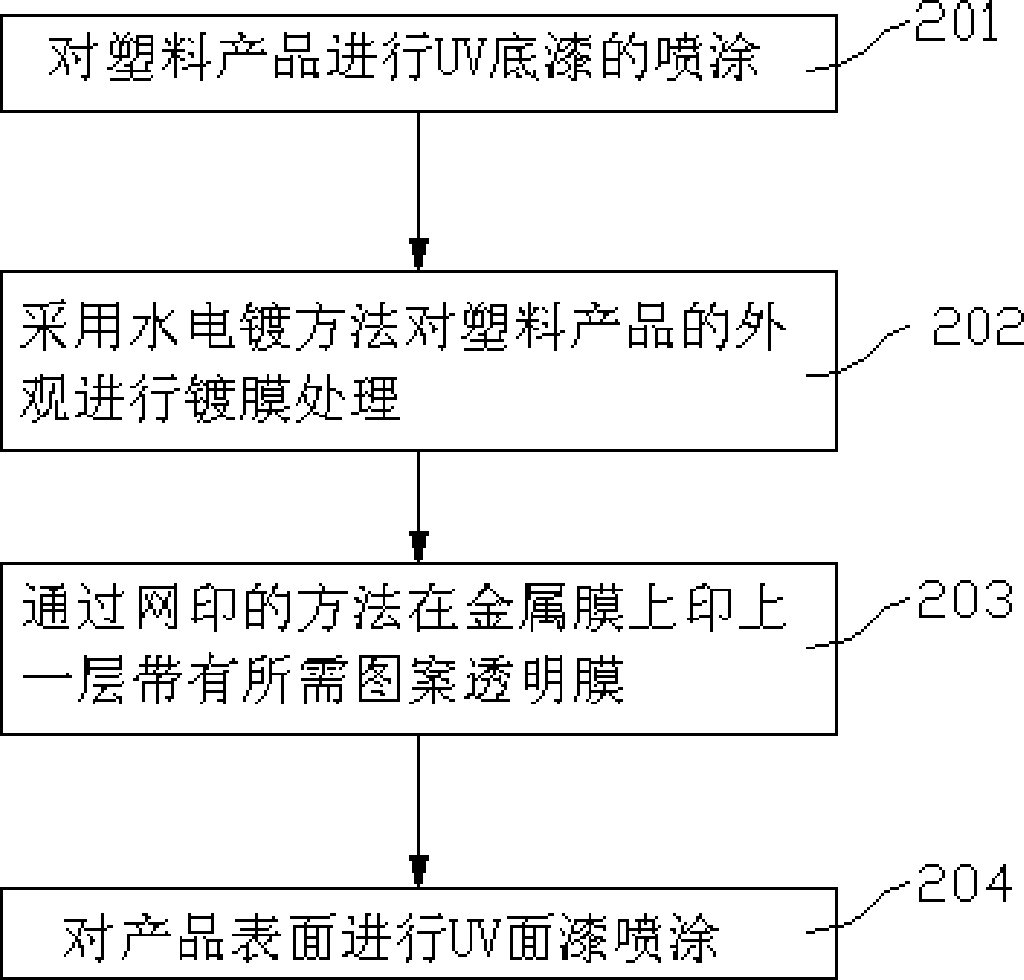

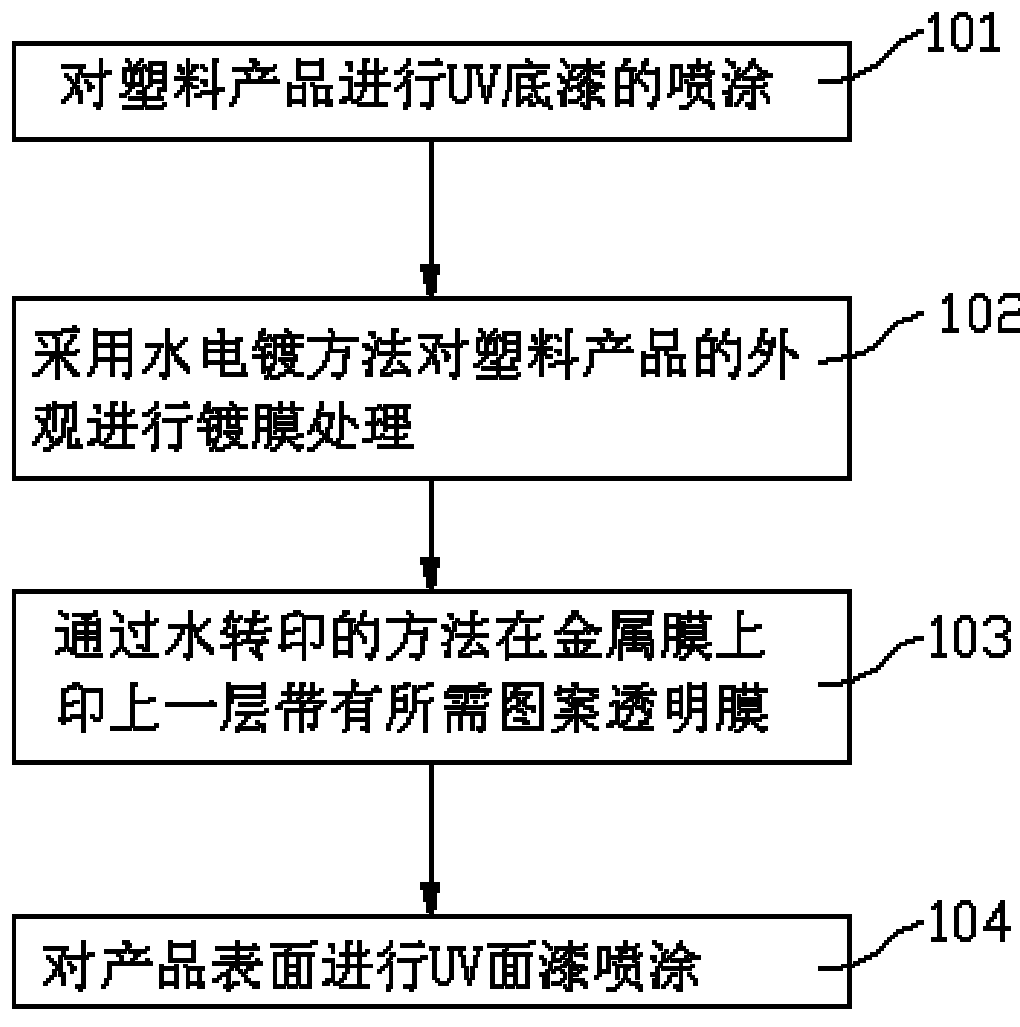

Decoration effect treatment method of plastic outer shell

The invention relates to a decoration effect treatment method of a plastic outer shell. The method comprises the following steps of: spraying UV (Ultra Violet) primer on a plastic product; coating a film on the surface of the plastic product; printing a layer of transparent film with needed patterns on a metal film through a surface treatment technology; and spraying UV primer on the plastic product. The method is combined with the metalation treatment and appearance treatment technologies of a plastic piece so that the brilliant metalline effect and different colors are obtained on the same product and even various brilliant patterns as required are made under the reflection of metalline texture.

Owner:SUZHOU MITAC PRECISION TECH

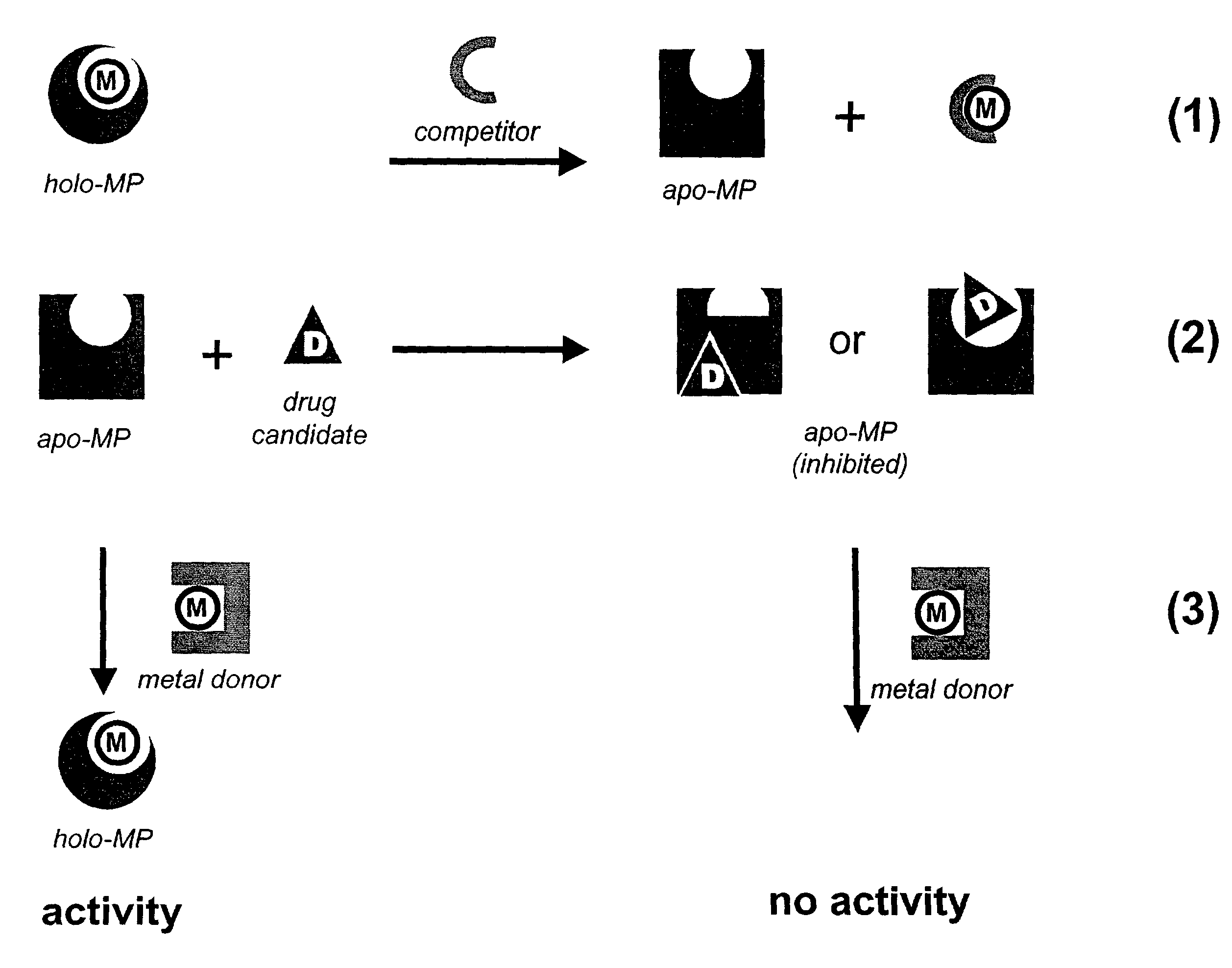

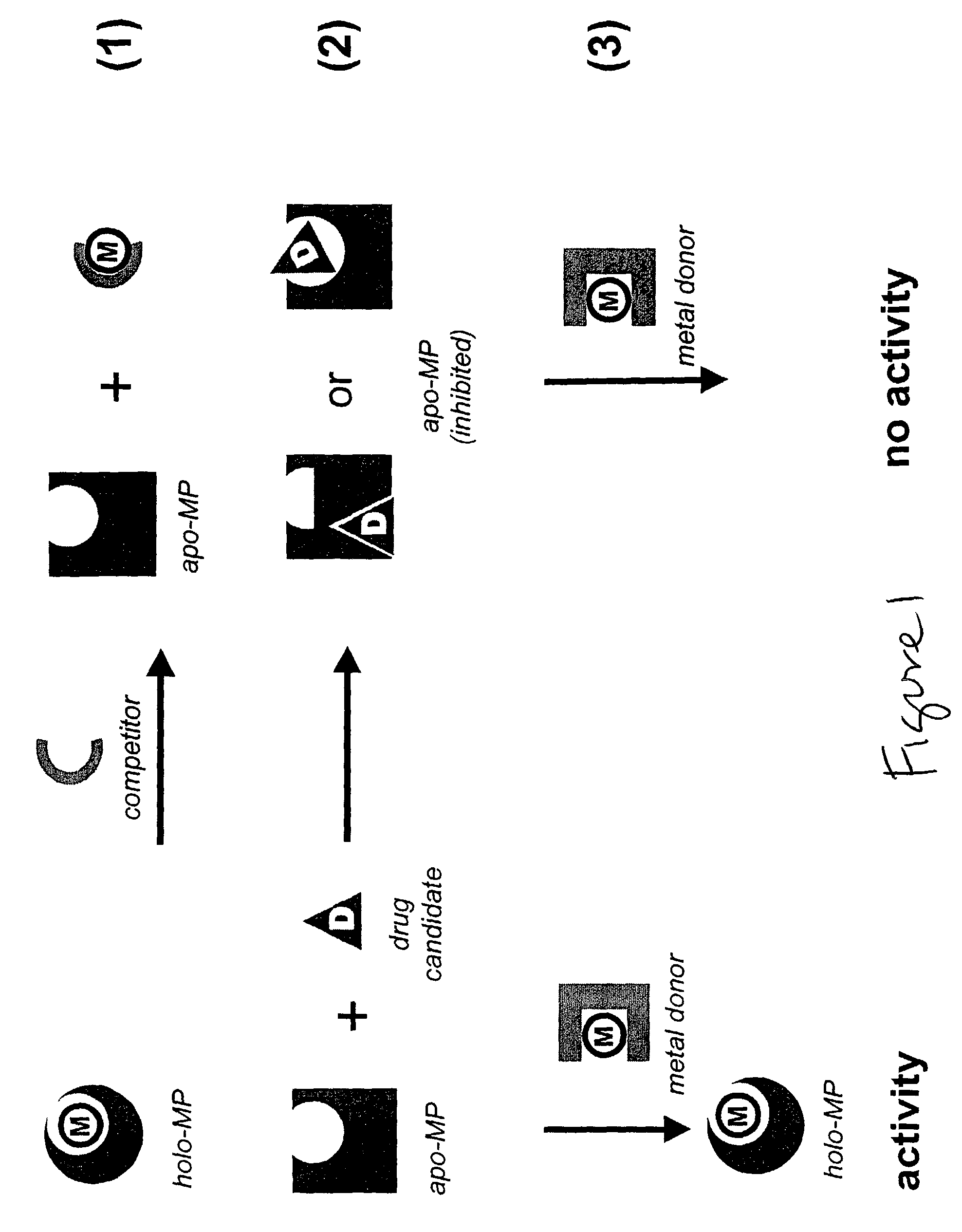

Compositions and Methods of Screening Apoproteins

InactiveUS20080318248A1Reduced form requirementsInhibit biological activityCompound screeningApoptosis detectionApolipoproteins EMetalation

The present invention is directed to compositions and methods of screening apoproteins for the elucidation of modulators of metalation of apoproteins.

Owner:VIAMET PHARMA

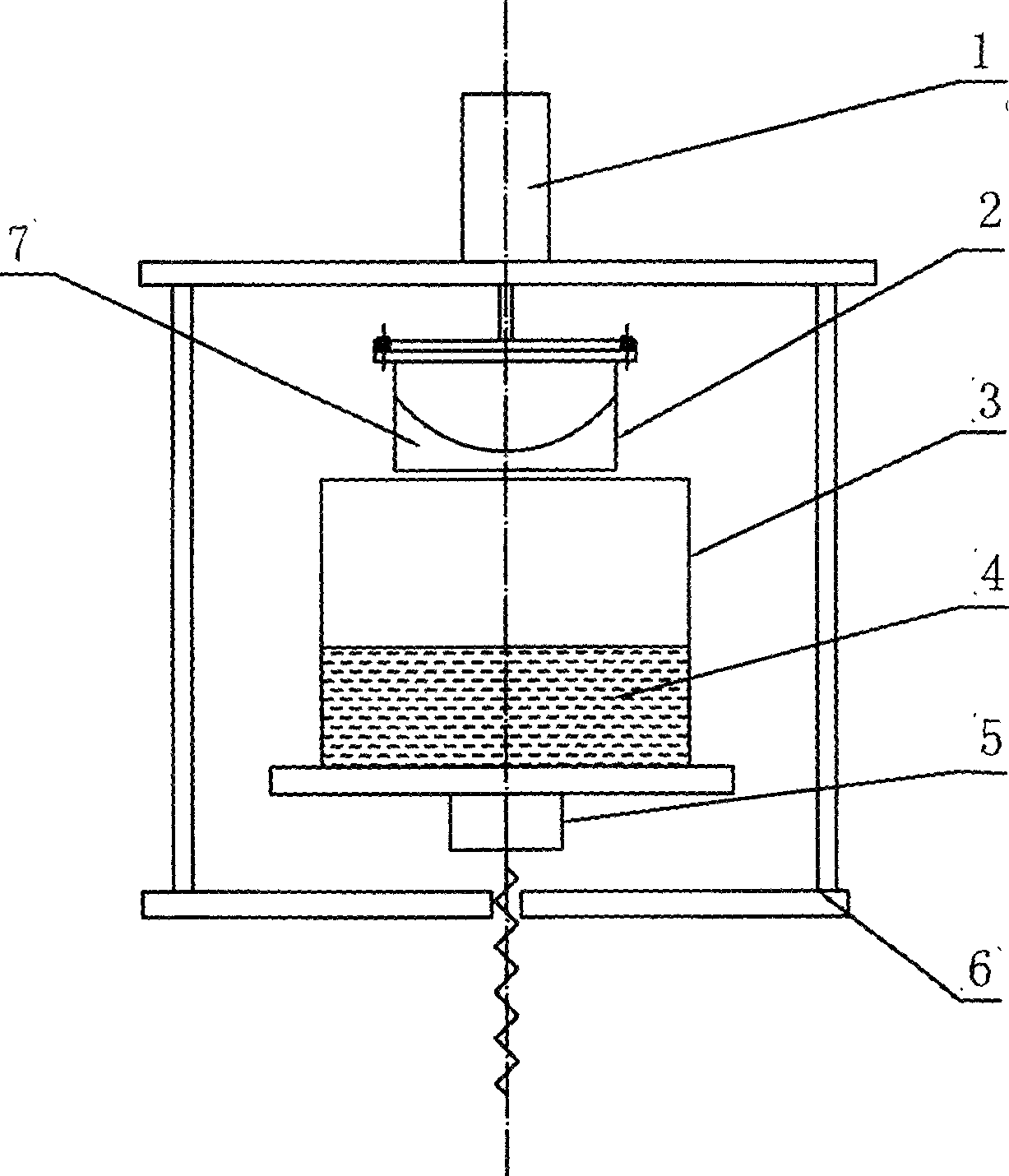

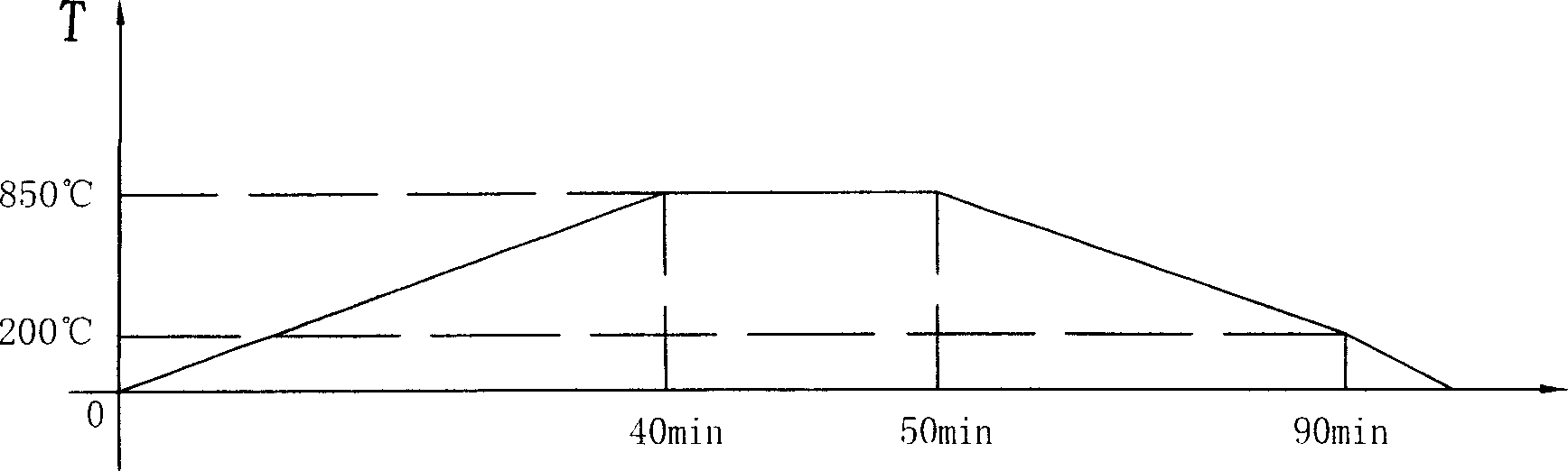

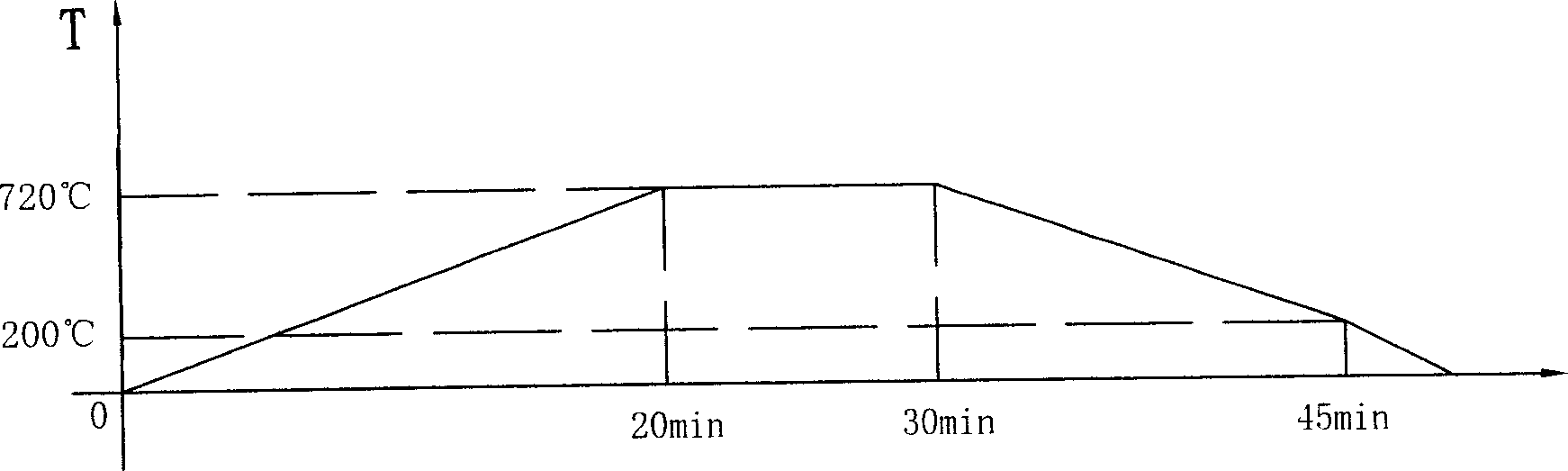

Metalation technology of microwave medium multicavity filter

ActiveCN1718839APromote environmental protectionEliminate pollutionSolid state diffusion coatingTunnel kilnMicrowave

A process for metallizing the internal and external surfaces of multi-cavity microwave medium filter includes such steps as putting the multi-cavity microwave medium ceramic body in a screening mesh, using speed-regulatable motor to drive the screening mesh to rotate in Ag slurry at 2-50 rps for 5-100 S and then at 50-500 rps for 100-200 S, baking at 200-500 deg.C, calcining and solidifying in tunnel kiln, and sintering at 700-900 deg.C.

Owner:严盛喜

Method for preparing full back electrode solar battery

InactiveCN102709386ASimple preparation processSimple processFinal product manufactureSemiconductor devicesSilicon oxideMetalation

The invention relates to the technical field of a solar battery preparation method, and especially relates to a method used for preparing a full back electrode solar battery. The method comprises the following steps: preparing a silicon oxide layer on a silicon slice back, carrying out selectivity sculpture on the back silicon oxide layer, and forming an n+ layer on a naked region which is not protected by the silicon oxide layer through phosphorus diffusion, and subsequently, coating metal aluminum on a region which needs to carry out metalation on the silicon oxide layer and the n+ layer, carrying out laser sintering in an aluminum region on the silicon oxide layer, enabling the aluminium to infiltrate Si so as to form a p+ layer, and forming an ohm touch. The method provided by the invention has the beneficial effects that the preparation flow path of a full back electrode is greatly simplified, the technological process is simple, the silicon layer sculpture is not needed, the silicon material is saved, and the cost of the whole preparation flow is reduced.

Owner:TRINASOLAR CO LTD

Light-emitting material

InactiveUS20090115327A1Good chemical stabilityImprove thermal stabilityRuthenium organic compoundsDischarge tube luminescnet screensHigh energyOrtho position

This invention pertains to light emitting materials comprising novel ortho-metalated transition metal complexes [ĈN]2M(T)(L), comprising chelate dialkylamino-substituted ĈN ligands, monodentate neutral ligand (L) having sp2 hybridized N atom and a monodentate anionic ligand (T) chosen among CN−, CNO−, CNS−. It has been surprisingly found that when the metal has bound thereto in addition to substituted orthometalated ligands, both an anion chosen among cyanide, thiocyanate, cyanate, possessing strong C donor and π acceptor properties, and a monodentate neutral ligand L, as above defined, said ligands advantageously participate in the emission process, significantly shifting emission towards higher energies (blue-shift) and enabling appreciable improvement of the emission efficiency of complexes [ĈN]2M(T)(L).Still objects of the invention are the use of said light emitting materials and organic light emitting device comprising said light emitting material.

Owner:SOLVAY SA

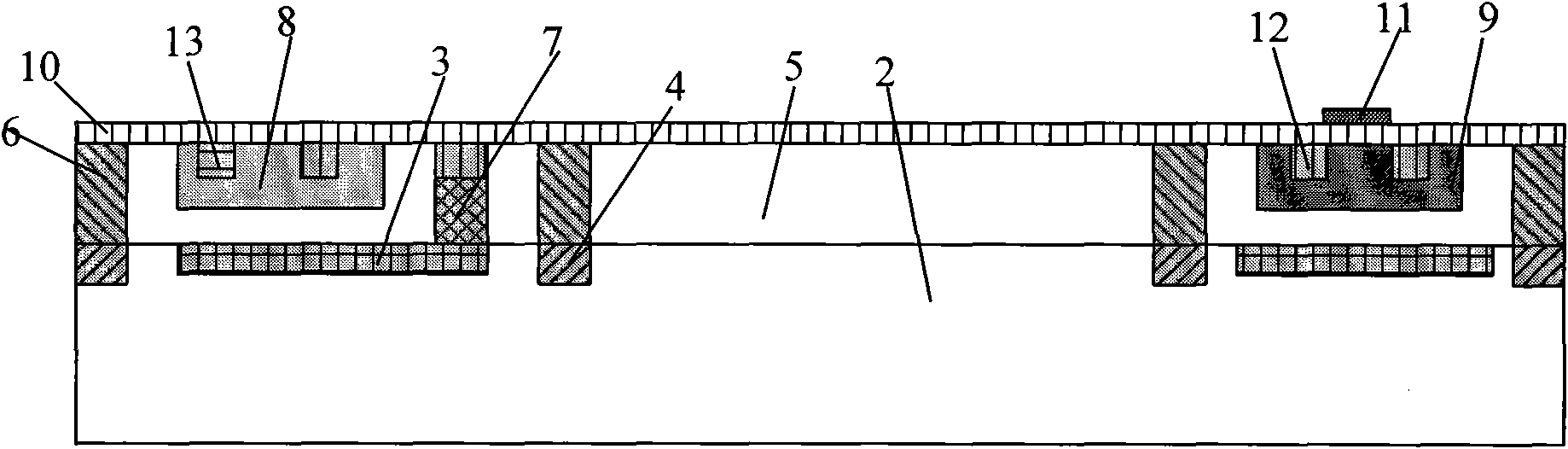

Waveguide micro-strip line converter

The invention provides a waveguide micro-strip line converter which comprises a double-face printing circuit board. Micro-strip lines (1) and a short circuit paster (2) are etched on a pattern on the upper layer of the double-face printing circuit board, a signal window is formed in a metal earth plate (5) arranged on the lower layer of the double-face printing circuit board, T-shaped gaps are formed in the rectangular side of the short circuit paster, the two micro-strip lines symmetrically stretch into a short circuit metal face through the T-shaped gaps in the two sides of the short circuit paster to form two micro-strip line ports, a dielectric substrate (3) with a metal via hole (4) is arranged between the upper layer pattern and the lower layer pattern, the metalation via hole formed between the upper layer pattern and the lower layer pattern of the double face printing circuit surrounds the edge of the signal window to form a ring-shaped gap opening ring, the ring-shaped gap opening ring, and the short circuit paster and an incentive oscillator (7) jointly form a rectangular metal cavity which is formed over a rectangular waveguide (8) and equivalent to a cavity filled with media, so that a load terminal of the rectangular waveguide is formed, and the load terminal and the two micro-strip line ports form the three-port converter. According to the converter, the problem that when an existing double-port waveguide micro-strip line converter forms a micro-strip array antenna, the loss is large is solved.

Owner:10TH RES INST OF CETC

Preparation method of cyclohexyl fluorine-containing cyanophenyl derivative liquid crystalline monomer

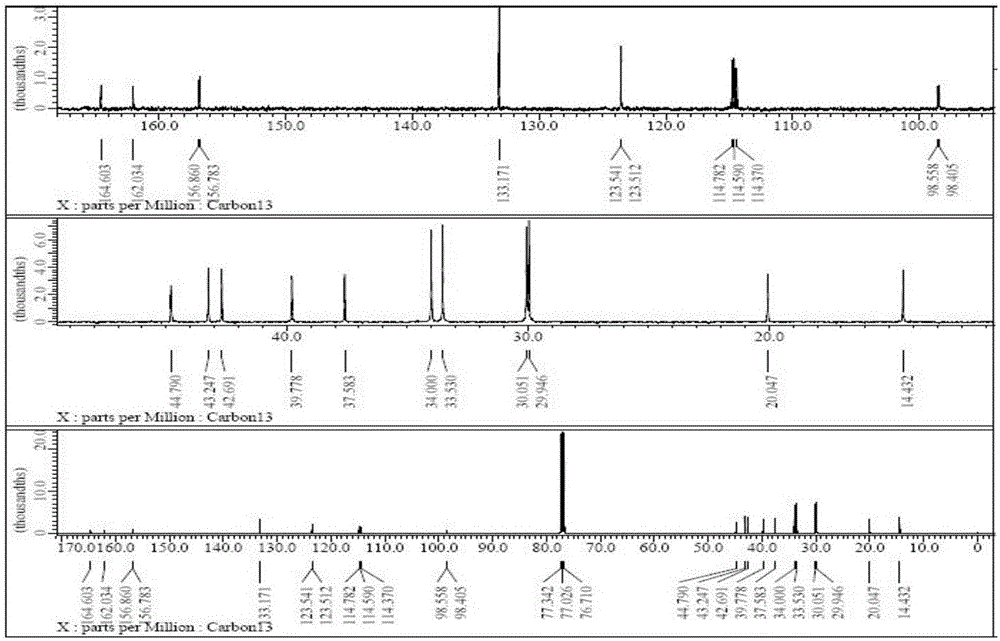

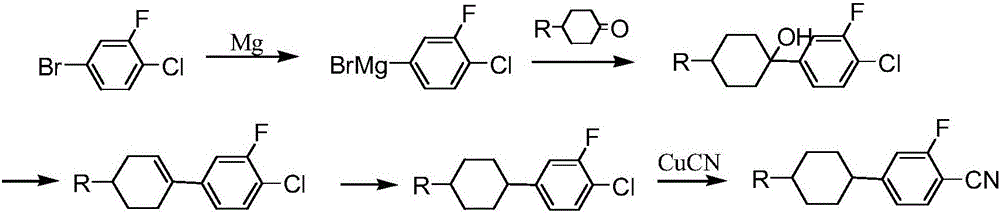

ActiveCN106316881AReduce operating costsShort reaction pathLiquid crystal compositionsCarboxylic acid nitrile preparationLiquid crystallineLiquid-crystal display

The invention discloses a preparation method of a cyclohexyl fluorine-containing cyanophenyl derivative liquid crystalline monomer, belonging to the technical field of liquid crystal display. The structural general formula of the liquid crystalline monomer is as shown in the description, wherein R1 represents C1-C5 linear chain alkyl, n is equal to 0 or 1, X and Y represent F or H atom, and at least one of X and Y represents the F atom. The preparation method comprises the steps of carrying out metallization reaction and cyclohexyl ketone compound reaction on the raw material, namely 2,6-difluoro-4-bromoxynil or 2-fluoro-4-bromoxynil, and carrying out dehydration and hydrogenation, so as to obtain the liquid crystalline monomer. The preparation method has the beneficial effects that the process route is simple, reaction conditions are mild, and the production cost is lowered; and the preparation method is beneficial to large-scale production and has a very good application prospect.

Owner:VALIANT CO LTD

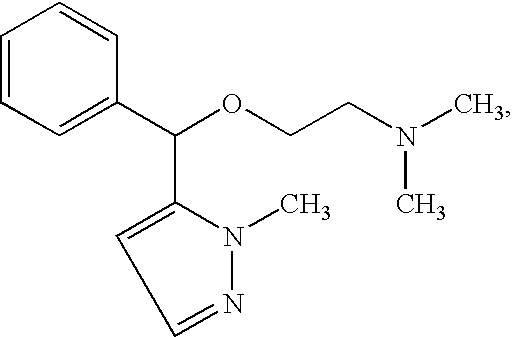

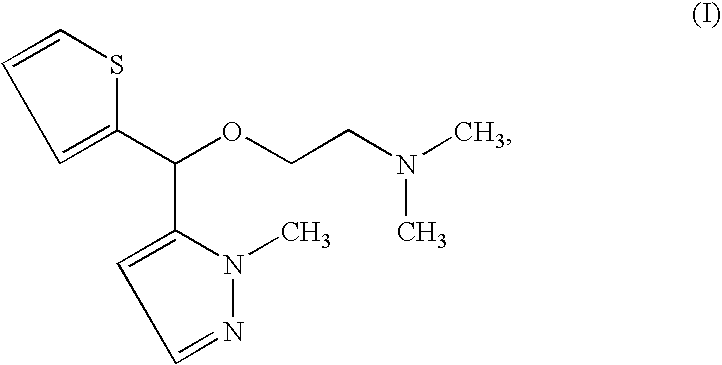

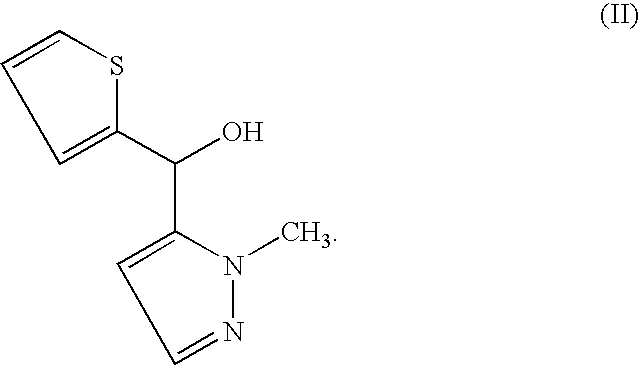

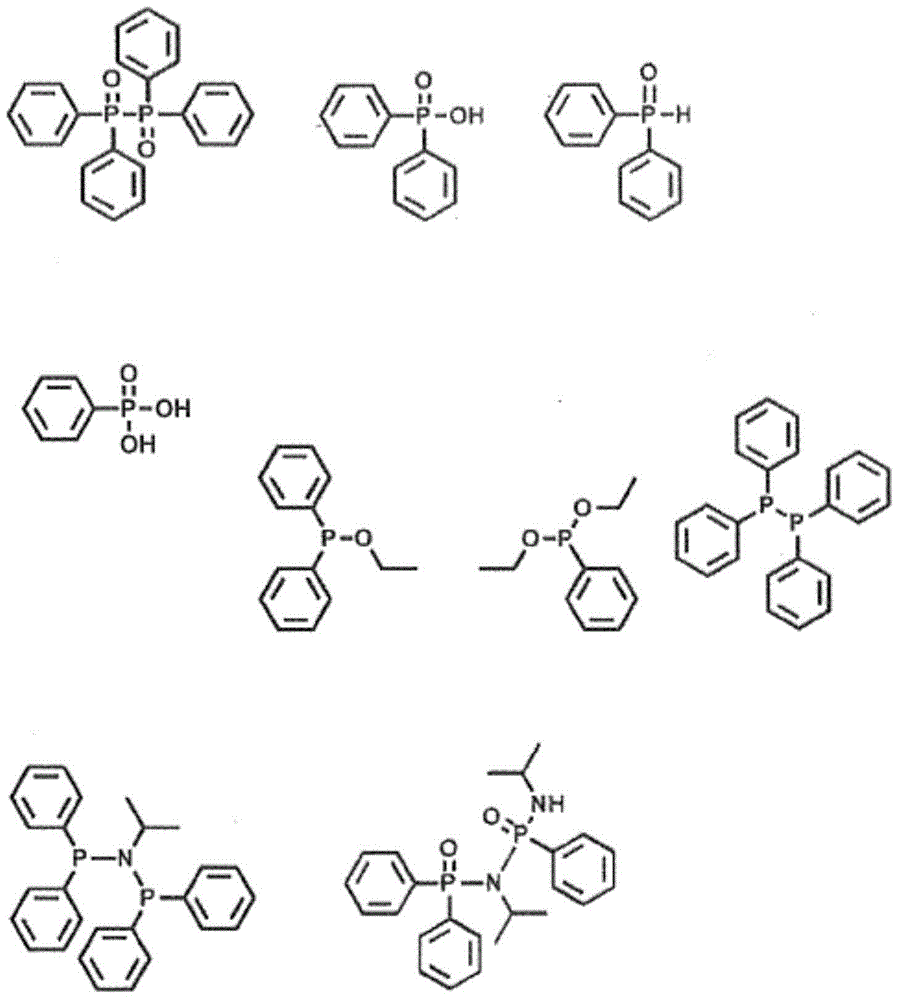

Process for obtaining enantiomers of thienylazolylalcoxyethanamines

InactiveUS7078531B2Speed up the conversion processAvoid problemsOrganic chemistryAlcoholEnantiomer

A process is described for the preparation of a precursor alcohol of (±)-2-[thienyl(1-methyl-1H-pyrazol-5-yl)methoxy]-N,N-dimethyletanamine and in general for thienylazolylalcoxyethanamines and their enantiomers. The process involves asymmetric addition of a metalated thienyl reagent to a pyrazolcarbaldehyde in the presence of a chiral ligand to yield chiral alcohols. The chiral alcohols are further O-alkylated to yield the corresponding pharmaceutically active thienylazolylalcoxyethanamines.

Owner:LAB DEL DR ESTEVE SA

Polymer composite metalation process

InactiveCN106521463AImprove bindingEasy to handleLiquid/solution decomposition chemical coatingChemical treatmentChemical plating

The invention discloses a polymer composite metalation process. The surface of a polymer composite component is polished; then, wax removal and oil removal treatment are carried out; after being cleaned by deionized water for several times, the component is placed in an activating solution to be activated; after being cleaned by the deionized water for several times, the component is subject to chemical plating treatment. Combination force of a chemical nickel plating layer obtained through the technology and a base body is good, through polishing, wax removal, oil removal and activating, chemical plating is directly carried out, processes of roughening, palladium activation and the like are not included, the flow process is simple, waste water is convenient to treat, heavy metal and cost are greatly saved, and multiple polymer composites can be treated.

Owner:XIAMEN RUNNER IND CORP

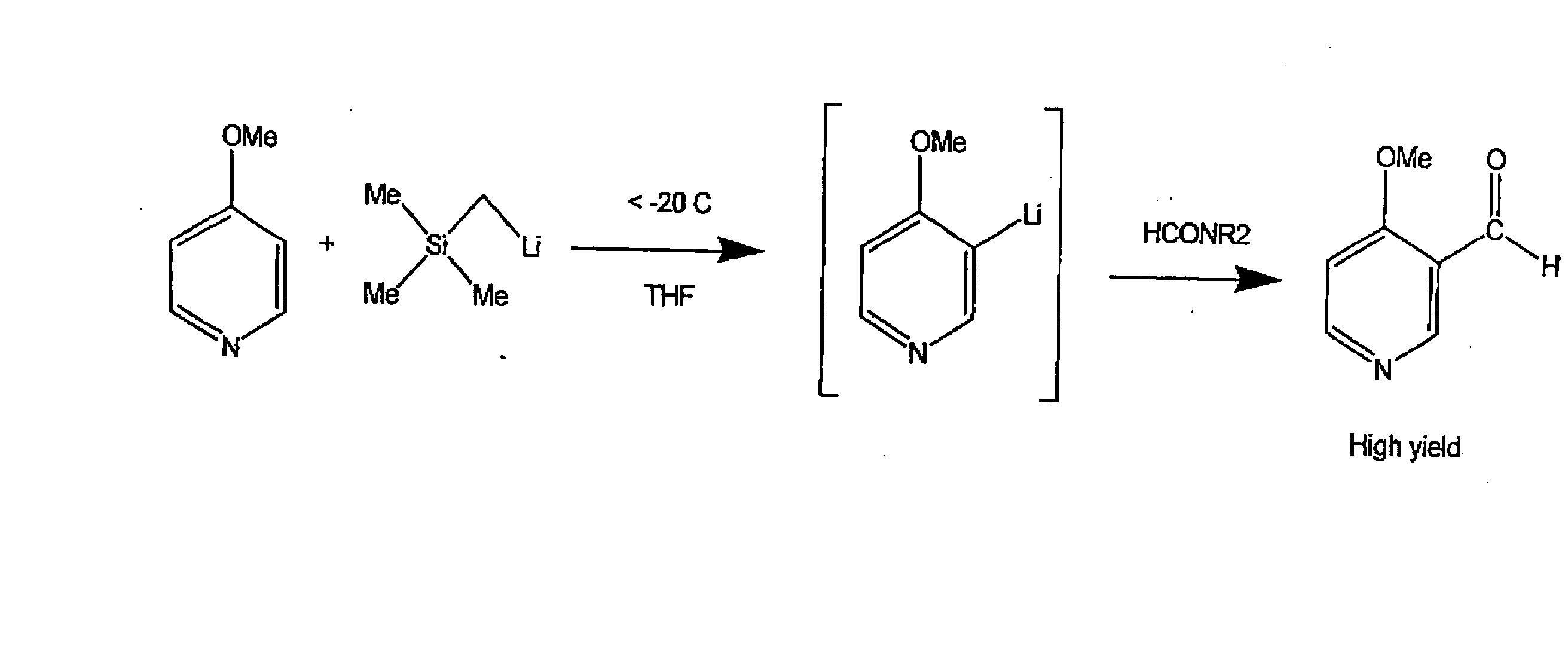

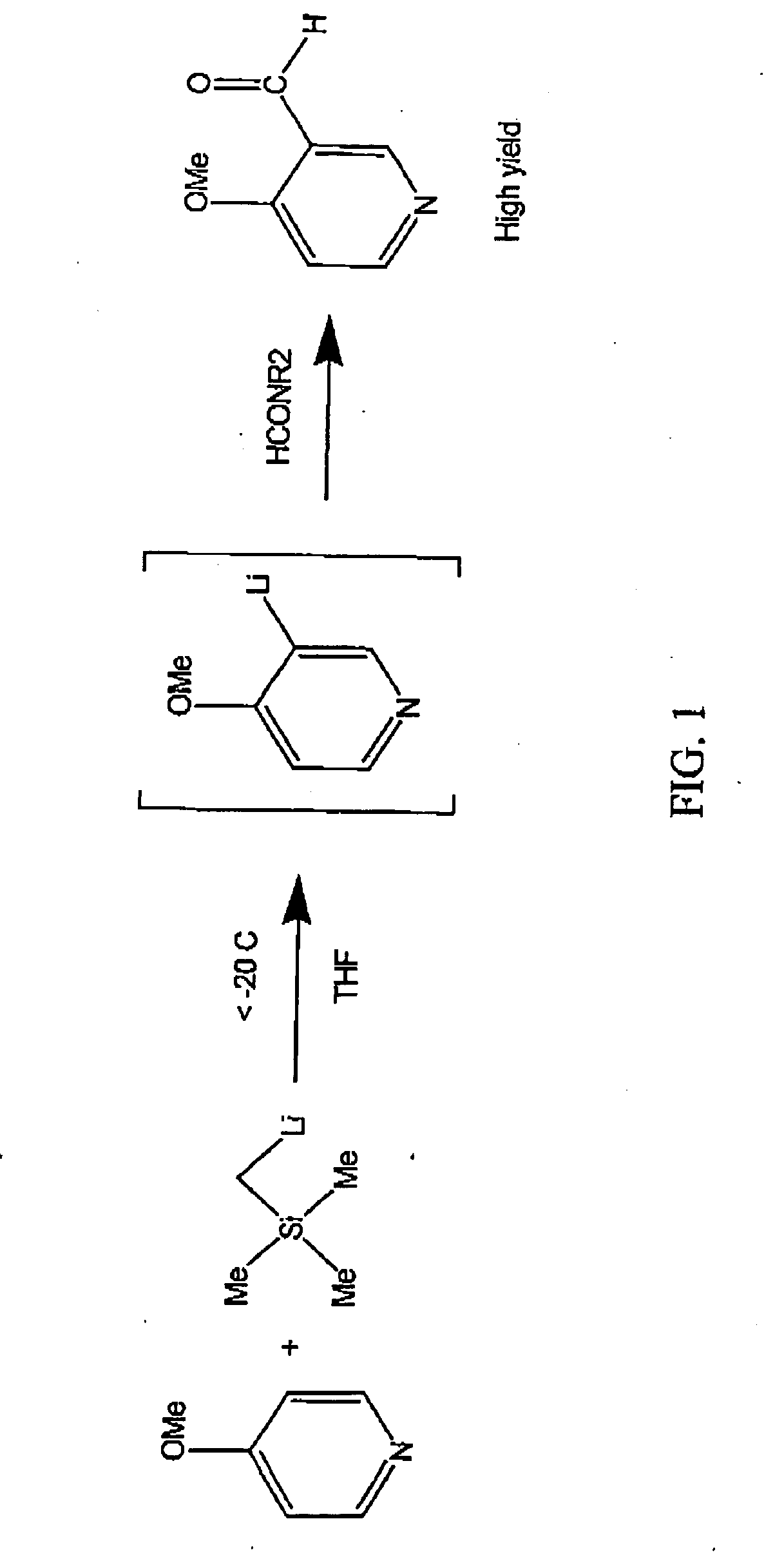

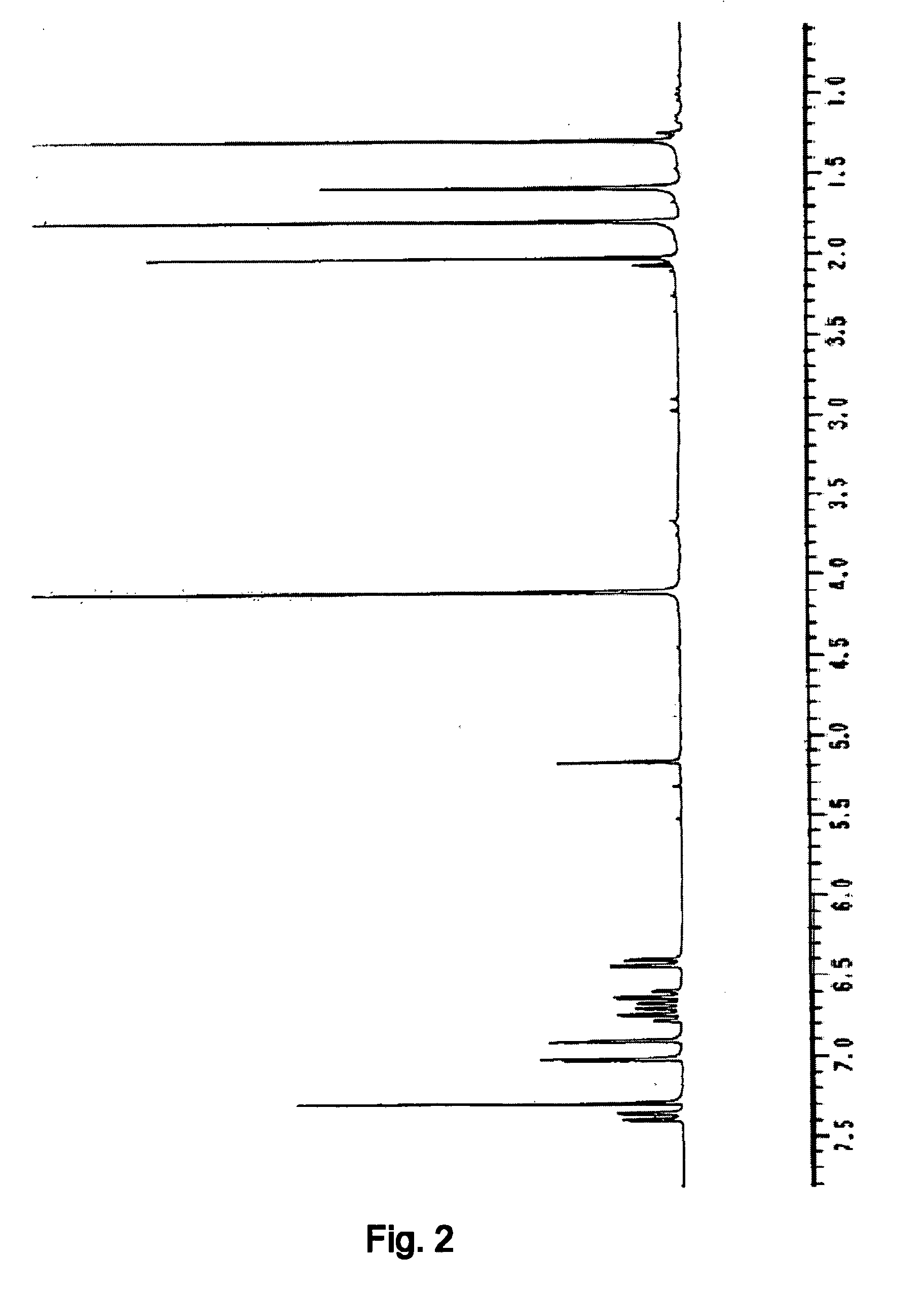

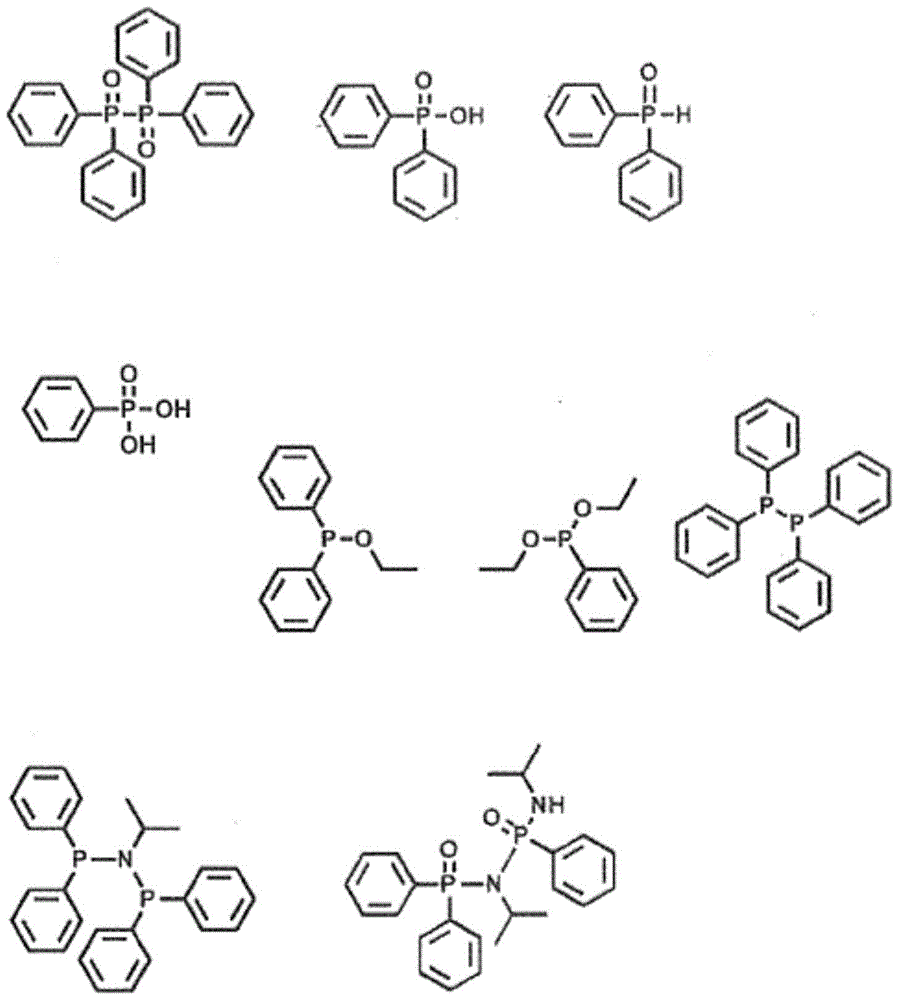

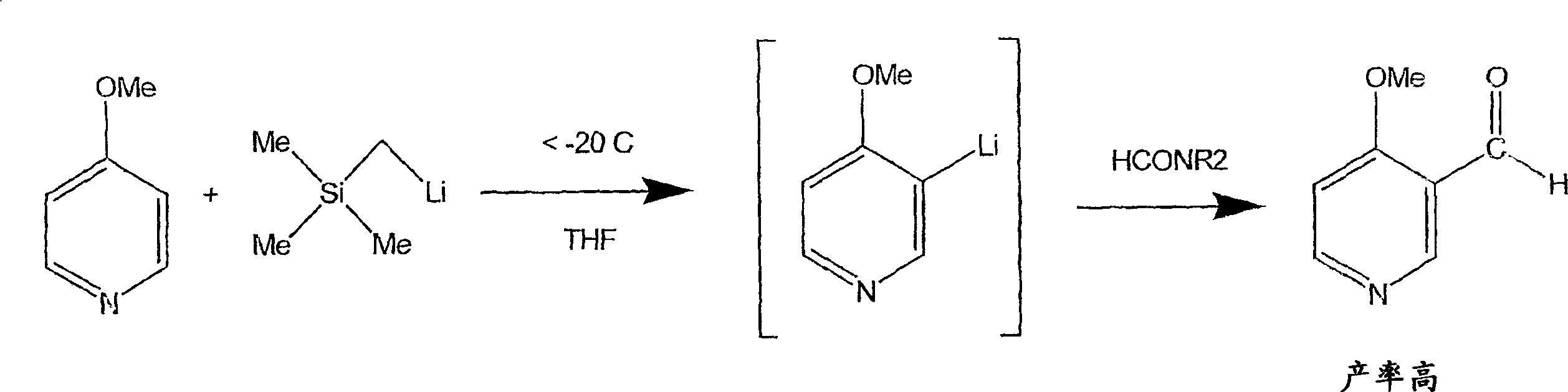

Using alkylmetal reagents for directed metalation of azaaromatics

InactiveUS20070249838A1Improve stabilityImprove solubilityGroup 4/14 element organic compoundsLithium organic compoundsTrimethylsilylCombinatorial chemistry

Substituted alkylmetal reagents such as (trimethylsilylmethyl)lithium are reacted with pyridinic compounds to produce functionalized pyridinic compounds.

Owner:FMC CORP

Light-emitting material

InactiveUS20100102711A1Accelerate emissionsImprovement of white emission efficiencyDischarge tube luminescnet screensGroup 8/9/10/18 element organic compoundsOrtho positionOrganic light emitting device

This invention pertains to light emitting materials comprising novel ortho-metalated transition metal complexes [ĈN]2ML comprising two orthometalated ligands having imidazole moieties and an ancillary ligand of β-diketonate type.It has been surprisingly found that when the metal has bound thereto both ortho-metalated ligands comprising imidazole moieties and an ancillary ligand of β-diketonate type, said ligands advantageously participate in the emission process, significantly broadening emission in the visible region and enabling appreciable improvement of the white emission efficiency of complexes [ĈN]2ML.Still objects of the invention are the use of said light emitting materials and organic light emitting device comprising said light emitting material.

Owner:SOLVAY SA

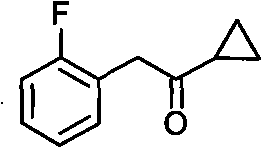

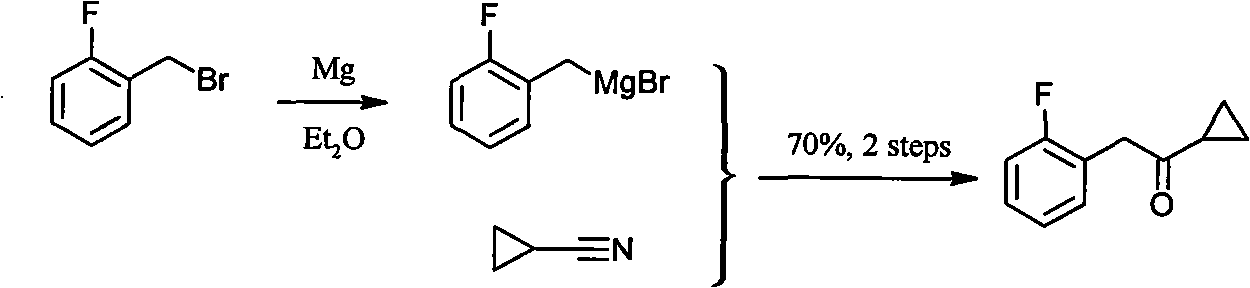

Method for preparing cyclopropyl o-fluobenzyl ketone

ActiveCN102040498AHigh metallization yieldImprove securityCarbonyl compound preparation by condensationCuprateKetone

The invention relates to a method for preparing cyclopropyl o-fluobenzyl ketone. The method comprises the following steps of: (1) carrying out metalized treatment on o-fluo benzyl halide by using tetrahydrofuran or methyl tetrahydrofuran as a reaction medium to obtain a metal reagent of the o-fluo benzyl halide, wherein the metal is the combination of Zn, or Zn / LiCl; and (2) reacting the obtained metalized reagent of the o-fluo benzyl halide with cyclopropyl formyl chloride to generate cyclopropyl o-fluobenzyl ketone, wherein the reaction also can be carried out in the presence of transition metal ions, and the reagent of the transition metal ions is palladium acetate or palladium chloride or triphenyl phosphine palladium or anhydrous nickel chloride or triphenyl nickel chloride phosphine or ferric trichloride or acetyl acetone iron or copper chloride or cuprous chloride or lithium cuprate tetrachloride. In the metalized method, the tetrahydrofuran or the methyl tetrahydrofuran is used as the reaction medium, thus the method has higher yield and better safety compared with a traditional method; and cyclopropyl formyl chloride which has low price and is easy to obtain is used as a raw material to react with the metalized o-fluo benzyl halide, thus the cost is greatly reduced.

Owner:ZHEJIANG HUABANG MEDICAL & CHEM

Organometallic Complex, and Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device Using the Organometallic Complex

ActiveUS20120280220A1Easy to synthesizeIndium organic compoundsElectroluminescent light sourcesSimple Organic CompoundsMetalation

To provide a novel organometallic complex capable of emitting phosphorescence by using an organic compound with which a variety of derivatives can be easily synthesized as a ligand. In addition, to provide an organometallic complex which exhibits red emission. To provide an organometallic complex formed by ortho-metalation of an m-alkoxyphenyl pyrazine derivative represented by General Formula (G0) below with respect to an ion of a metal belonging to Group 9 or Group 10. In addition, to provide an organometallic complex which exhibits red emission formed by ortho-metalation of an m-alkoxyphenyl pyrazine derivative represented by General Formula (G0) below with respect to an ion of a metal belonging to Group 9 or Group 10.

Owner:SEMICON ENERGY LAB CO LTD

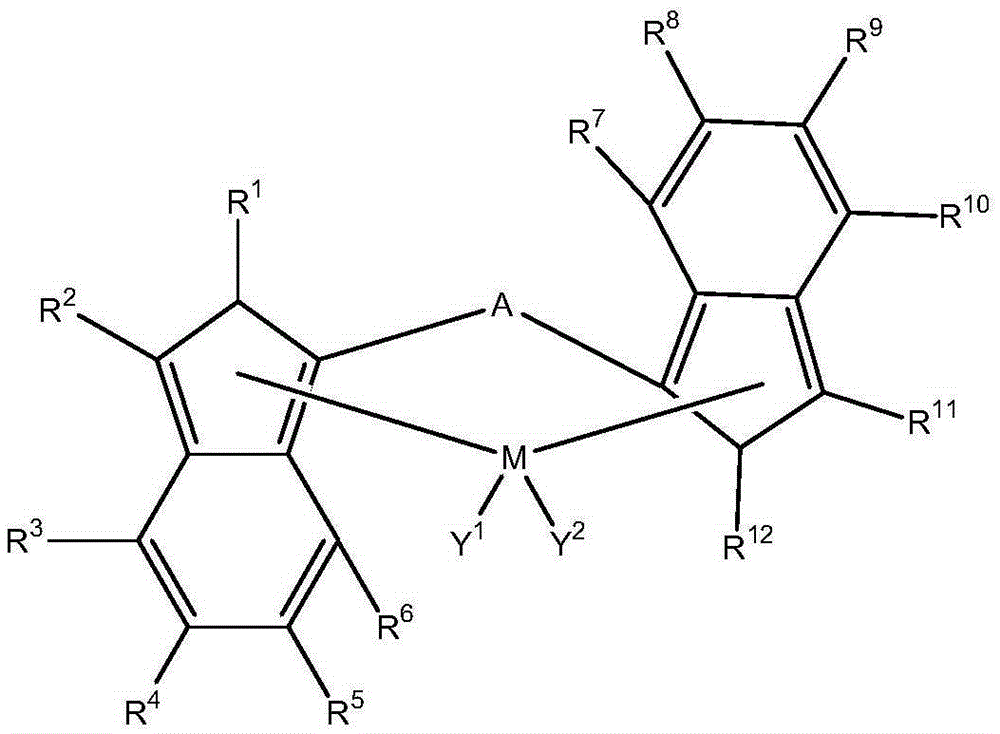

Racemo selective metallation process

This invention relates to racemic bridged bis(indenyl)metallocene transition metal compounds, rac-directing metallation reagents and a process to produce the racemic bridged bis(indenyl)metallocene transition metal compounds using the rac-directing metallation regents.

Owner:EXXONMOBIL CHEM PAT INC

Formulation for the etching of polymer materials prior to coating of the materials

ActiveUS10501852B2Pretreated surfacesLiquid/solution decomposition chemical coatingEtchingMetalation

Owner:AVANZARE INNOVACION TECHCA

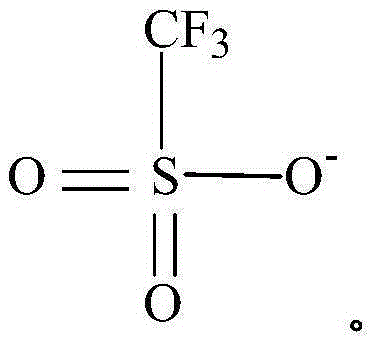

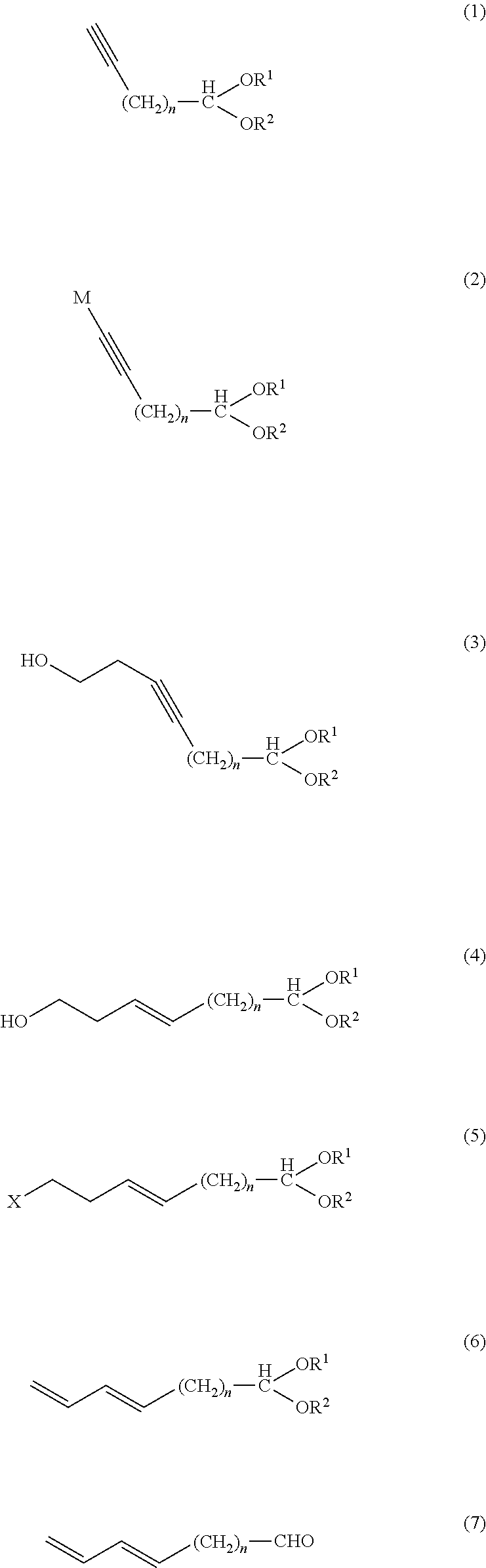

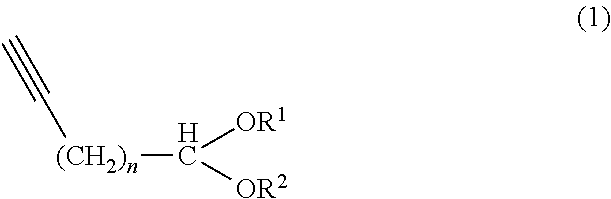

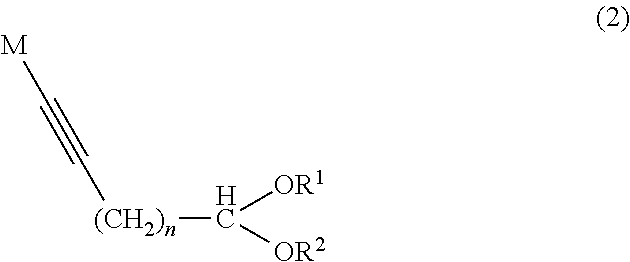

Method of producing aliphatic aldehyde compound having terminal conjugated diene structure and intermediate therefor

ActiveUS20170297987A1High purityHigh yieldOrganic compound preparationSulfonic acid esters preparationLeaving groupEthylene oxide

Provided are a method for producing a terminal conjugated dienal compound without an oxidation reaction and a terminal hydroxyacetal compound useful as an intermediate in the method. More specifically, provided are a method for producing an (E)-dienal compound comprising the steps of: a metalation reaction of an alkynal acetal compound (1) to obtain an organic metal compound (2), an addition reaction of (2) to ethylene oxide to obtain a hydroxyalkynal acetal compound (3), a reduction reaction of (3) to obtain an (E)-hydroxyalkenal acetal compound (4), a functional group conversion reaction of (4) to obtain an (E)-alkenal acetal compound (5) having a leaving group X, an elimination reaction of (5) to obtain an (E)-dienal acetal compound (6), and a hydrolysis reaction of (6) to obtain the (E)-dienal compound (7); and others.

Owner:SHIN ETSU CHEM IND CO LTD

Manufacture method of metal micro-nano structure for improving Raman scattering of molecule

InactiveCN101799420BSolve the key technical problems of low concentration detectionRaman scatteringMicro nanoInternal memory

The invention relates to a metal micro-nano structure for improving Raman scattering of molecule, which comprises the following steps: (1) estimating limitation of internal memory capacity of a computer; (2) determining parameters such as mesh partition, peripheral medium environment conditions and exciting light condition, and primarily determining initial parameters of the metal micro-nano structure; (3) calculating scattering property Qsca of the metal micro-nano structure; (4) calculating plasma resonant frequency gamma LSPR for simulating the metal micro-nano structure and comparing the plasma resonant frequency gamma LSPR with the system exciting light frequency gamma ex, if the plasma resonant frequency is basically equal to the system exciting light frequency, the next step is entered, and if the plasma resonant frequency is not equal to the system exciting light frequency, the parameters of the peripheral medium environment condition of the metal micro-nano structure is changed; (5) calculating Raman reinforcing factor of the metal micro-nano structure; (6) preparing the micro-nano structure through the parameters of the metal micro-nano structure obtained in the step (4); (7) and realizing the metalation of the micro-nano structure. The metal micro-nano structure can maximally strengthen the Raman scattering of the molecule to be tested, can realize the low-concentration detection, and is simple and practical.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

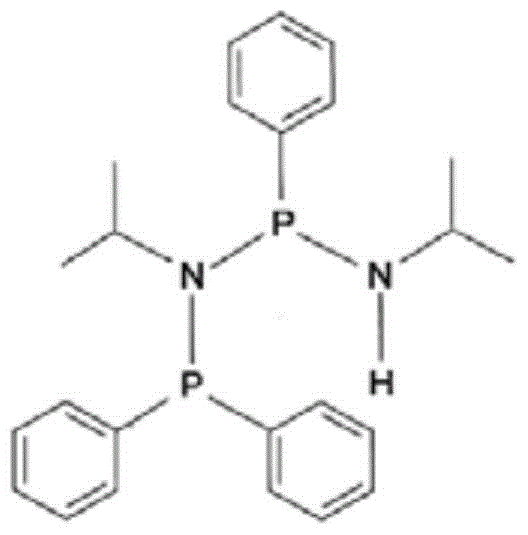

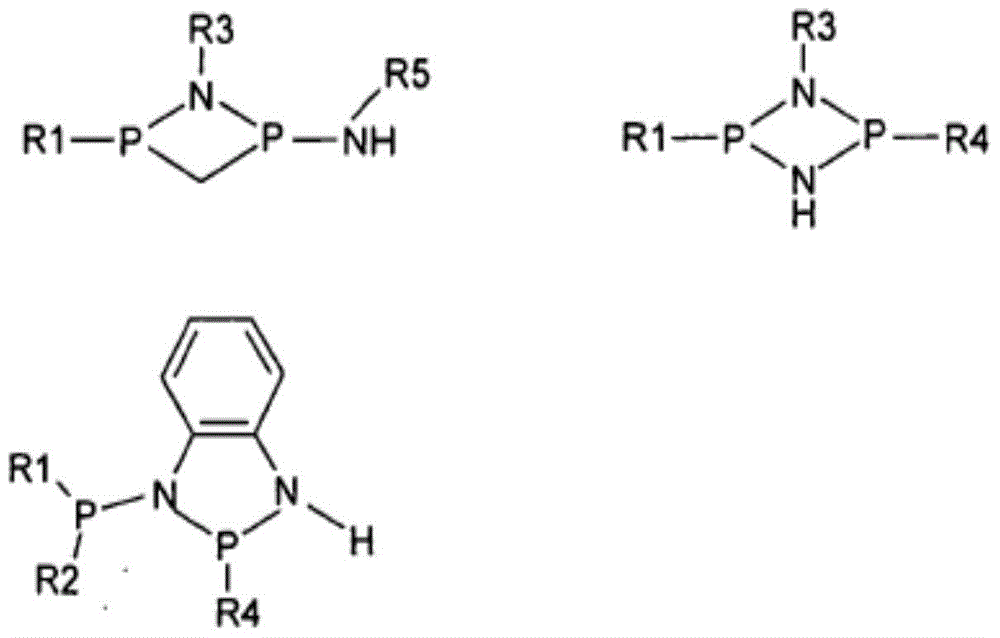

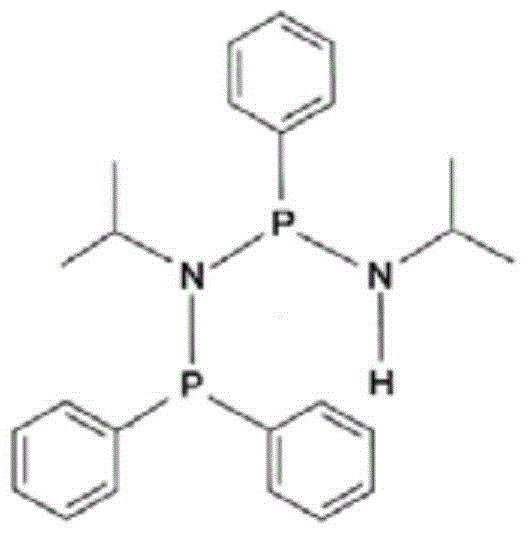

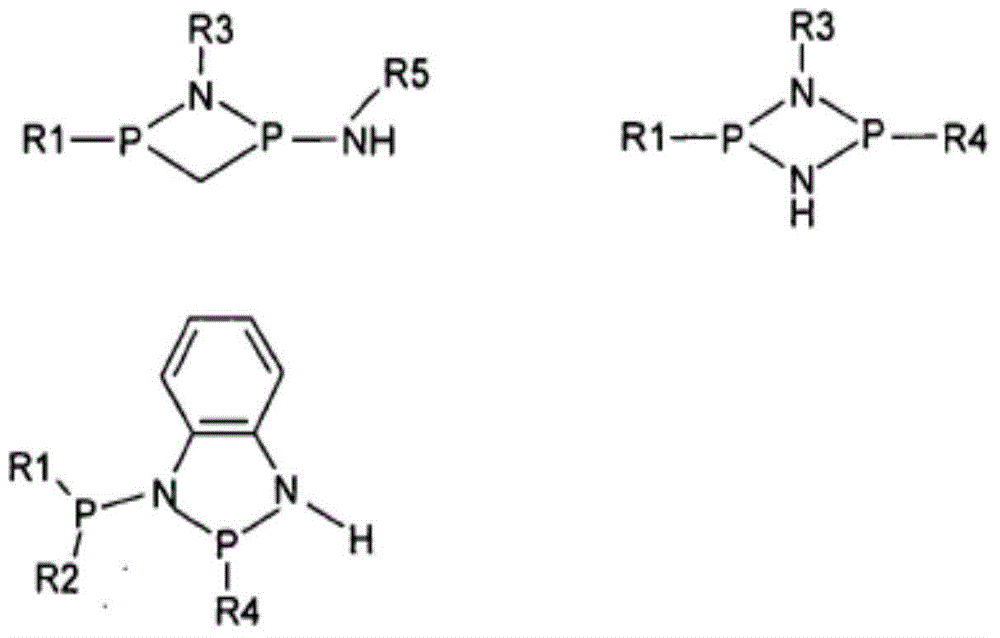

Method for purifying crude pnpnh compounds

InactiveCN104981292BGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsProtonationMetalation

The present invention relates to a process for the purification of crude PNPNH compounds by metalation and reprotonation.

Owner:SAUDI BASIC IND CORP SA +1

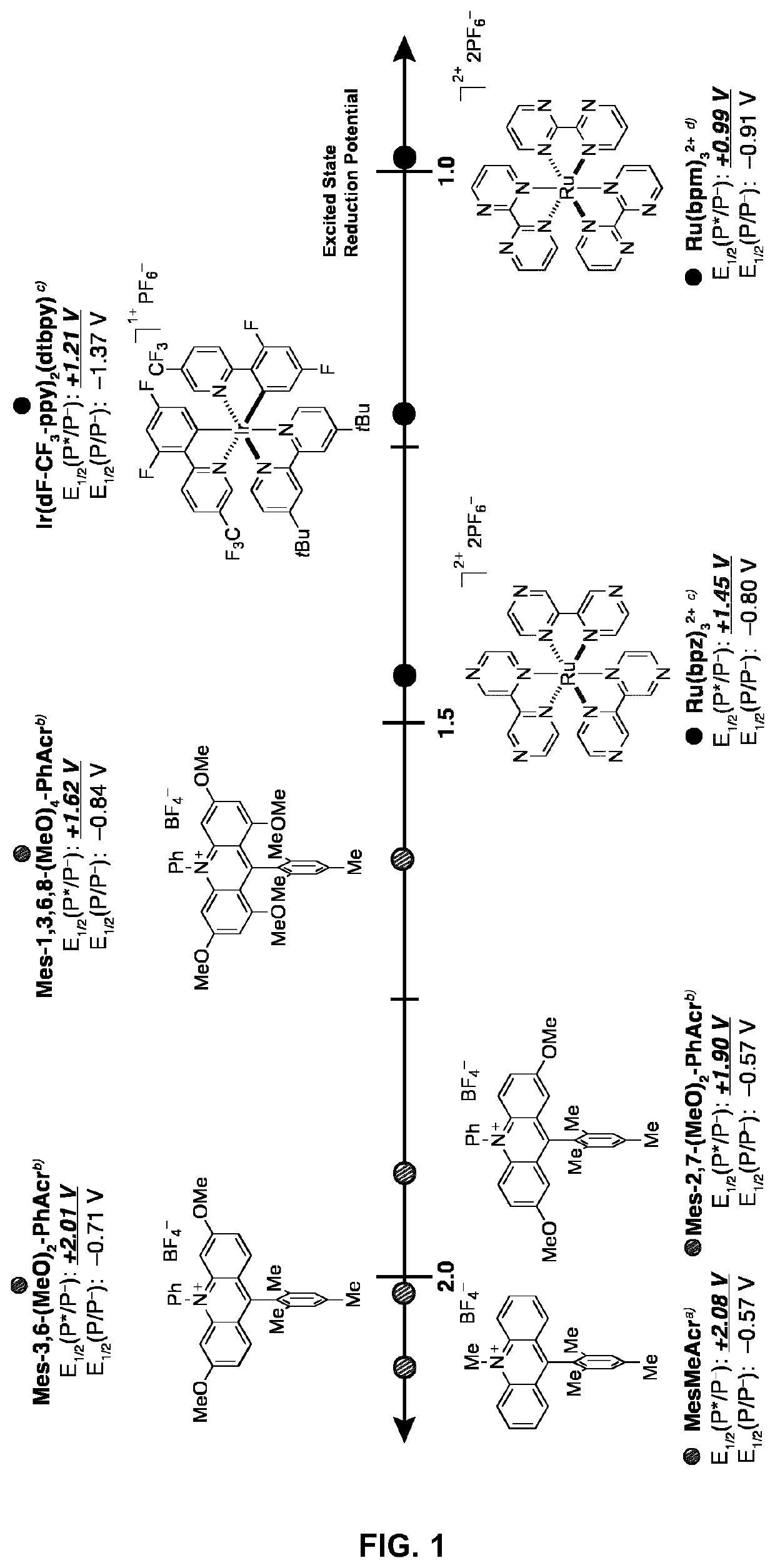

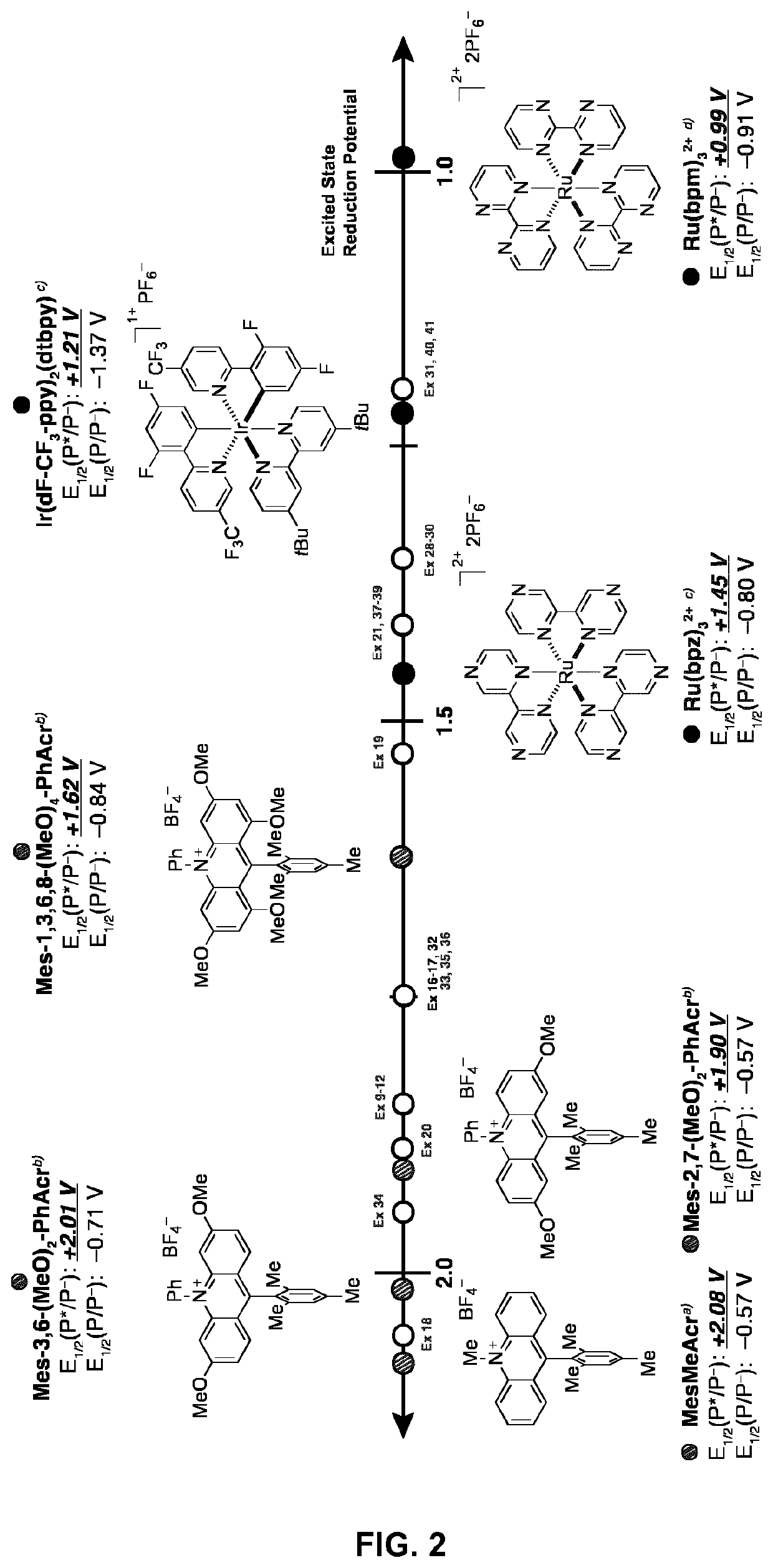

Small-molecule organic dyes

ActiveUS11214687B2Doubling the redox windowEfficient photocatalytic propertiesOrganic chemistryDiaryl/thriaryl methane dyesAcridinePhotosensitizer

The present invention relates to compounds of formula (A), wherein Z is NR10 or O. These compounds represent novel acridinium and xanthylium salts having an unprecedented substituted heterocyclic core. They are useful as fluorescent dyes or precursors thereof in different applications including various imaging and sensing techniques, and, in particular, as photosensitizers and hereby preferably as photocatalysts. The present invention further relates to processes for preparing the inventive compounds via 1,5-organodimetallic reagents from double directed ortho-metalation reactions or combined halogen-metal exchange / directed ortho-metalation reactions.

Owner:UNIVERSITY OF BASEL

Method for purifying a crude pnpnh compound

InactiveCN104981292AOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsProtonationMetalation

The present invention relates to a method for purifying a crude PNPNH compound by metalation and re-protonation.

Owner:SAUDI BASIC IND CORP SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com