Color filter substrate, manufacturing method thereof and liquid crystal display panel

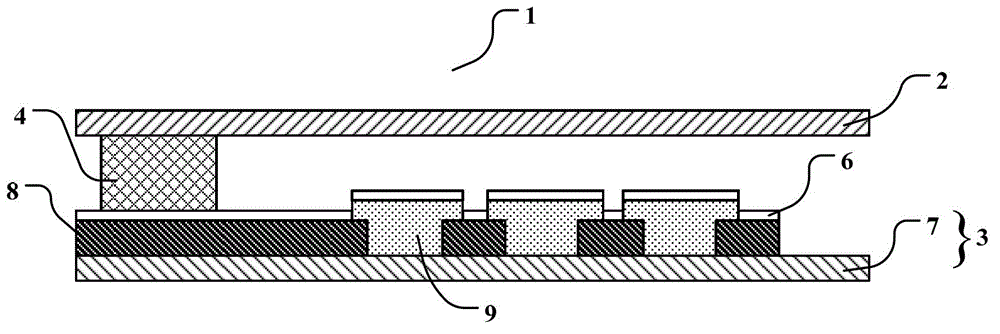

A color filter substrate, liquid crystal display panel technology, applied in the direction of filters, optics, optical components, etc., can solve the problem that the color filter substrate 3 and the sealant 4 are easy to peel off, the peeling test does not meet the requirements, and the product quality is affected. and other problems, to avoid liquid crystal leakage, change the shape of the contact surface, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

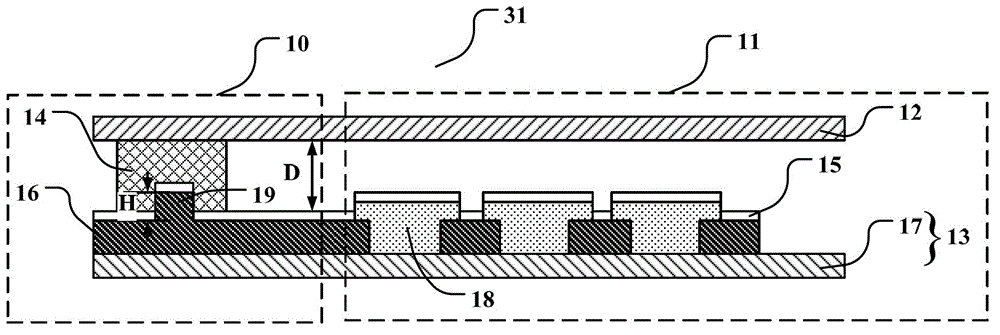

[0028] Please refer to figure 2 , figure 2 It is a partial cross-sectional schematic diagram of a liquid crystal display panel proposed in Embodiment 1 of the present invention, including a color filter substrate with a protrusion formed on the surface of a black matrix in a non-display area. Such as figure 2 As shown, the present invention provides a liquid crystal display panel 31, the liquid crystal display panel 31 has a display area 11 and a non-display area 10 located at the periphery of the display area 11, and the specific structure of the liquid crystal display panel 31 includes: a color filter substrate 13; a thin film transistor array substrate 12, arranged opposite to the color filter substrate 13; a liquid crystal (not shown in the figure), packaged between the color filter substrate 13 and the thin film transistor array substrate 12; also includes A sealant 14 disposed between the thin film transistor array substrate 12 and the color filter substrate 13 in t...

Embodiment 2

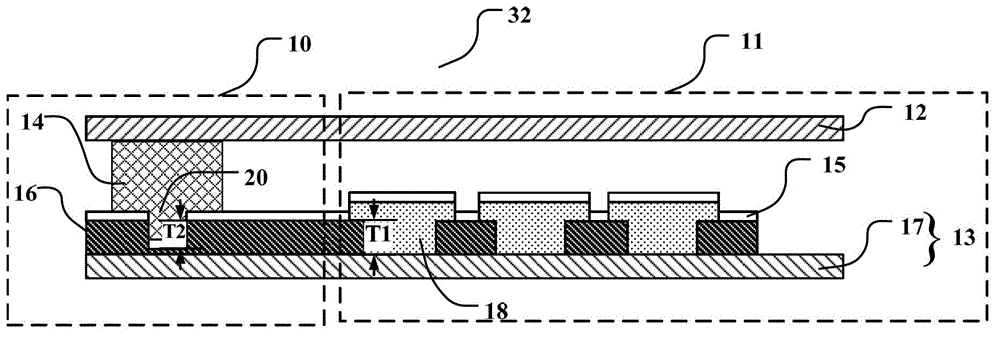

[0035] Please refer to image 3 , image 3 It is a partial cross-sectional schematic diagram of a liquid crystal display panel proposed in Embodiment 2 of the present invention, which includes a color filter substrate with a groove formed on the surface of a black matrix in a non-display area. Such as image 3 As shown, the present invention provides a liquid crystal display panel 32, the liquid crystal display panel 32 has a display area 11 and a non-display area 10 located at the periphery of the display area 11, the specific structure of the liquid crystal display panel 32 includes: a color filter substrate 13; a thin film transistor array substrate 12, arranged opposite to the color filter substrate 13; a liquid crystal (not shown in the figure), packaged between the color filter substrate 13 and the thin film transistor array substrate 12; also includes The sealant 14 is disposed between the thin film transistor array substrate 12 and the color filter substrate 13 in th...

Embodiment 3

[0042] Please refer to Figure 4 , Figure 4 It is a partial cross-sectional schematic diagram of a liquid crystal display panel proposed in Embodiment 3 of the present invention, which includes a color filter substrate with a plurality of protrusions formed on the surface of a black matrix in a non-display area. Such as Figure 4 As shown, the present invention provides a liquid crystal display panel 33, the liquid crystal display panel 33 has a display area 11 and a non-display area 10 located at the periphery of the display area 11, and the specific structure of the liquid crystal display panel 33 includes: a color filter substrate 13; a thin film transistor array substrate 12, arranged opposite to the color filter substrate 13; a liquid crystal (not shown in the figure), packaged between the color filter substrate 13 and the thin film transistor array substrate 12; also includes A sealant 14 disposed between the thin film transistor array substrate 12 and the color filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com