Patents

Literature

61results about How to "Avoid problems such as leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

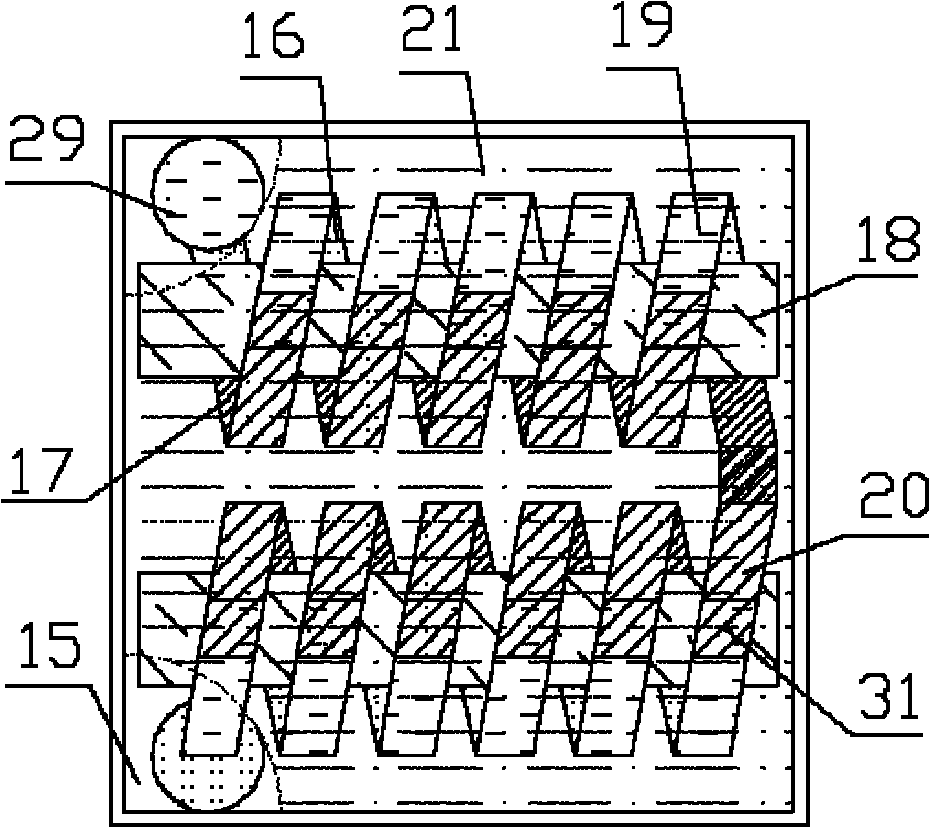

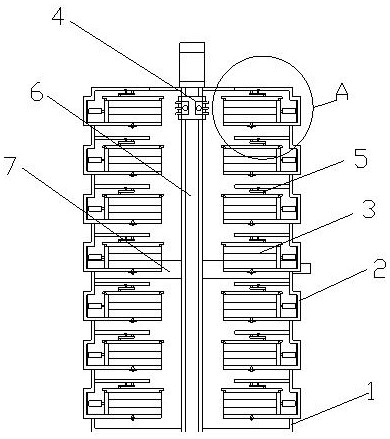

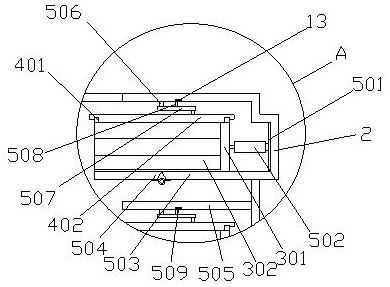

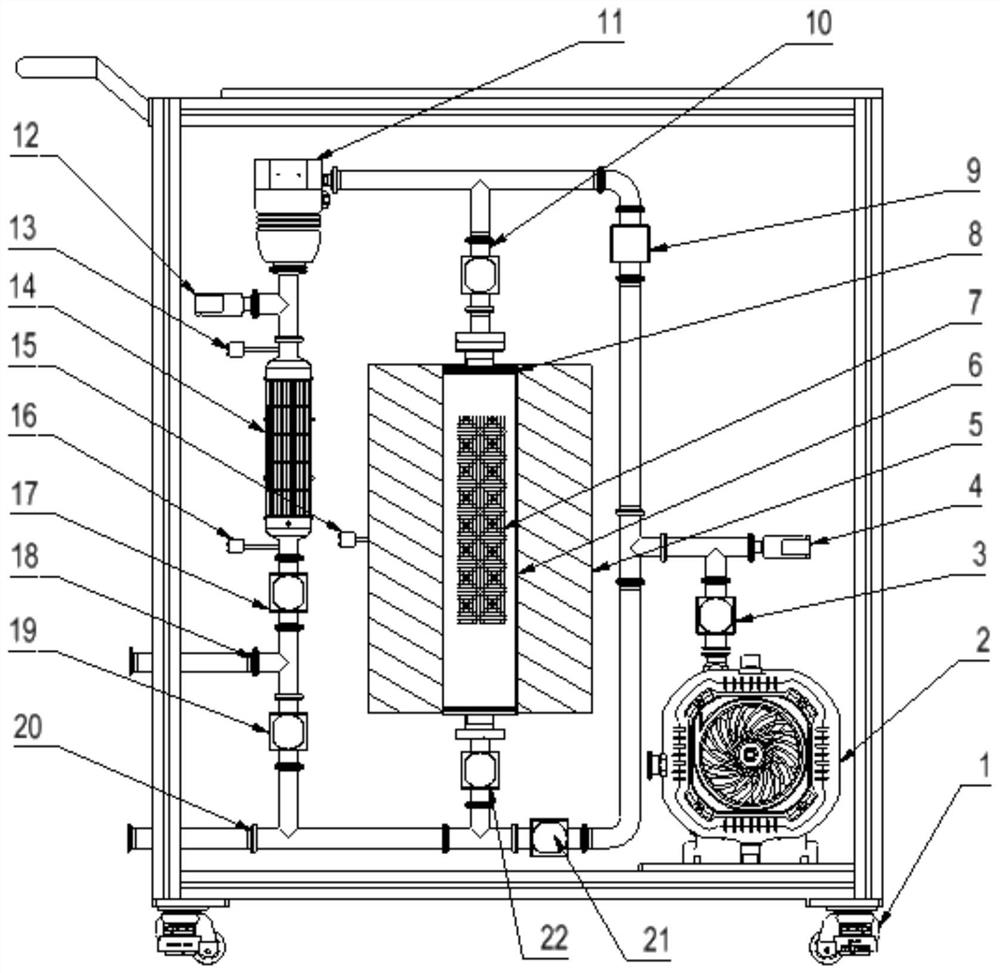

Microwave photocatalytic wastewater degradation device allowing greatly expanding single pot treating capacity

InactiveCN102849820AIncrease throughputContain unwanted dissipationWater/sewage treatment by irradiationMicrowaveUltraviolet

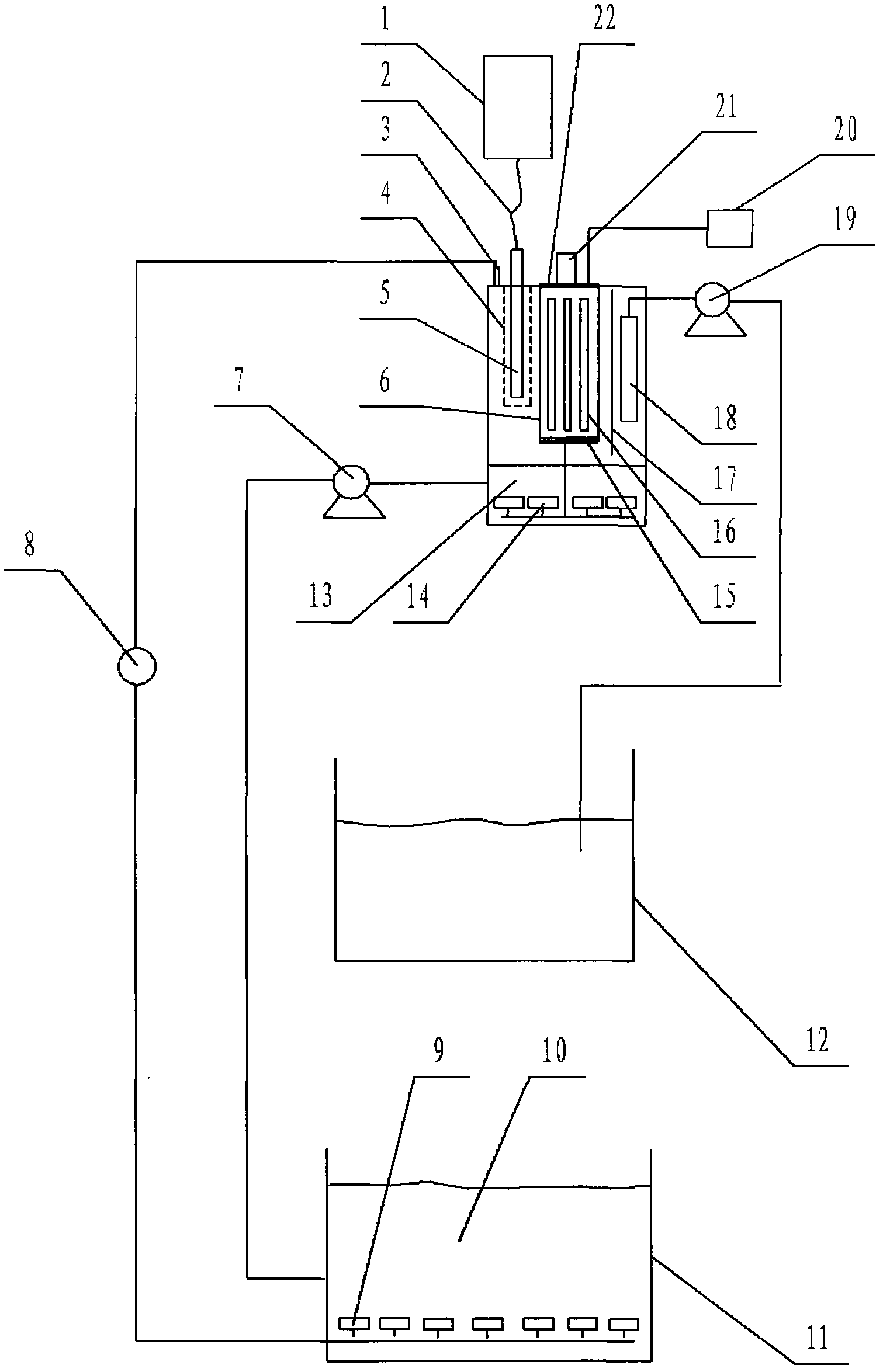

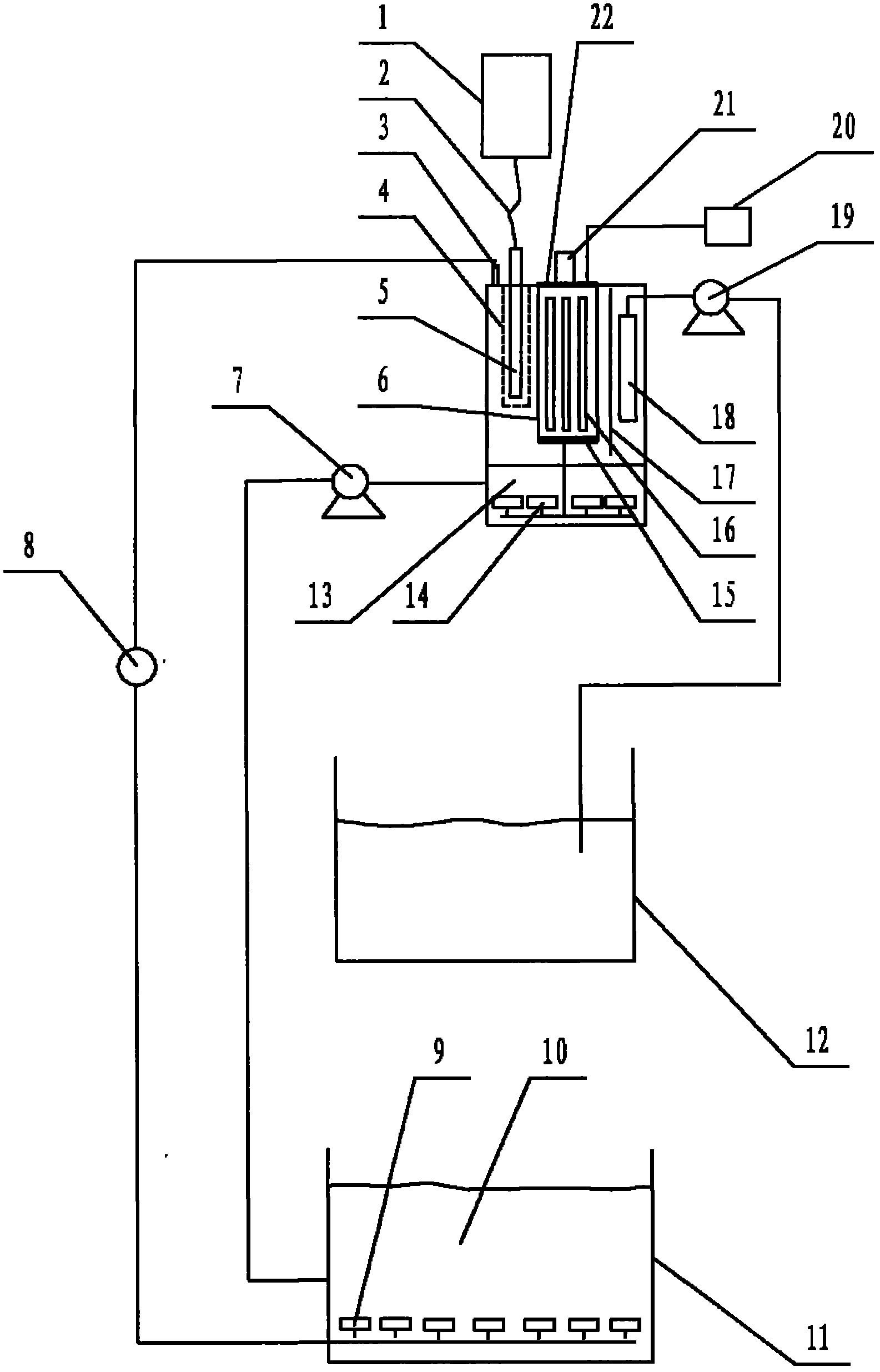

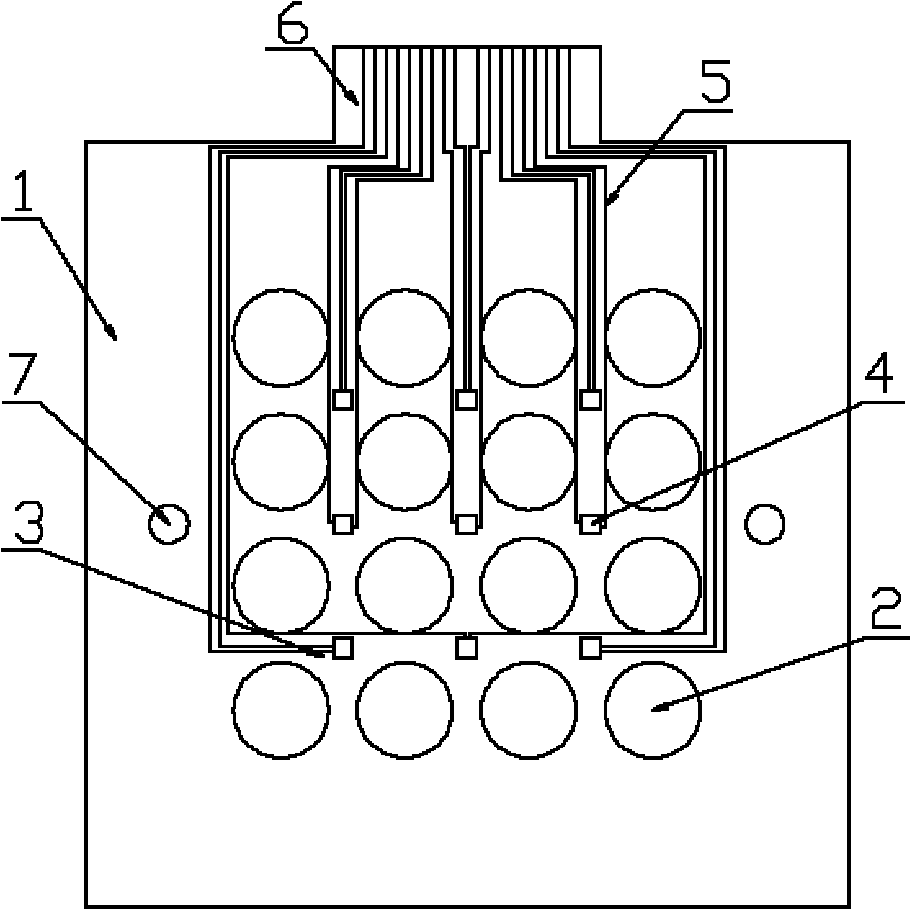

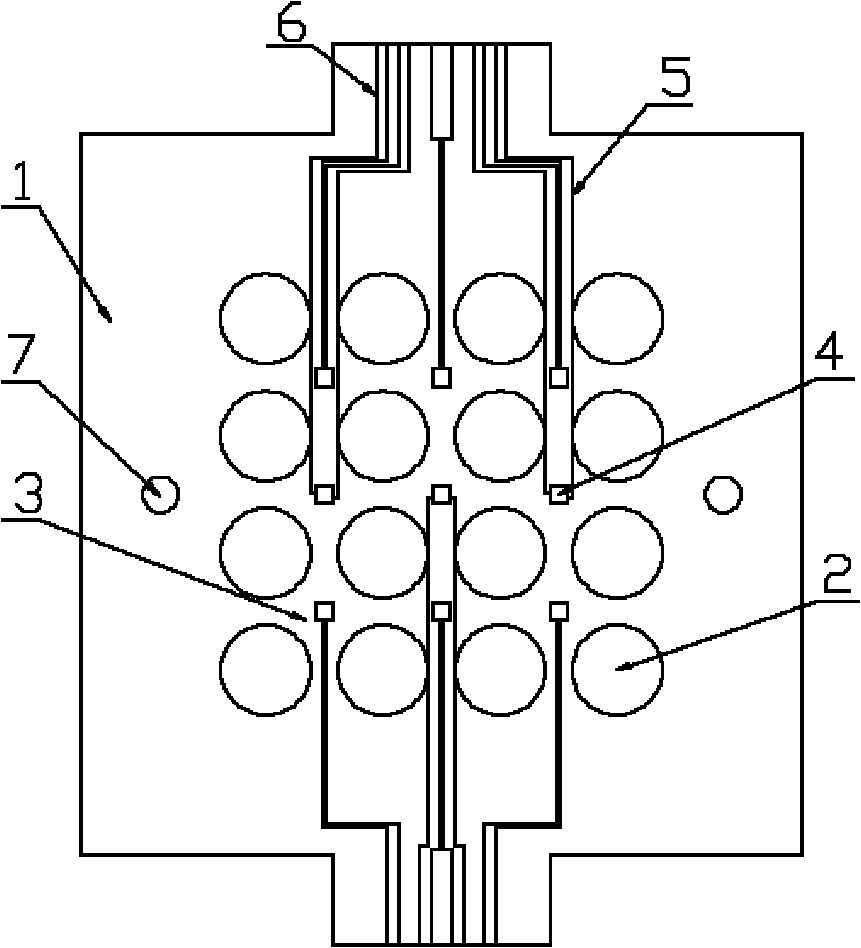

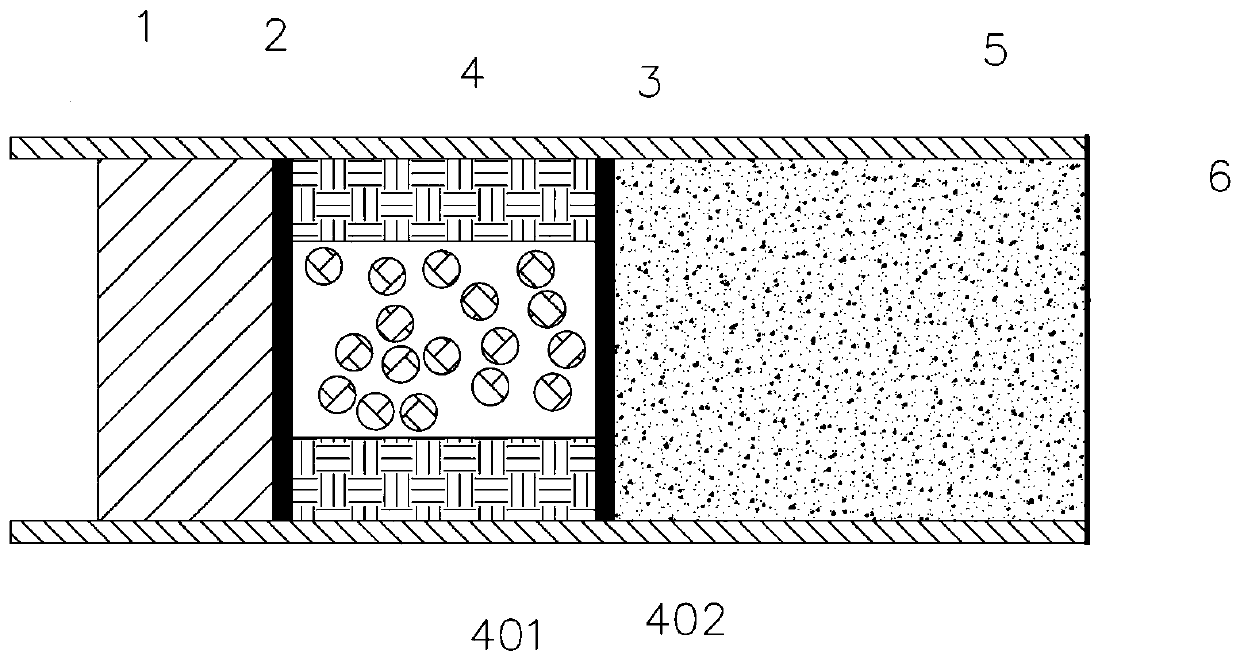

The invention relates to a microwave photocatalytic wastewater degradation device allowing greatly expanding single pot treating capacity and belongs to the technical field of wastewater treatment. The existing microwave photocatalytic degradation technology aiming at industrial wastewater containing organic pollutants has the problems of microwave energy waste and small practical single pot wastewater treating capacity; in addition, in the prior art, the phenomenon of scale deposit can occur after the outer side surface of a quartz tube for shielding an electrodeless ultraviolet lamp is soaked in wastewater for a long time, a scale layer formed by the scale deposit blocks the permeability of light and also affects the wastewater treatment efficiency of the existing device; and the microwave photocatalytic wastewater degradation device aims at solving all the problems. The device adopts the structure that the electrodeless ultraviolet lamp is arranged in a wire mesh cage-shaped non-light tight microwave restraint made of metal material, and leads microwave into the restraint to restrain the microwave, so that microwave is free from inconducive dissipation, the design volume of a reactor is allowed to be greatly expanded based on the structure, and further the single pot wastewater treating capacity of the reactor is greatly enhanced. The device instantaneously eliminates the scale layer through high-frequency ultrasonic wave.

Owner:NINGBO UNIV

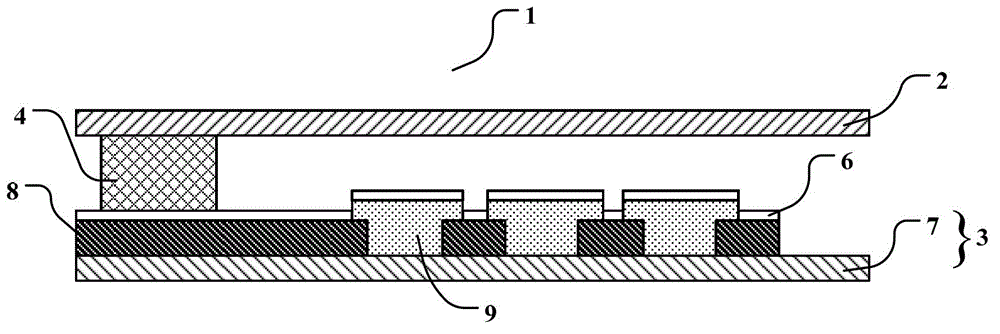

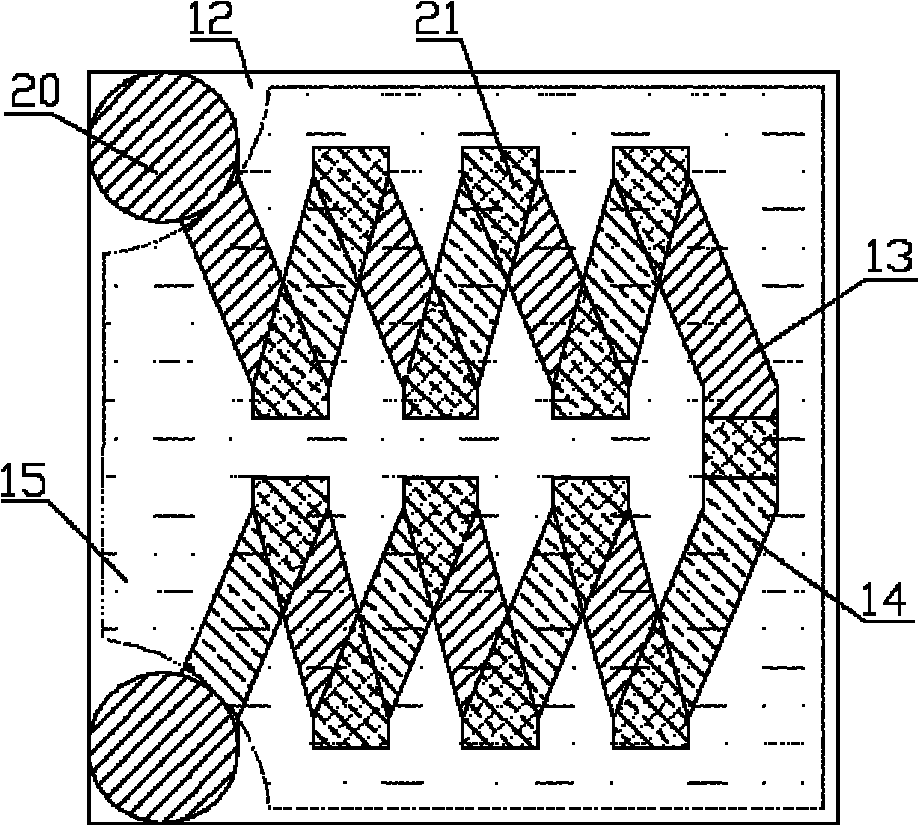

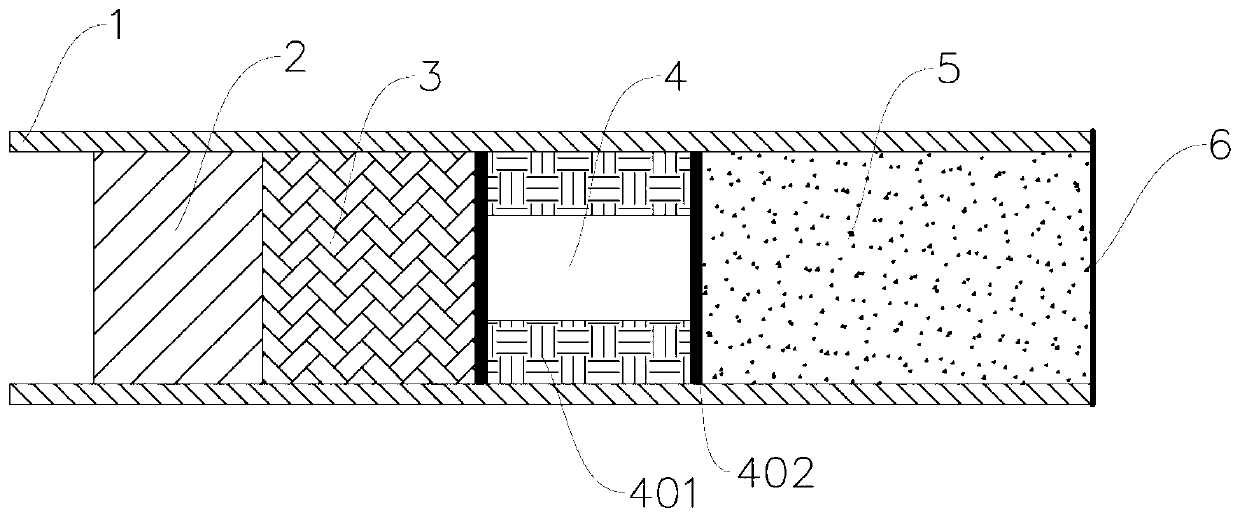

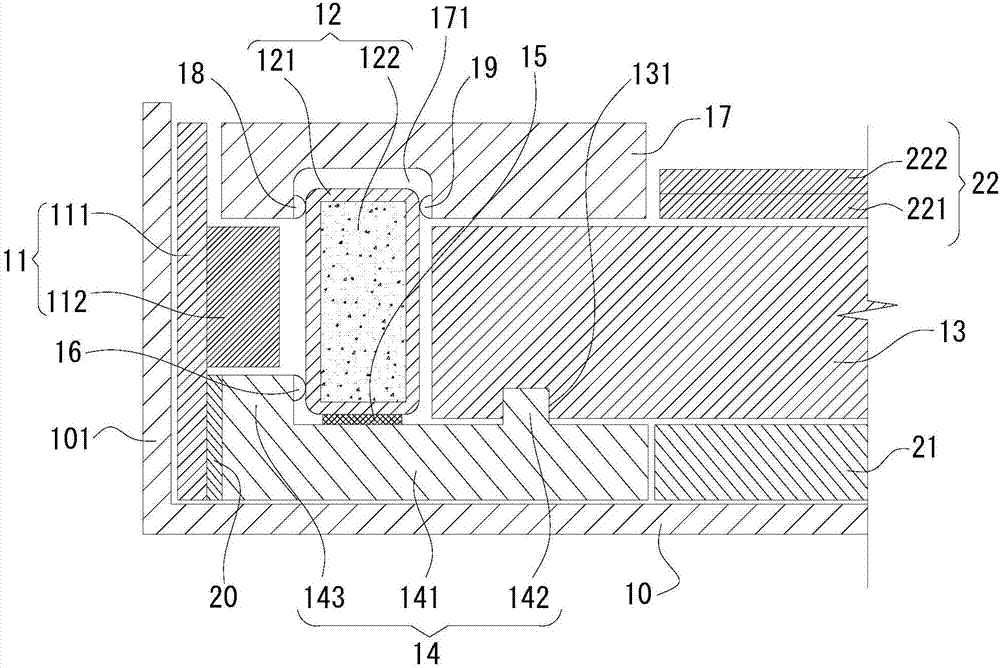

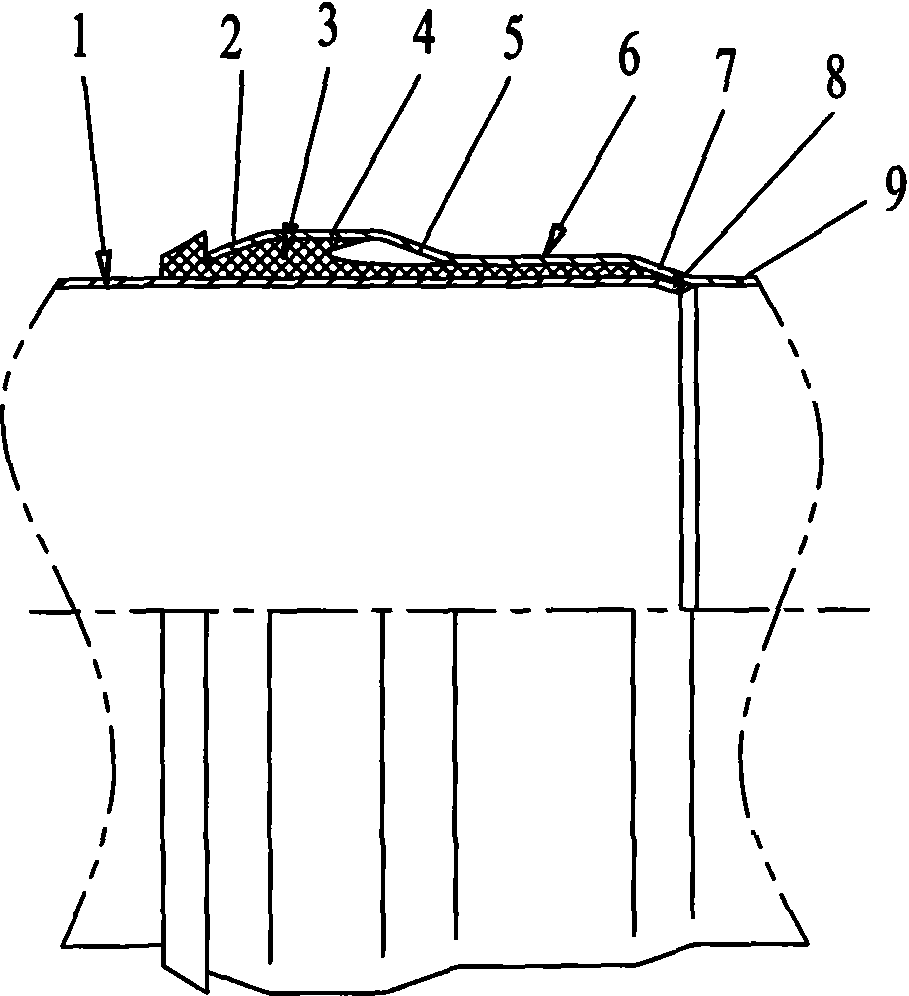

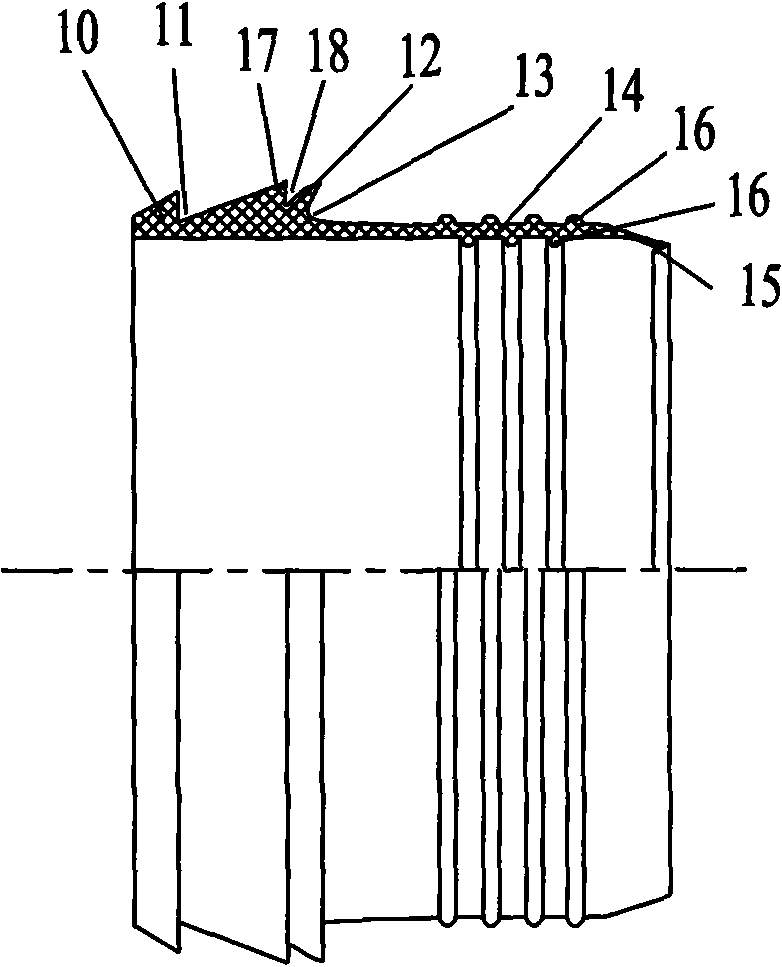

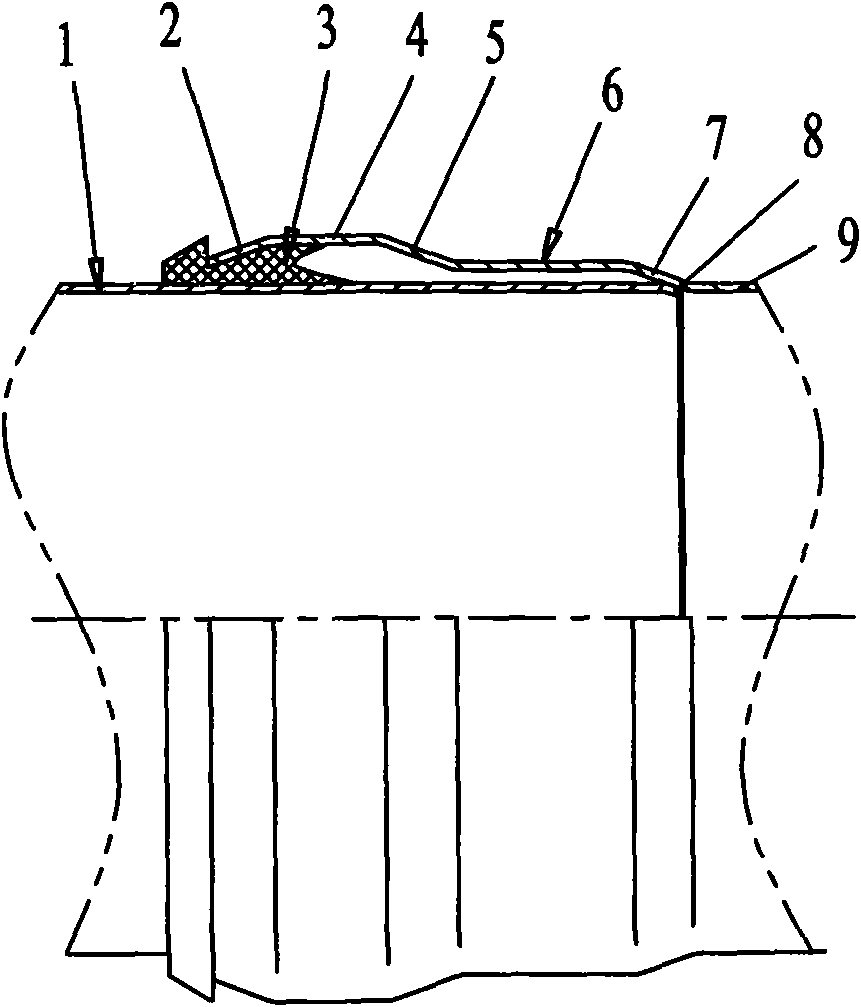

Color filter substrate, manufacturing method thereof and liquid crystal display panel

InactiveCN103941460AIncrease contact areaImprove adhesion strengthOptical filtersPhotomechanical apparatusLiquid-crystal displayAdhesion strength

The invention discloses a color filter substrate, a liquid crystal display panel comprising the color filter substrate and a manufacturing method of the color filter substrate. The color filter substrate comprises a substrate body, black matrixes and color filter patterns, wherein the substrate body is provided with display regions and non-display regions located on the peripheries of the display regions, the black matrixes are arranged on the substrate body, sub-pixel regions are defined on the black matrixes, corresponding to the display regions, of the substrate body and the surface of the black matrixes, corresponding to the non-display regions, of the substrate body are uneven surfaces and the color filter patterns are arranged in the sub-pixel regions. According to the color filter substrate, the black matrixes, located at the positions of the non-display regions, on the color filter substrate are provided with the uneven surfaces, the shape of the face, making contact with sealant, of the color filter substrate is changed, the contacting area between the color filter substrate and the sealant is increased, the adhesion strength between the color filter substrate and the sealant is enhanced, the stripping strength of the color filter substrate and a thin film transistor array substrate is enhanced and the problem that liquid crystal leakage is generated due to the fact that the color filter substrate and the sealant are easy to strip is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

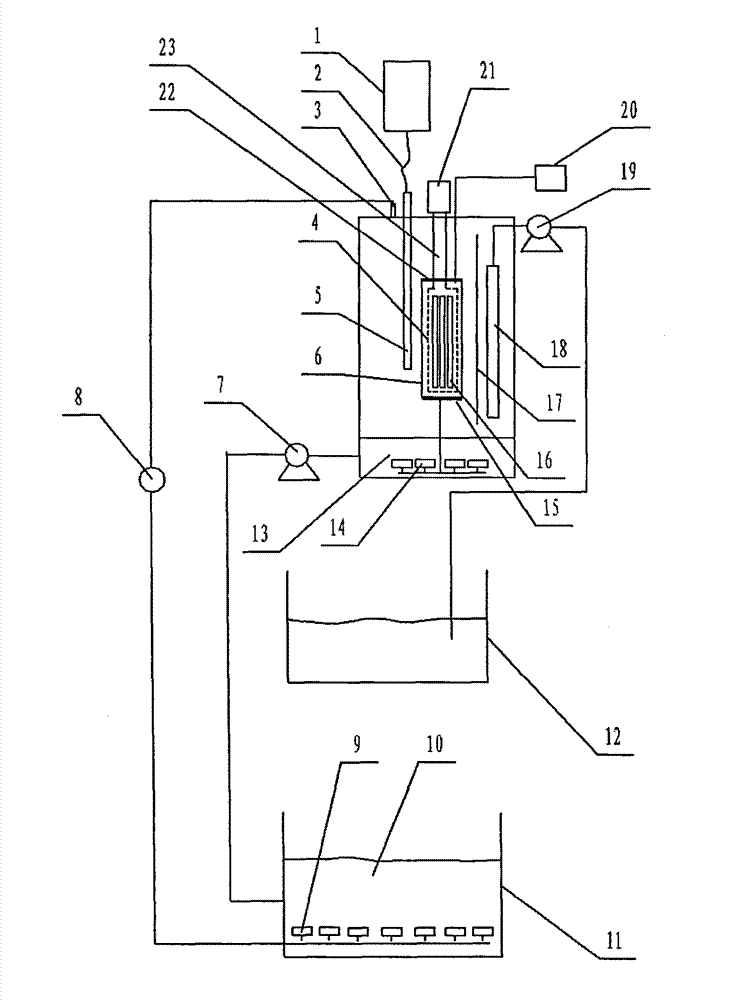

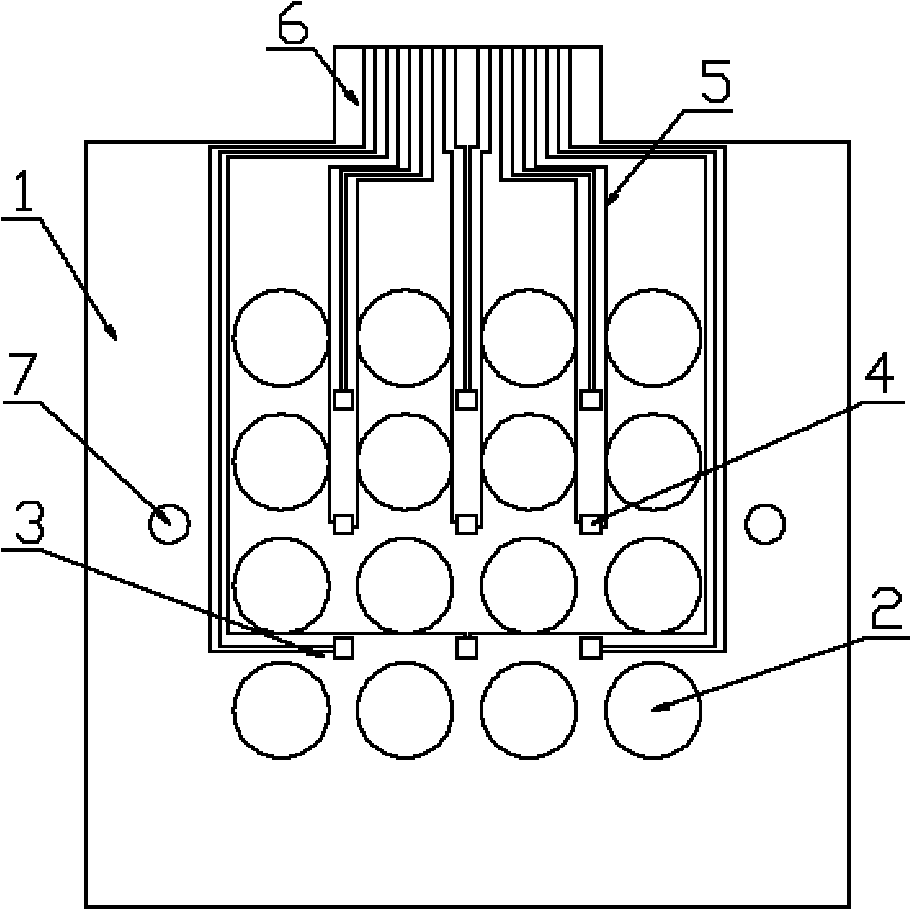

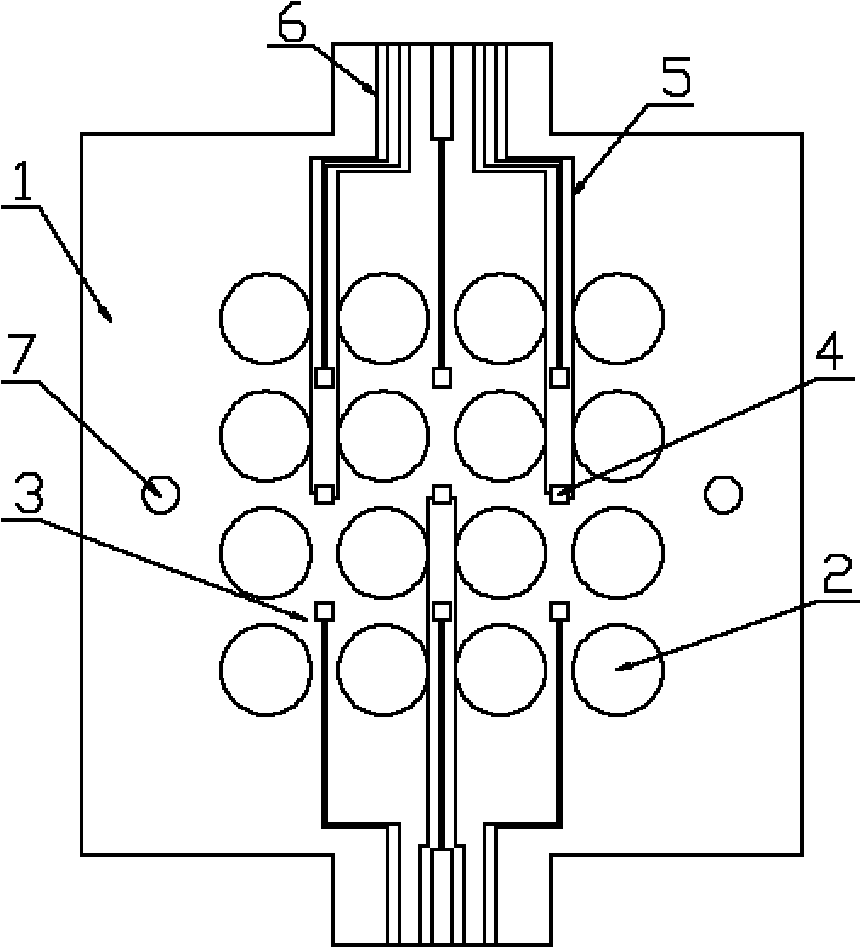

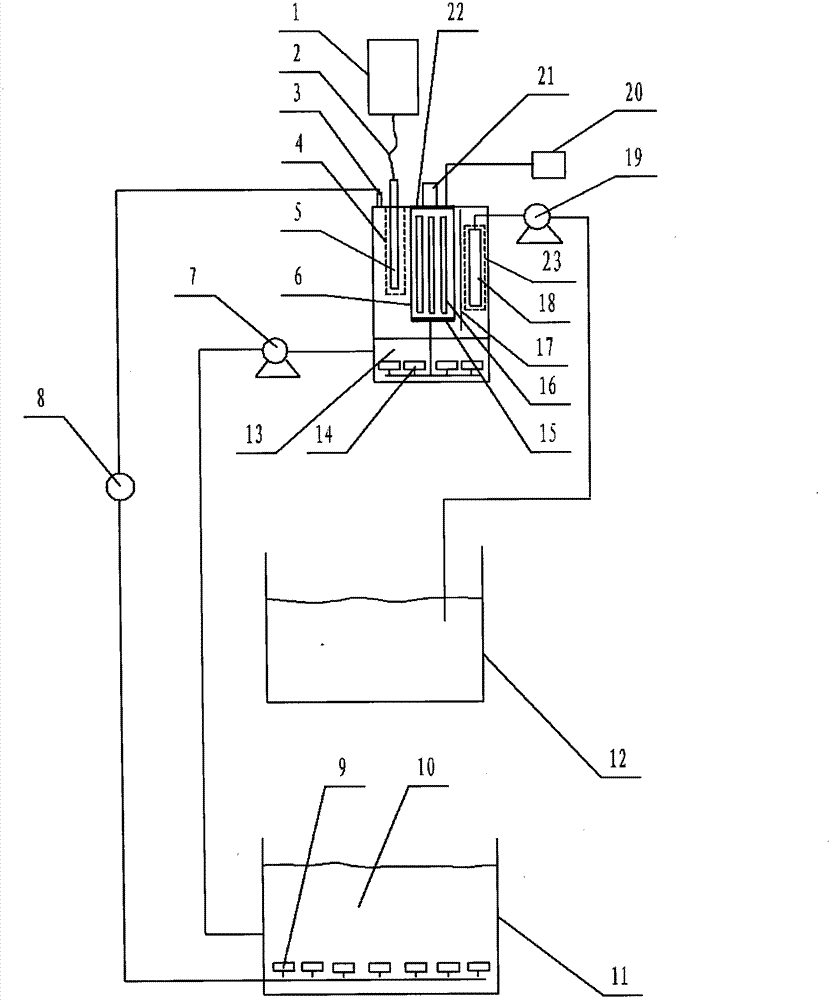

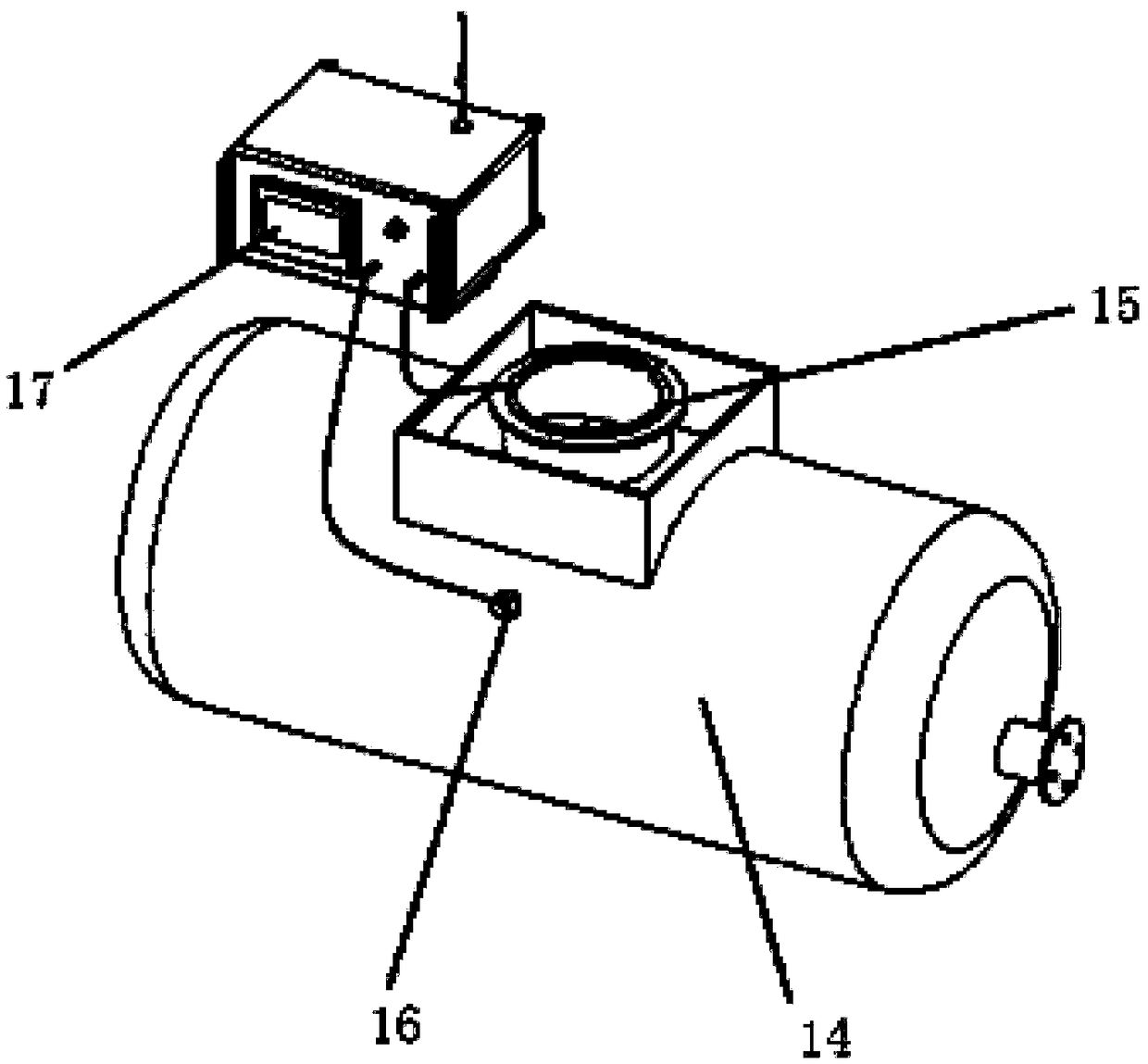

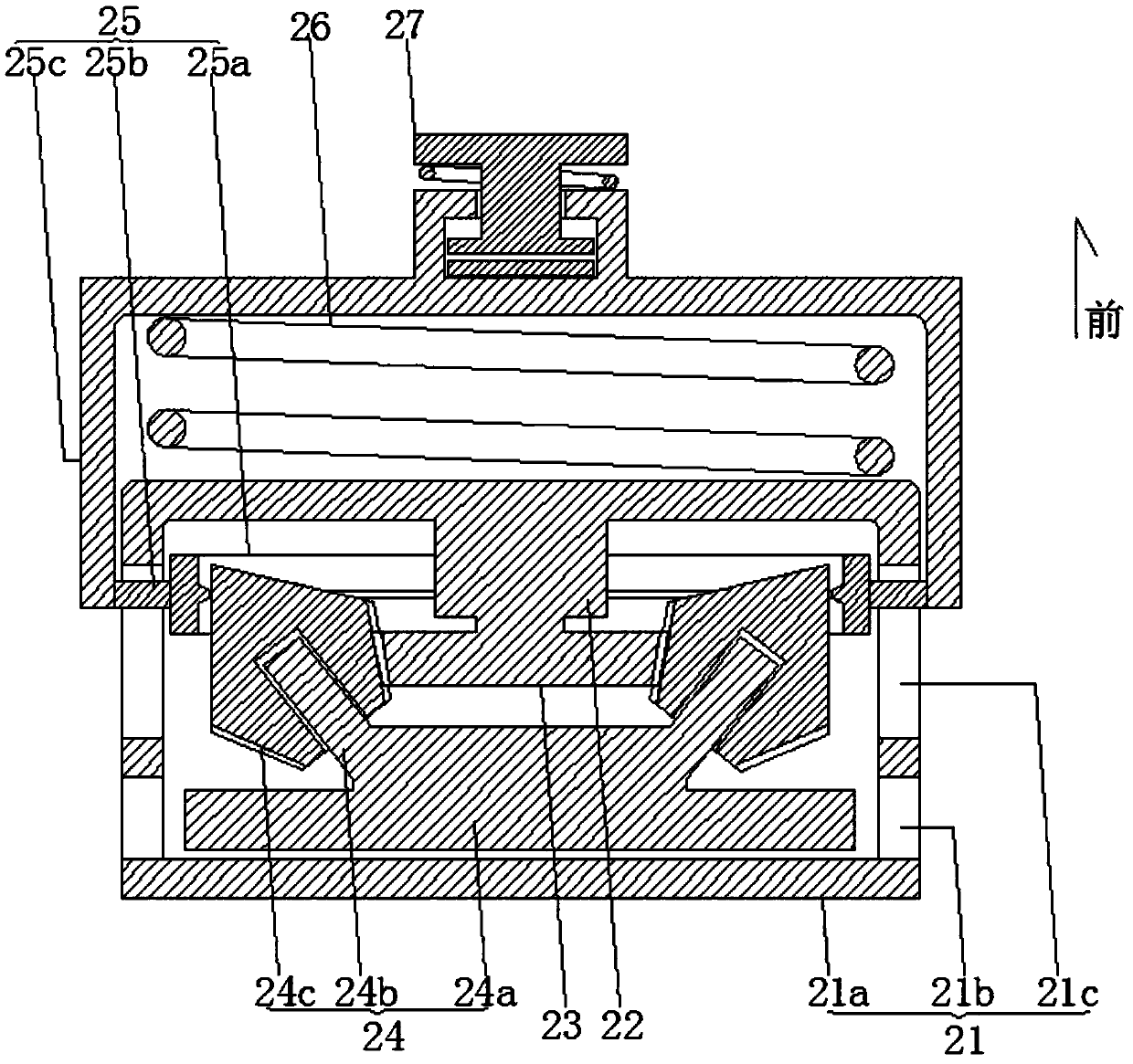

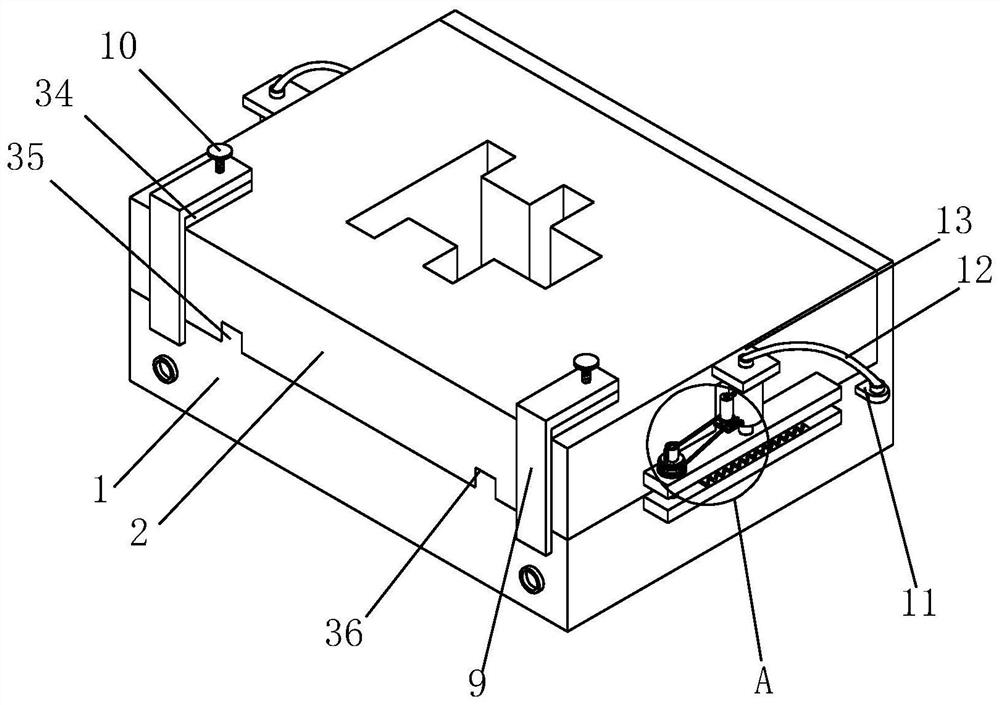

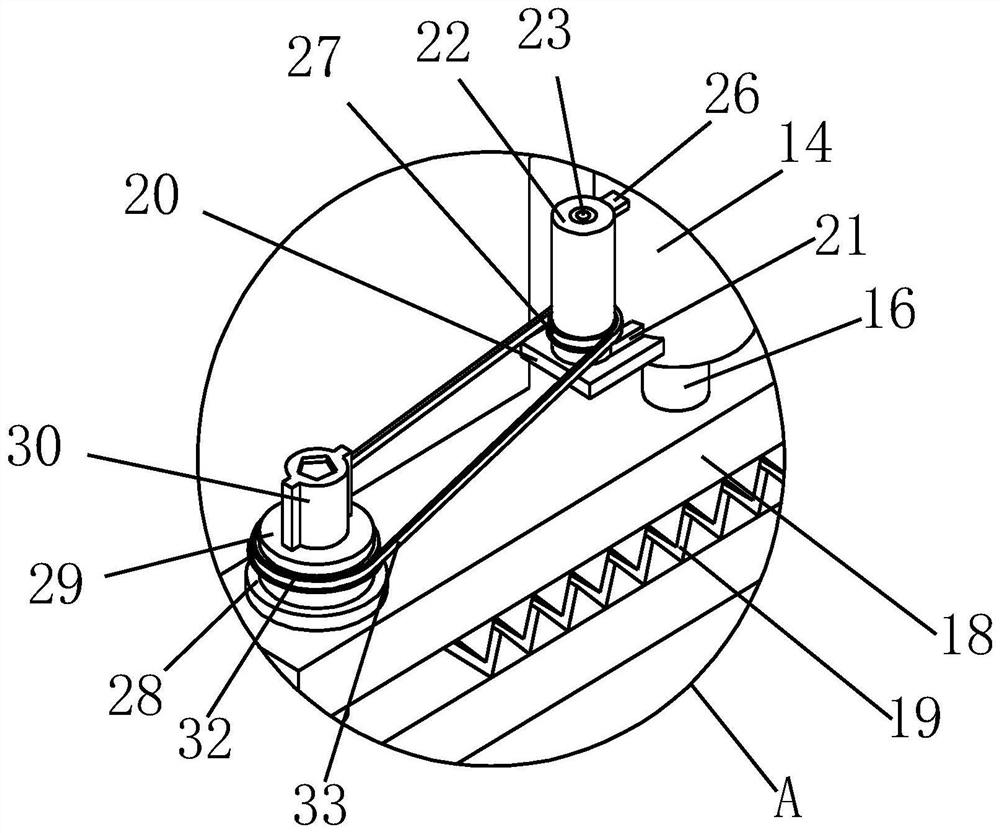

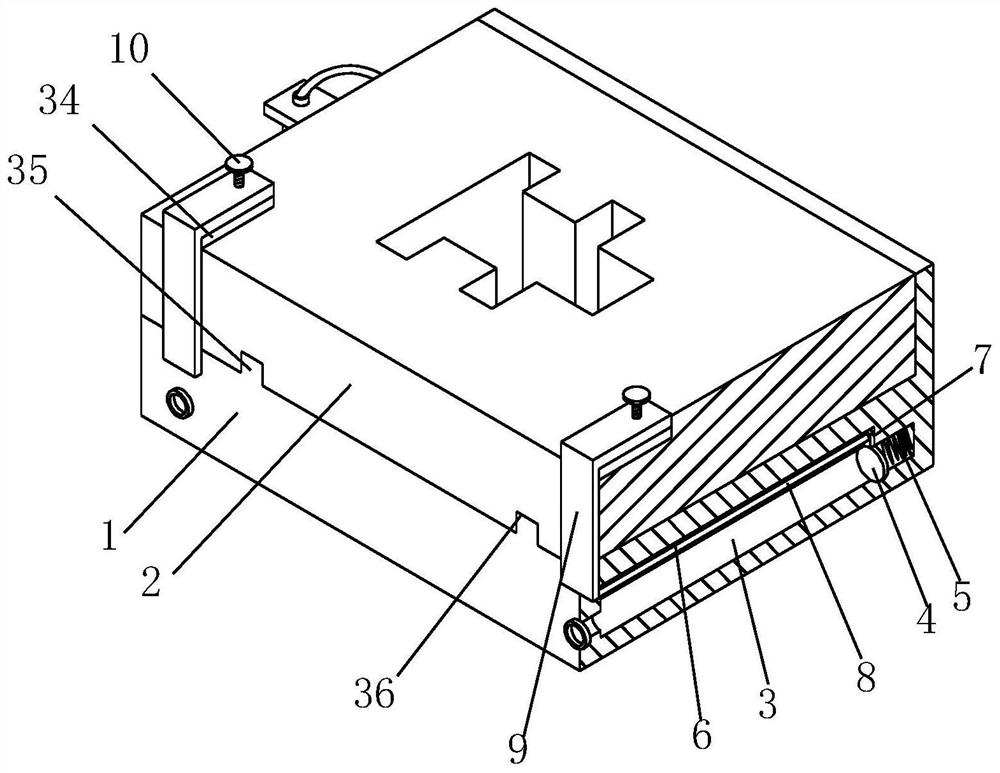

Microwave photocatalytic degradation treatment device for industrial wastewater containing organic pollutants

InactiveCN102616884AImprove permeabilityImprove efficiencyWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsPhotocatalytic reactionMicrowave

The invention relates to a microwave photocatalytic degradation treatment device for industrial wastewater containing organic pollutants, which belongs to the technical field of wastewater treatment. In existing microwave photocatalytic degradation technology for industrial wastewater containing organic pollutants, scale can be formed on the outer side surface of a quartz tube for shielding an electrodeless ultraviolet lamp in a microwave photocatalytic reaction device after the quartz tube is soaked in the wastewater for a long time, due to the scale, the ultraviolet light transmission performance of the quartz tube is affected severely, and the treatment efficiency of the microwave photocatalytic reaction device is greatly reduced. The scheme aims to resolve the problem. The microwave photocatalytic degradation treatment device in the scheme structurally comprises a rod-shaped ultrasonic probe which is inserted in a reactor via the top of the reactor, so that real-time ultrasonic removal for scale on the outer side surface of a quartz tube is realized without stopping or detaching, the high ultraviolet light transmission performance of the quartz tube is maintained, and continuous high efficiency of the microwave photocatalytic degradation reactor is maintained. Due to the assembly mode in the scheme, liquid is not easy to leak, and the device can be detached and replaced conveniently.

Owner:NINGBO UNIV

Insertion piece for measuring transient heat flow density distribution in fuel cell

ActiveCN102116679ADoes not affect deliveryEasy to disassembleMaterial heat developmentThermometers using electric/magnetic elementsHeat flowMeasurement device

The invention discloses an insertion piece for measuring heat flow density distribution in a fuel cell, which is a device for measuring the heat flow density distribution in the fuel cell. The insertion piece comprises a gold-plated stainless steel substrate, and leaks and ribs, which are in the same sizes, the same shapes and the corresponding positions with grooves and ridges on a flow field plate of the fuel cell to be measured, are arranged on the substrate. A thin film heat flow meter is arranged on the rib between the adjacent leaks or holes on the measuring insertion piece respectively, the vacuum film coating technology is adopted for vapor deposition of seven layers of thin films, leading-out wires of the thin film heat flow meters extend to the edge of the substrate by adopting the method of printing a circuit, and a standard wiring port connected with an external circuit is further formed. The measuring insertion piece is placed between the flow field plate of the fuel cell and a membrane electrode. The insertion piece for measuring the heat flow density distribution in the fuel cell is completely independent of a measured object, and the fuel cell does not need to be transformed; furthermore, as the placement position of the insertion piece is very near to the membrane electrode, the insertion piece can measure the real-time heat flow density distribution situation in the fuel cell.

Owner:BEIJING UNIV OF TECH

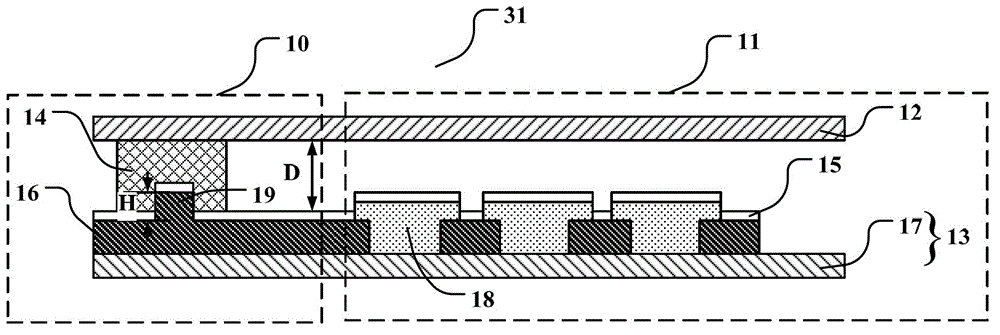

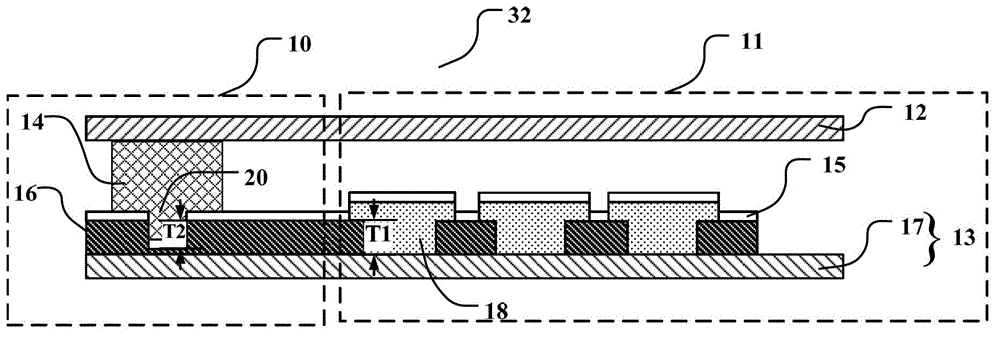

Transient temperature distribution sensor in fuel cell

ActiveCN102157743AAvoid problems such as leakageReduce volumeFuel cell heat exchangeThermometers using electric/magnetic elementsThin film thermocouplesCopper plating

The invention discloses a transient temperature distribution sensor in a fuel cell, and thin film thermocouples are arranged on ribs between adjacent flow passages on a graphite flow field plate of the fuel cell for measuring transient temperature distribution in the fuel cell. The single thin film thermocouple is formed by adopting a vacuum evaporation coating technology for evaporation of four layers of thin films, a silicon dioxide insulating layer with the thickness of 0.1-0.15 mu m is plated at the first layer, copper is plated at the second layer, nickel is plated at the third layer, the thicknesses of the copper plated layer and the nickel plated layer are 0.08-0.1 mu m respectively, and a silicon dioxide thin layer with the thickness of 0.01-0.02 mu m is finally plated. Leading-out wires of the thin film thermocouples extend to the edge of the graphite flow field plate by utilizing the process of a printed circuit, a standard wiring port for connecting with an external circuitis further arranged, and a data acquisition system is used for exporting signals. A measuring device is simple and easy to operate, the real-time temperature distribution in the fuel cell is measured, the cell is easy to disassemble and assemble, and the impacts on the overall performances of the fuel cell are small.

Owner:BEIJING UNIV OF TECH

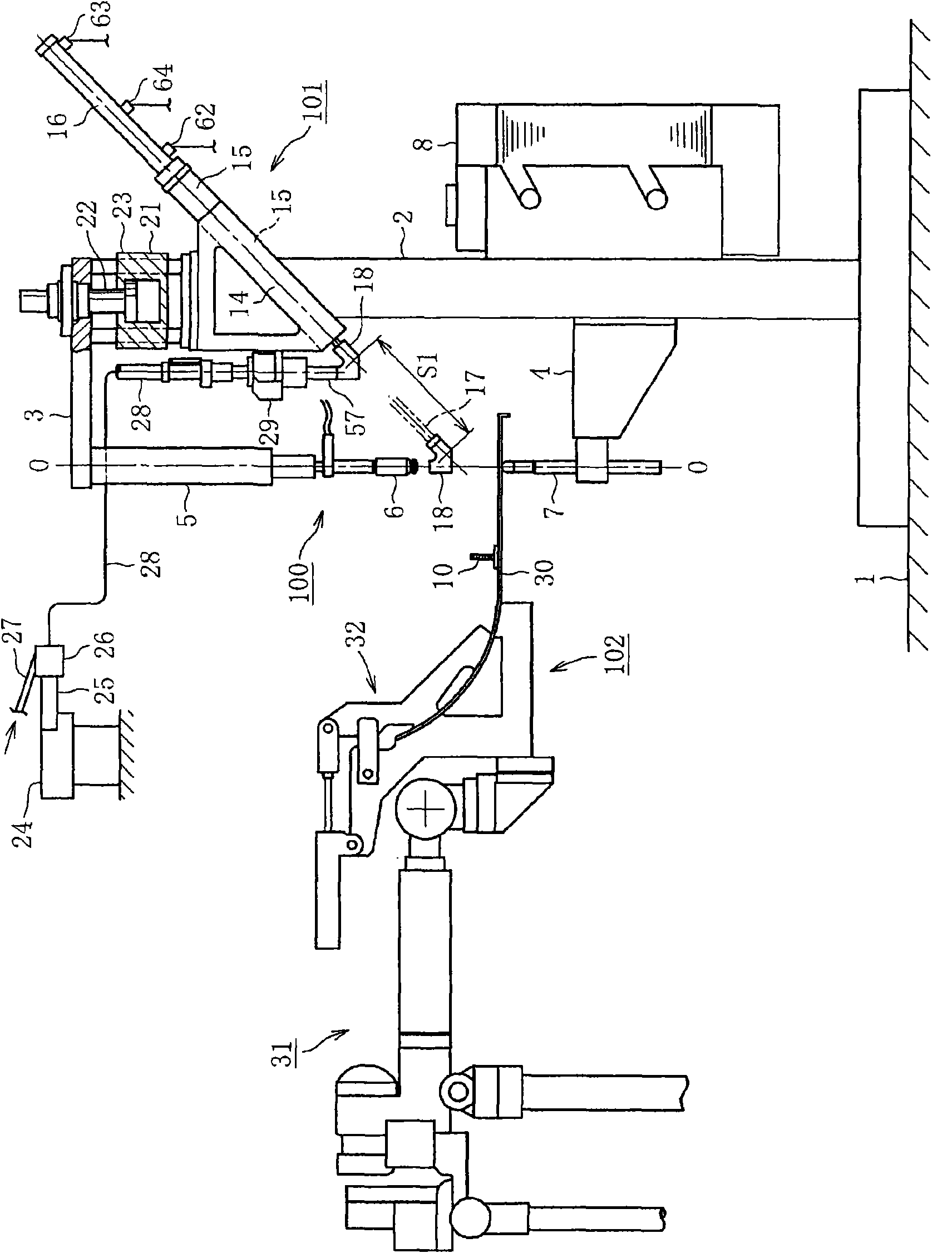

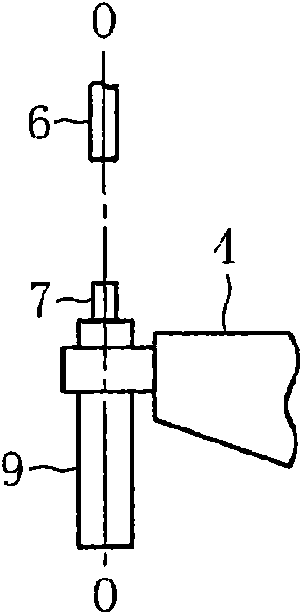

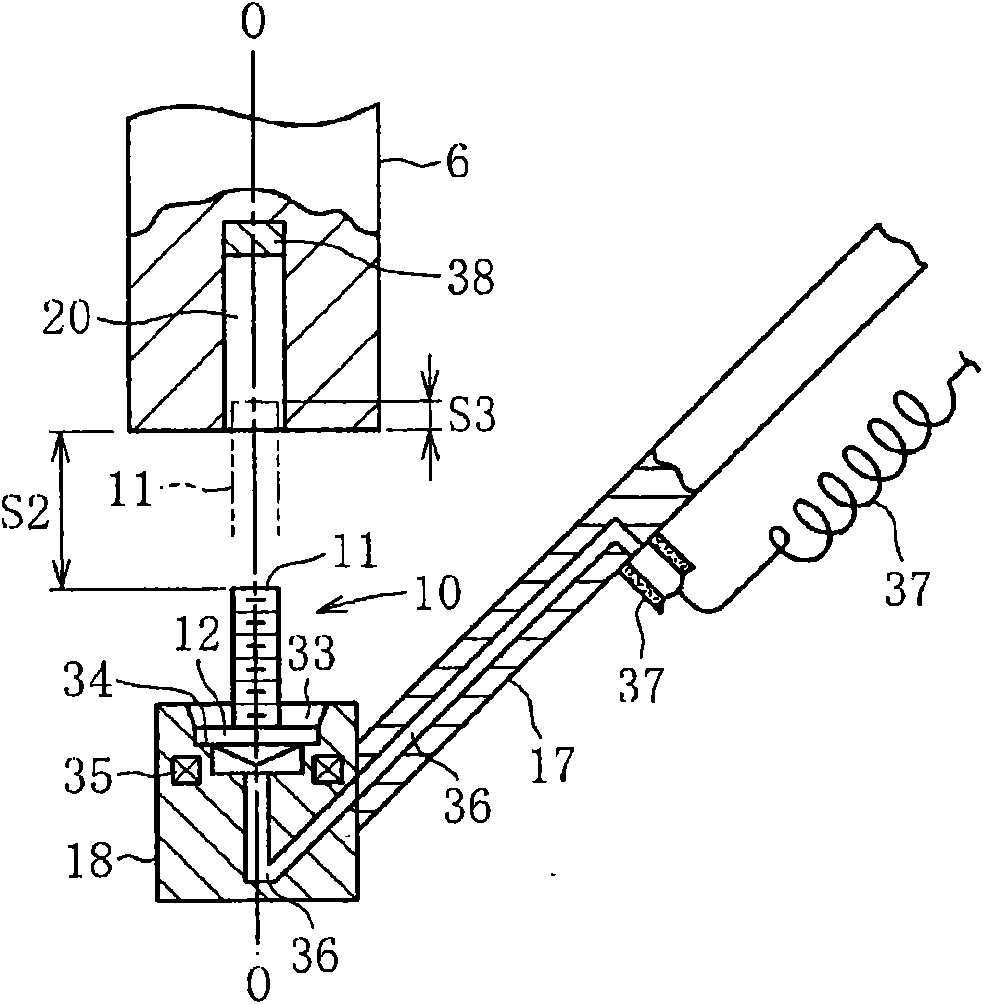

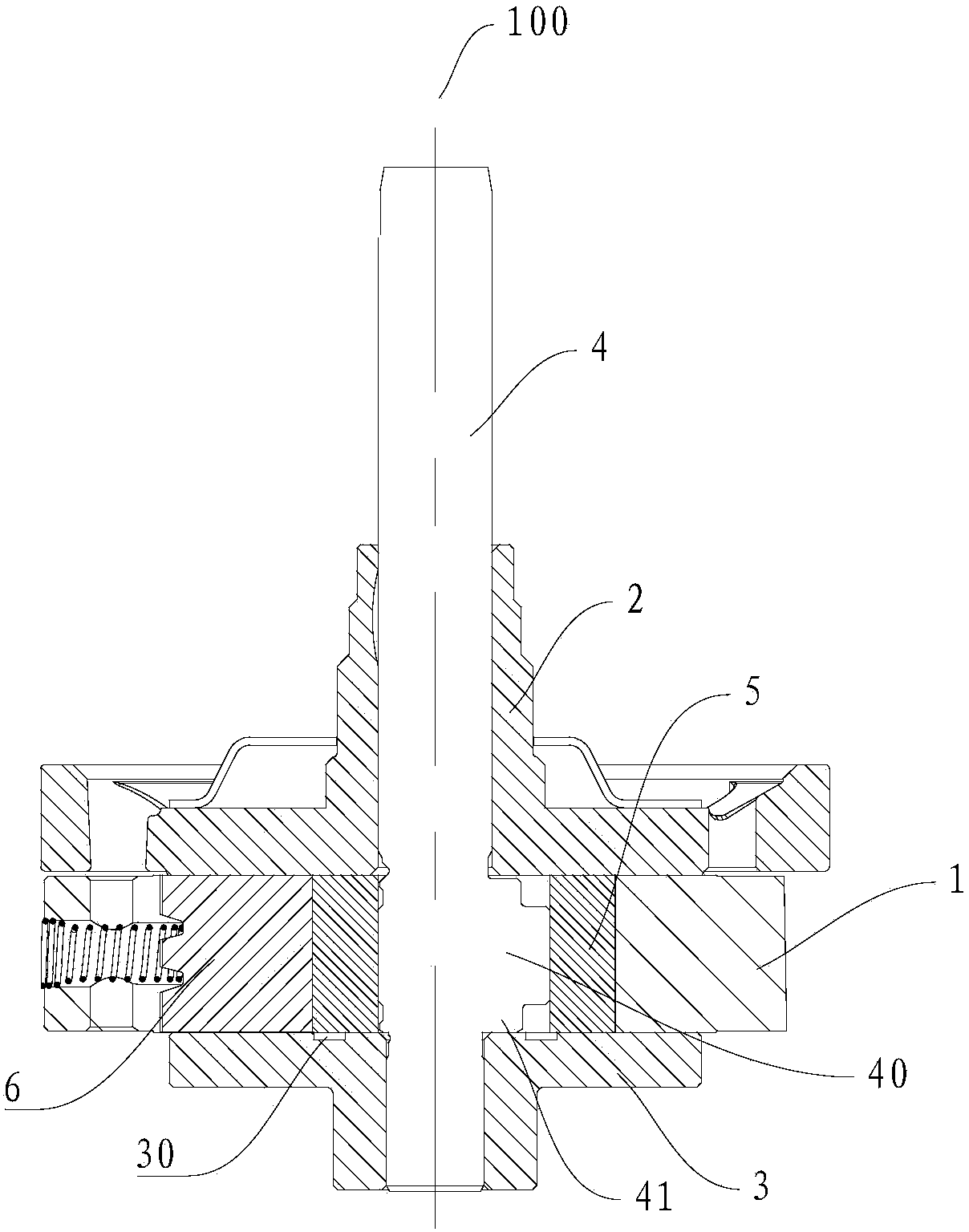

Projection bolt welding method, and welding apparatus

ActiveCN101622092AReduce sizeEasy to insertWelding/cutting auxillary devicesArc welding apparatusElectrical resistance and conductanceSheet steel

Provided are a welding method and a welding apparatus, which can start the proper advance of an electrode on the basis of both the positioning of the welded portion of a projection bolt with respect to a steel sheet and the completing state of the feed of the projection bolt with respect to the electrode. In the welding method, a bolt (10) held by a feed rod (17) is inserted into a receiving hole (20) of an electrode (6). Air is injected from a holding head (18) thereby to complete the bolt insertion into the receiving hole (20). Then, the feed rod (17) is retracted. After this, the electrode (6) is advanced to weld the bolt to a steel sheet (30) by the electric resistance method. In response to the signal issued by the insertion of the bolt and the signal issued by the positioning of the welded portion of the steel sheet (30), the electrode (6) is advanced relative to the steel sheet (30), and the pressurization and the power feed are then performed.

Owner:青山好高

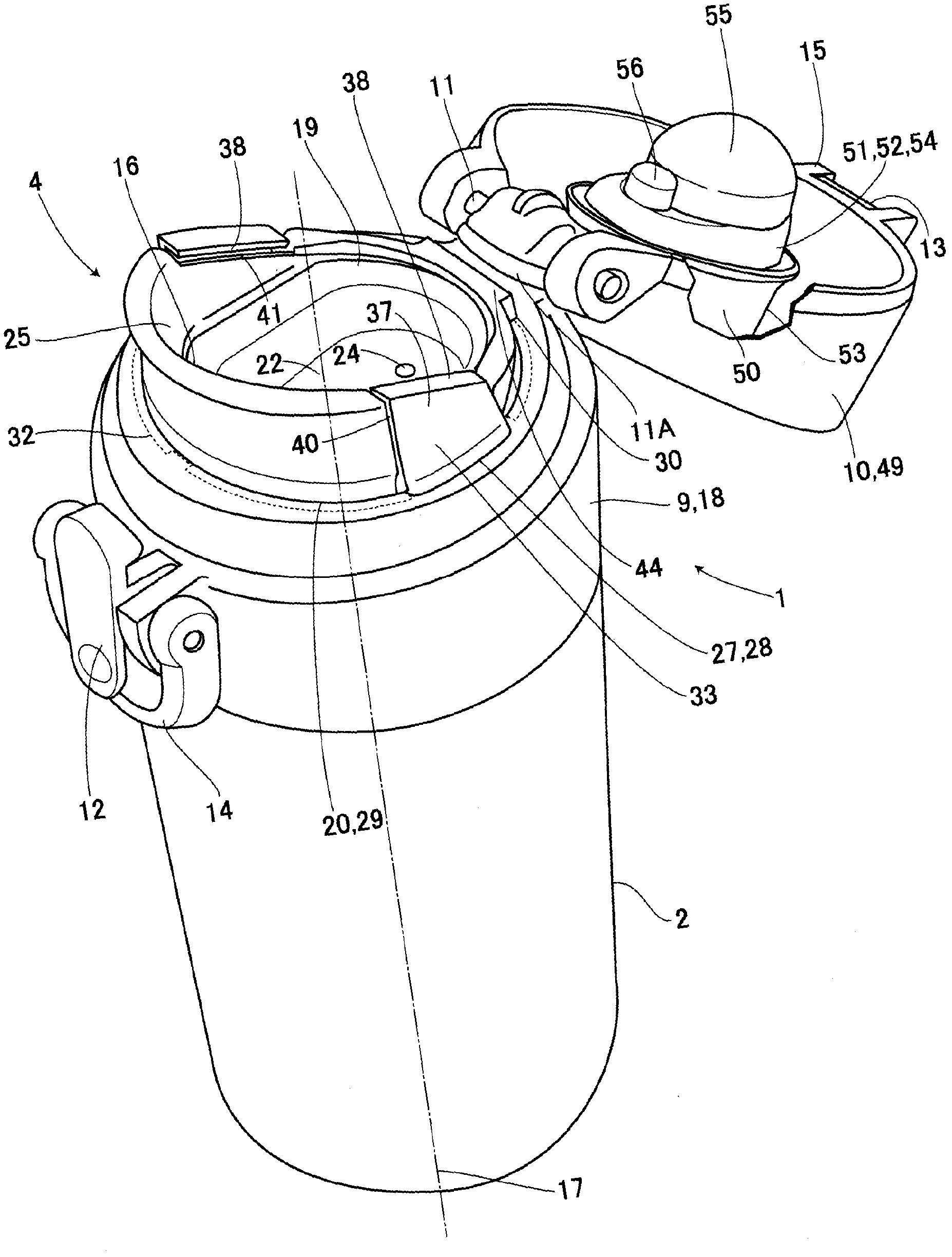

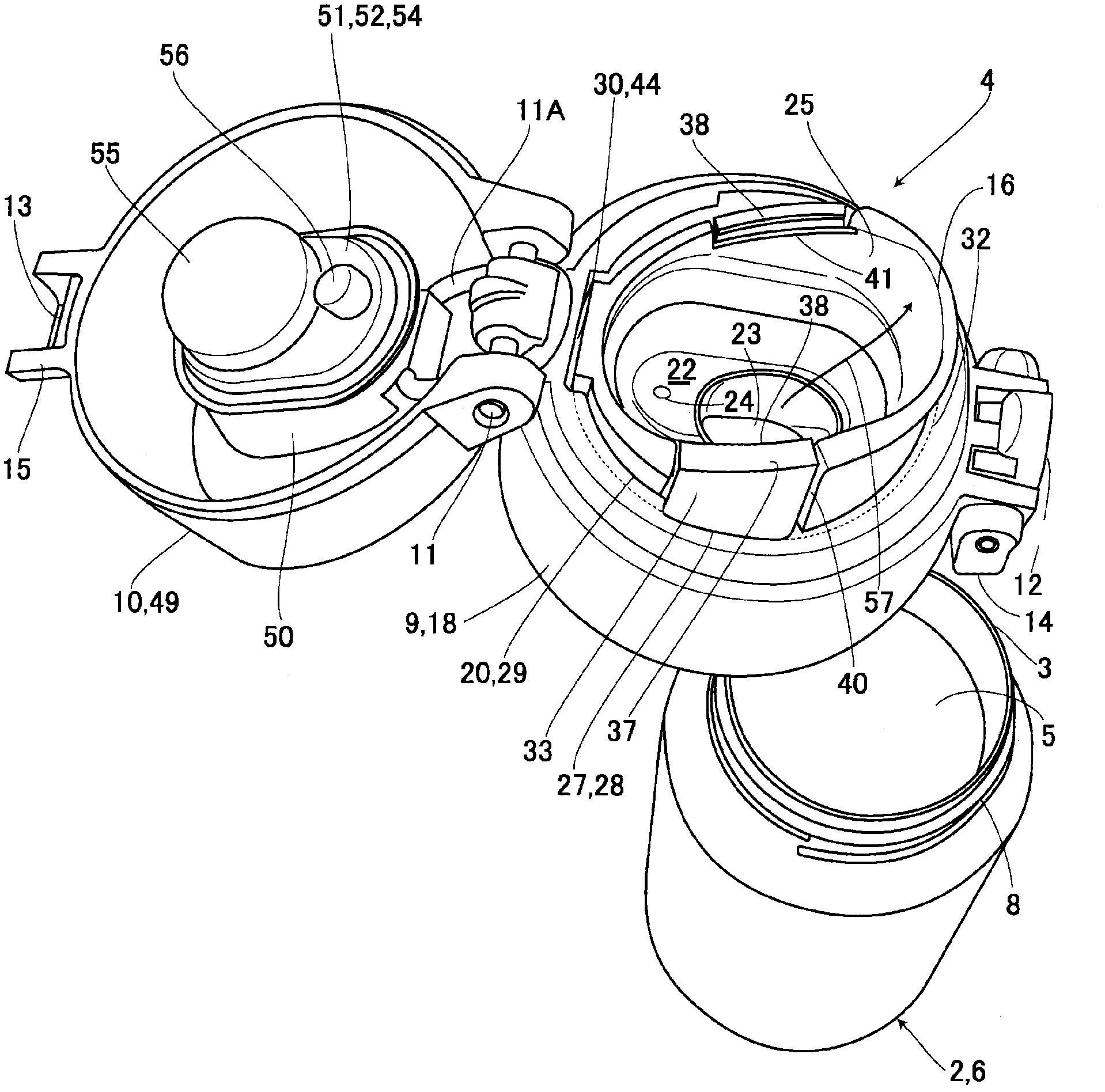

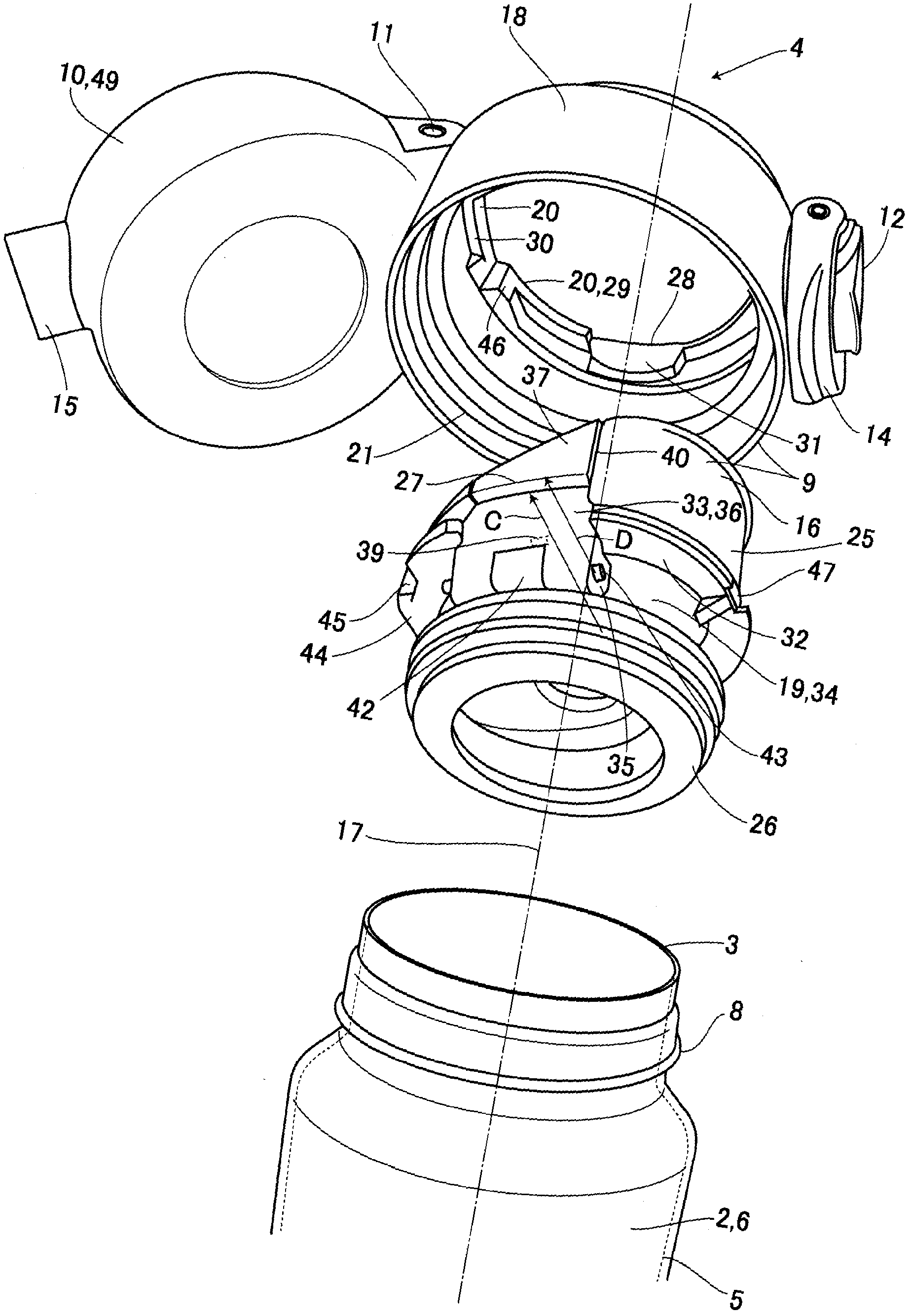

Plug body for beverage container

The invention provides a plug body for beverage container which improves cleaning performance through separating the plug body and can clearly distinguishes appearance difference between an installing state and a separating state. An inner plug part (19) is capable of inserting in and pulling out from the lower part of an outer plug part (18). In order to fix the inner plug part to the outer plug part, the inner plug part is provided with a clamping component (33), and an upper part opening (20) of the outer plug part is provided with a clamping receiving part (28). The clamping component of the inner plug part exposes upwardly from the upper part opening of the outer plug part and can be clamped in a loading and unloading manner. By means of an inward flange (29) and a lower part outward flange (32), the inner plug part can be positioned when inserting from the lower part into the outer plug part. Through clamping an upper part outward flange (27) with the upper part of the clamping receiving part, the inner plug part can be prevented from falling off. Through unassembling the inner plug part from the outer plug part, each corner of the plug body can be cleaned. Whether the inner plug part is reliably installed on the outer plug part can be observed and determined through the outer side of the plug body.

Owner:THERMOS CHINA HOUSEWARES +1

Discharging device for heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of junked tire

ActiveCN103672923ADoes not destroy physical propertiesFacilitate subsequent processingIncinerator apparatusDecompositionEngineering

The invention discloses a discharging device for a heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of a junked tire. The discharging device comprises a shell, a material laying plate used for containing the solid products, a chain board wheel transmission assembly, a driver and a plurality of material scraper blades. A discharge opening is formed in the shell. The material laying plate is movably arranged inside the shell. The chain board wheel transmission assembly is arranged inside the shell and placed above the material laying plate. The driver drives the chain board wheel transmission assembly to operate. The material scraper blades are respectively arranged on a transmission chain of the chain board wheel transmission assembly, the transmission chain drives the material scraper blades to move, and the material scraper blades push the solid products to the discharge opening. According to the discharging device, the traditional problems of material clamping, blocking and the like are solved, the continuous discharging purpose is achieved, the operating cost caused by abnormal maintenance and overhauling is greatly lowered, carbon black can be effectively prevented from being ground into powder, the potential risk caused by raised dust is avoided, and meanwhile the physical property of the solid products can not be damaged.

Owner:北京节净环保科技有限公司

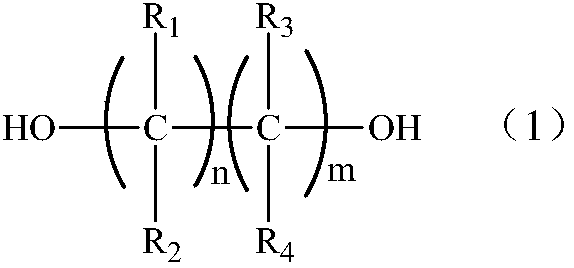

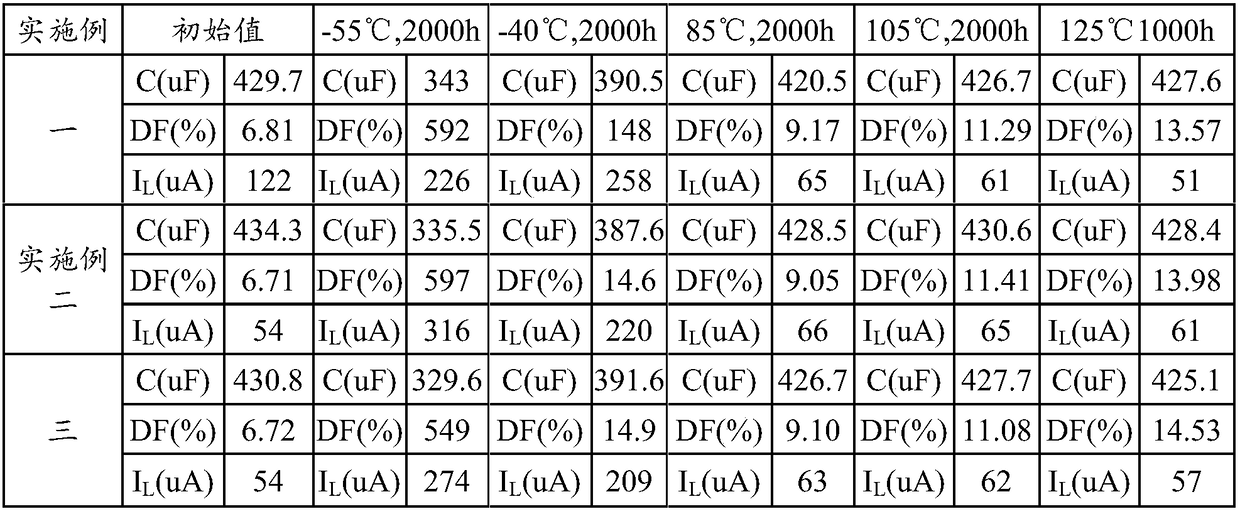

Aluminum electrolytic capacitor electrolyte solution and a preparation method thereof and aluminum electrolytic capacitor

The invention discloses an aluminum electrolytic capacitor electrolyte solution and a preparation method thereof, and an aluminum electrolytic capacitor using the aluminum electrolytic capacitor electrolyte solution, wherein, the aluminum electrolytic capacitor electrolyte solution comprises a main solvent, 40-70; auxiliary solvent, 10-30 part; Solute, 5-20 part; and additives, 1-10 part; Whereinthe main solvent is an alcohol solvent and the auxiliary solvent contains a polyhydroxy alcohol substance. The technical proposal of the invention can overcome the shortcomings existing in the existing electrolyte, effectively broaden the use range of the electrolyte, and can reduce the surface tension of the electrolyte, thereby improving the core immersion rate.

Owner:深圳市智胜新电子技术有限公司

Method for preparing initial molten salt system in molten salt electrolysis dry after-treatment process

ActiveCN104562089AReduce operating proceduresReduce volume and disposal costsProduction lineAfter treatment

The invention belongs to the technical field of nuclear fuel cycle dry after-treatment and discloses a method for preparing an initial molten salt system in a molten salt electrolysis dry after-treatment process. The method comprises the following steps: introducing chlorination gases into LiCl-KCl eutectic molten salt and spent fuel positioned in an electrolytic cell so as to introduce uranium ion into the molten salt, thereby obtaining the initial molten salt system needed by molten salt electrolysis dry after-treatment. The method has the advantages that the chlorination rate of the chlorination gases is high, the uranium ion can be introduced into the electrolytic cell in situ, and an extra uranium chloride production line does not need to be established.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

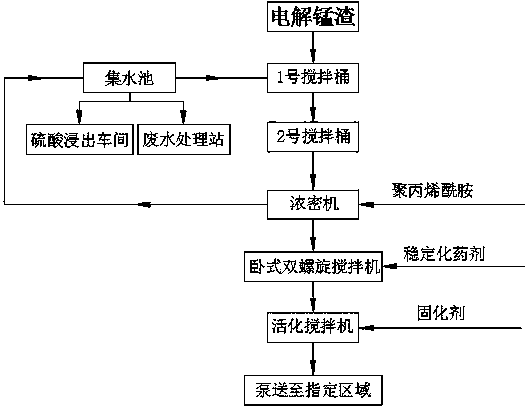

Harmless treatment method for electrolytic manganese slag

InactiveCN109622566AAchieve structural strengthAvoid interferenceSolid waste disposalElectrolysisSlag

The invention provides a harmless treatment method for electrolytic manganese residue, and belongs to the field of solid waste treatment. The harmless treatment method comprises the following step (1)of conveying fresh electrolytic manganese slag to a No.1 mixing tank through a belt conveyor for blending; the step (2) of enabling the electrolytic manganese slag prepared in the step (1) to automatically flow into a No.2 mixing tank for continuous stirring, and conveying the electrolytic manganese slag into a thickener through a slurry pump; the step (3) of concentrating the electrolytic manganese slag in the thickener for solid-liquid separation; the step (4) of collecting slag cleaning liquid separated by the thickener through a catchment basin, and enabling a part of slag cleaning liquidto return to a sulfuric acid leaching workshop for recycling, a part of slag cleaning liquid return to the No.1 mixing tank in the step (1) for blending, and a part of slag cleaning liquid to returnto a waste water treatment station for treatment; and the step (5) of conveying the electrolytic manganese slag concentrated by the thickener to a mixer for stabilization / solidification treatment, andconveying the treated electrolytic manganese slag to a specified area through a pipeline for stockpiling. The above steps are performed continuously. According to the scheme, the purposes of resourceutilization and harmless treatment of manganese slag are achieved, and no new contaminants are generated; and the harmless treatment method has double significances of economy and environmental protection.

Owner:FENY

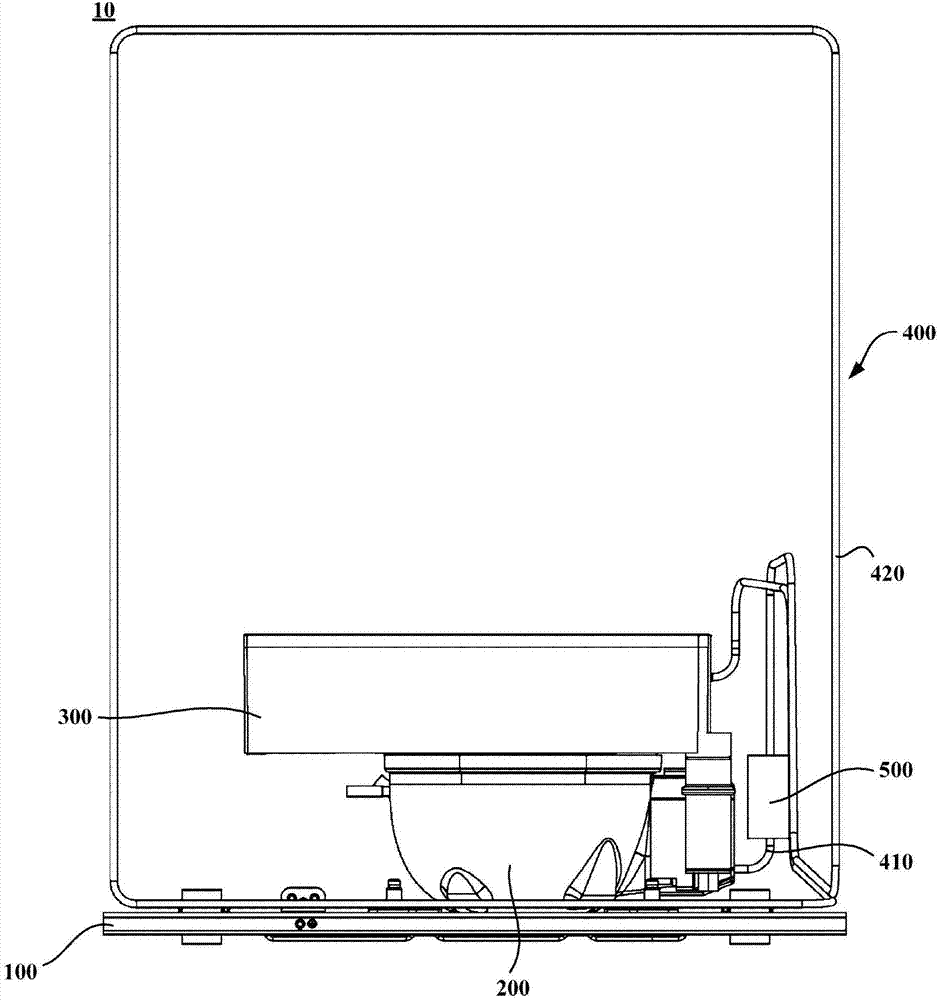

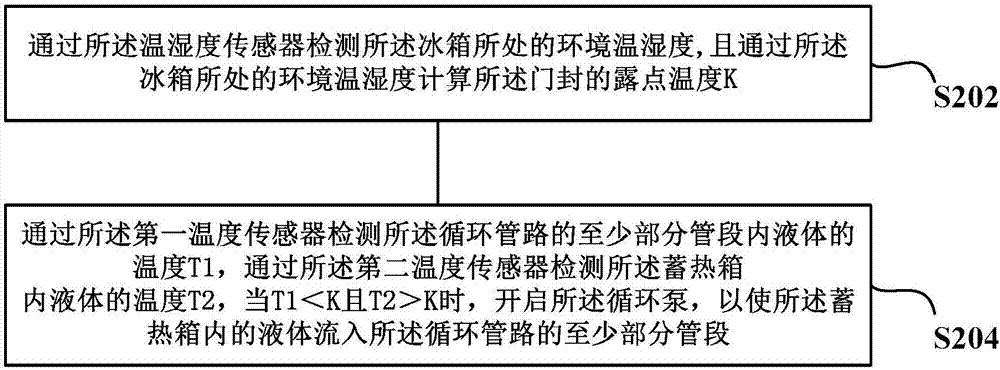

Refrigerator and condensate removing method of refrigerator door seals

InactiveCN106989560ARealize rational utilizationAvoid wastingLighting and heating apparatusCooling fluid circulationEngineeringEnergy consumption

The invention relates to a refrigerator and a condensate removing method for refrigerator door seals. The refrigerator comprises a heat accumulation box, a circulation pipe and a circulating pump, wherein the heat accumulation box is arranged in a compressor bin and located above a compressor, and the lower surface of the heat accumulation box is attached to the upper surface of the compressor; the heat accumulation box is internally provided with liquid for heat accumulation so as to store heat dissipated by the compressor; the two ends of the circulating pipe are connected with the heat accumulation box, and the circulating pipe and the heat accumulation box jointly form a loop; at least part of pipe section of the circulating pipe is attached to at least one door seal; the circulating pump is arranged on the circulating pipe to make liquid in the heat accumulation box to flow into at least part of pipe section of the circulating pipe and then make heat of the liquid in at least part of pipe section of the circulating pipe to be transmitted to at least one door seal. Besides, the invention provides the condensate removing method applied to the refrigerator. According to the refrigerator provided by the invention, condensate generated at the door seals of the refrigerator can be removed, and energy consumption of the refrigerator can be reduced in the condensate removing process.

Owner:HAIER SMART HOME CO LTD

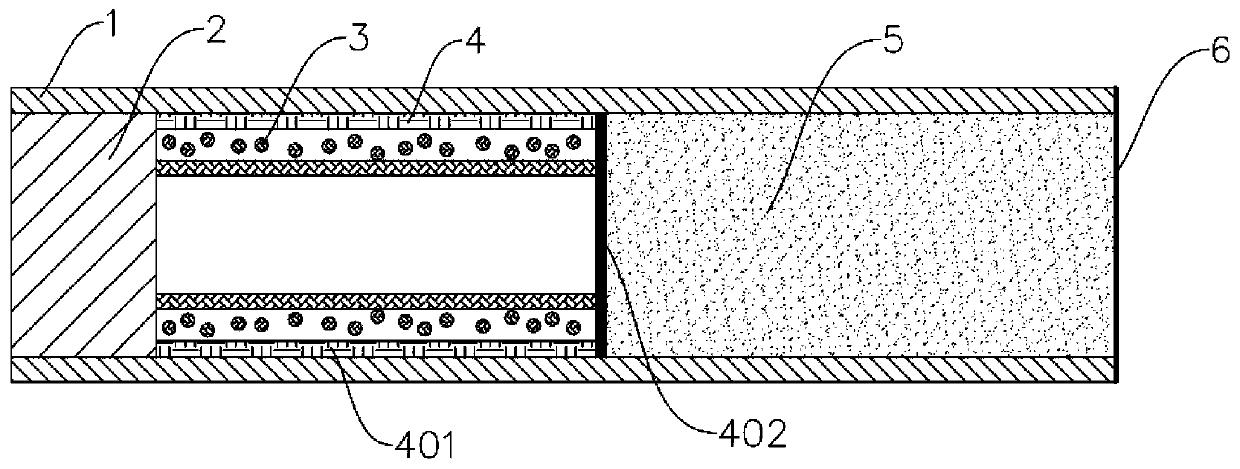

Waste water microwave photocatalytic degradation processing unit for preventing membrane separation component from thermal etching damage

InactiveCN102730893ATo curb the damage process of point-like thermal penetration erosionAvoid absorptionWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentPhotocatalytic reactionEtching

The invention relates to a waste water microwave photocatalytic degradation processing unit for preventing a membrane separation component from thermal etching damage, which belongs to the technical field of waste water processing. According to the conventional microwave photocatalytic degradation technology aiming at the industrial waste water containing organic pollutants, metal particles, carbon particles and the like which are inevitably adsorbed on the surface of the organic matter membrane separation component are good absorbing medium for microwave energy so as to generate the thermal etching damage problem of the membrane separation component, and in addition, the outer side surface of a quartz tube used for an electrodeless ultraviolet lamp screen shielding in a device generates the scaling phenomenon after being dipped in waste water liquid, the permeability of the quartz tube on ultraviolet is affected, and the processing efficiency of a microwave photocatalytic reaction device is lowered. According to the scheme disclosed by the invention, the problems are solved completely. According to the scheme, the membrane separation component is hidden in a box cage shaped microwave shielding cover made of metal so as to restrain the thermal etching damage problem, and a scale layer is instantly removed by high-frequency ultrasonic wave.

Owner:NINGBO UNIV

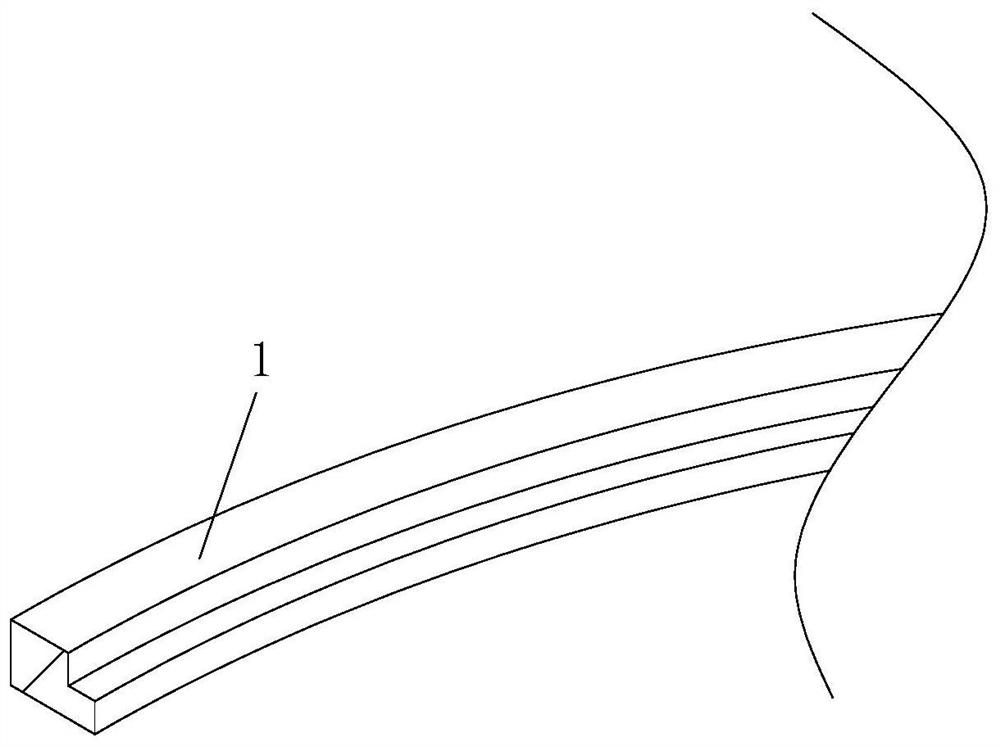

Flue gas treatment part, low-temperature incombustible particle type cigarettes using the same and production technique thereof

PendingCN110367587APrevent leakageImprove filtering effectCigar manufactureCigarette manufactureFlue gasFilter effect

The invention provides a flue gas treatment part. The flue gas treatment part takes a crude paper tube with a hollow structure as a main body and two ends sealed by breathable sheet layers. The invention further provides low-temperature incombustible particle type cigarettes. The low-temperature incombustible particle type cigarette comprises a smoke tube, a mouthpiece rod, a first flue gas treatment part, a second flue gas treatment part, tobacco particles and a plugging layer, wherein the mouthpiece rod, the first flue gas treatment part, the second flue gas treatment part, the tobacco particles and the plugging layer are arranged in the smoke tube, the second flue gas treatment part is in close contact with the inner wall of the smoke tube, and the plugging layer is used for sealing oneend of the smoke tube and forms a space for maintaining the tobacco particles in the smoke tube with the second flue gas treatment part. The invention further provides a production technique of the low-temperature incombustible particle type cigarettes. According to the flue gas treatment part, the low-temperature incombustible particle type cigarettes using the same and the production techniquethereof in the invention, it can be ensured that the tobacco particles filled in the low-temperature incombustible particle type cigarettes can be reliably maintained, so that loose and leakage of thetobacco particles are effectively avoided, the filtering effect is remarkably improved so as to meet the requirement for health of smokers, and the fragrance type of the cigarettes can be adjusted according to requirements of different consumers so as to adapt to the smoking preference of different consumers.

Owner:SOUL TOUR ELECTRONICS (HUIZHOU) CO LTD

Quantum dot backlight source and liquid crystal display with same

PendingCN107577087AImprove reliabilityAvoid squeezingOptical light guidesNon-linear opticsEnvironmentally friendlyLiquid-crystal display

The invention discloses a quantum dot backlight source and a liquid crystal display with the same. The quantum dot backlight source comprises a backboard, a light source component, a light guide plate, a quantum rod and a mounting seat, the light source component is arranged in the backboard, the light guide plate is arranged in the backboard, positioned on one side of the light source component and used for receiving light rays of the light source component, the quantum rod is arranged between the light source component and the light guide plate, separated from the light source component andthe light guide plate and used for transforming colors of the light rays of the light source component, the mounting seat is arranged in the backboard and positioned below the quantum rod and the light guide plate, and the quantum rod and the light guide plate are oppositely and fixedly mounted on the mounting seat. The quantum dot backlight source can solve the problem that quantum dot materialsleak as the quantum rod is cracked when the quantum rod is extruded by the light guide plate in expansion, use reliability of the quantum dot backlight source is improved, and the quantum dot backlight source is safer and more environmentally friendly.

Owner:SHENZHEN G WORLD TECH INC CO

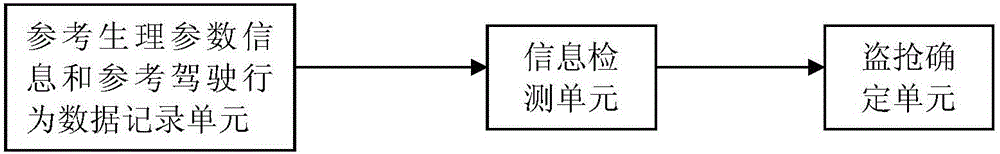

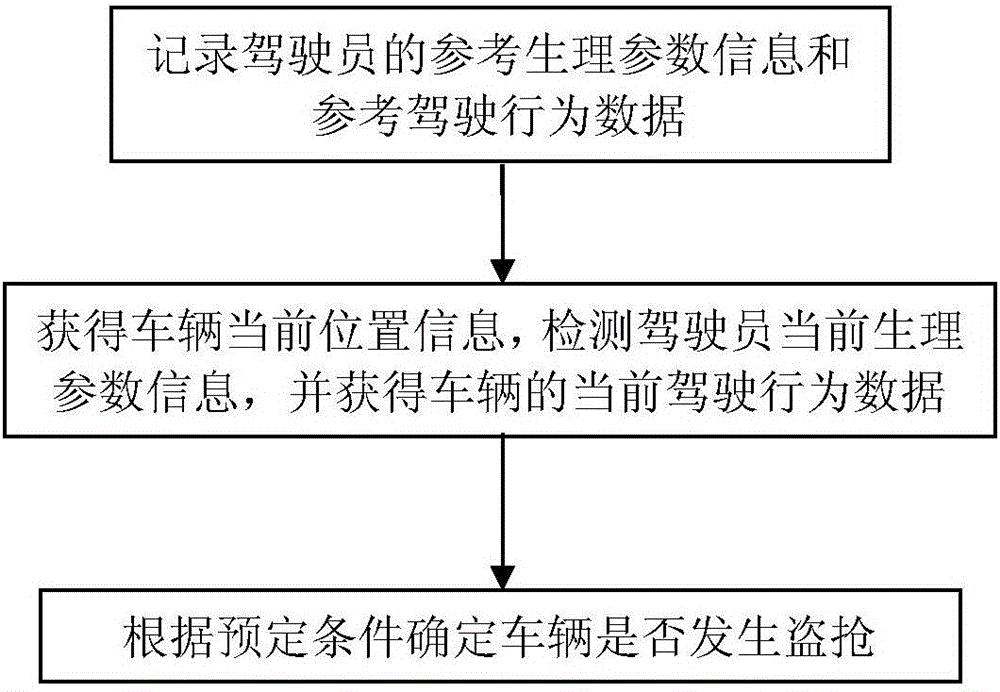

Parking/driving safety information detection system

The invention provides a parking / driving safety information detection system to overcome the defects in the prior art and improve the safety and reliability of monitoring on stealing and robbing of vehicles. The parking / driving safety information detection system comprises a reference recording reference physiological parameter information and reference driving behavior data of a driver in the parking period and the driving period respectively, an information detection unit used for obtaining the current position information of a vehicle, detecting the current physiological parameter information of the driver and obtaining the current driving behavior data of the vehicle, and a stealing and robbing determining unit used for determining whether stealing and robbing occur on the vehicle or not according to preset conditions. The reliability and safety for automatically detecting whether stealing and robbing occur or not in the driving process of the vehicle are improved, and the influence of misjudgment or neglected judgment generated when violent damage is detected only relying on a vibration sensor or the like and the vibration sensor is interfered is avoided.

Owner:桐乡市尚艺家纺产业服务有限公司

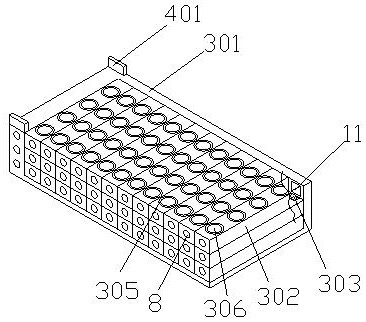

Microbial fertilizer producing strain screening device and fermentation process thereof

ActiveCN112251325ASmall footprintEasy to cultivate and observeBioreactor/fermenter combinationsBio-organic fraction processingFertilizerCulture mediums

The invention relates to the technical field of strain culture, and discloses a microbial fertilizer producing strain screening device and a fermentation process thereof. The microbial fertilizer producing strain screening device comprises a bearing box, wherein holes are formed in the left side surface and the right side surface of the bearing box at equal intervals; side frames are fixedly connected in the holes; the side frames are C-shaped bodies; the concave surfaces of the side frames on the left side and the right side correspond to each other; a transverse guide rail is fixedly arranged in the center of the front surface of the bearing box; a vertical guide rail is fixedly connected to a transmission shaft of the transverse guide rail; the vertical guide rail corresponds to the center of the bearing box; a plurality of side frames are provided with culture mechanisms and movement mechanisms; and a material taking mechanism is arranged on the inner wall of the bearing box. According to the microbial fertilizer producing strain screening device and the fermentation process thereof, the culture mechanisms and the material taking mechanism are arranged, so that culture equipment is stacked up and down in order to achieve the purposes of high flux and reduction of occupied space; and culture boxes loaded with culture media can be stored and taken through simple operation, the problem of rummaging caused by stacking of the culture equipment is avoided, workers can conveniently culture and observe strains, and therefore the screening efficiency is improved.

Owner:沈阳丰恒泰农业科技有限公司

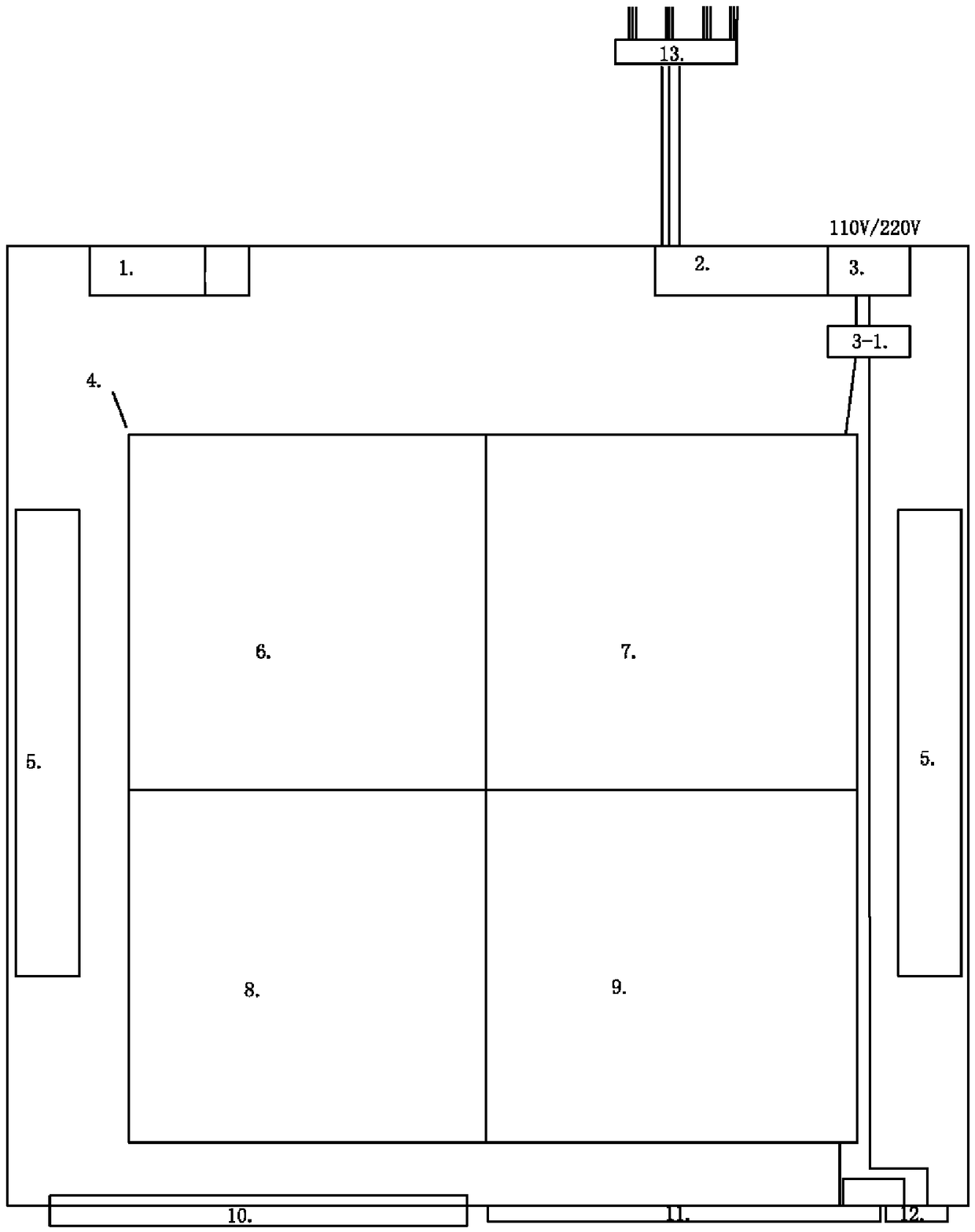

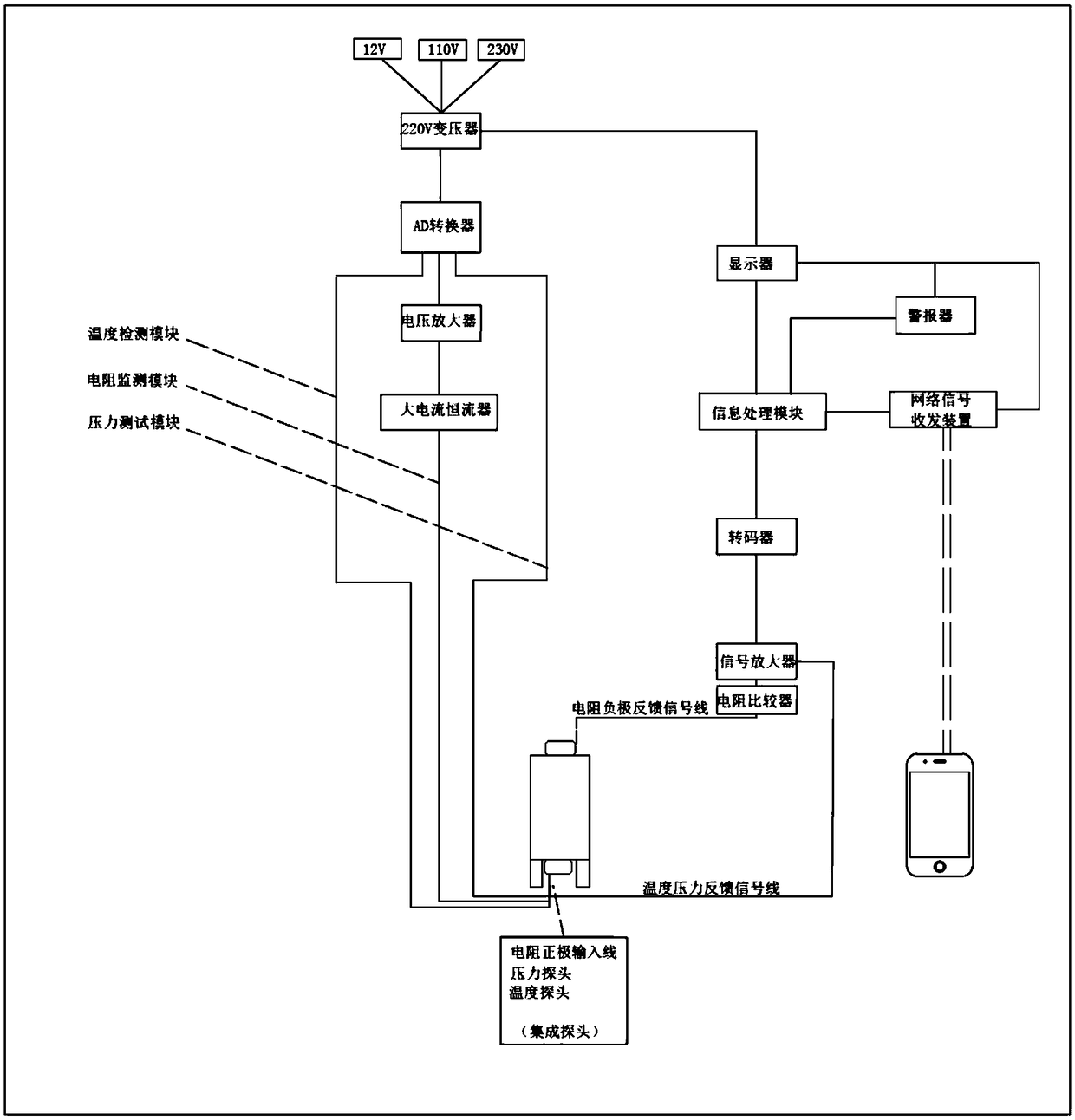

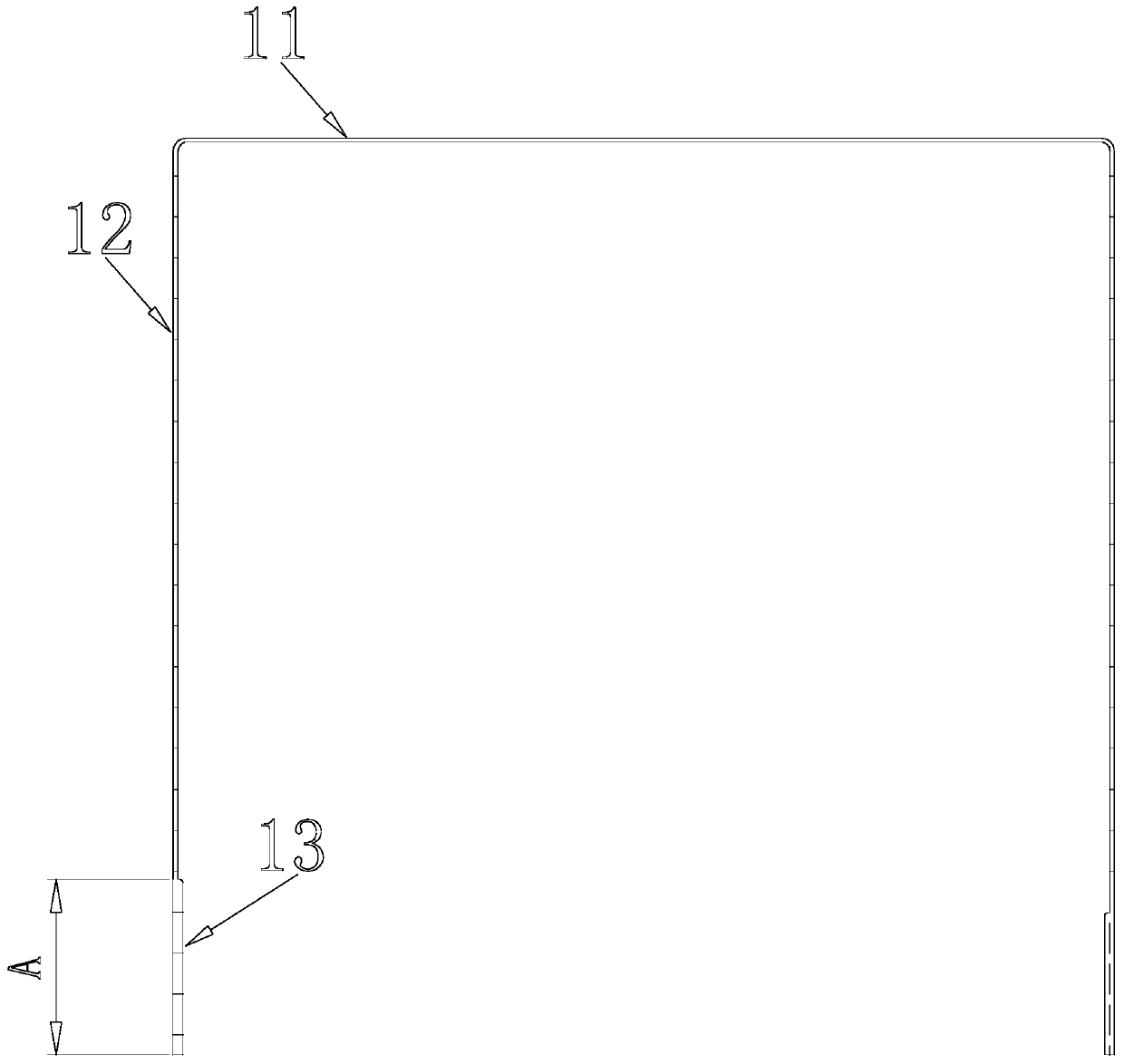

Online resistance temperature and pressure monitoring early-warning instrument

PendingCN108761206AShort response timeLow equipment loss and repair costsResistance/reactance/impedenceTransceiverData lines

The invention discloses an online resistance temperature and pressure monitoring early-warning instrument. The online resistance temperature and pressure monitoring early-warning instrument comprisesa box body; a signal transceiver device, a data line socket, a power module, a display module, a button module and a key module are arranged on the box body; a main board is arranged inside the box body; and the main board includes a resistance monitoring module, a temperature monitoring module, a pressure monitoring module, and an information processing module. The invention integrates the monitoring and early-warning device for a storage tank through the organic combination of hardware and software, combines with the instant messaging device such as the mobile phone to realize real-time online monitoring of a storage tank system, and can immediately issue an alarm before the storage tank is about to leak;, the problem can be fed back to the relevant personnel's mobile phone in the firsttime through the built-in communication software, thus minimizing the response time and minimizing the equipment loss and the maintenance cost. The invention can improve the safety and reliability ofthe storage tank, can effectively avoid the leakage of the storage tank and the like, and prevent the occurrence of production safety accidents.

Owner:江苏瑞能防腐设备有限公司

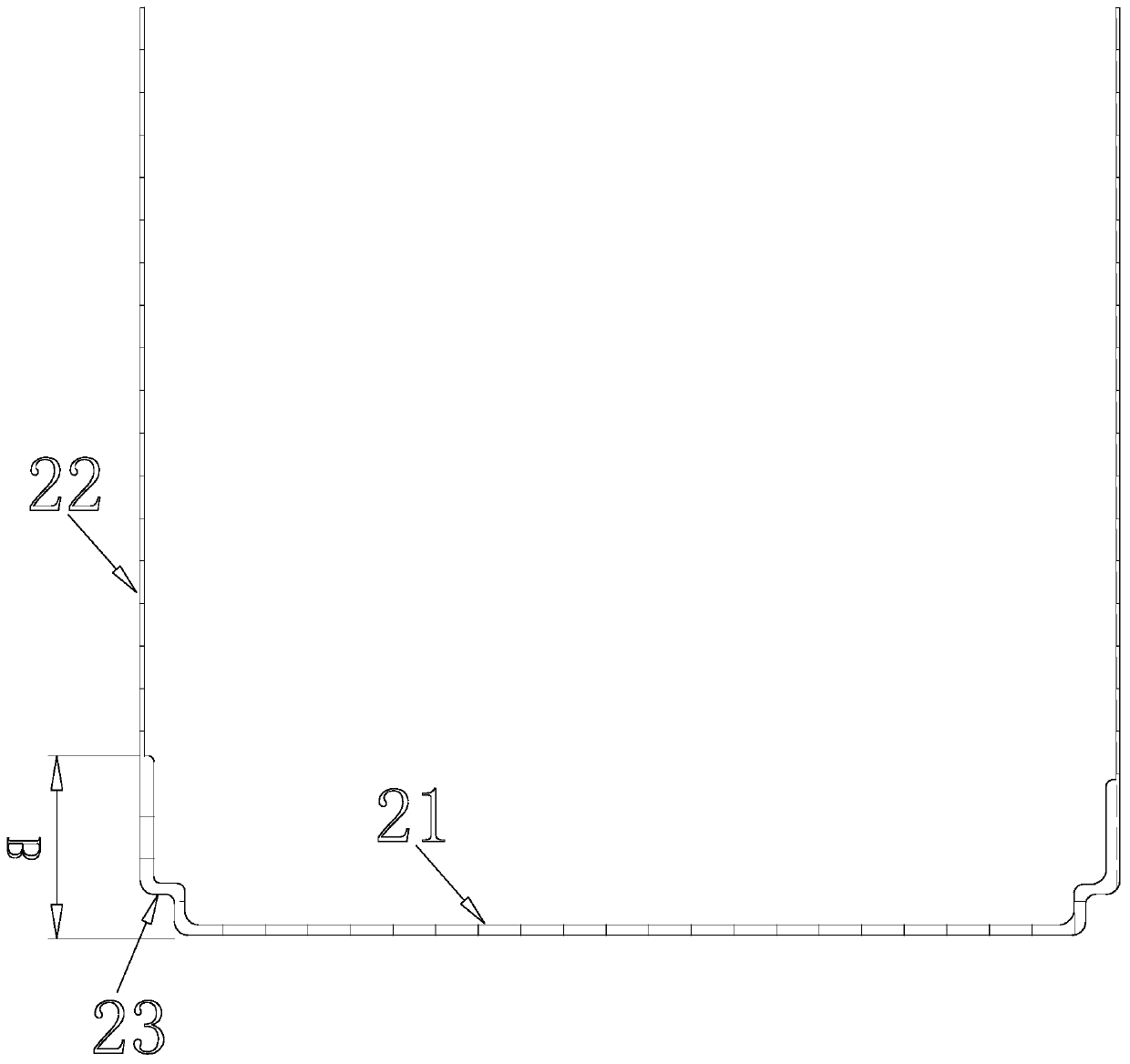

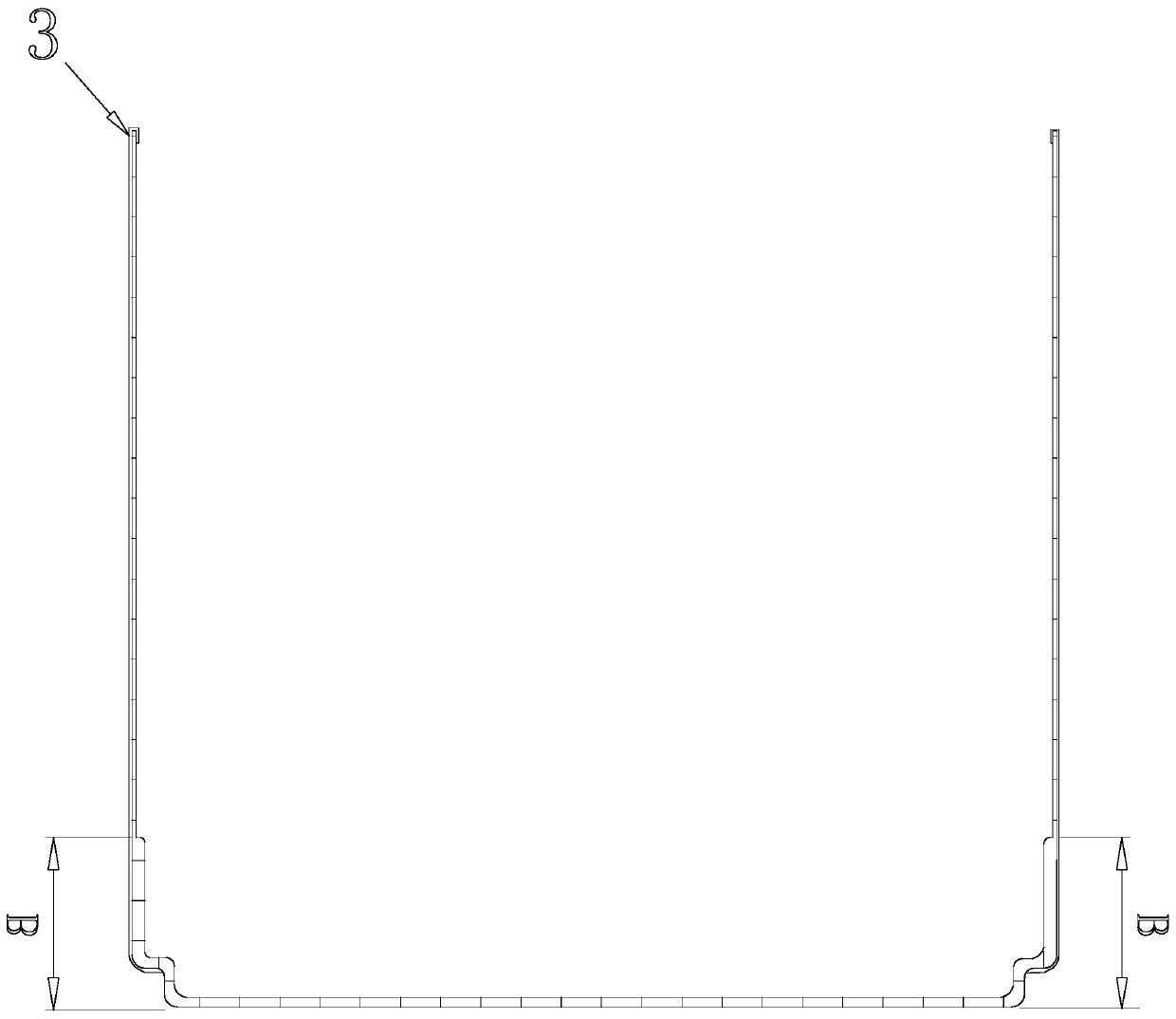

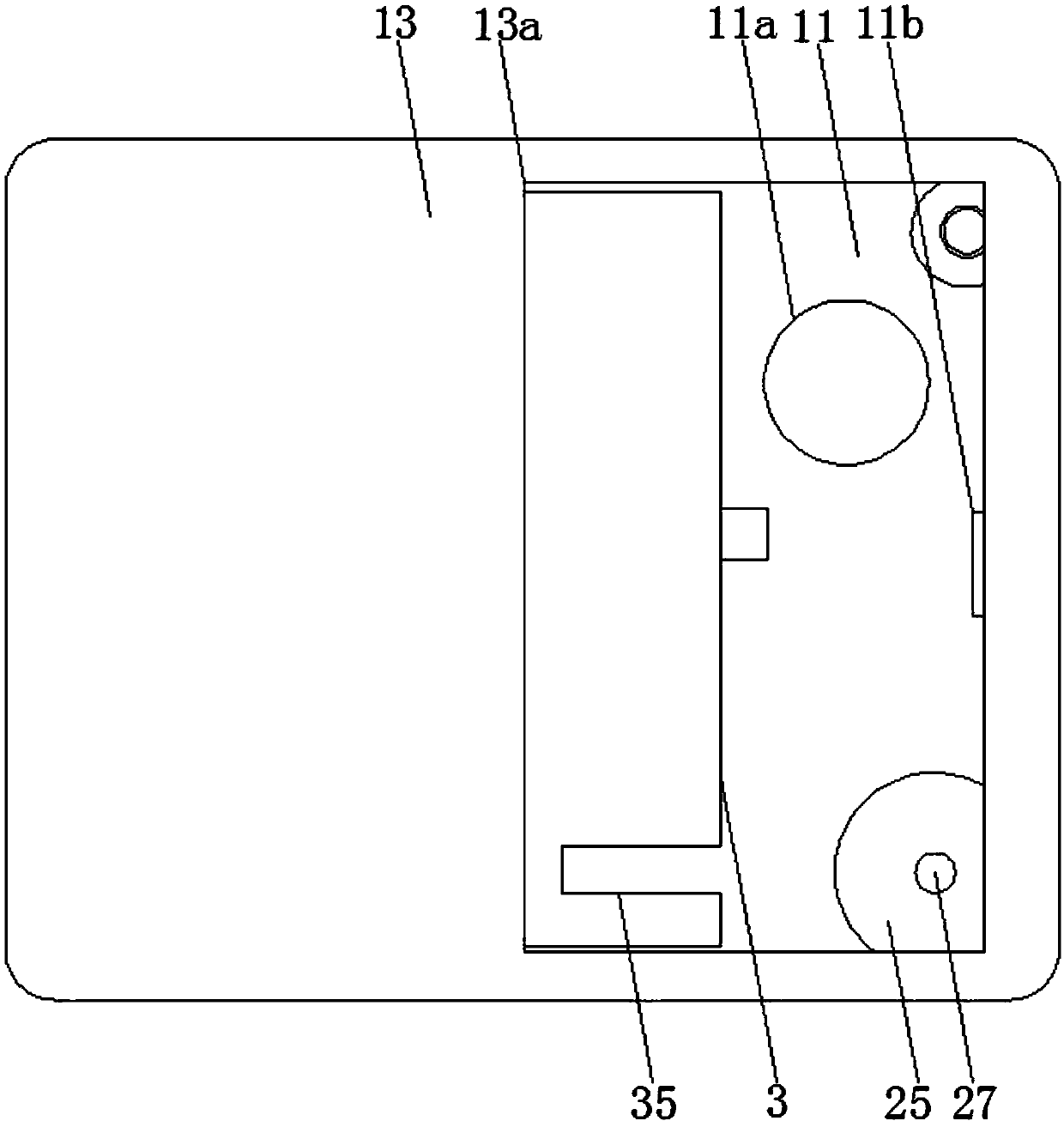

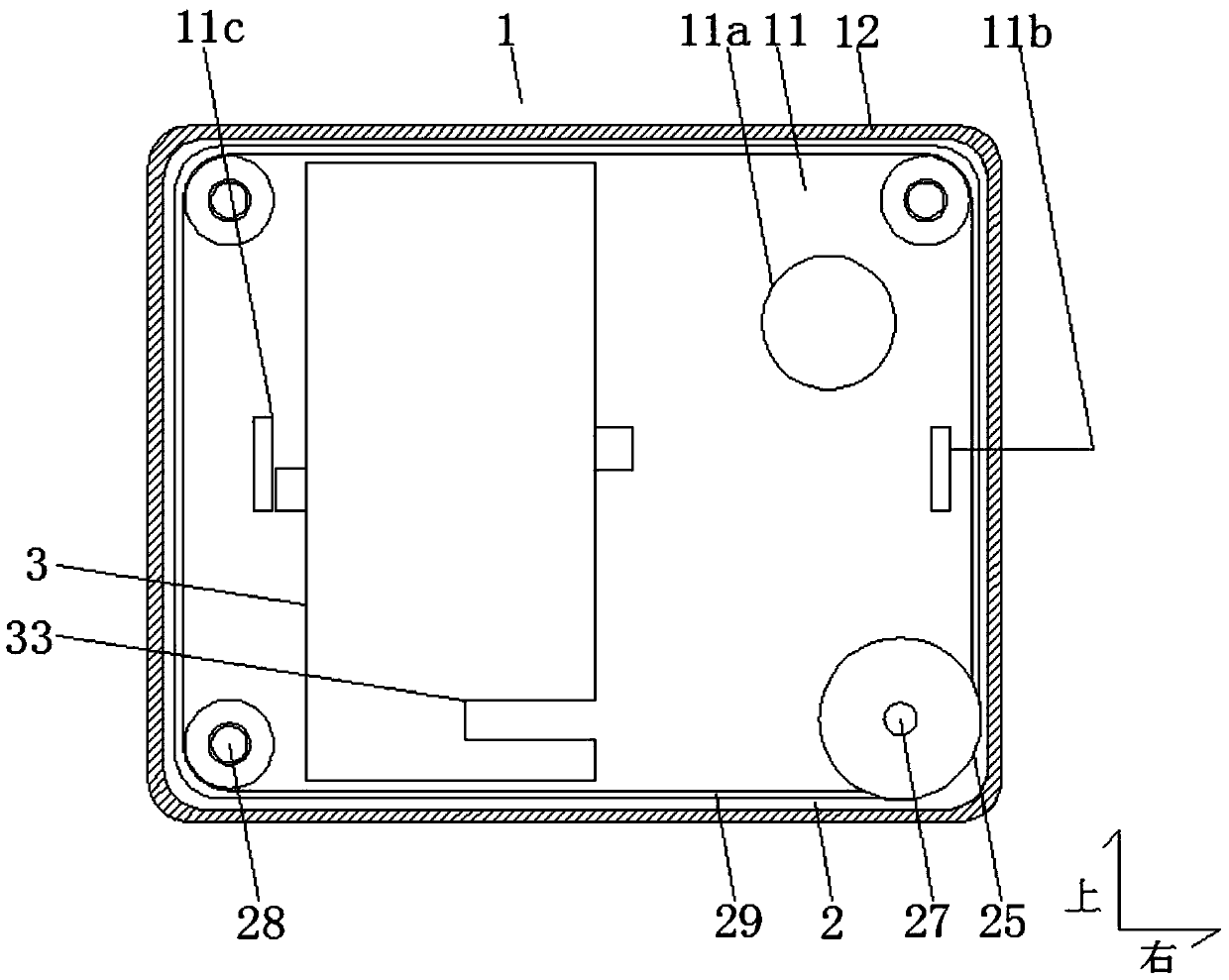

Button lithium ion battery and shell

PendingCN111341951AIncrease capacityEnsure rigiditySecondary cellsCell sealing materialsElectrical batteryLithium-ion battery

The invention relates to the field of lithium ion batteries, and discloses a button type lithium ion battery and a shell. The shell comprises: a negative electrode shell comprising a negative electrode top cover and a negative electrode shell wall, and the negative electrode shell wall surrounds the edge of the negative electrode top cover, is perpendicular to the negative electrode top cover andis located on one surface of the negative electrode top cover; the sealing ring is sleeved on the negative electrode shell; the positive electrode shell comprises a positive electrode top cover and apositive electrode shell wall, and the positive electrode shell wall surrounds the edge of the lower bottom shell, is perpendicular to the positive electrode top cover and is located on one surface ofthe positive electrode top cover; wherein the anode shell wall is sleeved outside the cathode shell wall, the sealing ring is arranged between the anode shell and the cathode shell at intervals, thetail end of the anode shell wall is an anode shell thick-wall annular section, the anode shell thick-wall annular section is bent and pressed outside the anode shell to form an annular seal, and the wall thickness of the anode shell thick-wall annular section is greater than that of other positions of the anode shell. By adopting the technical scheme, the air tightness of the shell is ensured on the basis of improving the capacity of the button lithium ion battery.

Owner:SHENZHEN GREPOW BATTERY CO LTD

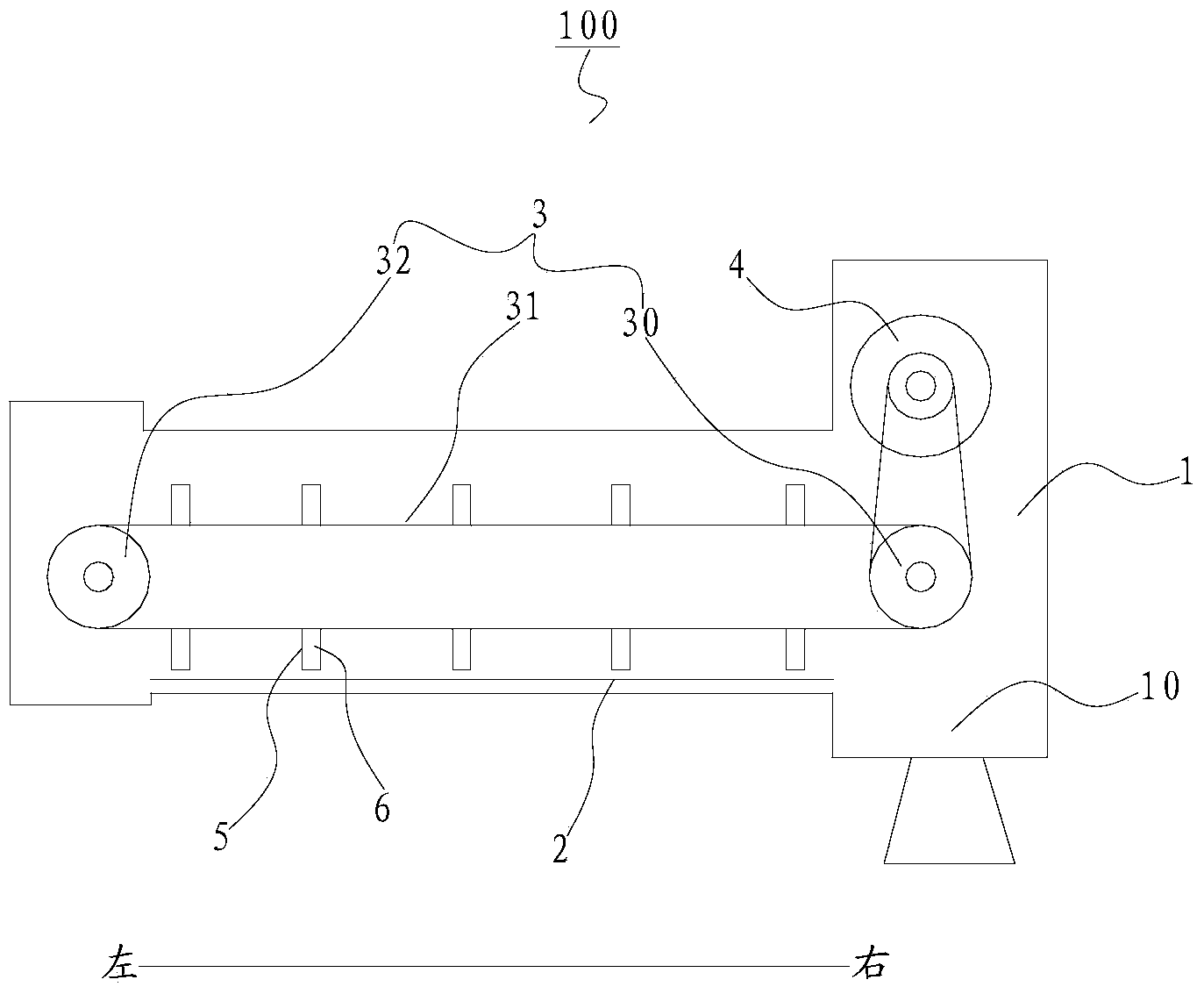

Automobile fuel tank cap automatically opened and closed

ActiveCN107696852AAvoid problems such as leakageAdjustable movement speedFuel supplyStart stopTransmission belt

The invention relates to an automobile fuel tank cap automatically opened and closed. The automobile fuel tank cap automatically opened and closed comprises a tank cap body, a power device and a driven baffle. The tank cap body is a rectangular hollow shell and comprises a rear bottom board, a peripheral side wall and a front top board. The power device comprises a drive barrel, a drive motor, a sun gear, a planet support, an outer sliding ring, a reset spring, a start-stop switch, turning rolls and a transmission belt. The driven baffle comprises a baffle body, a reversing insertion rod, a left contactor, a right contactor and a pressing side hole. By the adoption of the automobile fuel tank cap automatically opened and closed, the start-stop switch is turned on so that the driven bafflecan be controlled to automatically finish the automatic cap opening action, the cap closing preparation action and the complete cap closing action, fueling operation can be finished through cooperation of inserting and pulling out of a fueling gun, and the problem that gasoline leaks due to the fact that a driver forgets to close a fuel tank cap is solved; and the moving speed of the driven bafflecan be adjusted as well.

Owner:广州市铁研汽车零件有限公司

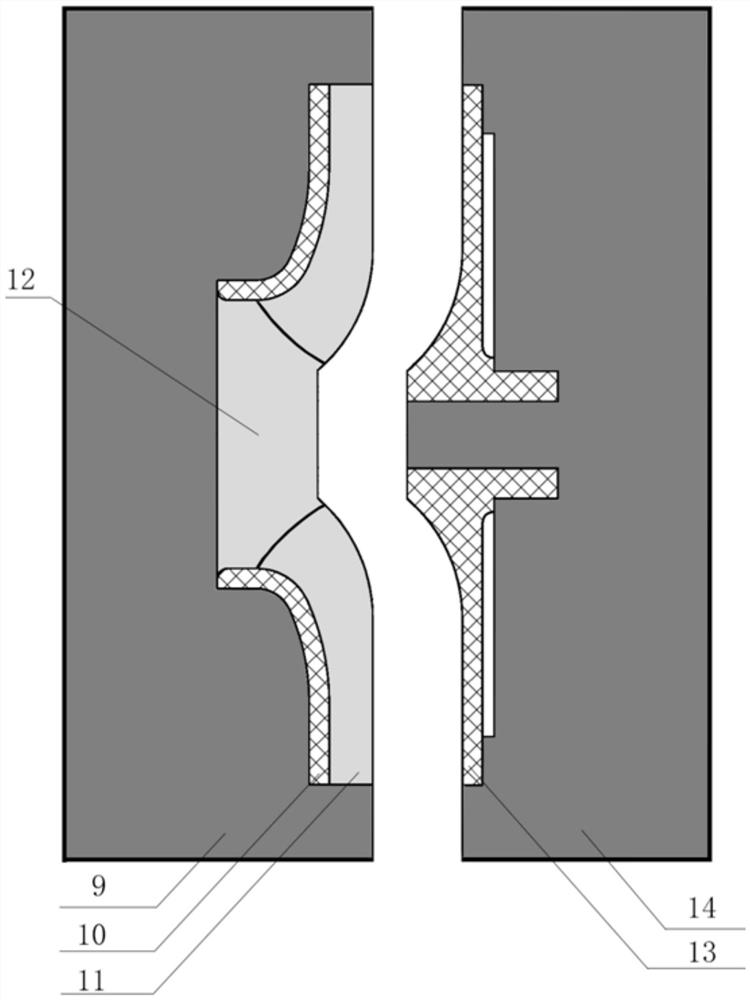

Drain pipe joint

InactiveCN101625057AImprove sealingAvoid problems such as leakageSleeve/socket jointsSiphonPipe fitting

The invention relates to a drain pipe joint, in particular to a drain pipe joint for a siphon principle, a vacuum principle and a gravity principle. According to the technical scheme of the invention, the drain pipe joint comprises a pipe fitting and a pipe stock and is characterized in that the end part of the pipe stock is inserted into the end part of the pipe fitting; the end part of the pipe stock is provided with a contracting section which contracts inwards; the pipe fitting is provided with a first expanding section which expands outwards and corresponds to the contracting section of the pipe stock; the minimum outside diameter of the pipe stock contracting section is slightly longer than the inside diameter of the pipe fitting; the end part of the pipe fitting is provided with a pipe fitting contracting section which contracts inwards, and the minimum inside diameter of the pipe fitting contracting section is longer than the outside diameter of the pipe fitting; space is formed at an overlaid part of the pipe stock and the pipe fittings, and the space is provided with a rubber sealing ring. The invention can enhance the sealing effect of the connection of drain pipes and simplify the installation process.

Owner:无锡金羊管件有限公司

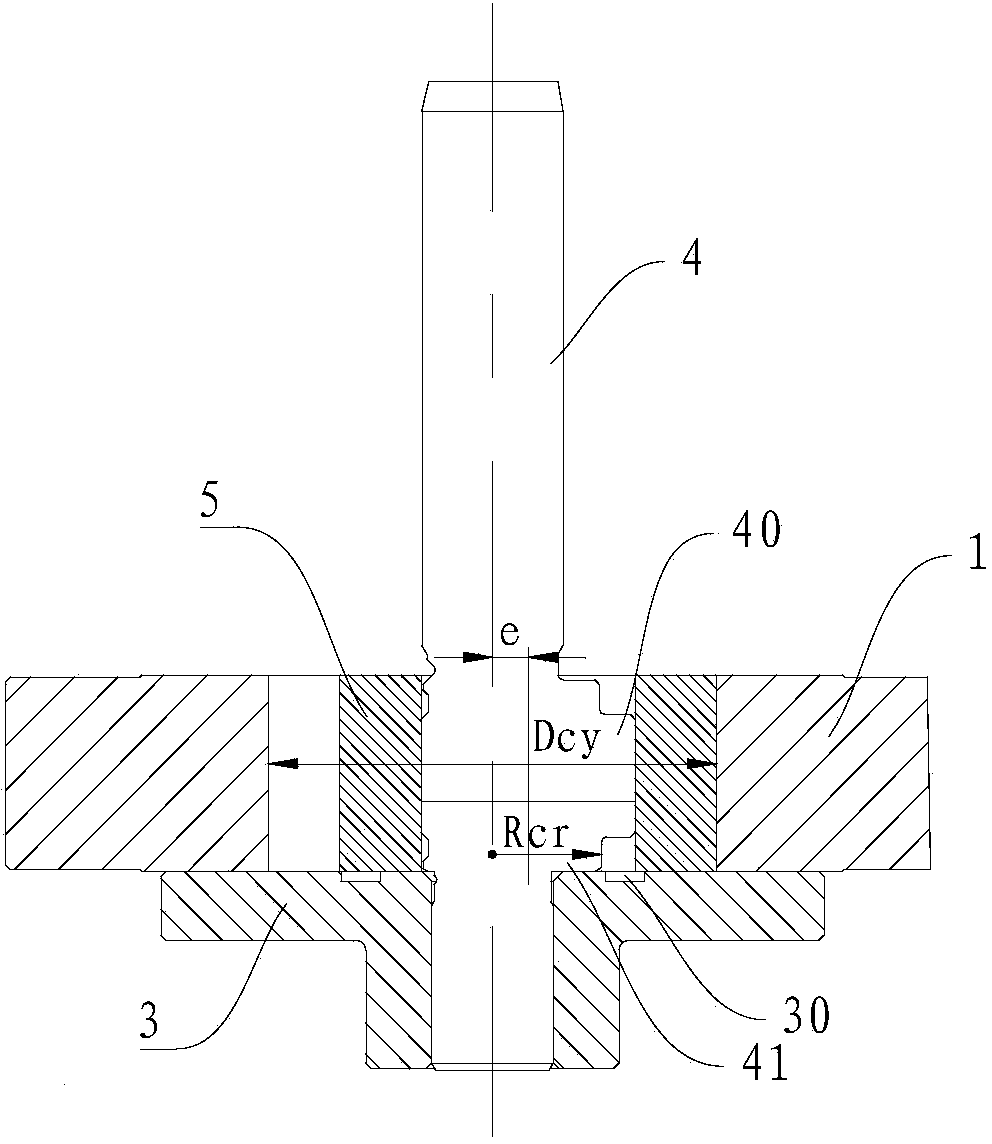

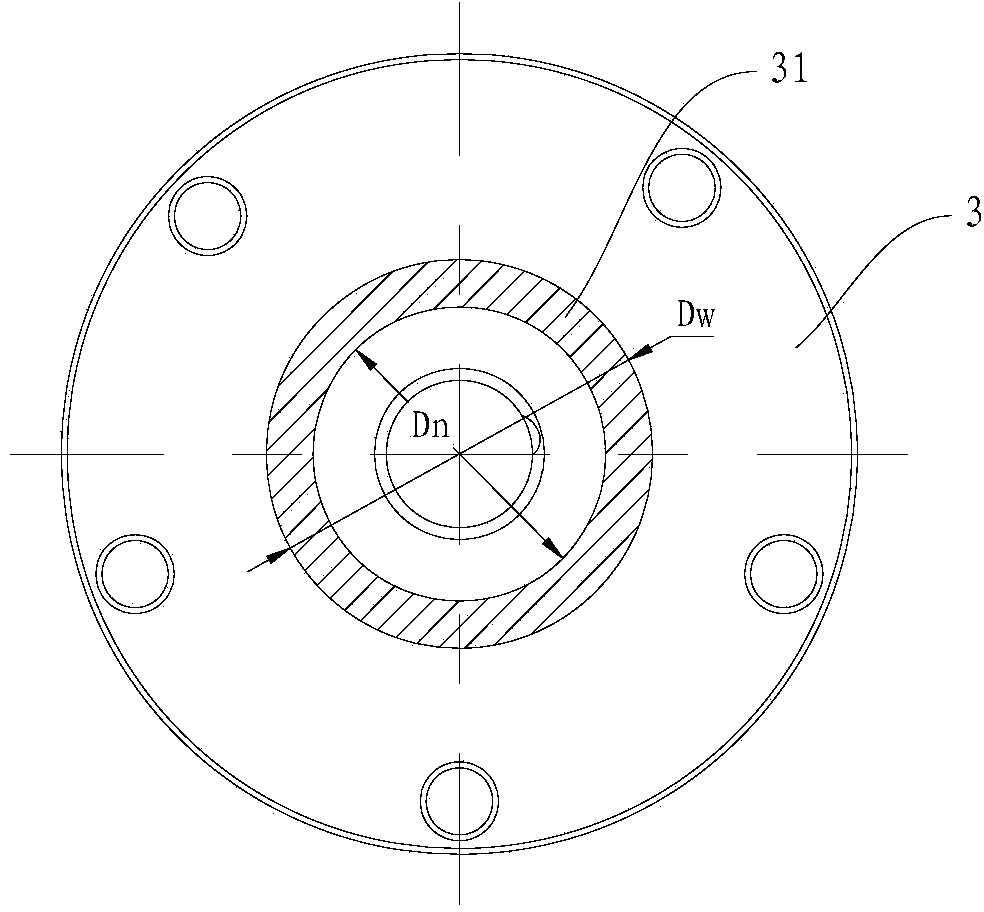

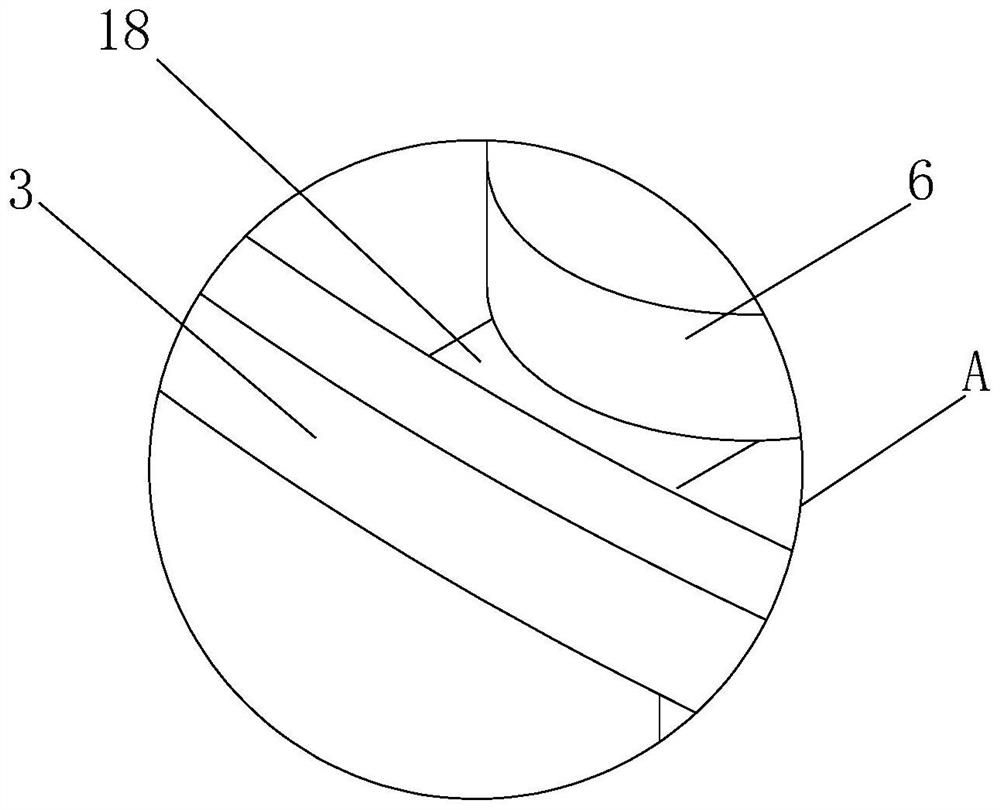

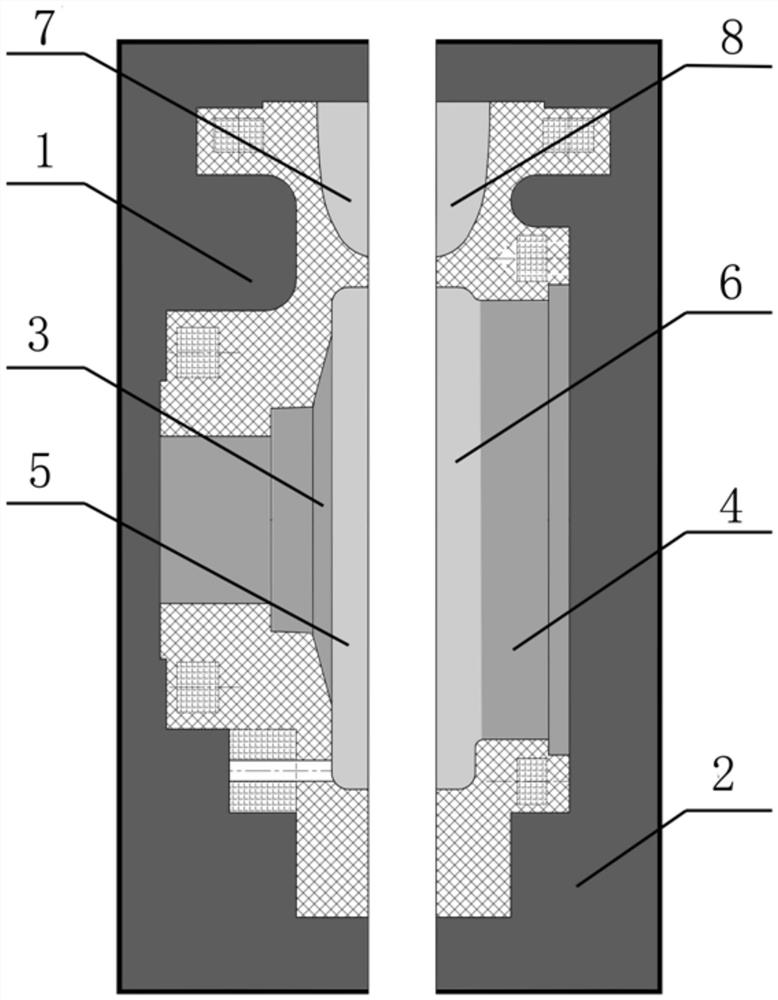

Compression pump body of rotary compressor

ActiveCN103742414AGuaranteed reliabilityReduce contact areaRotary piston pumpsRotary piston liquid enginesCompression PumpPulp and paper industry

The invention discloses a compression pump body of a rotary compressor. The compression pump body comprises a cylinder assembly, an upper bearing, a lower bearing and a bent axle, wherein the cylinder assembly comprises at least one cylinder. The upper bearing and the lower bearing are arranged above and below the cylinder assembly, respectively; the end face, facing the cylinder assembly, of the lower bearing is provided with a groove. The bent axle penetrates through the upper bearing, the cylinder assembly and the lower bearing, wherein the inner diameter of the cylinder closely bonded to the lower bearing is Dcy, the semi-diameter of the eccentric shaft shoulder of the bent axle is Rcr, the eccentricity of the bent axle is (e), the groove is arranged in a annular area which is arranged on the end face, facing the cylinder assembly, of the lower bearing; the central axis of the annular area and the central axis of the bent axle are coincident; the outer-diameter Dw of the annular area and the inner diameter Dn satisfy the following relation: (Dcy-4e) is more than Dw, and Dn is more than 2Rcr. Due to the adoption of the compression pump body of the rotary compressor provided by the embodiment of the invention, the contact area between a piston and the lower bearing is reduced, and consequently, the frictional loss is reduced.

Owner:GUANGDONG MEIZHI PRECISION MFG

Device for reducing background leakage rate of large vacuum chamber at high temperature

ActiveCN113252251AHigh detection sensitivityReduce background leak rateDetection of fluid at leakage pointFinal product manufactureEngineeringLow vacuum

The invention belongs to the technical field of vacuum application, and particularly relates to a device for reducing the background leakage rate of a large vacuum chamber at high temperature. According to the device, a dry pump, a reaction furnace and a liquid nitrogen heat exchanger are installed in a box body, the dry pump is fixedly installed at the bottom in the box body, and the dry pump, the reaction furnace and the liquid nitrogen heat exchanger are connected in parallel through a pipeline; one end of an air inlet extends out of the box body, and the other end of the air inlet is connected with a pipeline of the liquid nitrogen heat exchanger; an air outlet is simultaneously connected with a pipeline of the liquid nitrogen heat exchanger and a pipeline of the reaction furnace; the dry pump is used for exhausting the whole pipeline of a hydrogen removal system to achieve low vacuum; the reaction furnace is used as a gas reaction container, and a getter material is arranged in the reaction furnace; the liquid nitrogen heat exchanger exchanges heat with high-temperature gas from shielding block hot helium leak detection equipment, so that the temperature of the high-temperature gas is reduced. According to the invention, the background leak rate of the large vacuum chamber at high temperature can be effectively reduced, and the detection sensitivity of the whole set of hot helium leak detection test system can be improved, so that stricter leak detection requirements can be met.

Owner:SOUTHWESTERN INST OF PHYSICS

Stretchable composite aluminum foil material and cold forming technology thereof

InactiveCN106626672AElegant silvery white lusterImprove barrier propertiesSynthetic resin layered productsLaminationCold formedHeat resistance

The invention belongs to the field of composite aluminum foil materials and in particular relates to a stretchable composite aluminum foil material and a cold forming technology thereof. The composite aluminum foil material sequentially comprises the following structures from outside to inside: a PE layer with the thickness of 26-32mu m, a PA layer with the thickness of 12-25mu m, an aluminum foil with the thickness of 7-13 mu m and a PP layer with the thickness of 20-25 mu m, wherein the layers are bonded together by virtue of a binder; and film rolling moulding is carried out by virtue of a mould and a compressed air cold moulding method. The obtained composite aluminum foil material is easy to stretch, resistant to stamping, resistant to puncture, strong in barrier property, antioxidant, waterproof and good in fragrance protectiveness and heat resistance, can be used for high temperature steaming and is high in flexibility and good in heat sealability; and a unique cold moulding technology of the stretchable composite aluminum foil material avoids the phenomena that the traditional thermal forming way enables a packaging film material to be easily burst, folded and retracted and not beautiful in appearance after being heated and cooled and shelf life of a product is influenced due to crack.

Owner:SHUNHUA DUCK INDAL DEVMET LINWU COUNTY HUNAN

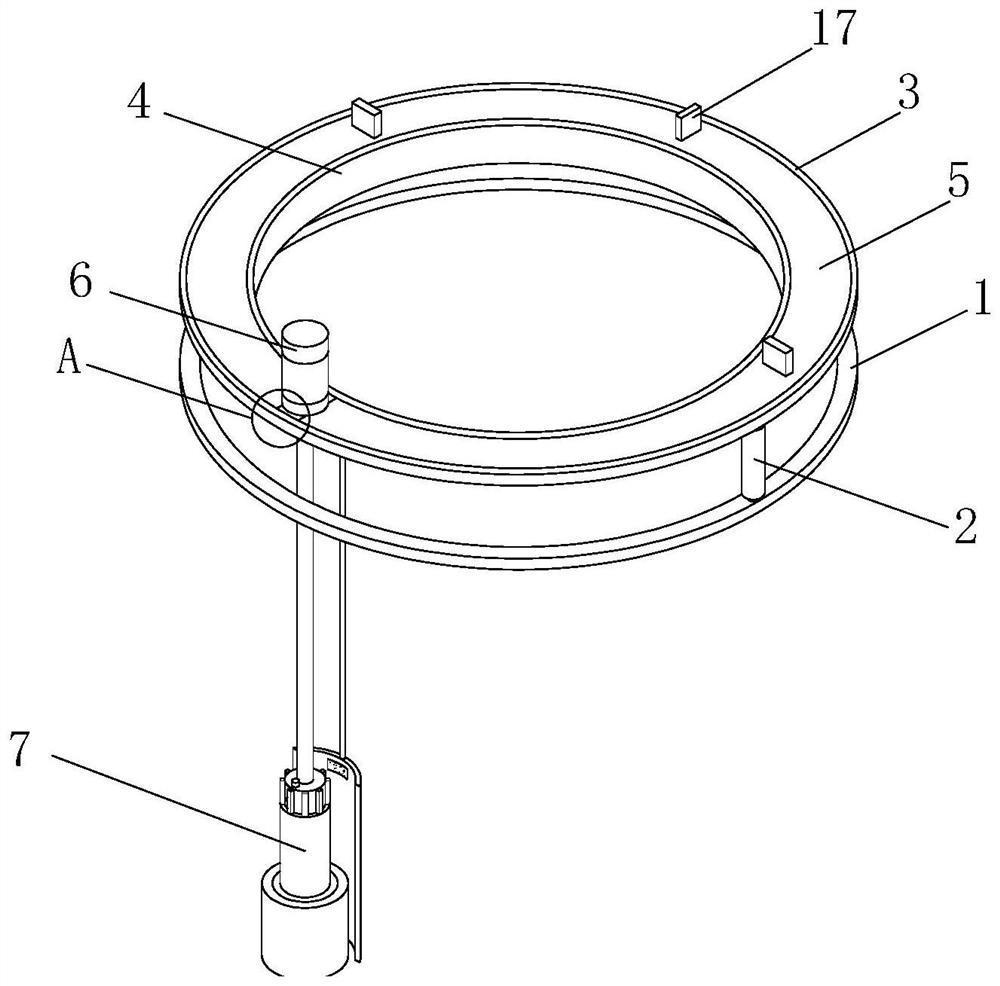

Chemical preparation container cleaning device

ActiveCN112742814AIncrease in sizeWeight increaseHollow article cleaningUsing mechanical meansElectric machineStructural engineering

The invention relates to the technical field of chemicals, and discloses a chemical preparation container cleaning device which comprises a fixing ring, wherein an annular groove is sectioned in the bottom end of the inner wall of the fixing ring, telescopic mechanisms are arranged on the top surfaces of two sides of the fixing ring correspondingly, transmission shafts of the telescopic mechanisms are fixedly connected with the top surface of the fixing ring, and connecting rings A are fixedly connected to the top surfaces of the telescopic mechanisms; an annular groove is formed in the inner wall of the connecting ring A, a rotating ring sleeves the annular groove in the inner wall of the connecting ring A, the cross section of the rotating ring is in a cross shape, a connecting ring B sleeves the outer wall of the inner ring of the rotating ring, and an annular groove is formed in the outer wall of the connecting ring B. A rotating motor is arranged on the left side of the top surface of the rotating ring, and a transmission shaft of the rotating motor penetrates through the rotating ring and is fixedly provided with a cleaning mechanism. By arranging the fixing ring, disassembly and assembly on the chemical preparation container can be achieved through simplest operation, so that the cleaning efficiency is improved. The size and weight of the chemical preparation container cannot be increased after disassembly, so that it is favorable to carry and store the chemical preparation container.

Owner:江西瑞思博新材料有限公司

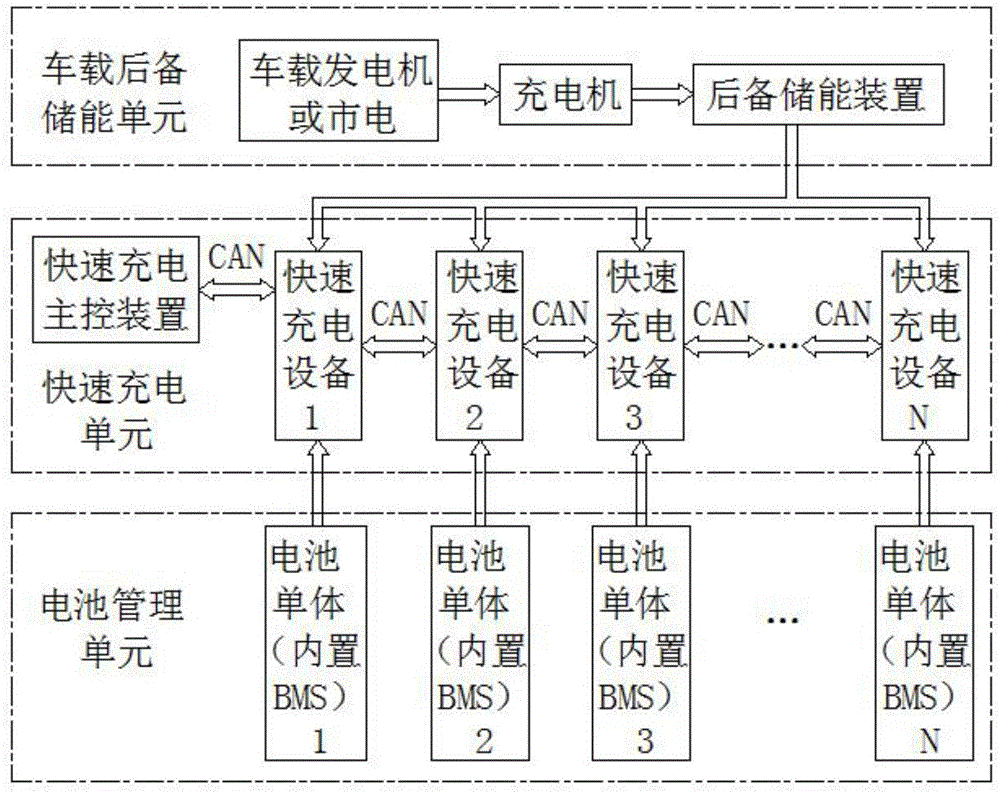

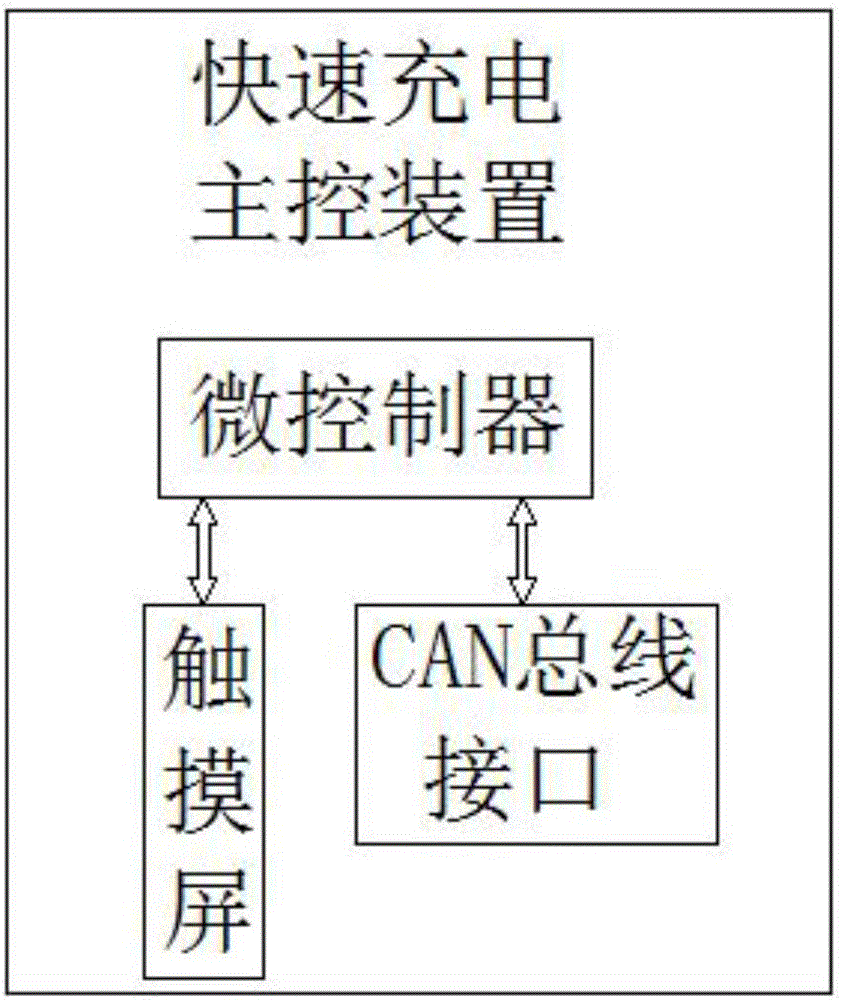

Unmanned aerial vehicle energy management system

PendingCN106849234AEnsure safetyExtended service lifeCharge equalisation circuitSecondary cellsManagement unitIn vehicle

The invention discloses an unmanned aerial vehicle energy management system which comprises a vehicle-mounted backup energy storage unit, a rapid charging unit and a battery management unit. The output end of the vehicle-mounted backup energy storage unit and the output end of the battery management unit are connected to the input end of the rapid charging unit. The vehicle-mounted backup energy storage unit comprises a vehicle-mounted generator or a mains supply, a charger and a backup energy storage device. The unmanned aerial vehicle energy management system has the advantages that the battery safety is ensured; the service life of a battery is prolonged; the charging time is shortened, and the charging efficiency is improved; the usage environment of the battery is widened; a diesel generator in the prior art is omitted, the battery of an external unmanned aerial vehicle is directly charged by directly using a backup battery, the whole vehicle operating efficiency is improved, the cost is reduced, and the system saves energy and is environmentally friendly; the energy conversion efficiency is improved by adopting a DC-DC charging system; the battery is adopted as an energy source, the overall power is related to the output power of the battery, and improvement of the charging output power of a whole vehicle is promoted.

Owner:合肥市融宇电子有限公司

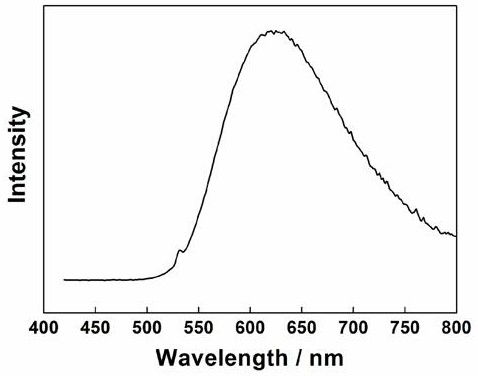

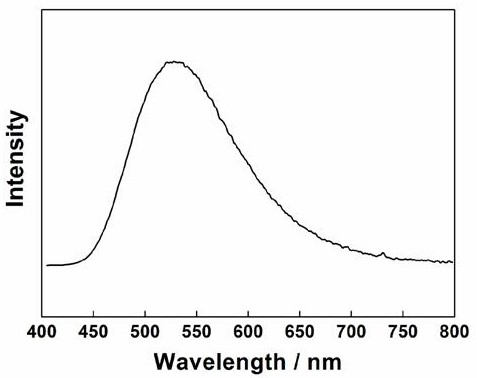

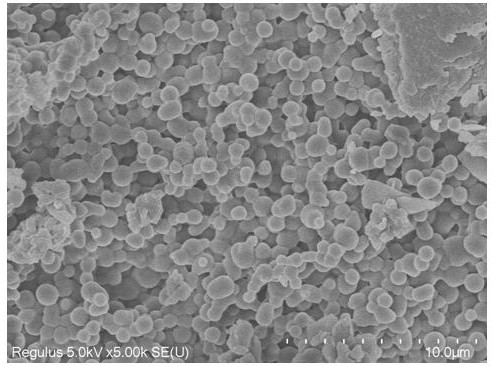

Photoluminescence organometallic complex microcapsule and preparation method thereof

ActiveCN112159655AGood weather resistanceAvoid problems such as leakageMicroballoon preparationLuminescent compositionsWeather resistancePhotoluminescence

The invention provides a photoluminescence organometallic complex microcapsule and a preparation method thereof, and belongs to the technical field of polymer composite material synthesis. The preparation method thereof comprises the following steps: (1) preparing an internal water phase, (2) preparing an oil phase, (3) adding the internal water phase prepared in the step (1) into the oil phase prepared in the step (2) at one time, and heating to obtain a water-in-oil type primary emulsion, (4) preparing an external water phase, (5) dropwise adding the water-in-oil type primary emulsion prepared in the step (3) into the external water phase and stirring in 20-80 DEG C; and carrying out post-treatment to obtain the photoluminescence organometallic complex microcapsule. The preparation method thereof provided by the invention is simple to operate, the weather resistance of the prepared photoluminescence organometallic complex microcapsule is enhanced, and the compatibility of the photoluminescence organometallic complex and a coating is improved; and the industrial application range of the photoluminescence organic metal complex is greatly improved.

Owner:UNIV OF JINAN +1

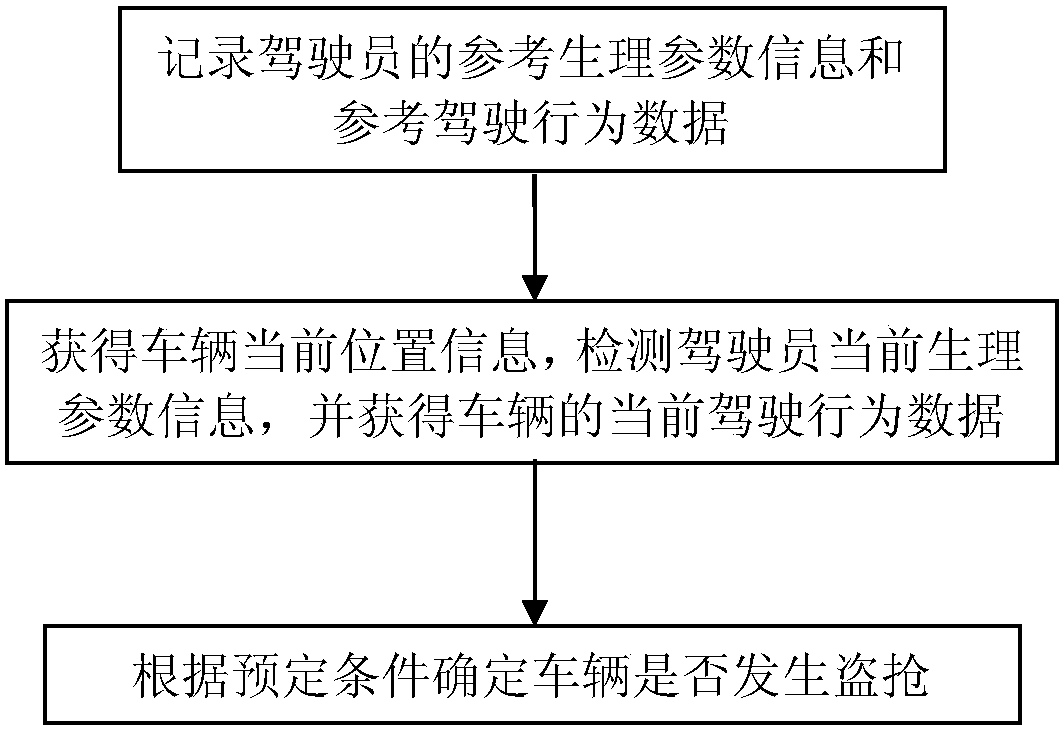

Car theft monitoring method

ActiveCN105966406BImprove reliabilityImprove securityRegistering/indicating working of vehiclesElectric/fluid circuitDriver/operatorEngineering

To make up for deficiencies of the prior art, and improve robbing monitoring safety and reliability of a vehicle, the invention provides a robbing monitoring method for the vehicle. The method comprises the following steps of (1) recording referenced physiological parameter information and referenced driving behavior data of a driver; (2) obtaining current position information of the vehicle, detecting current physiological parameter information of the driver, and obtaining current driving behavior data of the vehicle; and (3) according to preset conditions, determining whether the vehicle is robbed. According to the robbing monitoring method disclosed by the invention, the reliability and the safety for automatically detecting whether the vehicle is robbed of the vehicle during driving are improved, and the situation that the vehicle only relies on a vibration sensor and the like for detection, so that during violence destruction, the vibration sensor is influenced by a jammer and the like to generate misjudgment or judgment omission is avoided.

Owner:徐州天骋智能科技有限公司

Manufacturing method for integrally forming carbon fiber composite material pump body and impeller for pump

The invention provides a manufacturing method for integrally forming a carbon fiber composite material pump body and an impeller for a pump. The manufacturing method comprises the following steps that1, the carbon fiber material with a proper specification is prepared; 2, MgO, a curing agent, a low-shrinkage agent and a wetting dispersant are added into an epoxy vinyl resin raw material, and themixture is stirred for 2-4 h at the normal temperature and fully mixed; 3, the carbon fiber material is mixed with the mixture; 4, the temperature of a molding press is raised to a preset temperature,and a mold is preheated; 5, a mixing material is put into a preheated pump body mould pressing mold or ab impeller mould pressing mold, and mold closing is performed; and 6, the mixing material is pressurized and heated to a preset temperature, the temperature is kept, and after cooling, demolding is performed. According to the method, the complexity of the forming process of the carbon fiber composite material pump body and the impeller for the pump is greatly reduced, integral forming is achieved, the problems of gluing and bolt fastening connection are solved, the structural strength of the pump body and the impeller is enhanced, the problems of low structural strength, pressure-bearing deformation, cracking, leakage and the like are solved, the manufacturing process is simple, the cost is low, and the application prospect is wide.

Owner:殷艾伯特

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com