Flue gas treatment part, low-temperature incombustible particle type cigarettes using the same and production technique thereof

A low-temperature non-combustion and flue gas treatment technology, applied in the fields of smoker's products, tobacco, and applications, can solve the problems affecting the quality and market value of low-temperature non-combustible particulate cigarettes, improve filtering and drying effects, and ensure effective The effect of maintaining and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

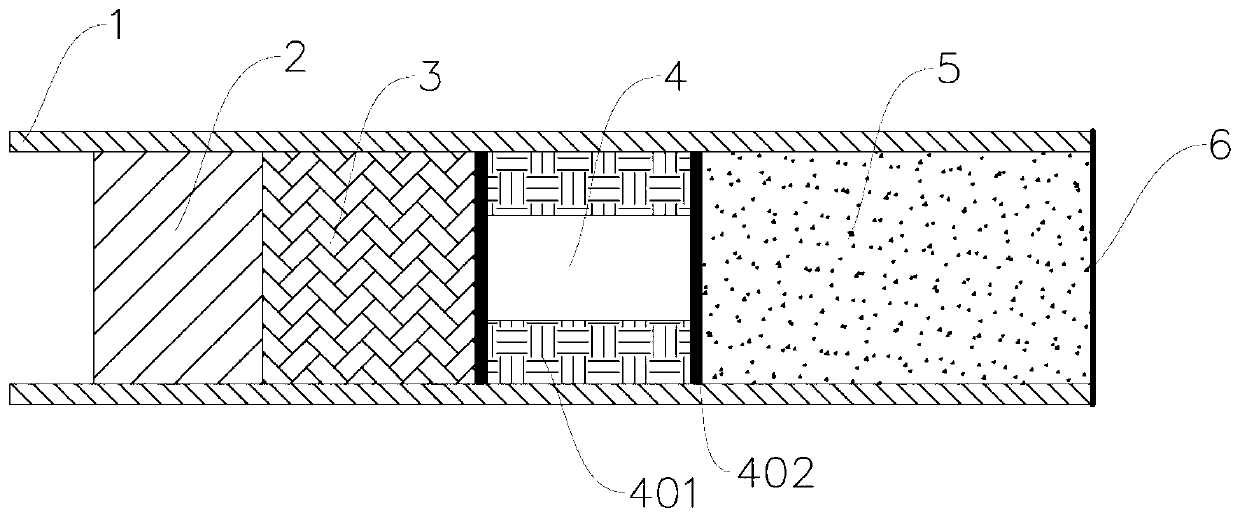

[0032] The low-temperature non-combustible particulate cigarette of Example 1 includes a cigarette pipe 1 , a mouthpiece 2 , a first smoke treatment part 3 , a second smoke treatment part 4 , tobacco particles 5 and a blocking layer 6 . Such as figure 1As shown, the mouthpiece 2 , the first smoke treatment part 3 , the second smoke treatment part 4 and the tobacco particles 5 are sequentially arranged inside the smoke tube 1 along the axial direction, and the sealing layer 6 seals the end of the smoke tube 1 . Among them, the smoke pipe 1 uses white glue as a binder, and is made of pulp fibers rolled, demolded and dried, with an outer diameter of 7.2 mm, a wall thickness of 0.25 mm, and a length of 60 mm. The mouth stick 2 is a hollow acetate stick, and the hollow shape is a square. The first smoke treatment part 3 is a fiber cylinder rolled by glass fiber. In order to enhance the filtering and drying effect of the first smoke treatment part 3 and make it have the function of...

Embodiment 2

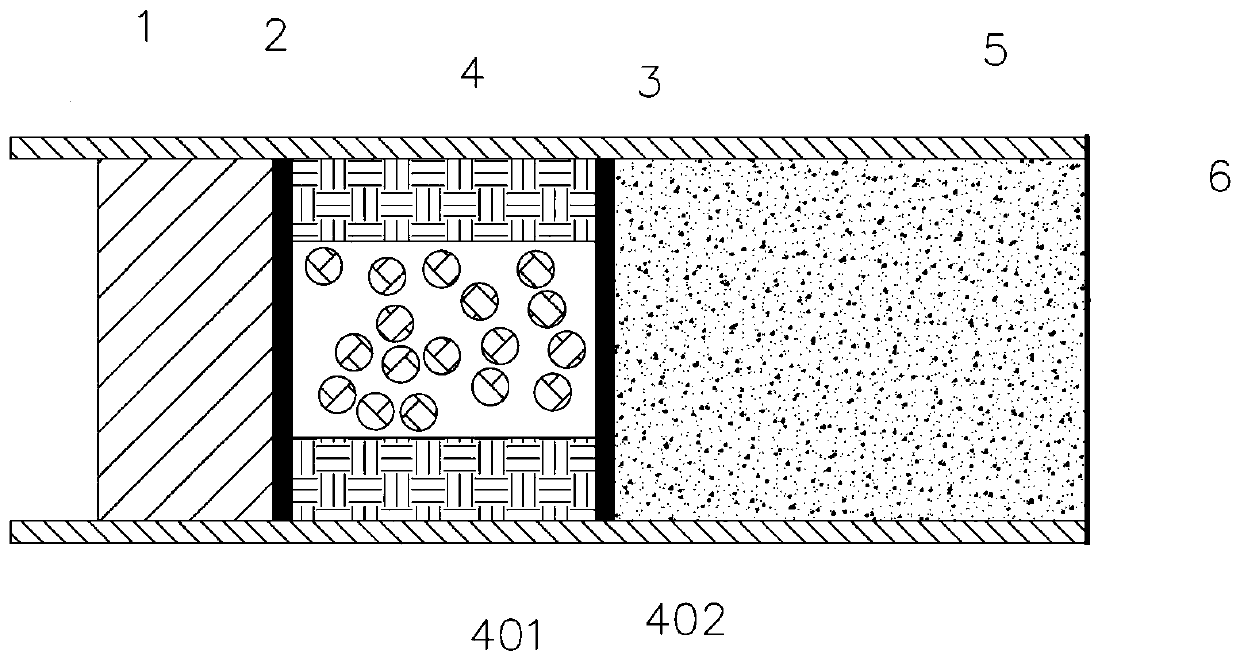

[0035] The low-temperature non-combustible particulate cigarette of Example 2 includes a cigarette pipe 1 , a mouthpiece 2 , a first smoke treatment part 3 , a second smoke treatment part 4 , tobacco particles 5 and a blocking layer 6 . Such as figure 2 As shown, the mouthpiece 2, the second smoke treatment part 4 and the tobacco particles 5 are sequentially arranged in the inside of the smoke pipe 1 along the axial direction, and one end (that is, the bottom end) of the smoke pipe 1 is closed by the sealing layer 6, and the mouthpiece The outer end surface of 2 is lower than the other end (ie, the top end) of the smoke pipe 1 by a certain distance.

[0036] The smoke pipe 1 uses starch glue as a binder, and is made of pulp fiber rolled, demolded and dried. Its outer diameter is 8.5 mm, wall thickness is 0.20 mm, and length is 45 mm. The mouth stick 2 is a fiber stick with a cylindrical hollow structure, and fine particles of essence and activated carbon are added to the fib...

Embodiment 3

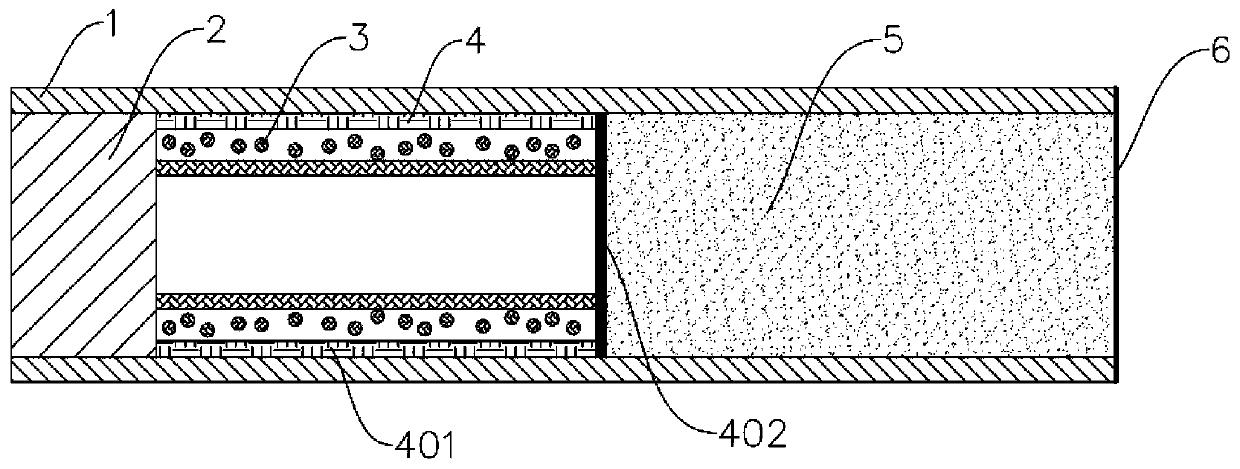

[0039] The low-temperature non-combustible particulate cigarette of Example 3 includes a cigarette pipe 1 , a mouthpiece 2 , a first smoke treatment part 3 , a second smoke treatment part 4 , tobacco particles 5 and a blocking layer 6 . Such as image 3 As shown, the mouthpiece 2 , the second smoke treatment part 4 and the tobacco particles 5 are sequentially arranged inside the smoke tube 1 along the axial direction, and the sealing layer 6 seals the end of the smoke tube 1 .

[0040] The smoke pipe 1 uses vegetable glue as an adhesive, and is made of pulp fibers rolled, demolded and dried, with an outer diameter of 7.0 mm, a wall thickness of 0.30 mm, and a length of 50 mm. The mouth stick 2 is a fiber stick with a cylindrical hollow structure, and essence microparticles and activated carbon are added to the fiber stick to enhance the effect of filtering and adding fragrance. The main body of the second flue gas treatment part 4 adopts a rough paper tube 401 and is in close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com