Drain pipe joint

A technology for drain pipes and pipe fittings, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, through components, etc., can solve the problem of leakage of the connection part, no sealing measures, etc., to avoid leakage and no power supply. and welding equipment, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

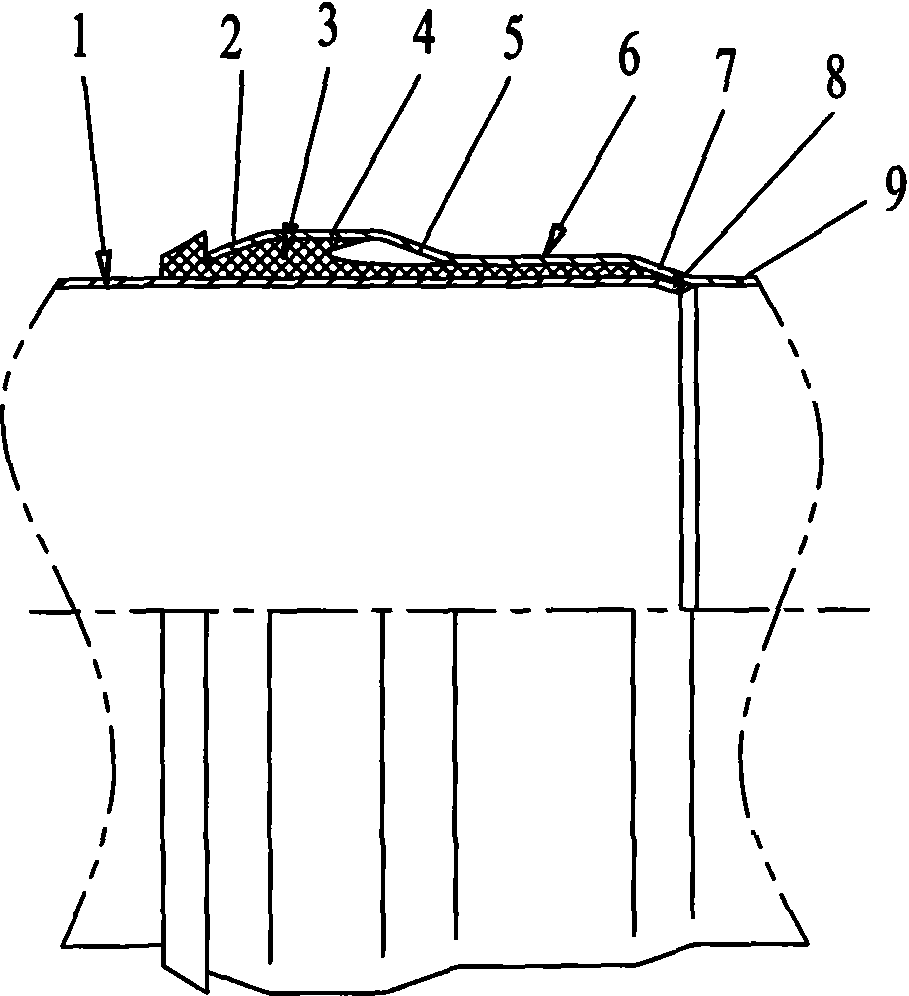

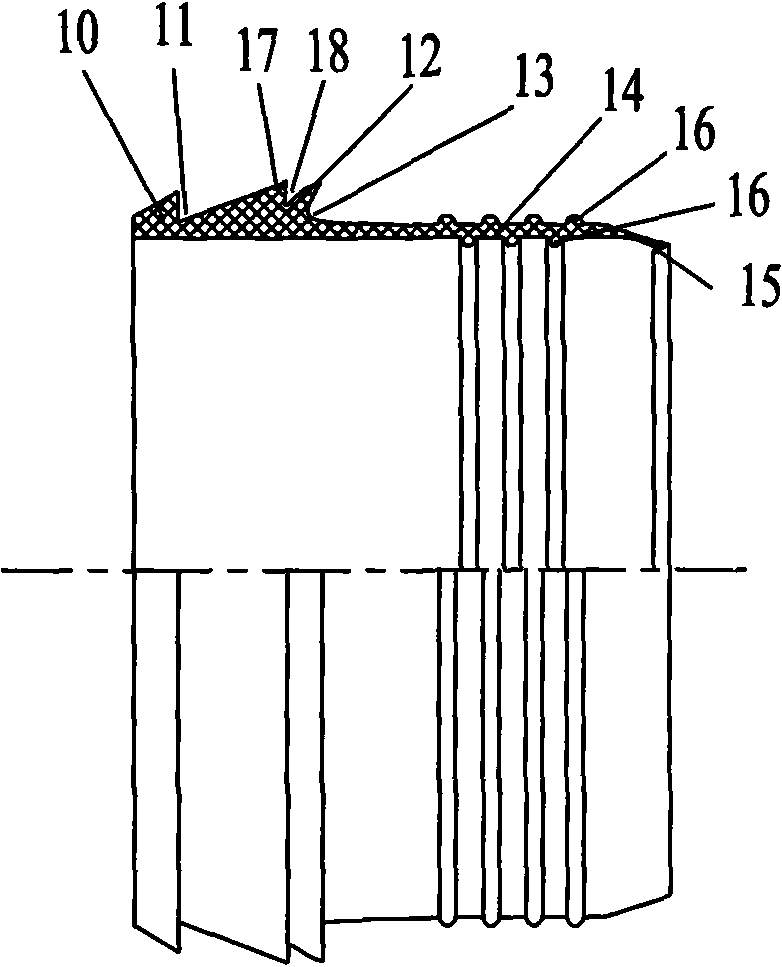

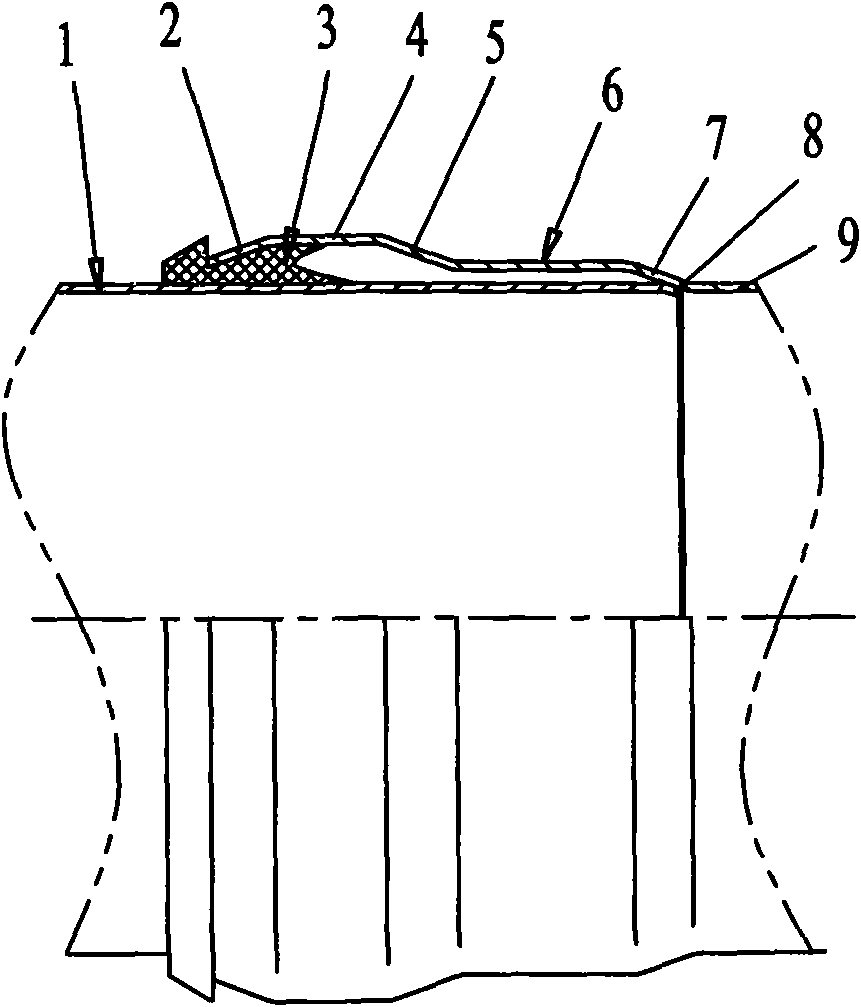

[0012] As shown in the figure: a drainage pipe joint, including a pipe fitting 9 and a pipe material 1, is characterized in that: the end of the pipe material 1 is inserted into the end of the pipe fitting 9, and the end of the pipe material 1 is provided with an inward shrinkage Segment 8, the first expansion section 7 that expands outward is arranged on the position corresponding to the pipe shrinkage section 8 on the pipe fitting 9; the minimum outer diameter of the pipe shrink section 8 is slightly larger than the inner diameter of the pipe fitting 9, so The end of the pipe fitting 9 is provided with an inwardly shrinking pipe fitting shrinkage section 2, the smallest inner diameter of the pipe fitting shrinkage section 2 is larger than the outer diameter of the pipe material 1, and a space is formed at the overlapping portion of the pipe material 1 and the pipe fitting 9, and in the space Rubber sealing ring 3 is arranged inside.

[0013] At the end of the first expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com