Method for manufacturing monolithic polysilicon cantilever structure

A manufacturing method and polysilicon technology are applied in the field of monolithic manufacturing of polysilicon cantilever beam structures and monolithic integrated manufacturing of polysilicon cantilever beam structures and BiCMOS signal processing circuits, which can solve the problems of difficult process realization and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

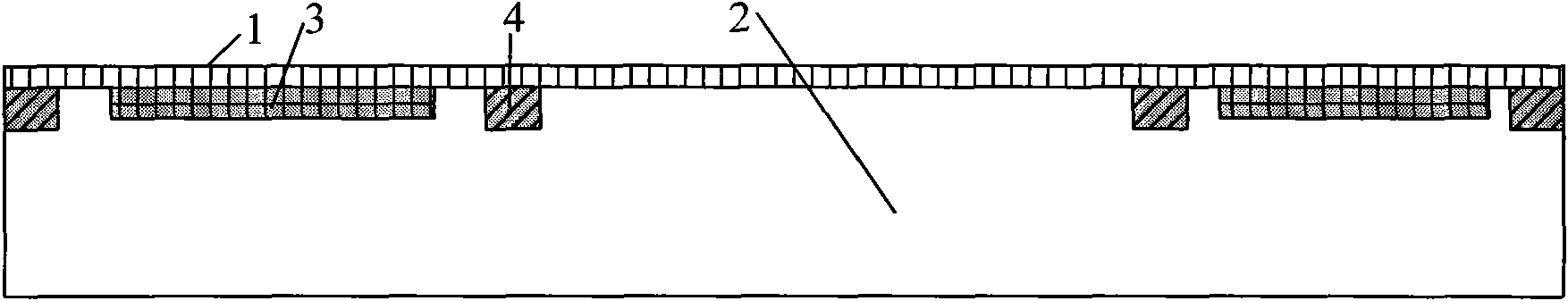

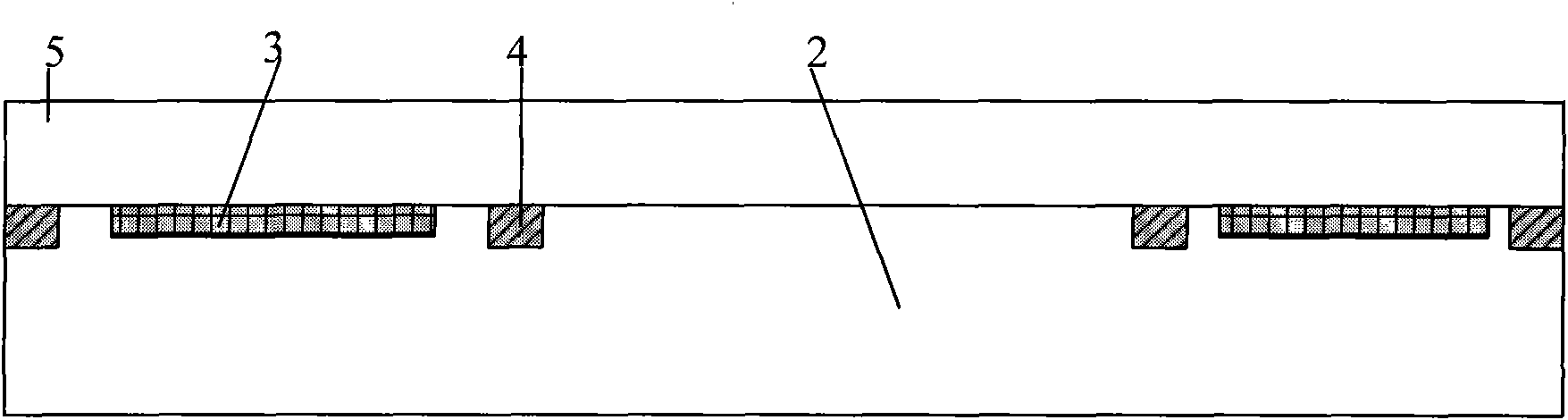

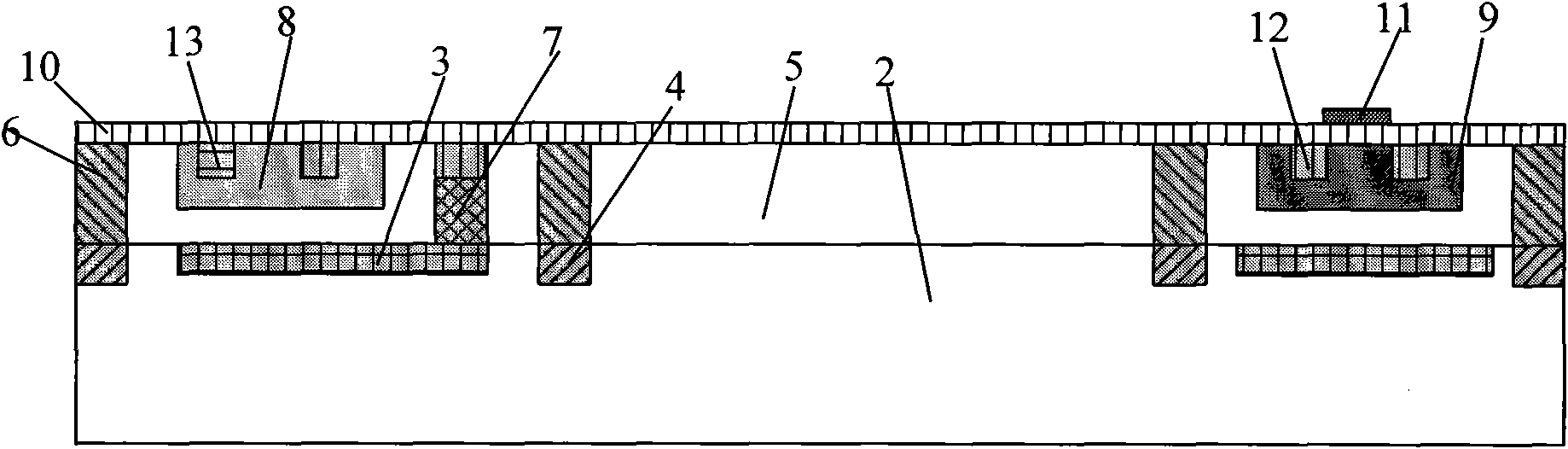

[0116] The specific embodiment of the present invention is not limited to the following description, the present invention is further described in conjunction with the accompanying drawings, wherein the detailed steps of a specific embodiment are as follows:

[0117] 1. On the P-type substrate sheet 2, the steps of making a conventional BiCMOS signal processing circuit are as follows:

[0118](1) Select a P-type silicon substrate 2 with a crystal orientation of , a thickness of 525±20 μm, and a resistivity of 7-13Ω·cm, clean and oxidize, and the thickness of the oxide layer is 0.6±0.05 μm;

[0119] (2) photoetching N+ buried layer region 3;

[0120] (3) Wet etching, removing the oxide layer above the N+ buried layer region 3, and removing the glue;

[0121] (4) cleaning, oxidation, the thickness of oxide layer is 14-18nm;

[0122] (5) photoetching the N+ buried layer region 3;

[0123] (6) Adhesive arsenic injection, dose 3.2E15 / cm 2 , energy 100keV, glue removal;

[0124...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com