Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

An electrodeless ultraviolet light, industrial wastewater technology, applied in animal husbandry wastewater treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex structure design, short light source life, high energy consumption, etc. The effect of improved removal rate and improved decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

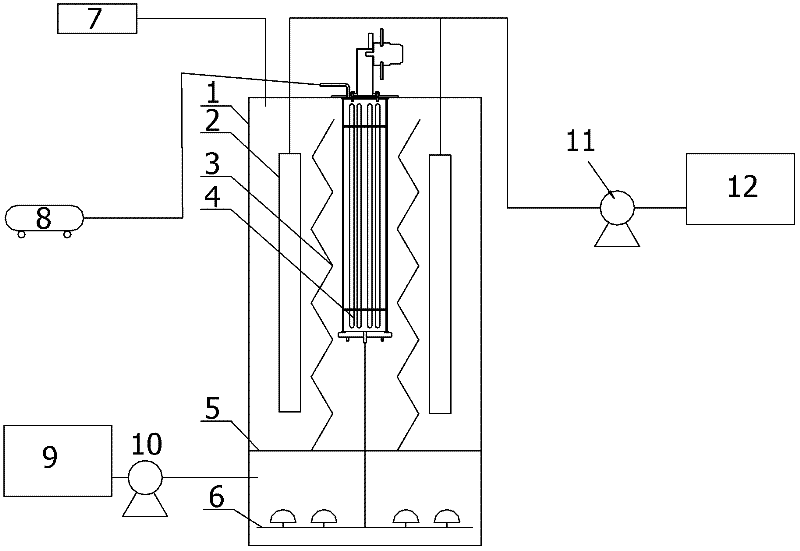

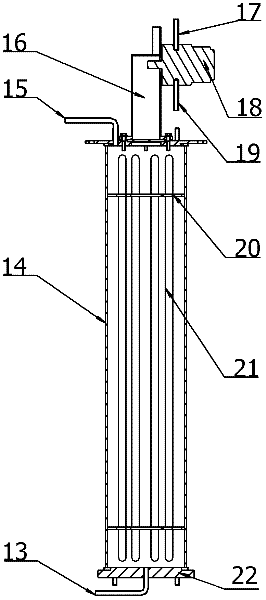

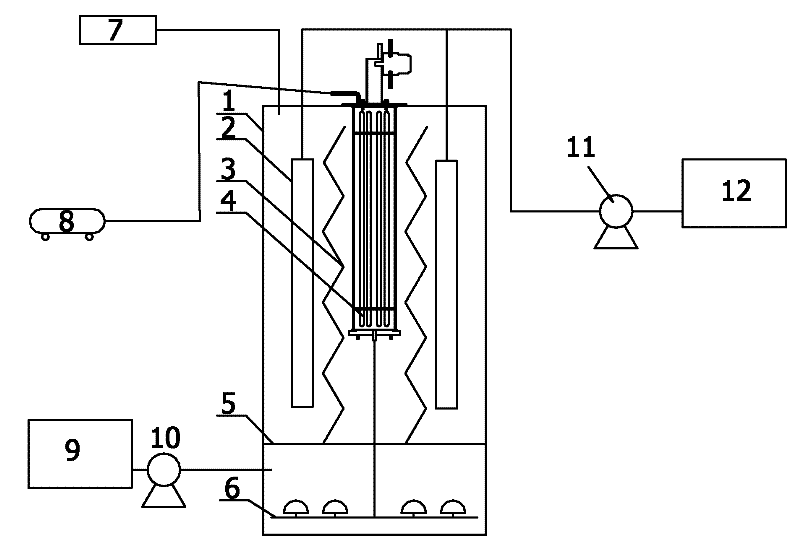

[0026] The industrial wastewater microwave electrodeless ultraviolet photocatalysis-double-membrane separation coupling treatment device provided by the present invention has a structure such as figure 1 As shown: it mainly consists of a reactor 1, a membrane separation system 2, a microwave electrodeless ultraviolet light source system 4, an aeration system, an ozone tail gas decomposition device 7 connected to the reactor 1, and an inlet and outlet water system. Wherein: the upper and lower parts of the reactor 1 are respectively the reaction zone and the aeration zone, which are separated by the water distribution plate 5 . The membrane separation system 2 and the microwave electrodeless ultraviolet light source system 4 are located in the reaction zone and separated by a corrugated partition 3 . The aeration system consists of a blower 8 and a micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com