Harmless treatment method for electrolytic manganese slag

A technology of harmless treatment and electrolysis of manganese slag, which is applied in the direction of solid waste removal, etc., can solve the problems of ammonia gas overflow and large dosage of chemicals, and achieve the effects of avoiding dust, reducing consumption and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

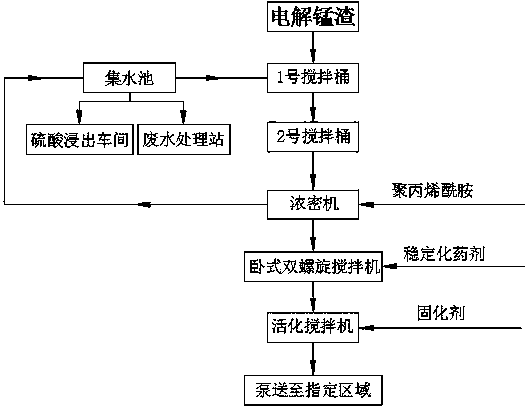

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the scope of protection of the present invention is not limited to the content described.

[0029] Taking the electrolytic manganese slag produced by an electrolytic manganese factory in Tongren, Guizhou as an example, the harmless treatment is carried out as follows:

[0030] (1) Transport the fresh electrolytic manganese slag to No. 1 mixing tank with a belt conveyor to form a slurry with a mass concentration of 12%;

[0031] (2) The electrolytic manganese slag prepared in step (1) flows automatically to the No. 2 mixing tank for continuous stirring, and the electrolytic manganese slag is transported to the thickener through the slurry pump;

[0032] (3) After adding polyacrylamide to the electrolytic manganese slag, it is concentrated in a thickener. The molecular weight of polyacrylamide is 16 million, and the addition amount is 15g / t ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com