Decoration effect treatment method of plastic outer shell

A decorative effect and treatment method technology, applied in the crafts and decorative arts used to produce decorative surface effects, can solve the problems of inability to achieve pattern effects, lack of changes, etc., and achieve the effect of gorgeous metallic texture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

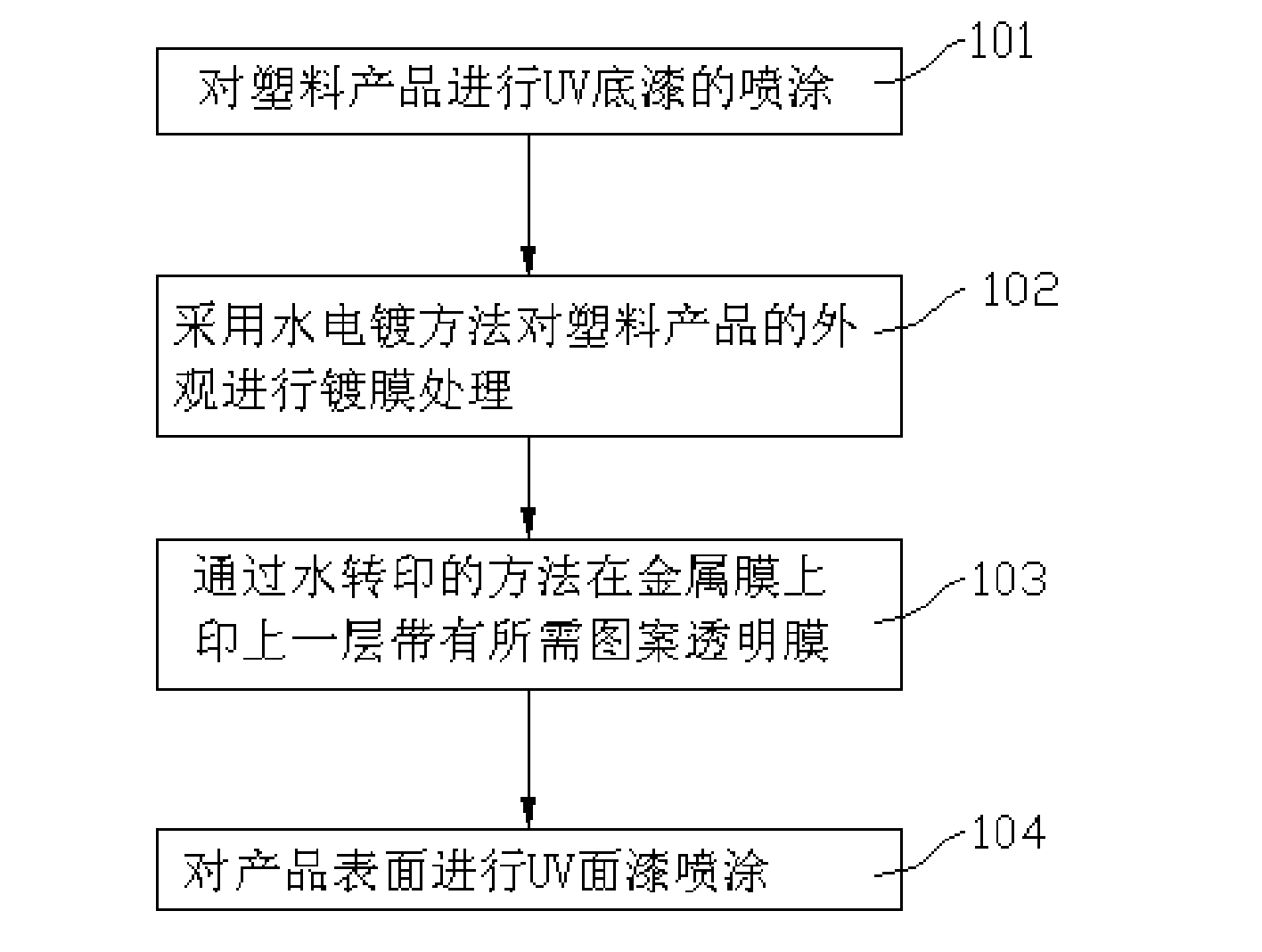

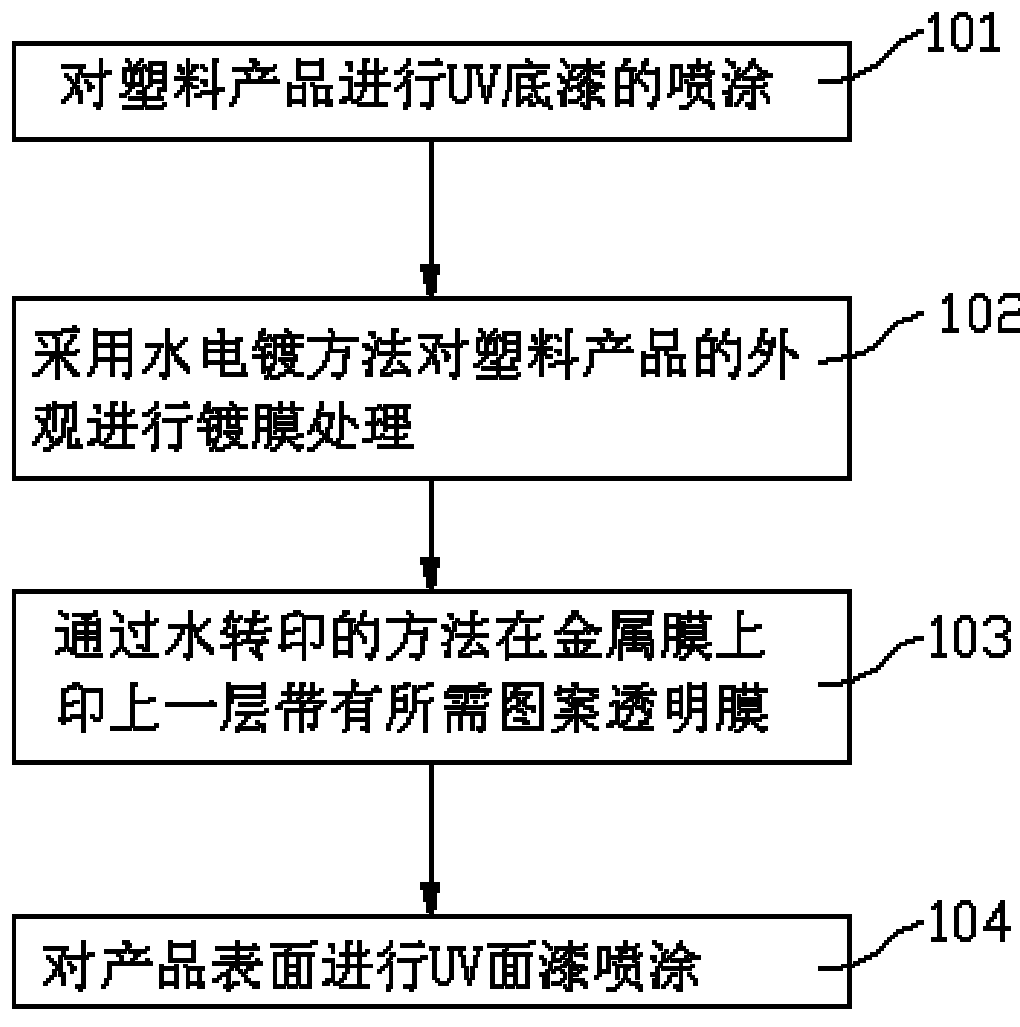

[0017] Such as figure 1 As shown, it is a flow chart of steps in the first embodiment of the method for processing the decorative effect of the plastic casing of the present invention.

[0018] In the first preferred embodiment, the decorative effect processing method of the plastic shell of the present invention comprises the following steps:

[0019] Step 101: Adopt traditional techniques (traditional techniques in this embodiment refer to spraying / wetting etc. currently being used to evenly attach materials such as resin to the surface of the plastic material, and then solidify to form a dense layer on the surface of the plastic material The method of film layer) spray UV primer on the surface of plastic products to achieve the effect of making the surface of the material very smooth;

[0020] Step 102: The method of electroplating with water (i.e., by electrochemical method, metal ions are deposited on the surface of the material after the first step of treatment to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com