Automatic feeding device improving punching precision of clutch coil shell

A technology of automatic feeding and clutch, which is applied in the field of stamping equipment, can solve the problems of low efficiency and labor-intensive manual feeding of stamping, and achieve the effects of simple structure, improved production efficiency, and stable conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

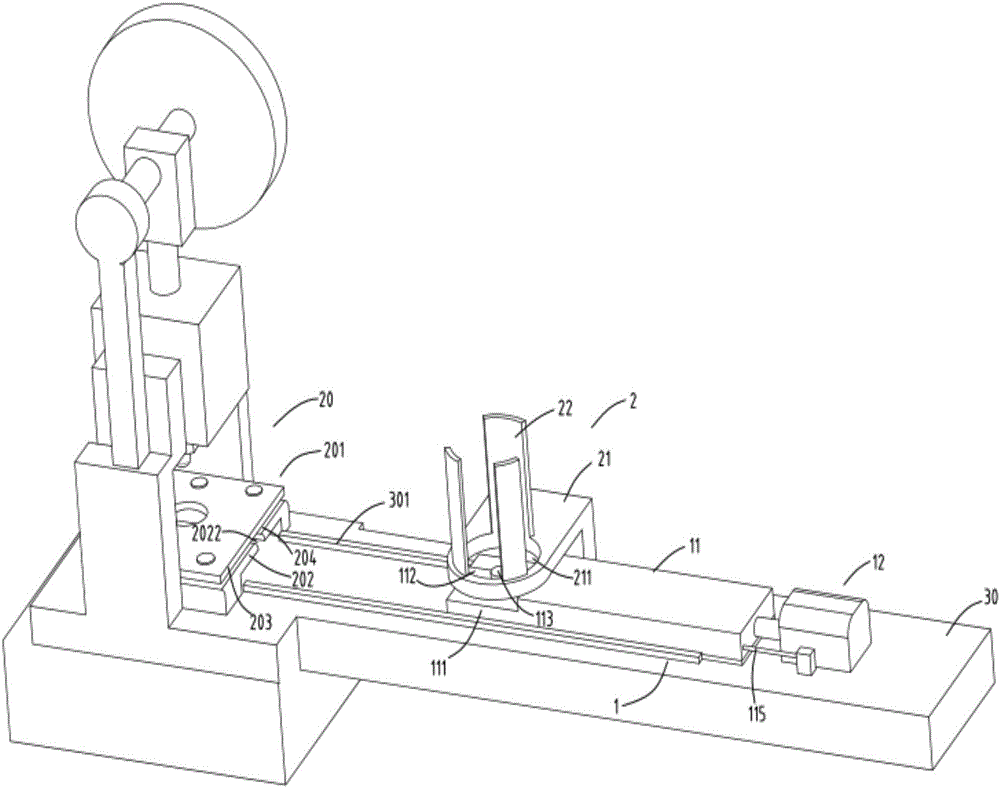

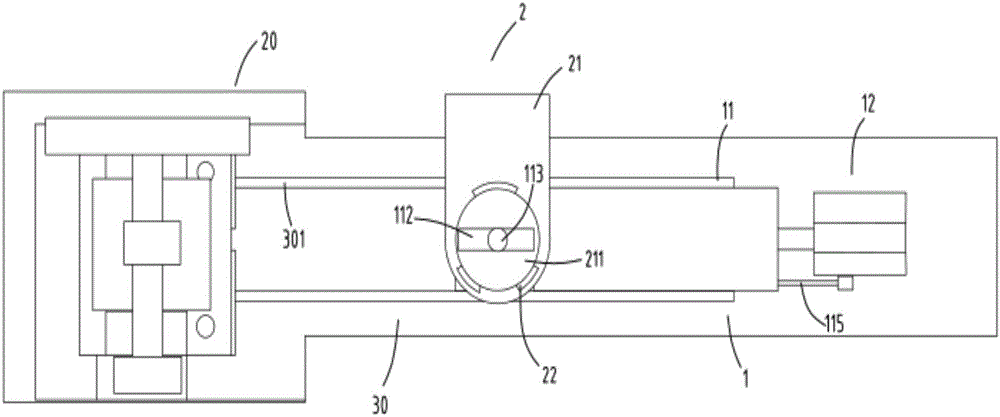

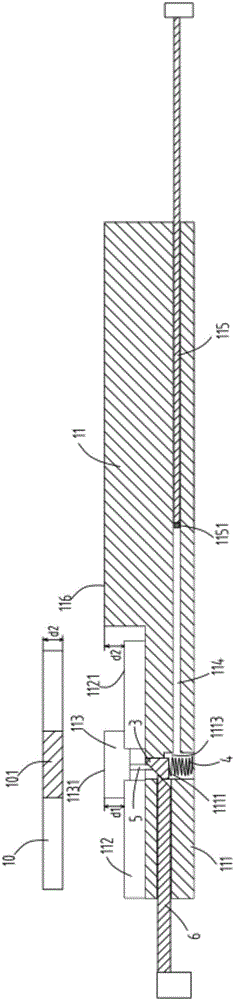

[0026] figure 1 Schematic diagram of the three-dimensional structure of the automatic feeding device for improving the stamping accuracy of the clutch coil housing, figure 2 Schematic diagram of the top view of the automatic feeding device for improving the stamping accuracy of the clutch coil housing, image 3 It is a schematic cross-sectional view of the carrier when it is about to reach the stamping processing position, Figure 4 is a schematic cross-sectional view of the carrier when it reaches the stamping processing position, Figure 5 It is a schematic cross-sectional view of the carrier when it is about to return to the feeding position, Image 6 is a schematic cross-sectional view of the internal structure of the carrier step position, Figure 7 A three-dimensional schematic diagram of part of the structure of the automatic feeding device for improving the stamping accuracy of the clutch coil housing. Such as figure 1 , figure 2 , image 3 , Figure 4 , Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com